Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduced torque ripple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

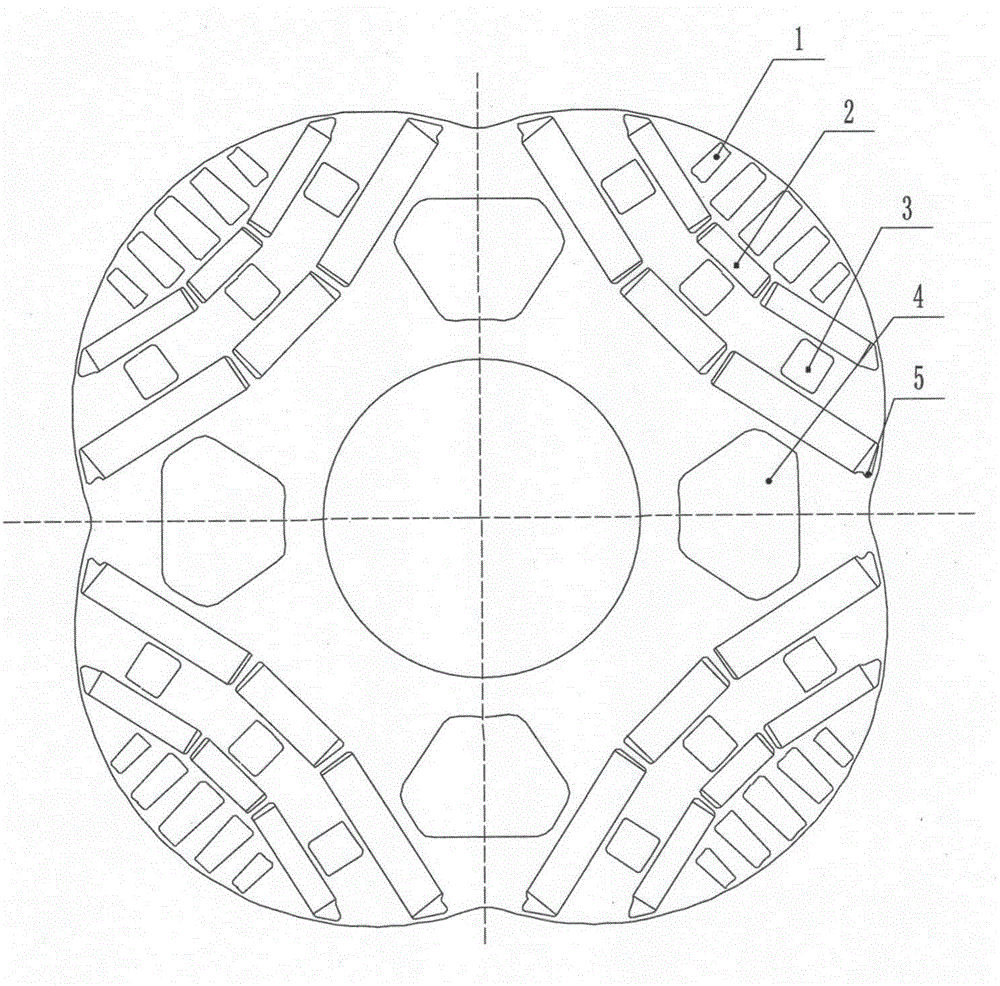

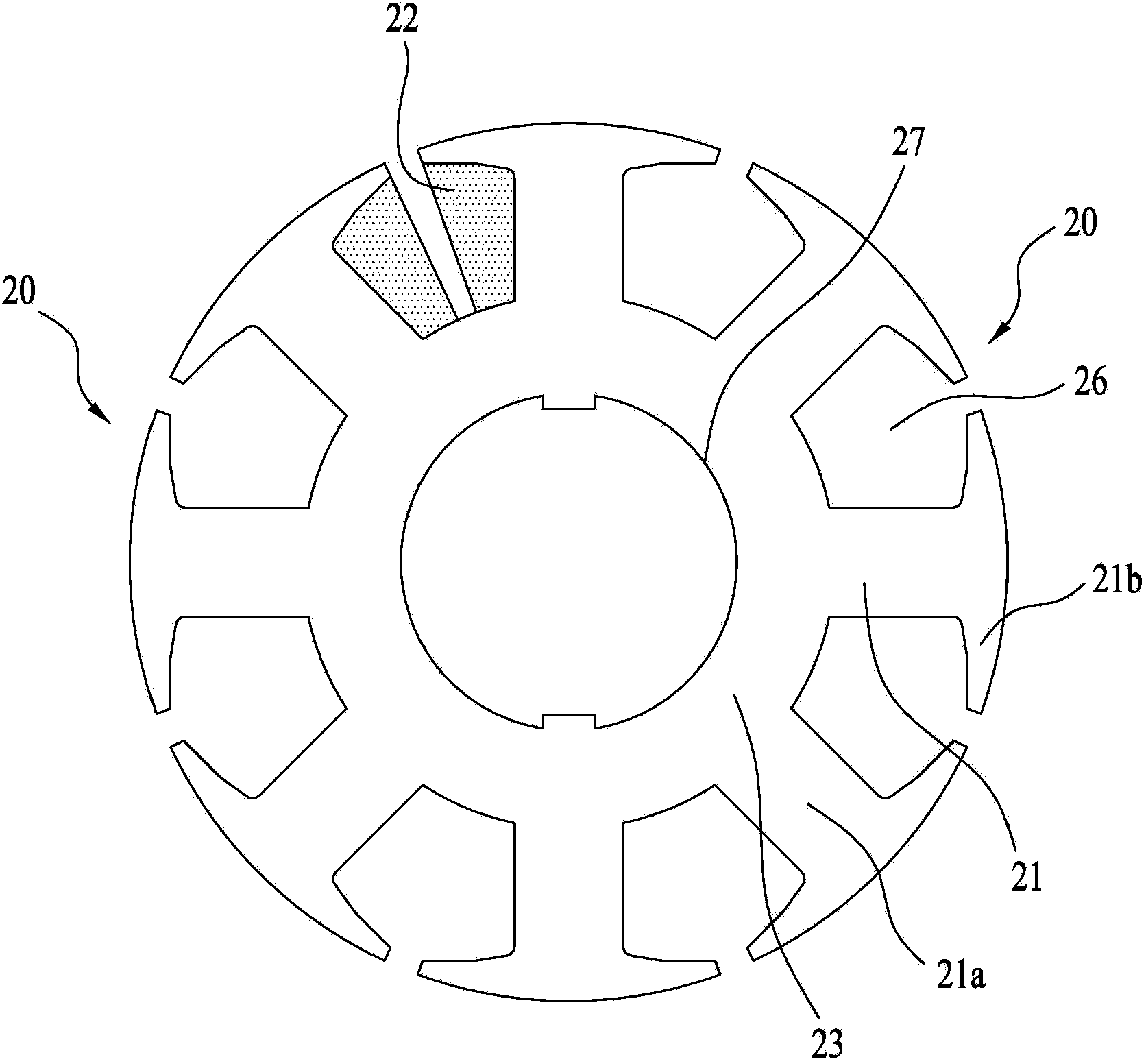

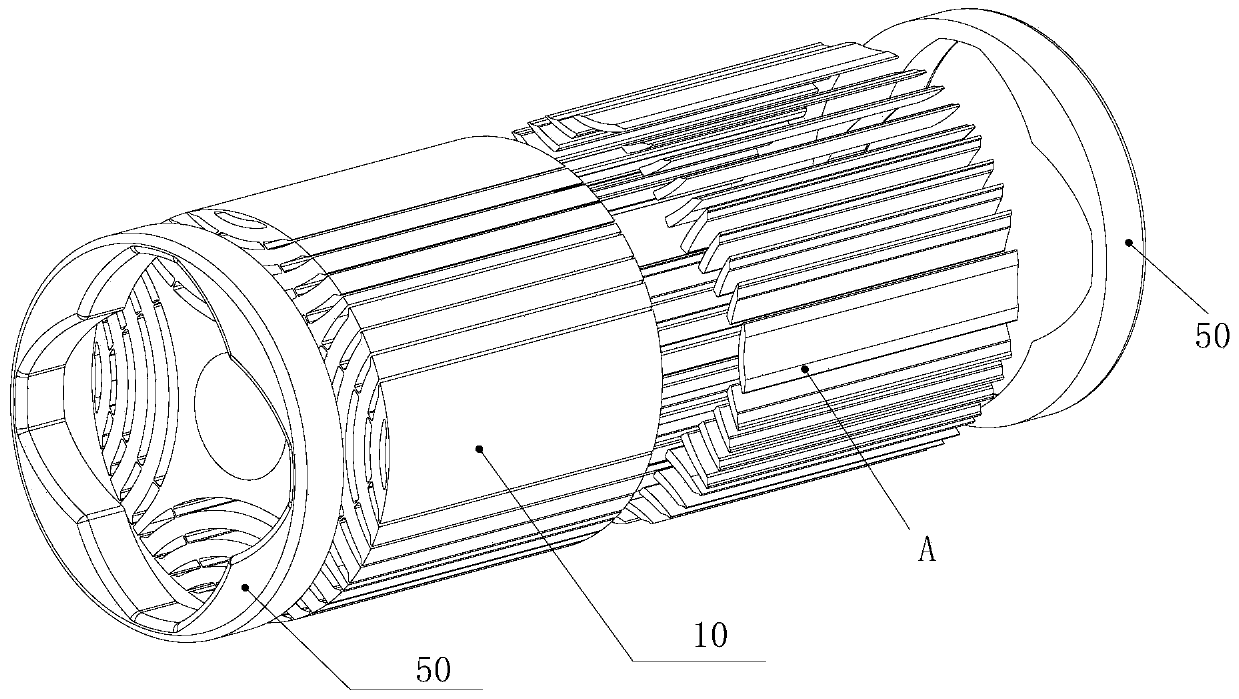

