Method for preparing butterfly wing/colloidal crystal microsphere composite structure color film by vertical deposition method

A technology of colloidal crystal and composite structure, which can be applied to devices and coatings for coating liquid on the surface, which can solve the problems of inability to meet actual needs, difficulty in achieving high brightness and high saturation, and achieve great application value and application. Wide-ranging, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

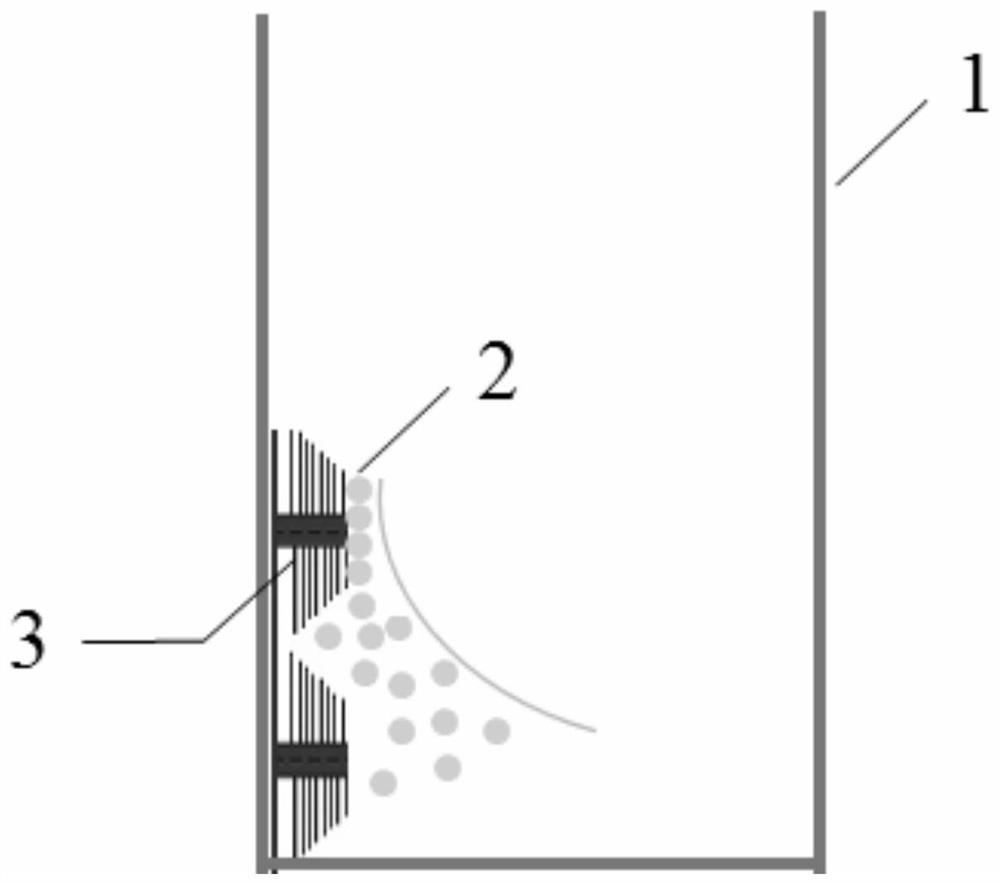

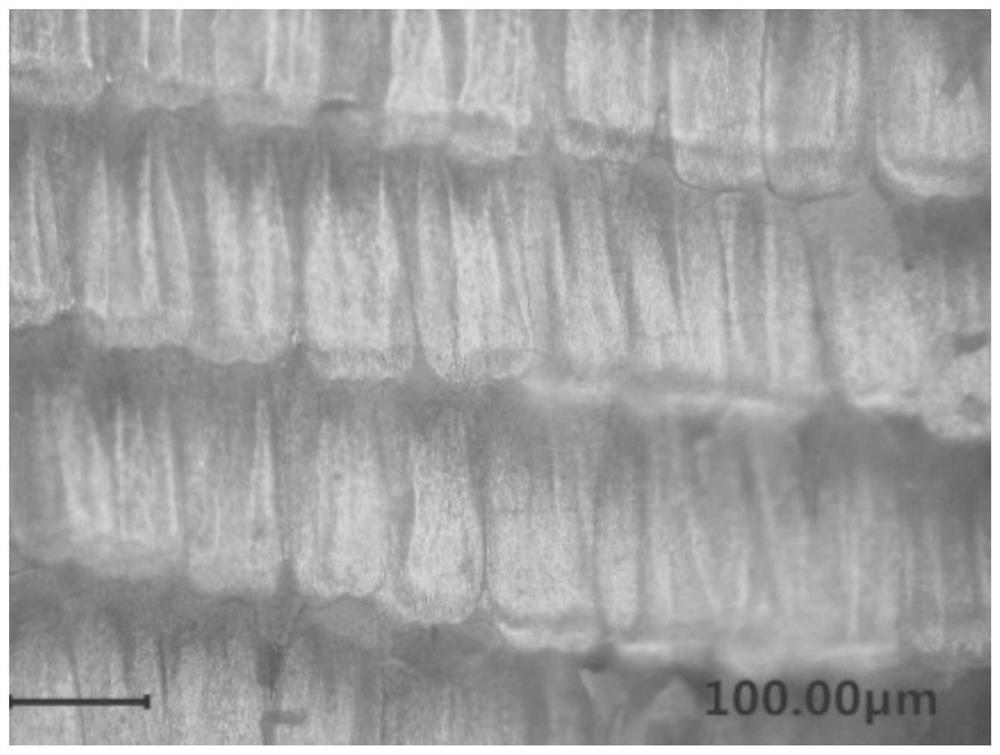

[0073] In this example, the vertical deposition method is used to prepare butterfly wing / colloidal crystal microsphere composite structural color film, and the specific steps of the method include:

