One-dimensional photonic crystal-based colorful contact lenses and preparation method thereof

A technology of dimensional photonic crystals and contact lenses, which is applied in the field of color contact lenses and its preparation, to achieve the effects of good practicability, broad market prospects, and safe wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of colored contact lenses based on one-dimensional photonic crystals:

[0032] (1) Selection of contact lens molds:

[0033] Select the contact lens mold that can be bought on the market as the base material for preparing colored contact lenses;

[0034] (2) Preparation of hydrogel prepolymer solution for colored contact lenses:

[0035] Select two media with different refractive indices, the size of the media is between 5 nanometers and 300 nanometers, and the mass volume ratio concentration of the prepared hydrogel prepolymer solution is between 2% and 80%;

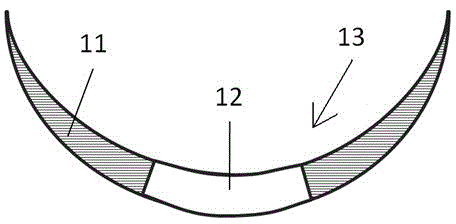

[0036] (3) Preparation of the iris area of colored contact lenses:

[0037] Add the hydrogel prepolymer solution prepared in step (2) alternately to the iris area of the contact lens mold selected in step (1), and repeatedly drop it several times to form a layer-by-layer structure on the surface of the contact lens mold. One-dimensional photonic crystal structure, wherein the thi...

Embodiment 2

[0040] Example 2 Preparation of structural color contact lenses by layer-by-layer self-assembly method:

[0041] (1) Selection and preparation of hydrogel prepolymer solution for colored contact lenses:

[0042] Select two media with different refractive indices, the size of the media material is between 5 nanometers and 300 nanometers, and the mass volume ratio concentration of the prepared hydrogel prepolymer solution is between 2% and 80%;

[0043] (2) Preparation of the iris area of the colored contact lens:

[0044] The colored contact lens hydrogel prepolymer solution obtained in step (1) is sequentially coated on the iris area of the contact lens mold, dried in a nitrogen-saturated state, and a one-dimensional photon Crystal structure of the iris region;

[0045] (3) Curing and hydration of colored contact lens lenses:

[0046] After the pupil area of the contact lens is polymerized with HEMA solution, it is hydrated in ultrapure water for 48 hours, and then ...

Embodiment 3

[0047] Embodiment 3 Performance testing of colored contact lenses based on one-dimensional photonic crystals:

[0048] (1) Light transmission test:

[0049] Structural colored contact lenses based on one-dimensional photonic crystals were selected as the test object, and the light transmittance of the pupil area was tested, and the results showed that the light transmittance of white light was above 94%;

[0050] (2) Water content test:

[0051] After the contact lens material is saturated with water, the moisture accounts for 40%-64% of the total weight, and the lens is a medium or high water content lens.

[0052] (3) Lens center thickness test:

[0053] Select the central pupil area of the lens, and measure its thickness to be 0.05-0.06mm. The result shows that the lens is a medium-standard lens.

[0054] (4) Cytotoxicity test of lenses:

[0055]The test adopts the ISO9363-1 method to observe the safety performance of the contact lens by examining the cytotoxicity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com