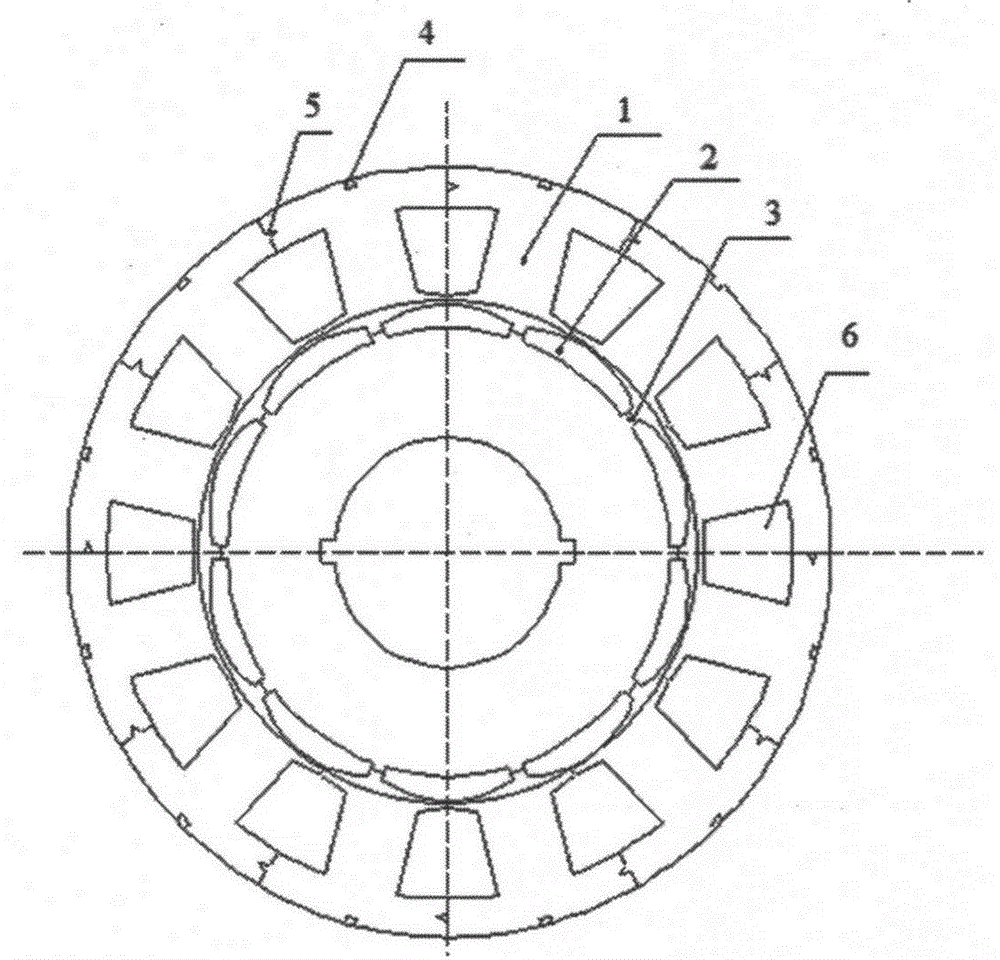

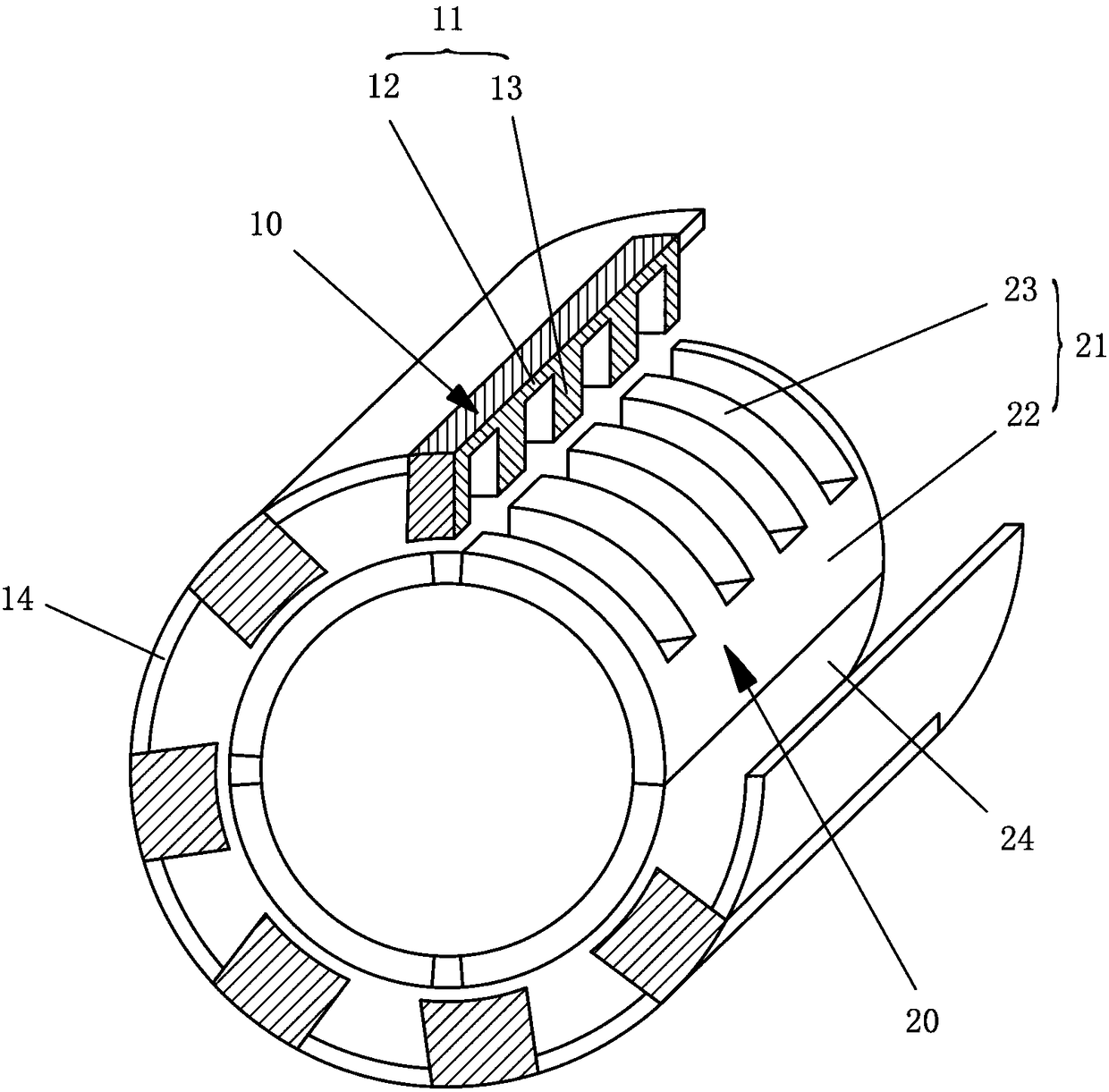

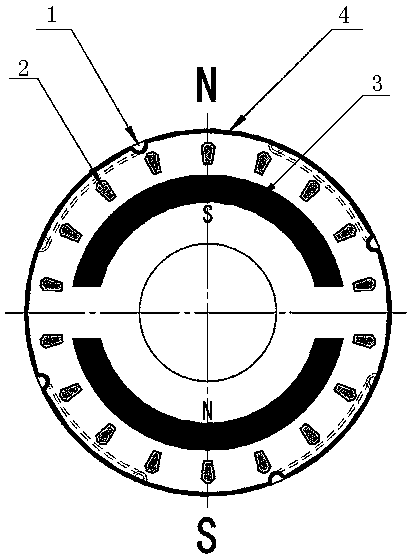

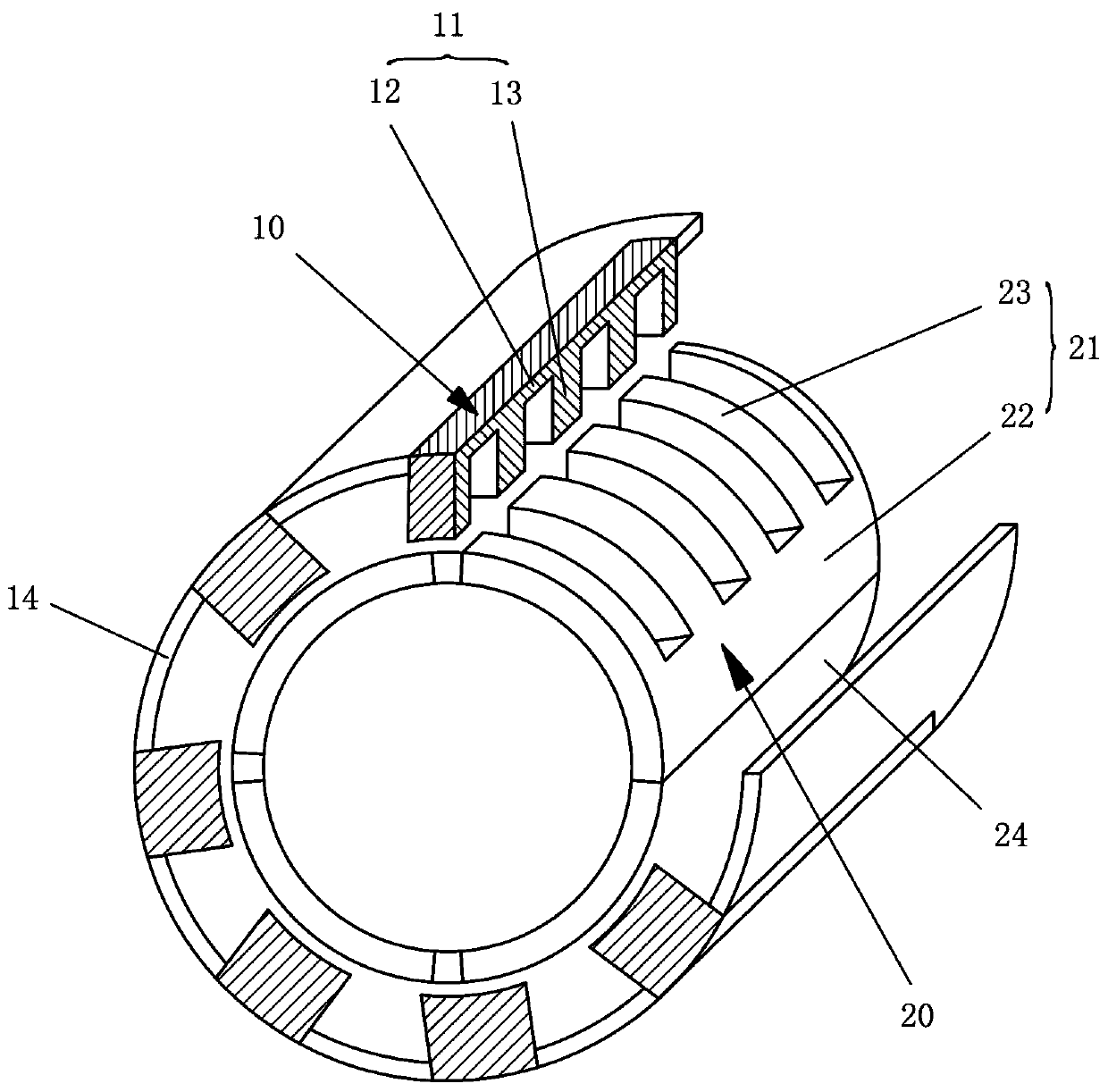

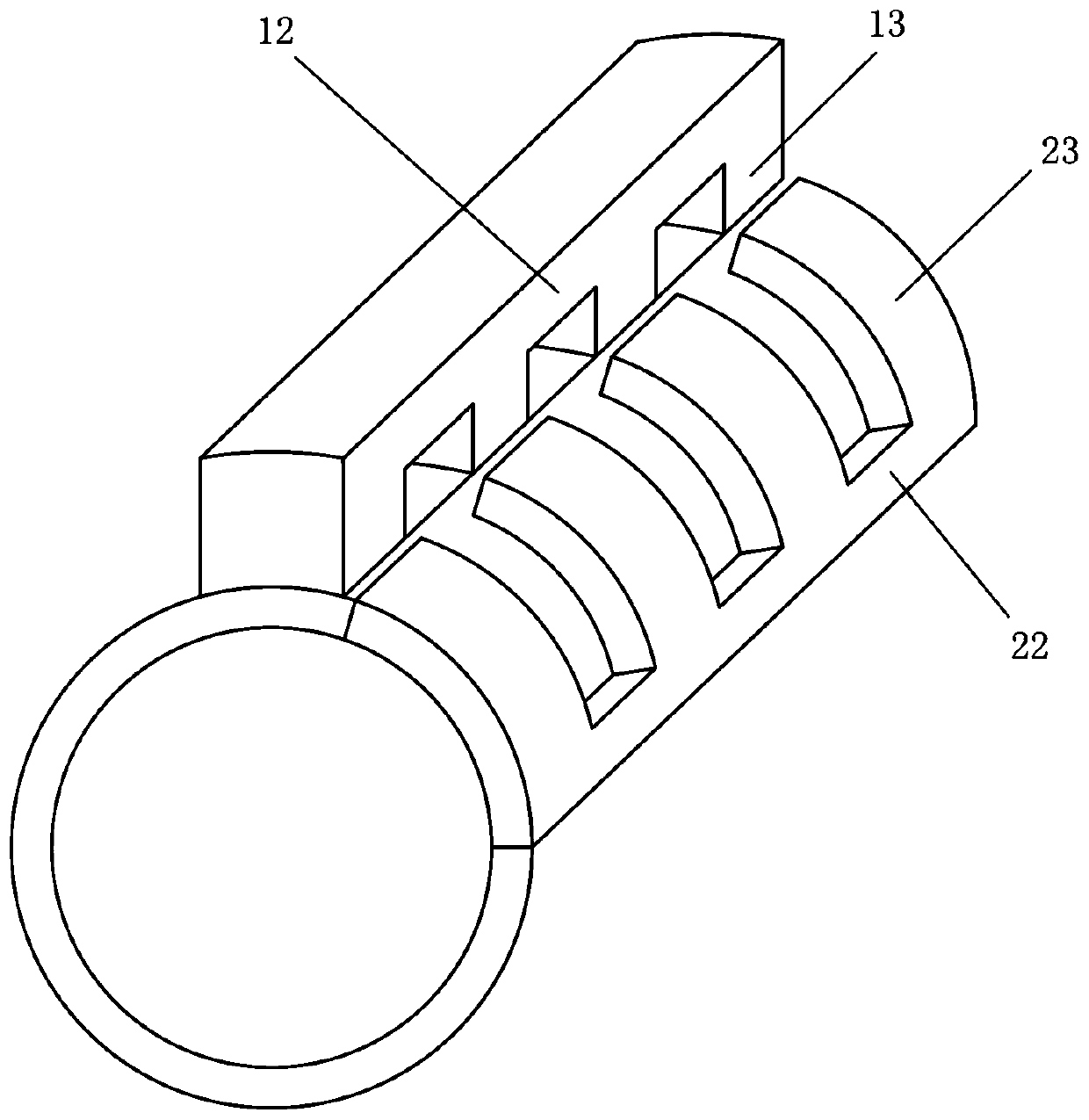

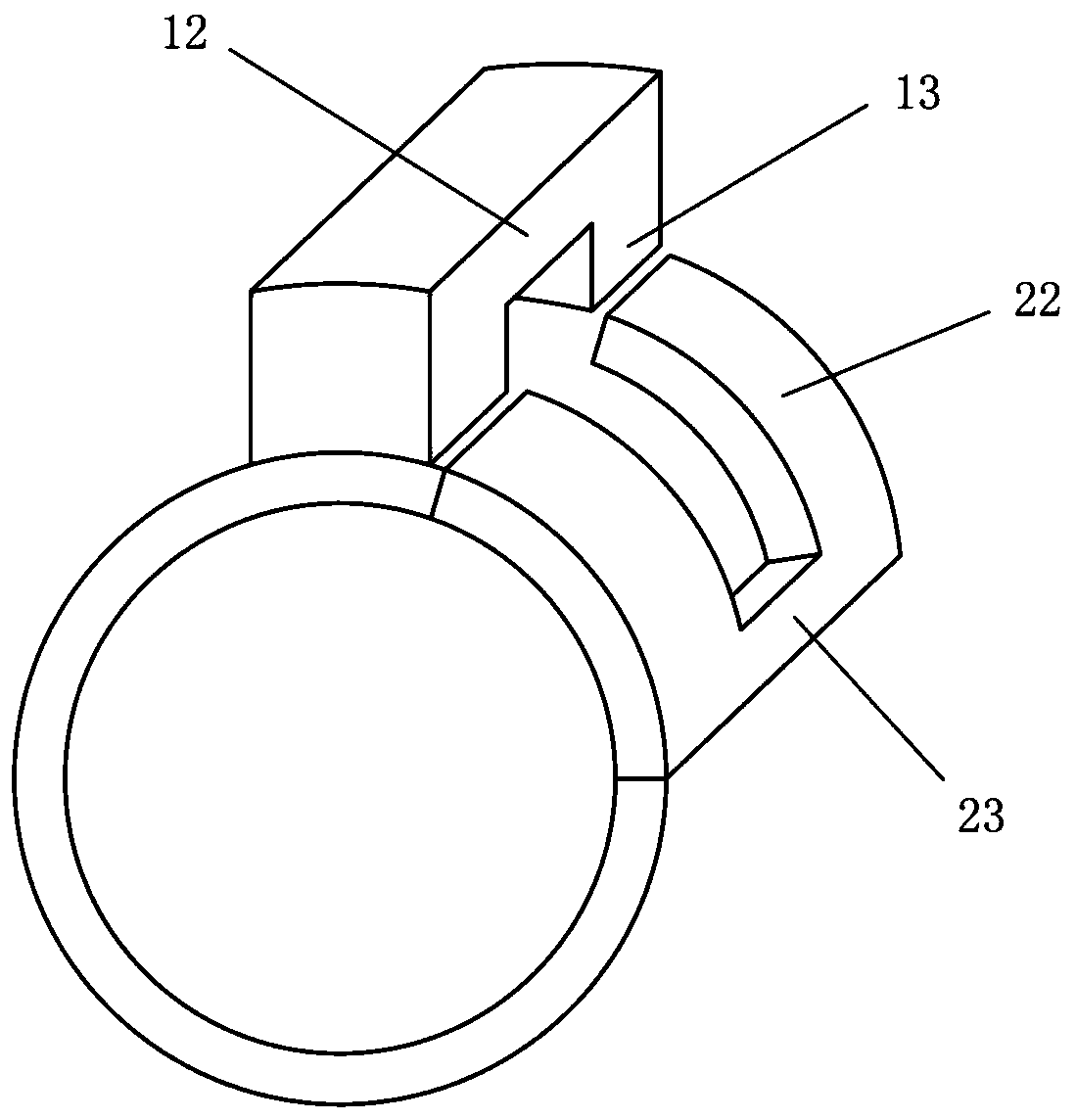

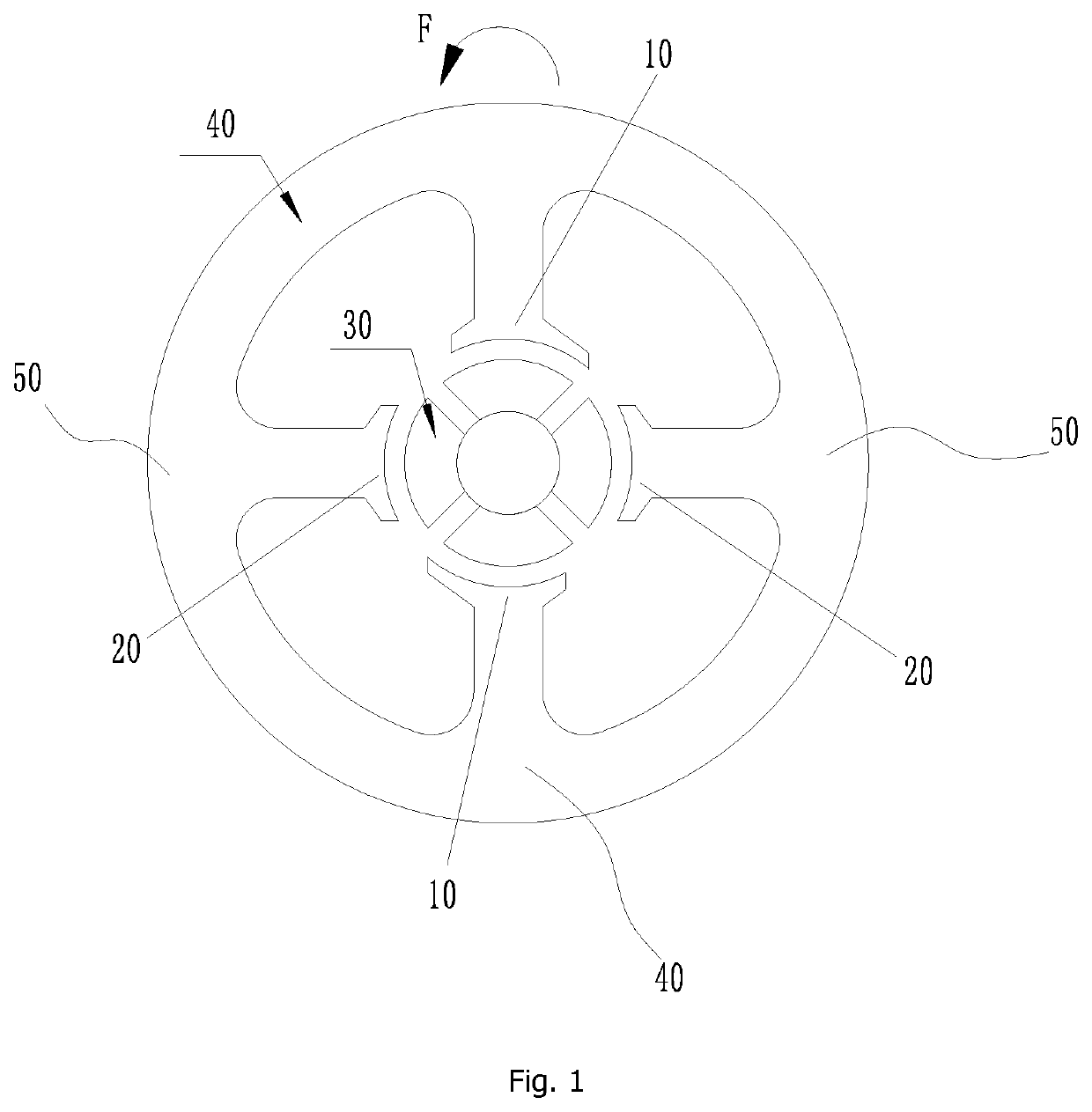

