Method for manufacturing glazed interior wall bricks with two glazed effects

A manufacturing method and glazed technology, which is applied in the field of special-shaped glazed interior wall brick manufacturing, can solve the problems that cannot be realized, the pattern and color are not the same, and cannot be used in large quantities, so as to achieve high definition, improved product pattern clarity, and color expressive rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

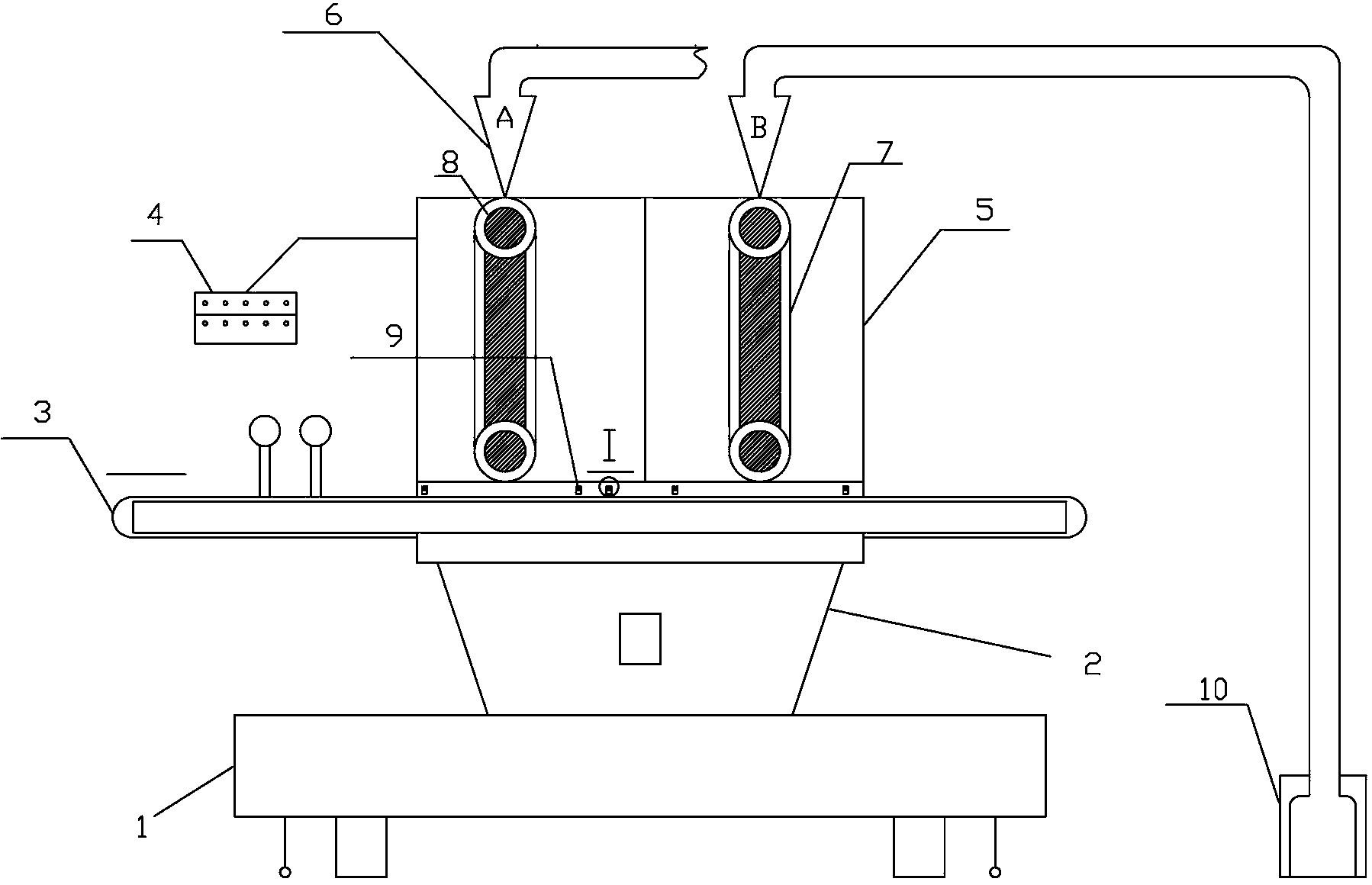

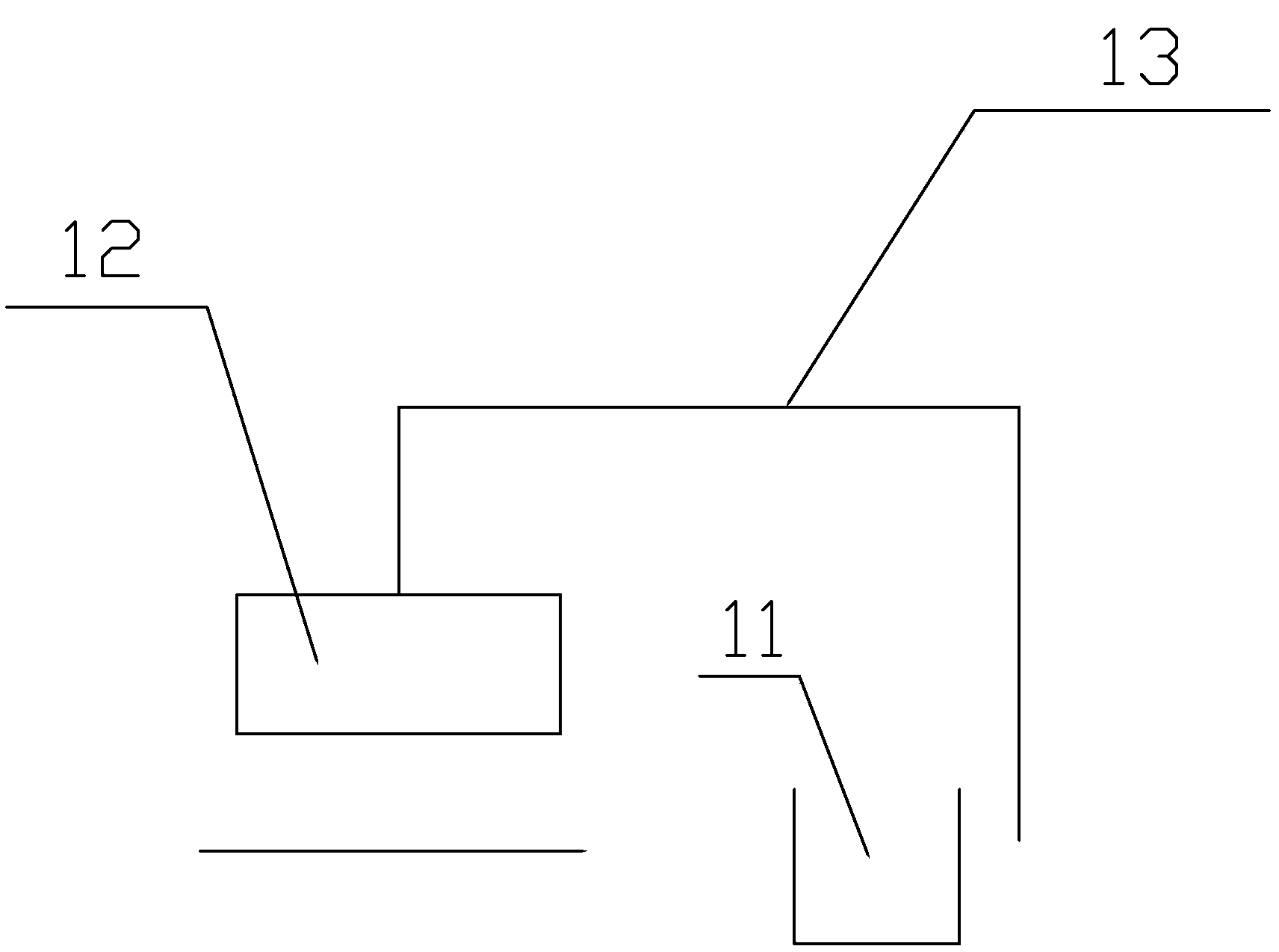

[0029] Such as figure 1 As shown in the present invention, a method for manufacturing glazed interior wall tiles with two types of effect glazes, the manufacturing method process includes the following steps: raw material selection → ball milling → iron removal → spraying powder → pressing molding → biscuit firing Bisque→spray bottom glaze→glue spray→dry method cloth glaze→inkjet printing printing→glaze firing; among them, dry method cloth glaze is to apply matt surface glaze first, then apply glossy surface glaze, or apply glossy surface glaze first, Re-cloth matte glaze.

[0030] Among them, a better ratio of green raw materials is (mass fraction): 30-40% of quartz, 15-20% of porcelain stone, 5%-10% of hard clay, 20-30% of plastic clay, and 8-12% of limestone. %, wollastonite 8~12%.

[0031] The first embodiment of the process of the dry glaze is as follows: select the surface glaze dry powder particles, wherein, the bright dry powder A is placed in the front hopper 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com