[0074] Step 1: Select the Morphobis butterfly wing 3 with a periodic structure as a template, and perform surface pretreatment on the butterfly wing. First, degreasing treatment: the sample was repeatedly rinsed with physiological saline (0.65% Nac1 solution), fixed with 3% glutaraldehyde, and ultrasonically treated for 4 minutes to remove the dirt attached to the surface; then dehydration treatment: the degreased sample After taking it out, it was dehydrated with ethanol series. The ethanol concentrations used were 40%, 50%, 70%, pure ethanol, soaked for 10 minutes at each stage, and the samples were dried naturally.

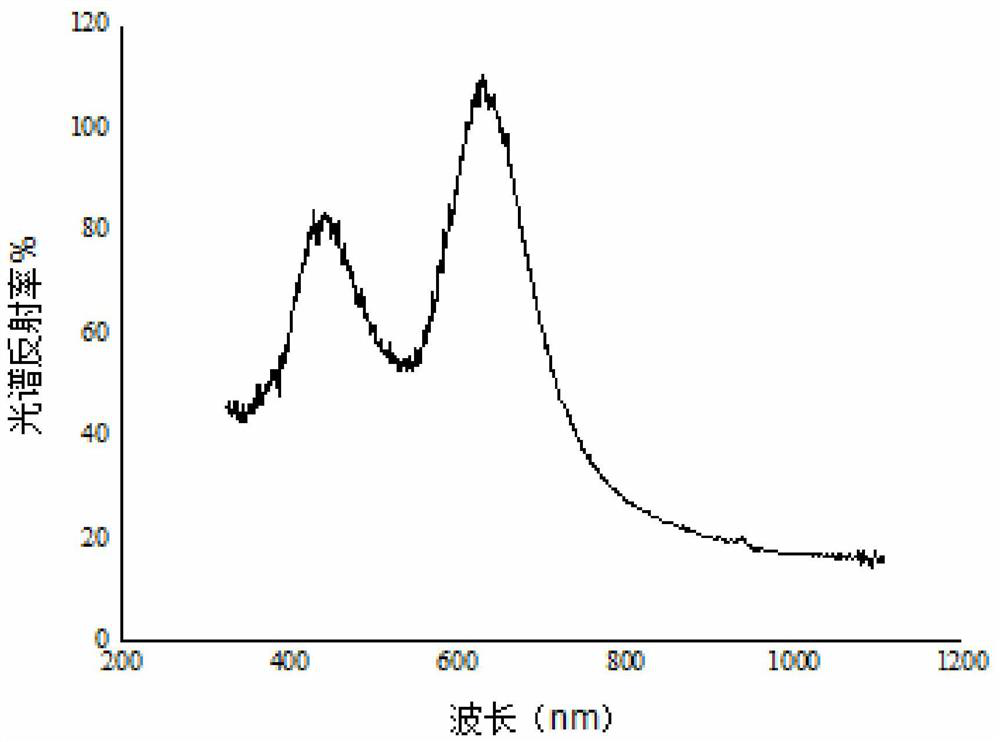

[0075] Step 2: Prepare 2.5 mL of polystyrene microsphere dispersion (colloidal crystal micro 2) with a particle size of 350 nm and a mass concentration of 5%, and ...

Embodiment 2

[0081] In this example, the butterfly wing / colloidal crystal microsphere composite structural color film is prepared in batches by vertical deposition method, as shown in Figure 4 As shown, it is a schematic diagram of the imitation butterfly wing structure prepared in batches in this embodiment, wherein, 3 is the butterfly wing of the Morpho butterfly, 4 is the PDMS film, and 5 is the glass substrate. The butterfly wing of the great blue morpho butterfly has a whole wing structure, and the ratio of PDMS prepolymer to curing agent is 10:1.

[0082] The concrete steps of this method include:

[0083] Step 1: Select the Morphobis butterfly wing 3 with a periodic structure as a template, and perform surface pretreatment on the butterfly wing. First, degreasing treatment: the sample was repeatedly rinsed with physiological saline (0.65% Nac1 solution), fixed with 3% glutaraldehyde, and ultrasonically treated for 4 minutes to remove the dirt attached to the surface; then dehydrat...

Embodiment 3

[0090] In this example, the vertical deposition method is used to prepare butterfly wing / colloidal crystal microsphere composite structural color film, and the specific steps of the method include:

[0091] Step 1: Select the Morphobis butterfly wing 3 with a periodic structure as a template, and perform surface pretreatment on the butterfly wing. First, degreasing treatment: the sample was repeatedly rinsed with physiological saline (0.65% Nac1 solution), fixed with 3% glutaraldehyde, and ultrasonically treated for 4 minutes to remove the dirt attached to the surface; then dehydration treatment: the degreased sample After taking it out, it was dehydrated with ethanol series. The ethanol concentrations used were 40%, 50%, 70%, pure ethanol, soaked for 10 minutes at each stage, and the samples were dried naturally.

[0092] Step 2: Prepare 2 mL of silica microsphere dispersion (colloidal crystal micro 2) with a particle size of 300 nm and a mass concentration of 3%, and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com