Rotor punching structure for permanent-magnet servo motor

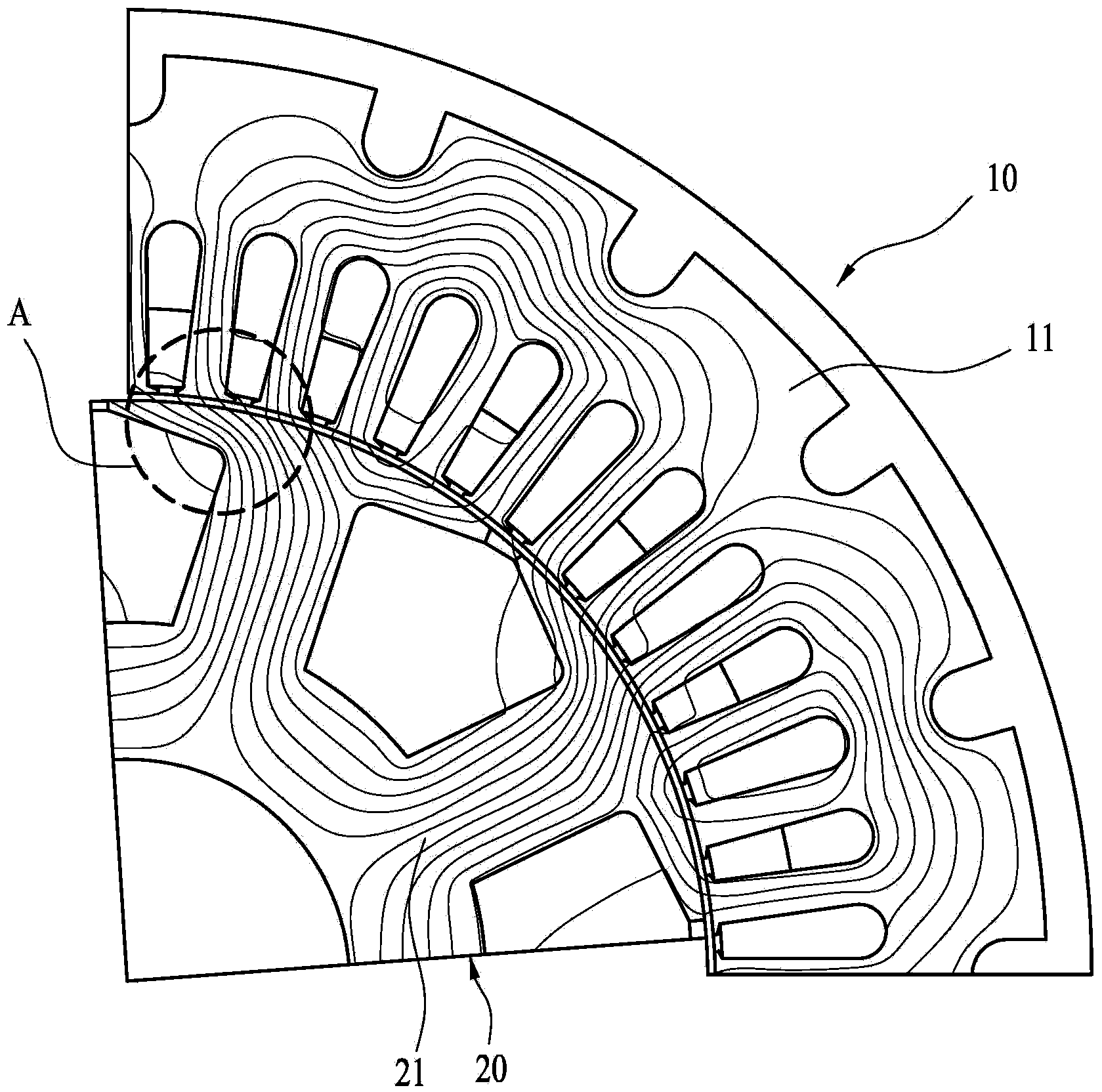

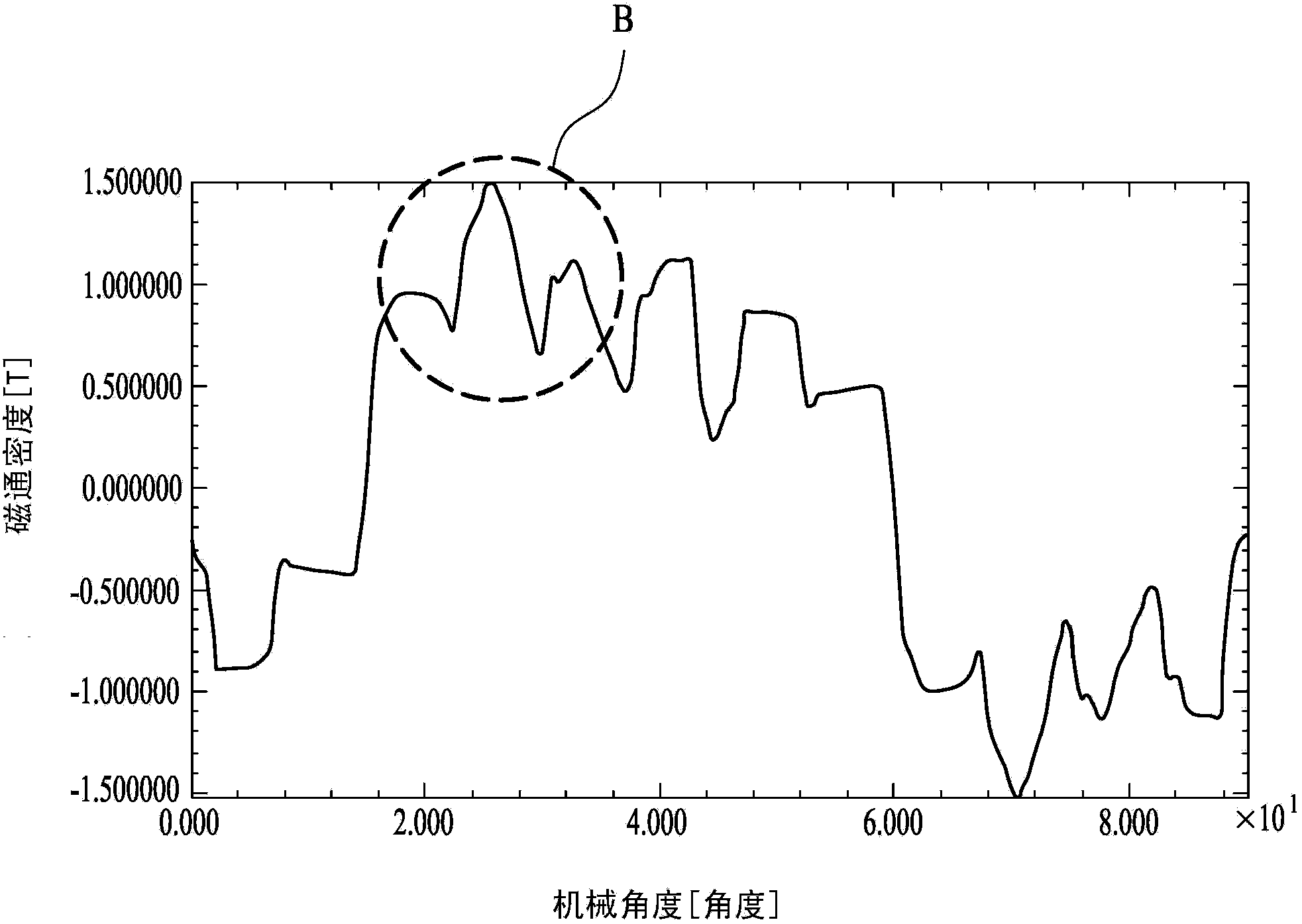

ActiveCN104882981AImprove back EMF waveformReduce additional stray lossMagnetic circuit rotating partsPunchingCoupling

The invention provides a rotor punching structure for a permanent-magnet servo motor, and the structure comprises a rotor punching body. The peripheral surface of the rotor punching body is provided with permanent magnet tanks, and the interior of each permanent magnet tank is provided with a permanent magnet in an embedded manner. The external circle of the rotor punching body above the permanent magnet tanks is not concentric with the internal circle of a stator. The rotor punching body above the permanent magnet tanks is provided with magnetic isolation holes which are arranged horizontally, and the rotor punching body below the permanent magnet tanks is provided with an axial cooling channel. The permanent magnet tanks are radially arranged in a layered manner, and magnetic isolation tanks are respectively disposed between the adjacent permanent magnet tanks. Magnetic isolation bridges are disposed among the magnetic isolation tanks and the permanent magnet tanks. Through the improvement of the rotor punching structure and the control of the direction of a magnetic field, the nonlinear impact, caused by the coupling of quadrature-axis and direct-axis magnetic circuits, on motor parameters is reduced, and the space of a rotor punching is used fully for placing permanent magnets as many as possible. Moreover, the capability of resistance to demagnetizing and the overbearing capability of the permanent-magnet servo motor are improved, and the operation performance of the permanent-magnet servo motor is effectively improved.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

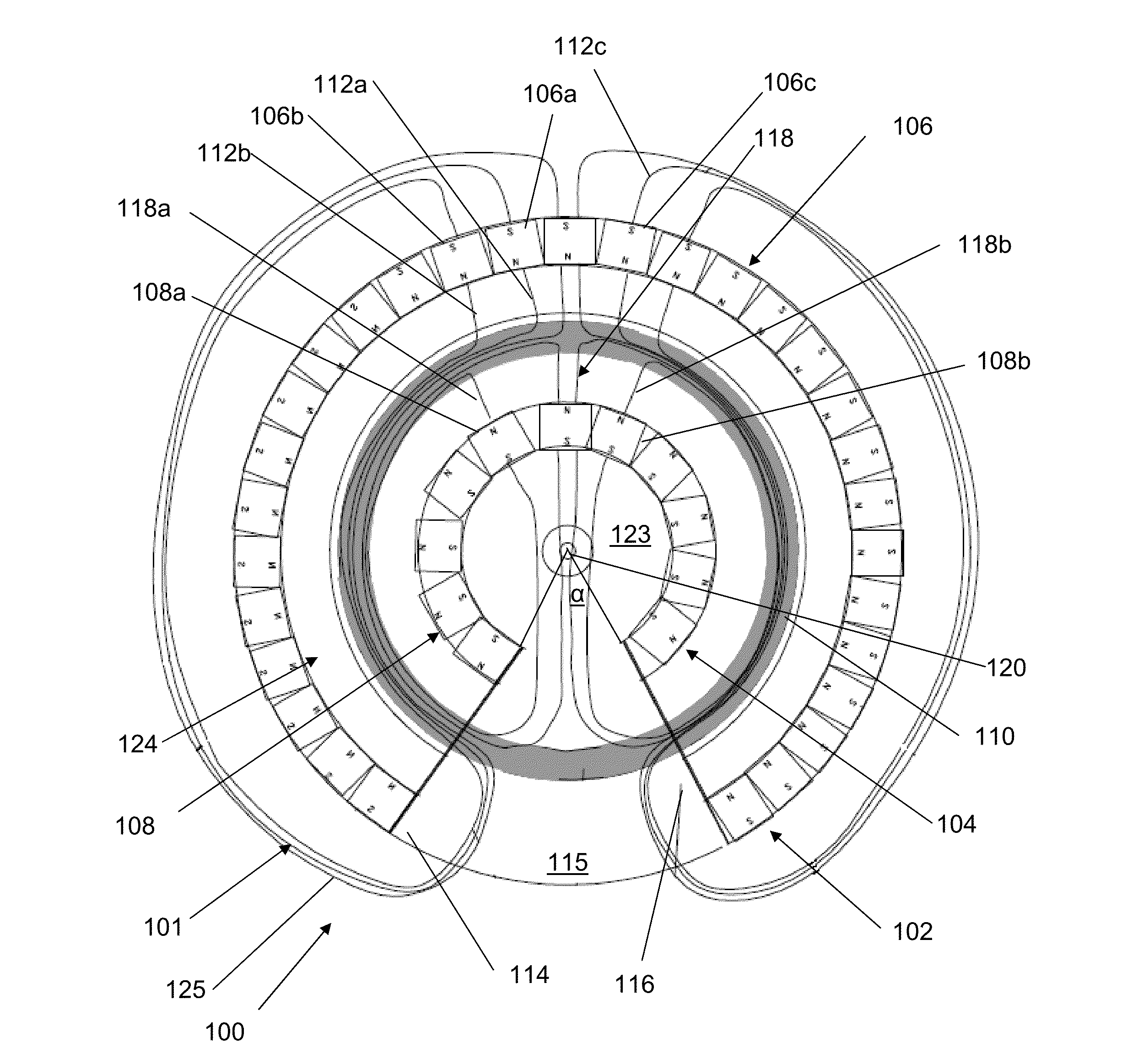

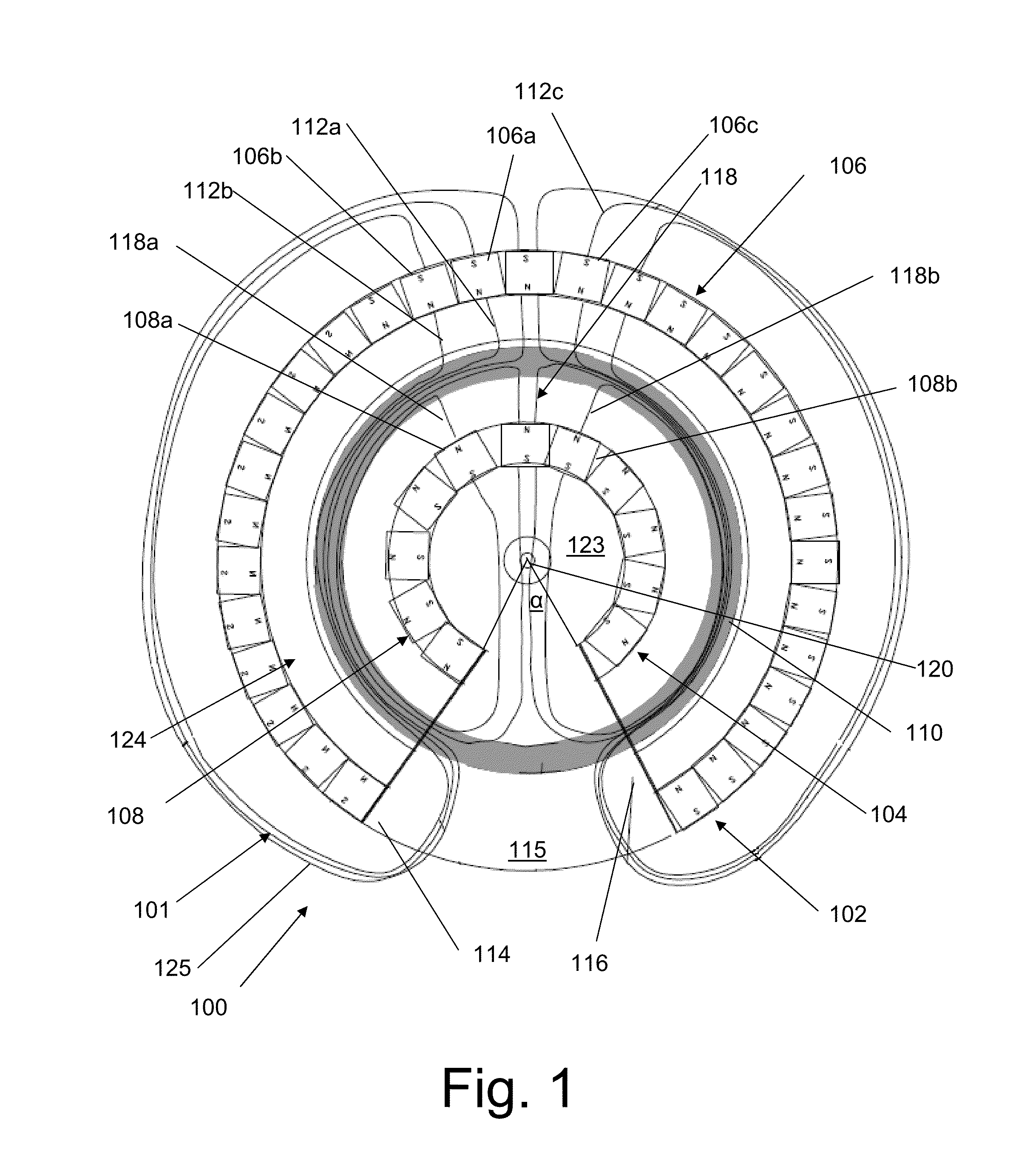

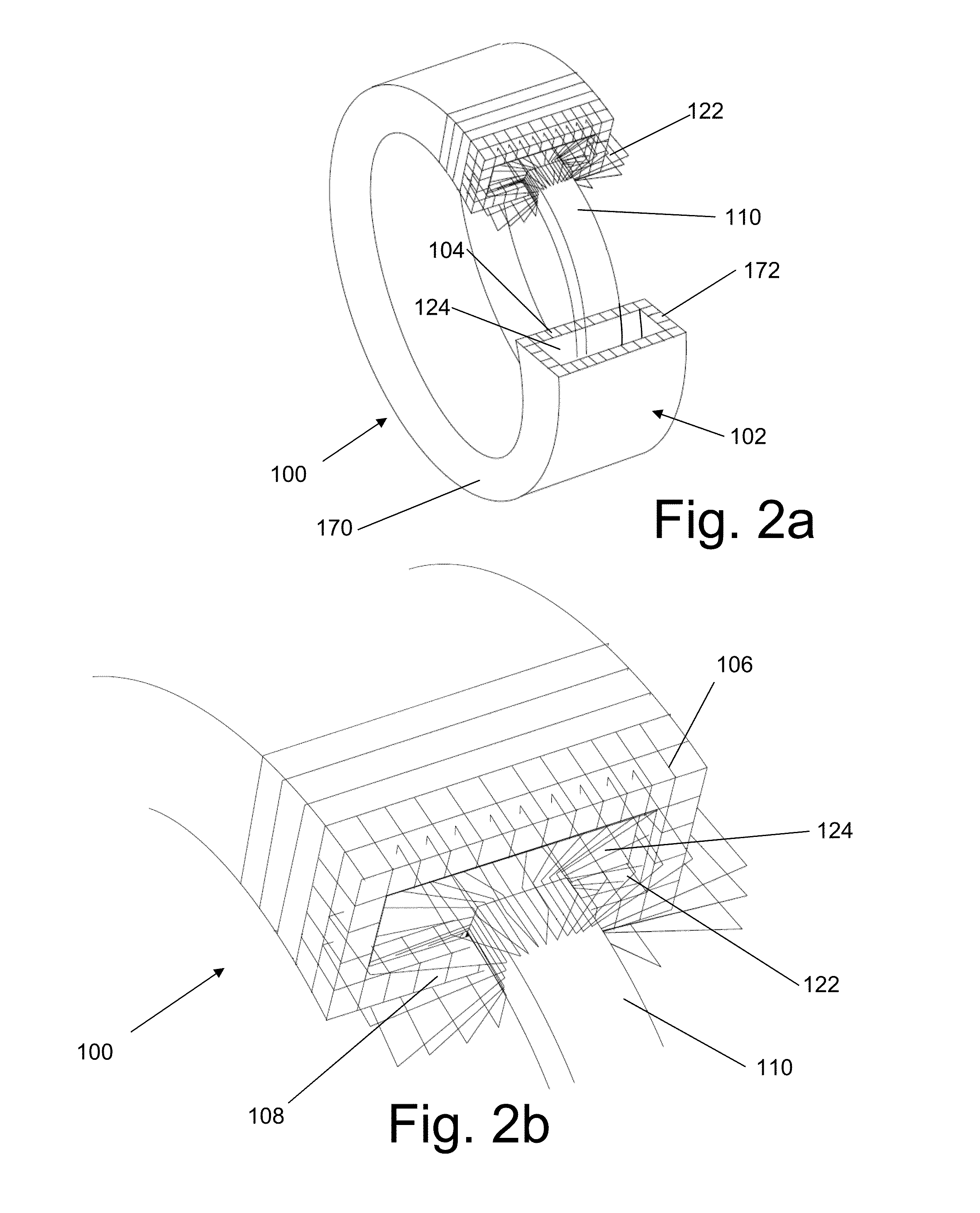

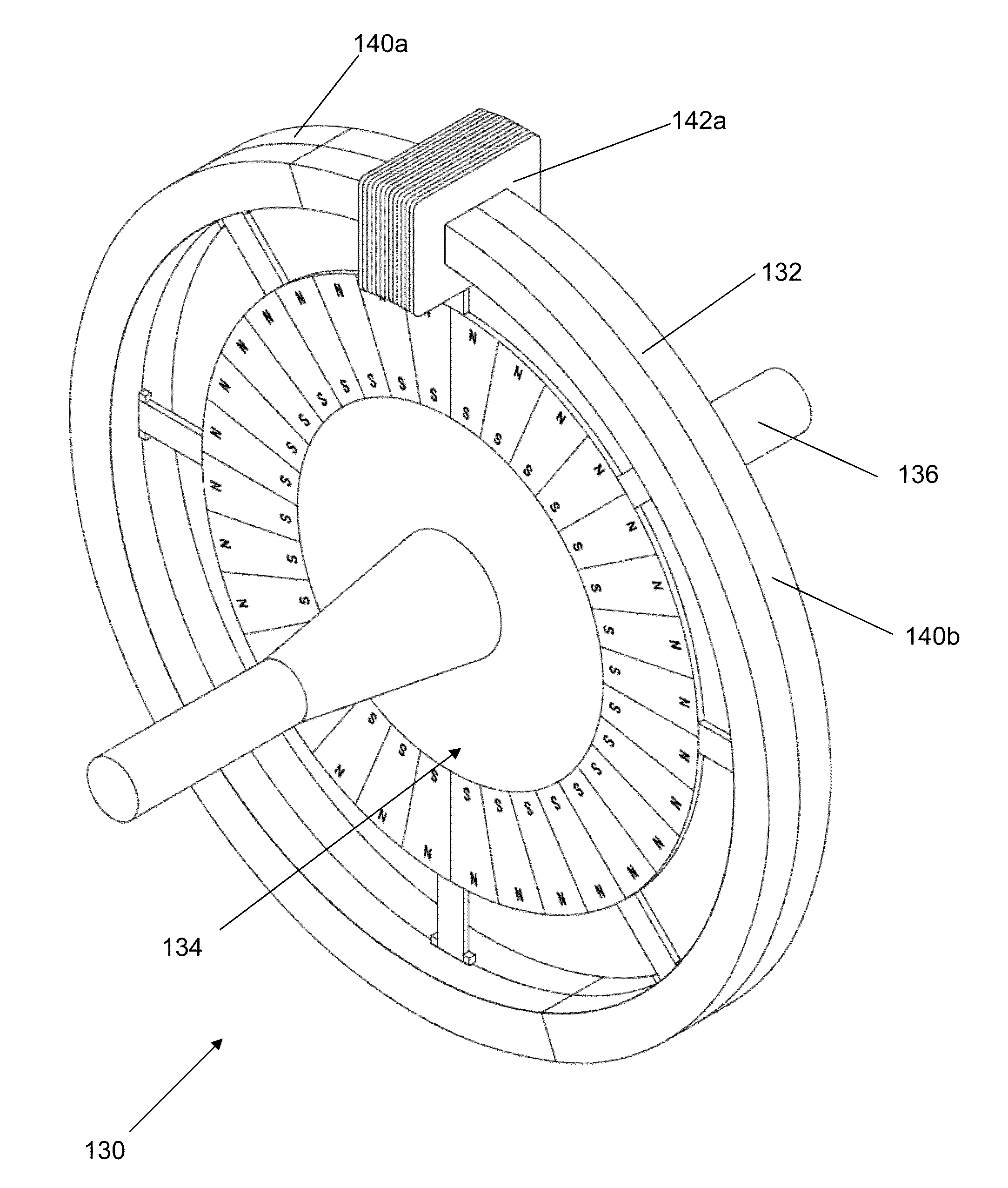

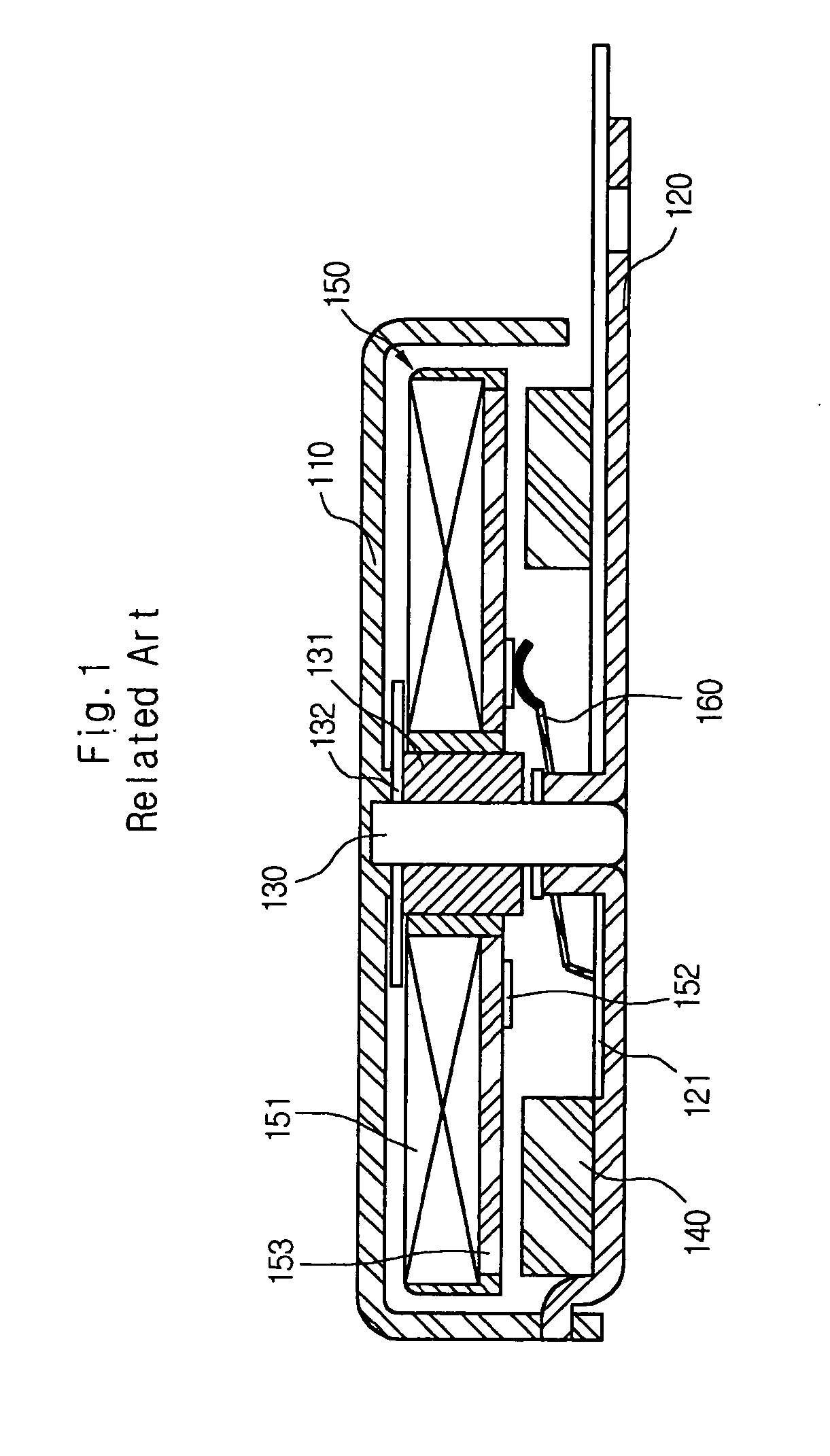

Brushed Electric Motor/Generator

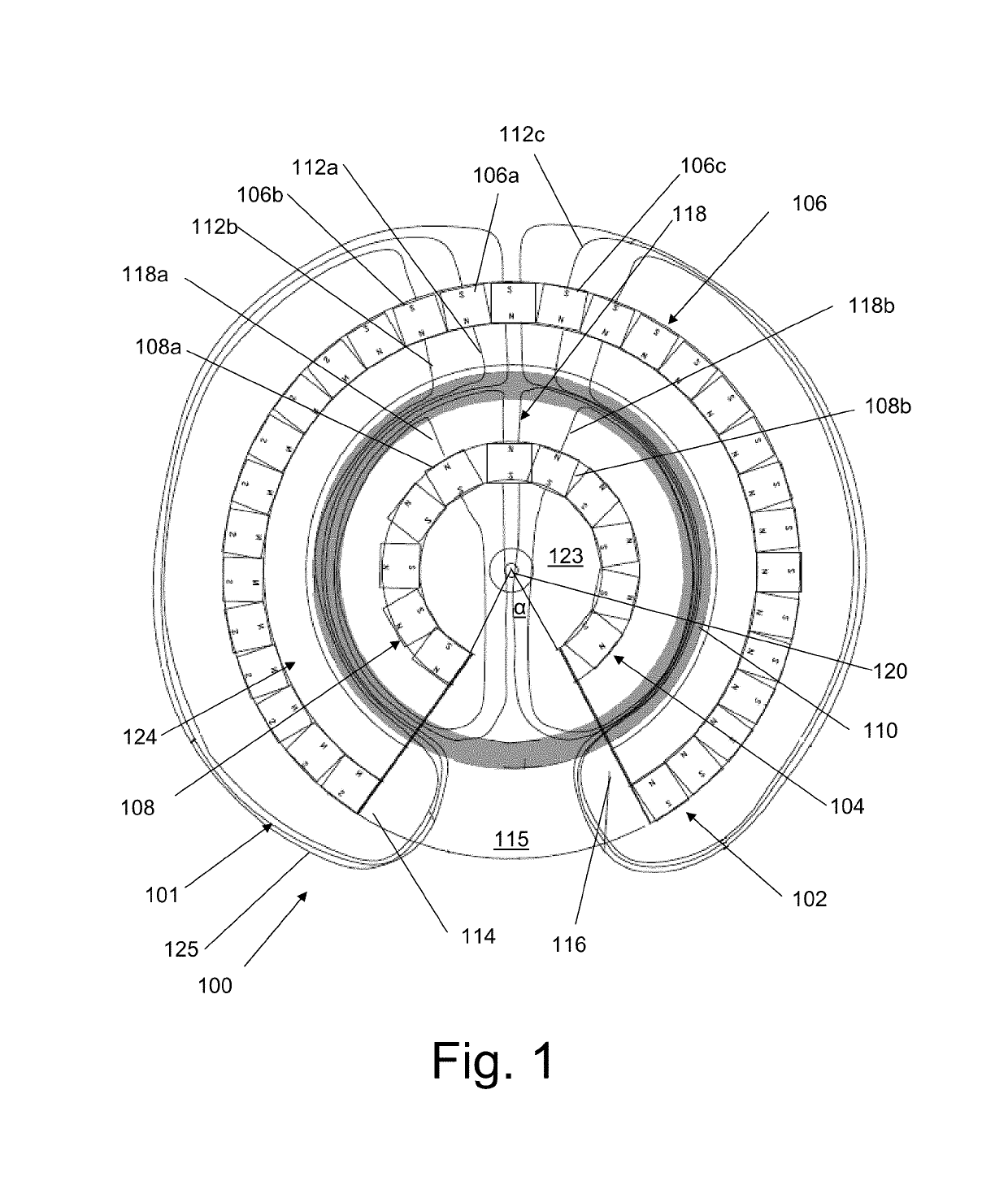

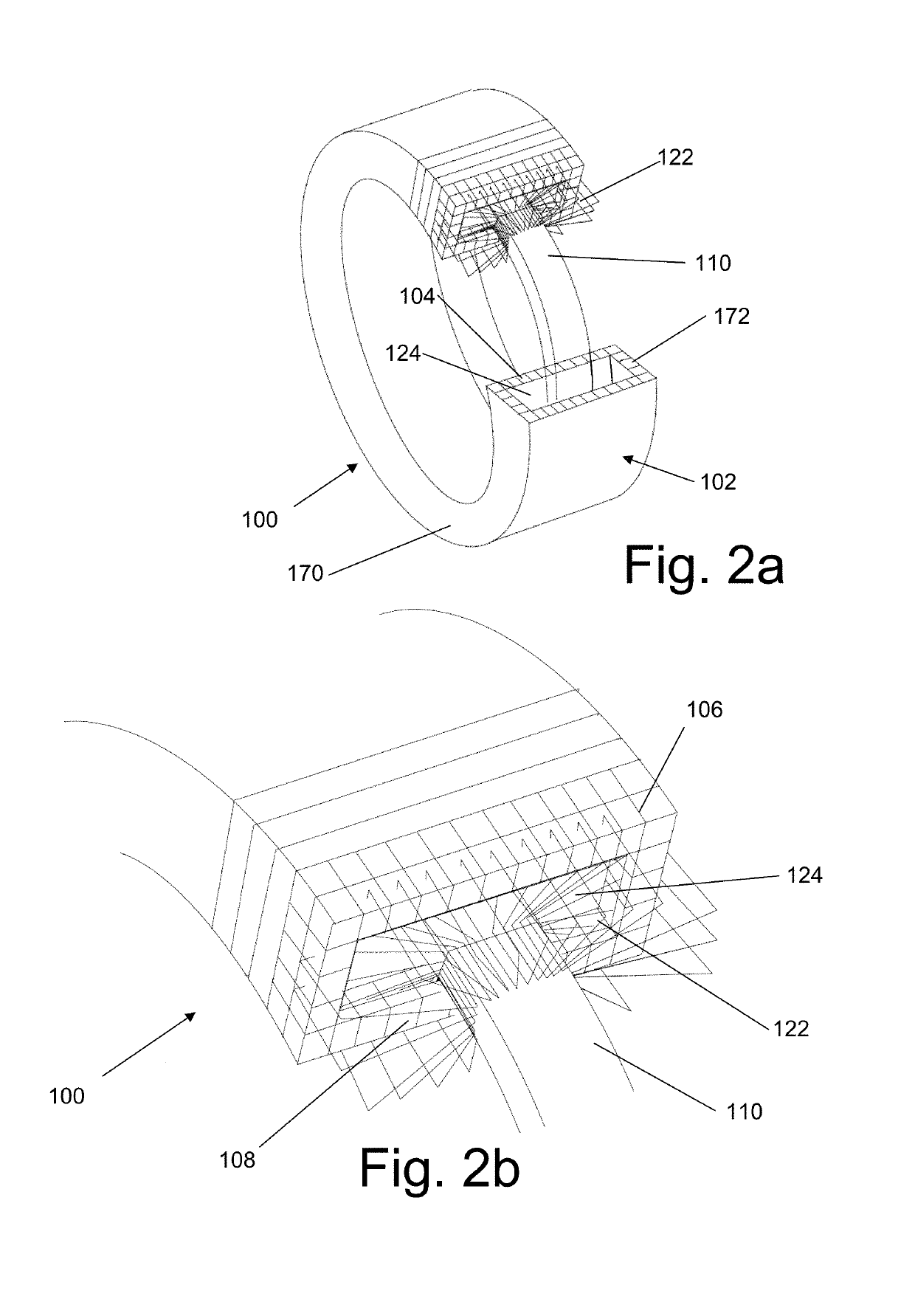

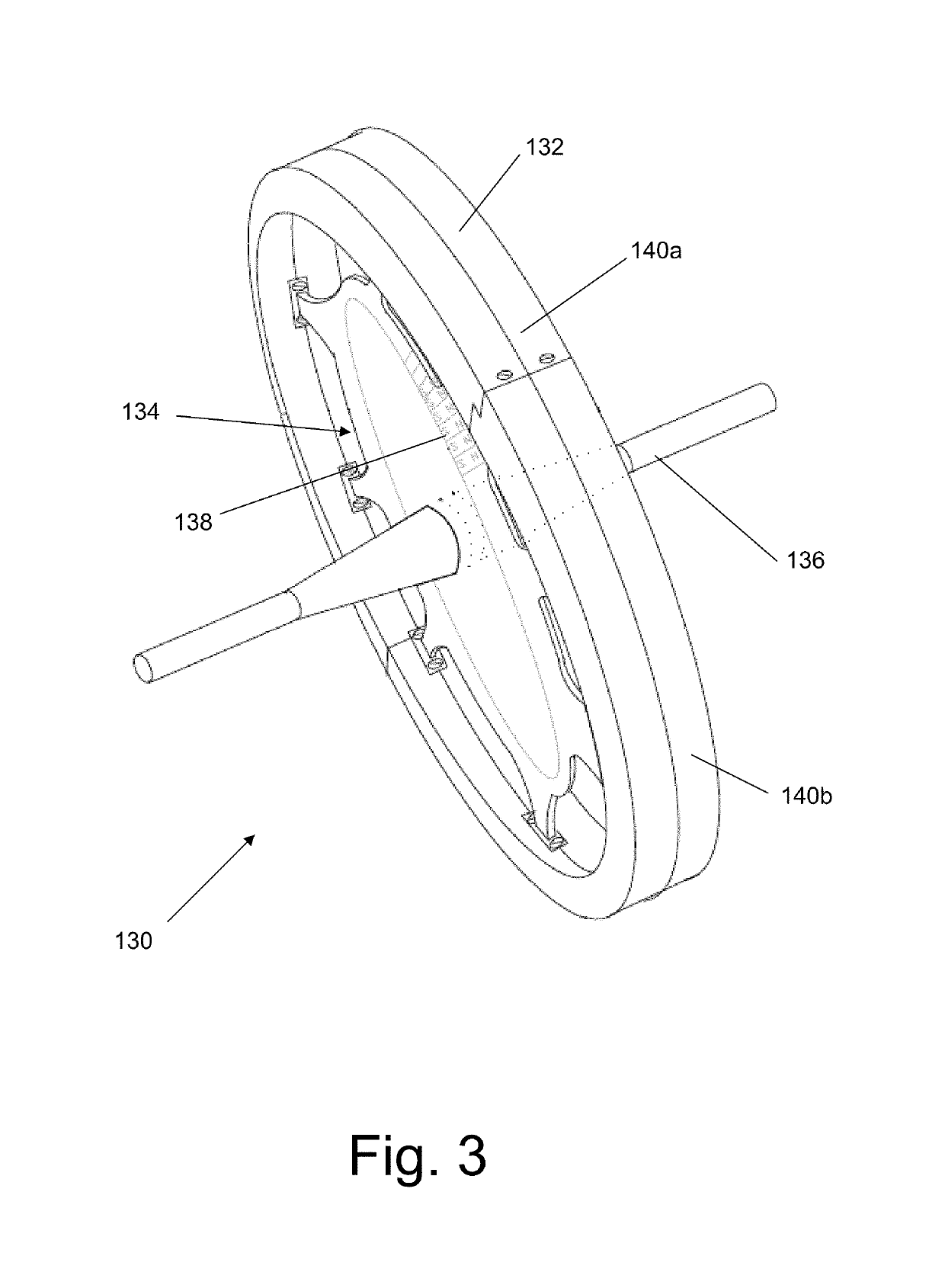

ActiveUS20160094096A1Reduced torque rippleEfficient outputMagnetic circuit rotating partsMagnetic circuit stationary partsPower flowDynamo

Disclosed are various embodiments for an improved generator / motor and a method of generating current, the method comprising providing a circular rotation path, generating a concentrated magnetic field around a portion of the circular rotation path; rotating a coil along the circular path and through the concentrated magnetic field; generating current within the coil as a result of the rotating, and extracting the current from the coil.

Owner:LINEAR LABS

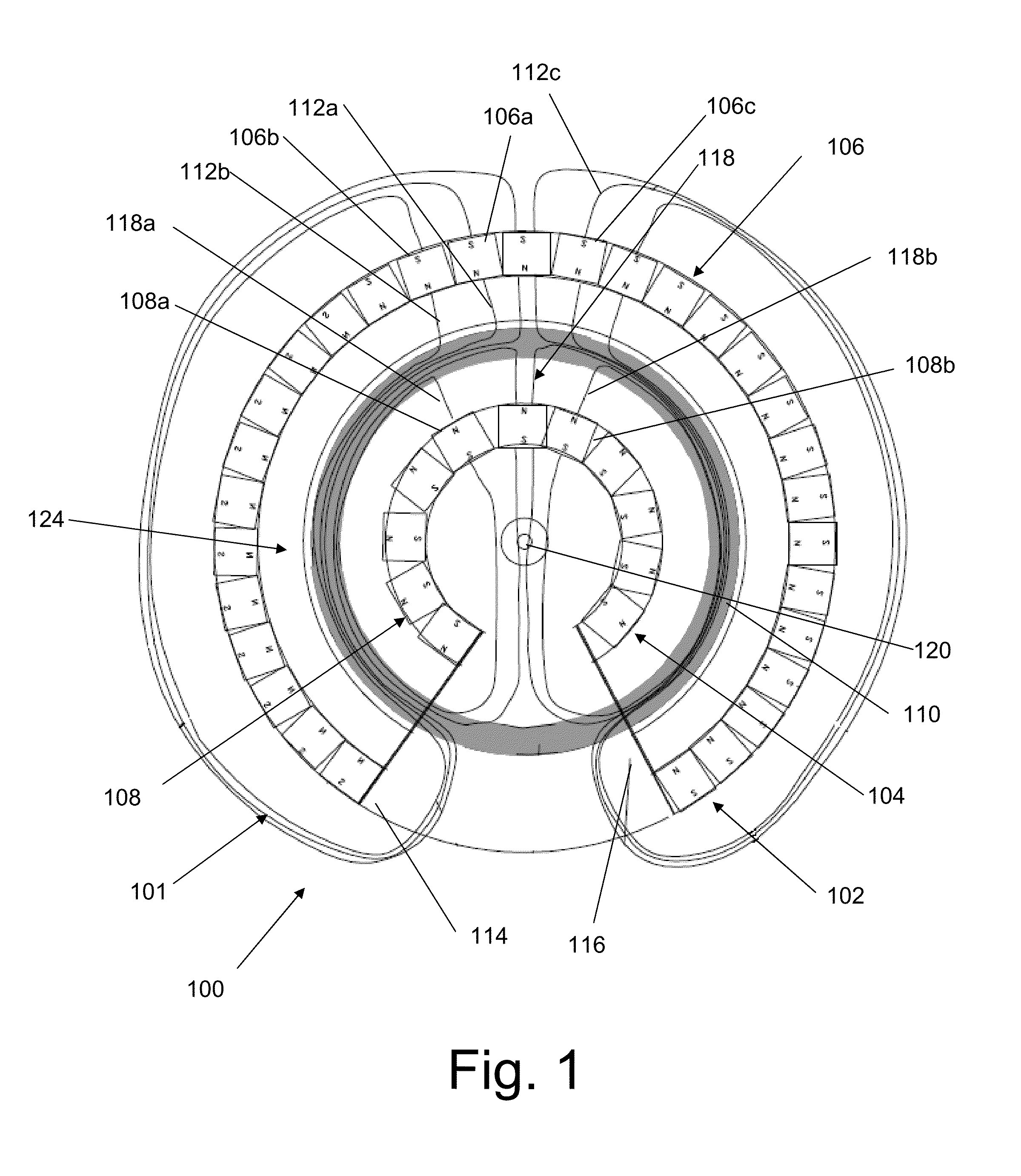

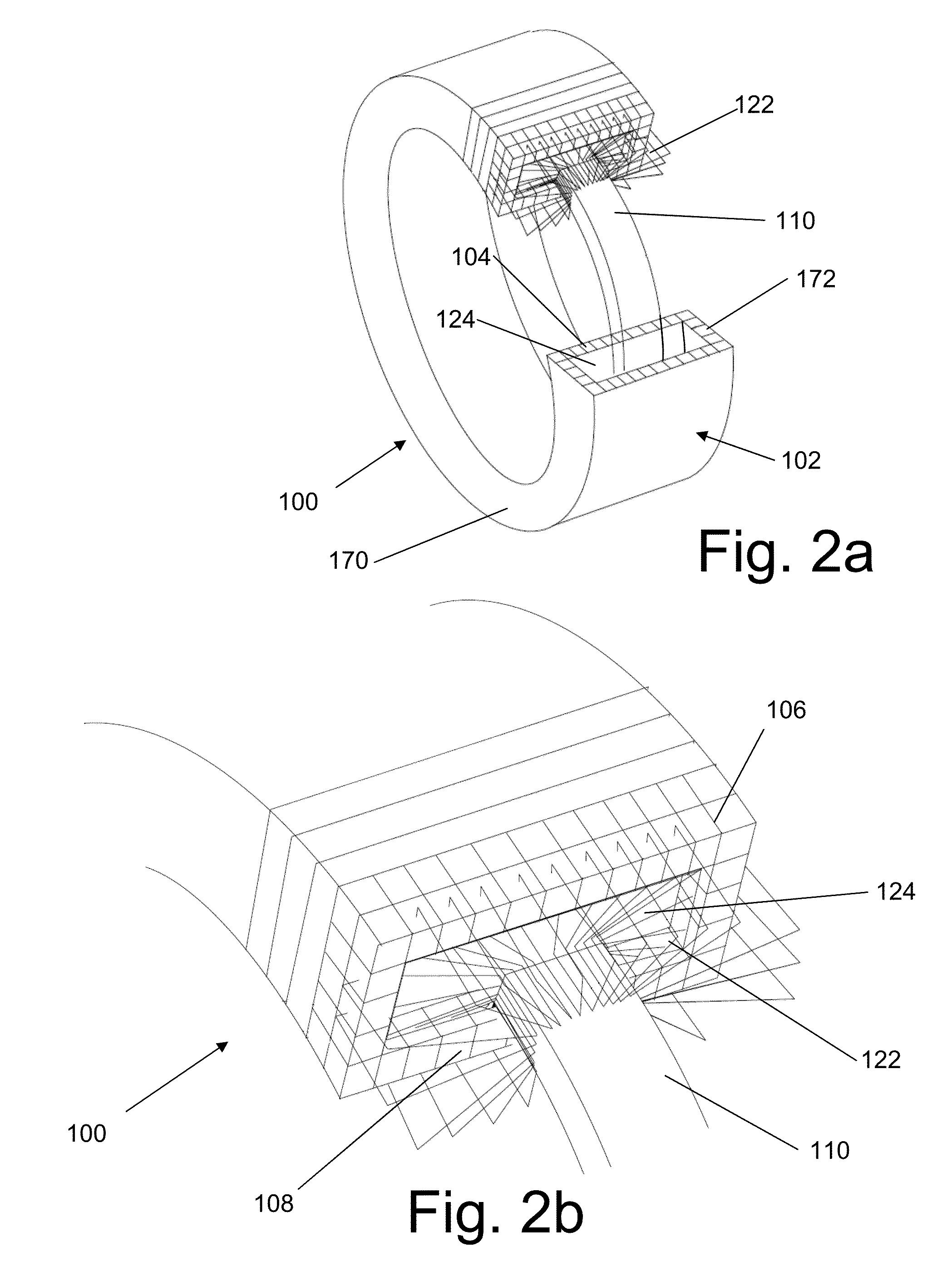

DC Electric Motor/Generator with Enhanced Permanent Magnet Flux Densities

ActiveUS20150001976A1Reduced torque rippleEfficient outputMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic tension forceImproved method

This disclosure relates in general to a new and improved method for producing electric energy or mechanical power, and in particular to an improved system and method for producing rotary motion from a electro-magnetic motor or generating electrical power from a rotary motion input by concentrating magnetic forces due to electromagnetism or geometric configurations.

Owner:LINEAR LABS

Rotor and motor and/or electric vehicle driving apparatus including the same

InactiveCN103812244ATorque value reductionReduced torque rippleMagnetic circuit rotating partsElectric machinesElectric machinePole piece

The invention provides a rotor and motor and / or electric vehicle driving apparatus including the same. The motor includes a plurality of tooth bodies extending from a rotor core. A pole shoe extends from an end of at least one tooth body at opposite sides where both sides of the pole shoe have a curved outer part opposite to each other and asymmetric to each other in that a radius of curvature of the curved outer part of the one side of the pole shoe that is in a rotational direction of the rotor has a smaller radius than a radius of curvature of the other side of the pole shoe that is not in the rotational direction of the rotor.

Owner:LG ELECTRONICS INC +1

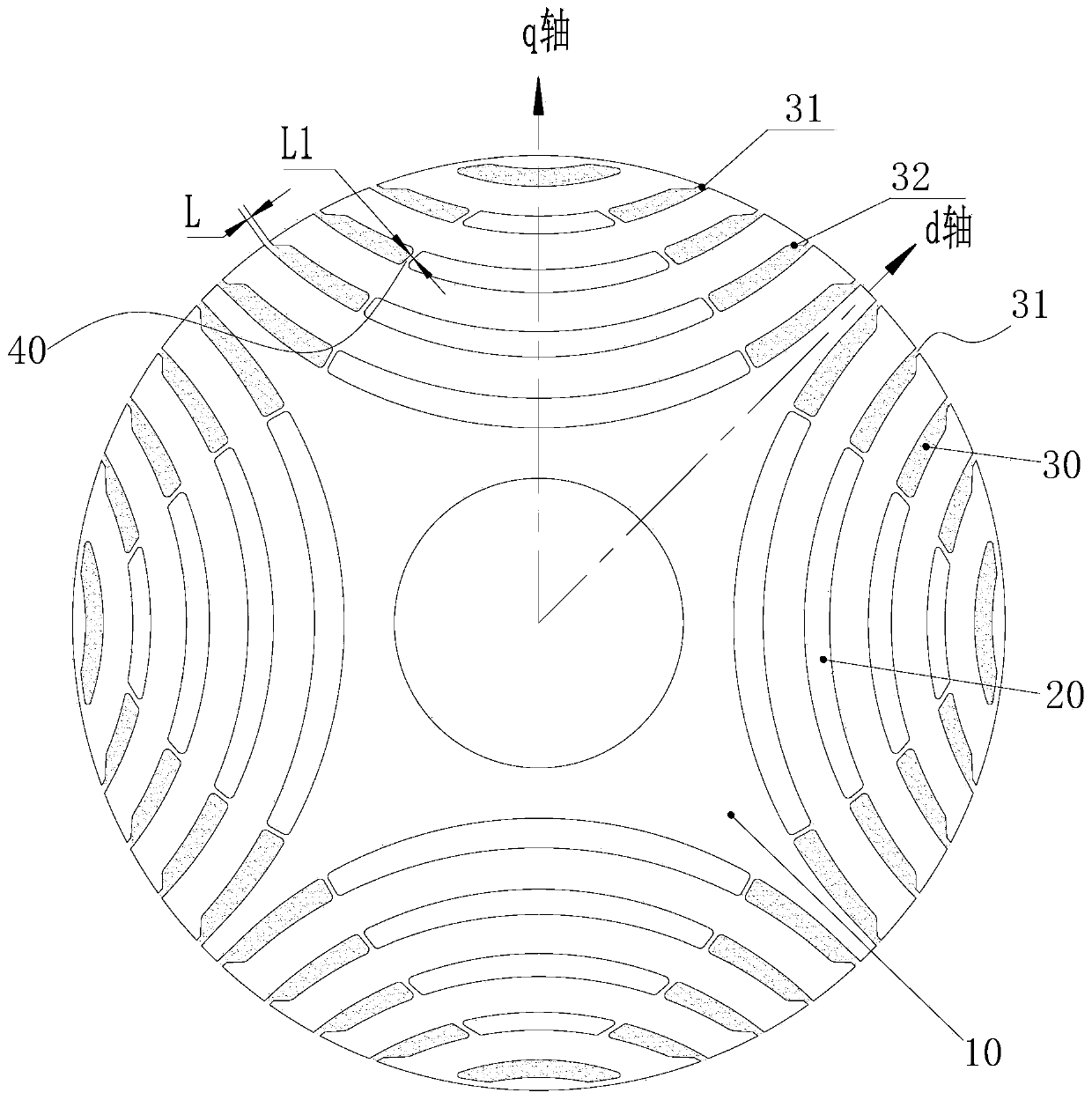

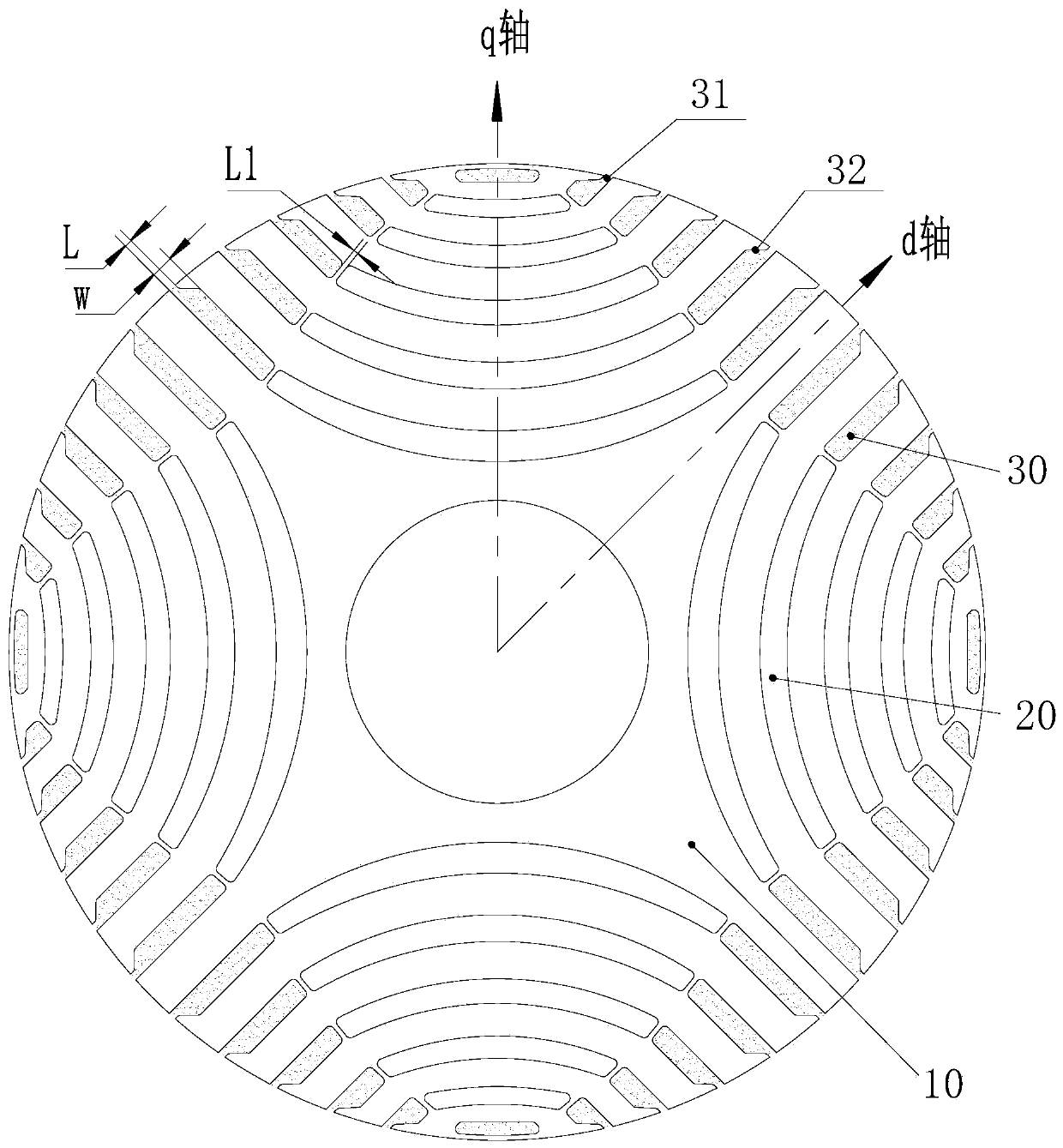

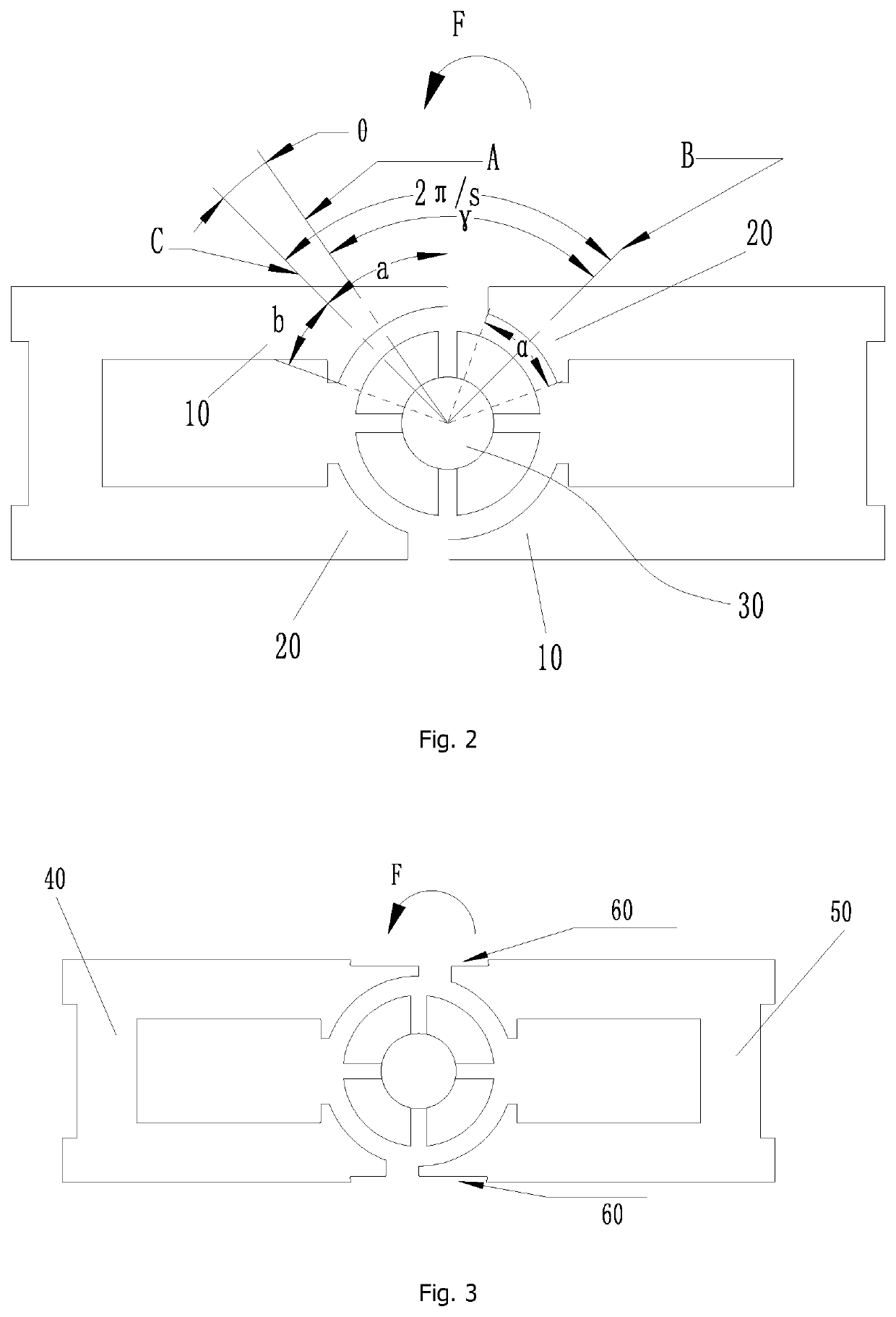

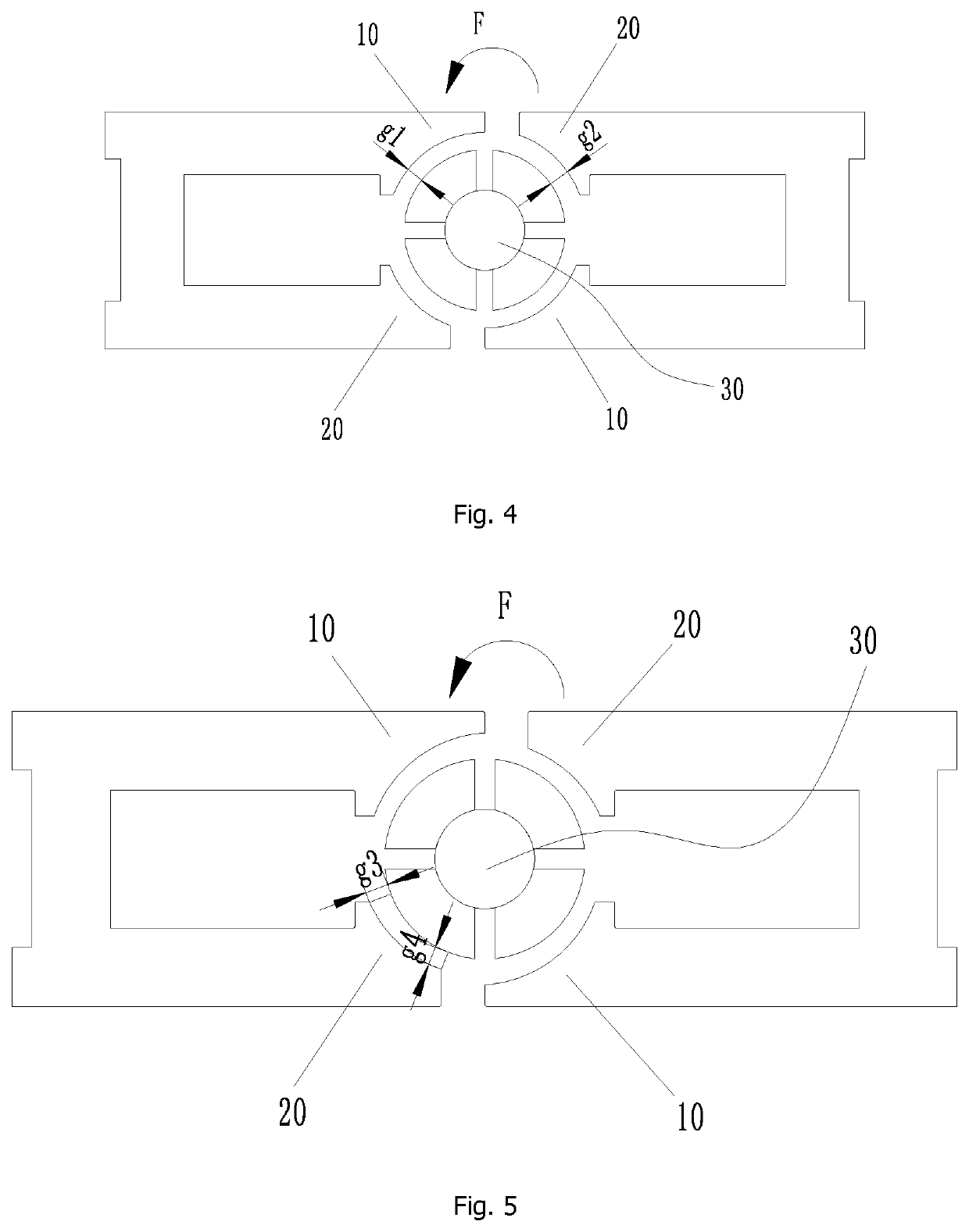

Synchronous reluctance motor rotor structure, motor and manufacturing method of rotor structure

ActiveCN110138117AReduced torque rippleReduce vibration and noiseMagnetic circuit rotating partsSynchronous motorsMagnetic barrierSynchronous reluctance motor

The invention provides a synchronous reluctance motor rotor structure, a motor and a manufacturing method of the rotor structure. The synchronous reluctance motor rotor structure comprises a rotor core which is provided with multiple slit slots, two ends of each of the slit slots are provided with two filling grooves to form a magnetic barrier layer, a first end of each of the filling grooves is adjacent to a slit slot, a second end of each of the filling grooves extends in the radial direction of the rotor core, and the outer peripheral surface of the rotor core is provided with a notch communicating with an end of the second end each of the filling grooves. By setting notches and bevels at the ends of the filling grooves, the reluctance torque of the motor can be increased, the torque ripples generated by a rotor and a stator tooth space can be weakened by each other, the purpose of reducing the torque ripple of the motor is achieved, the vibration noise of the motor is reduced, theefficiency of the motor with the rotor structure is improved, and the starting ability of the motor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

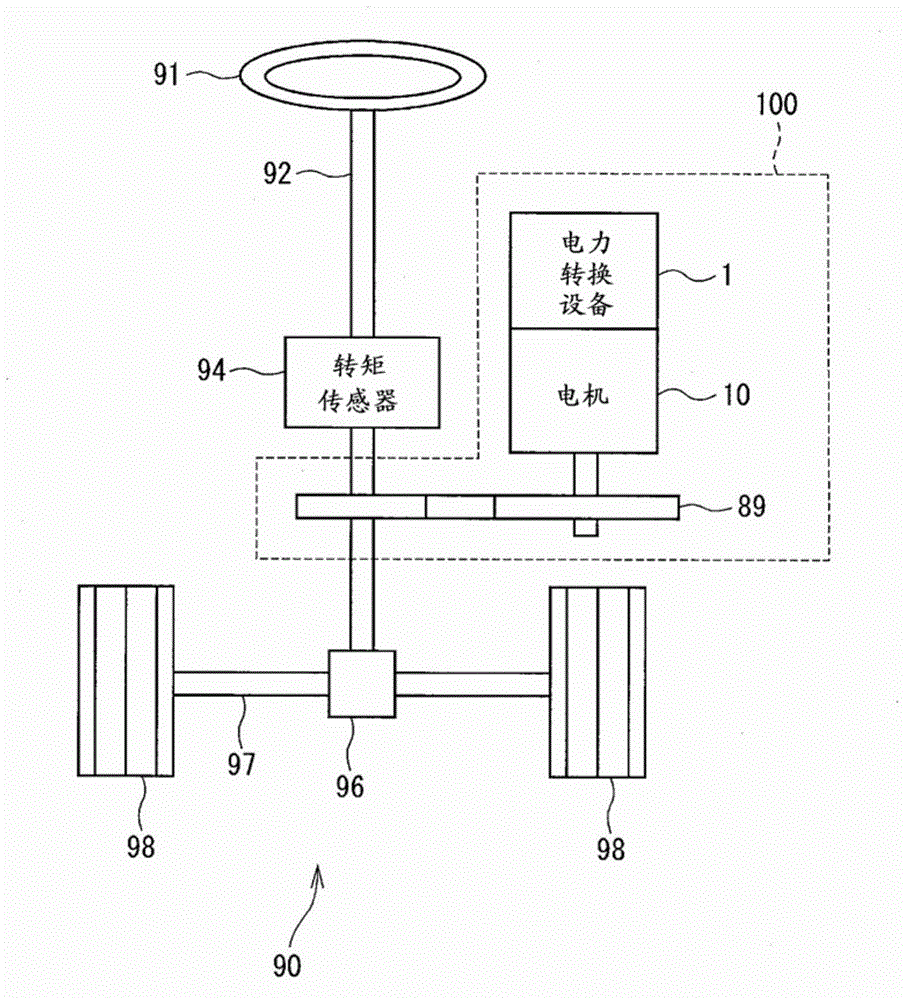

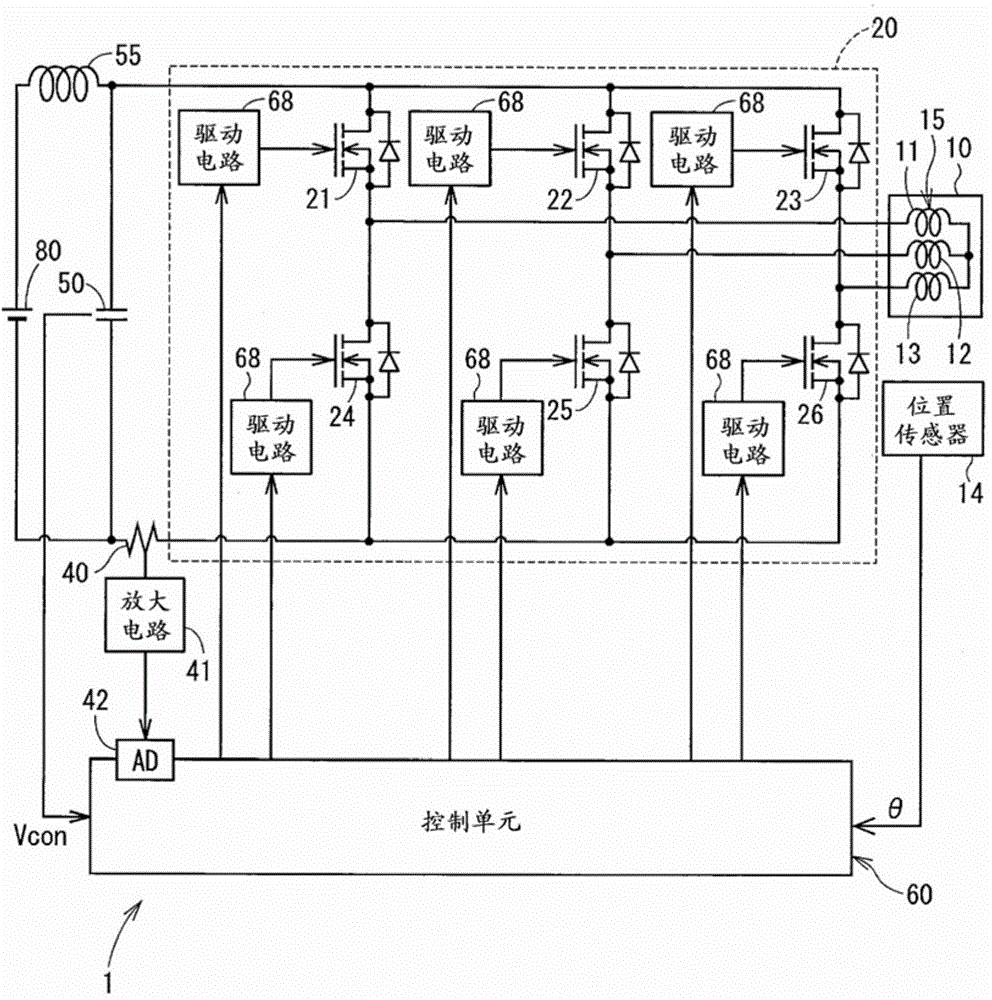

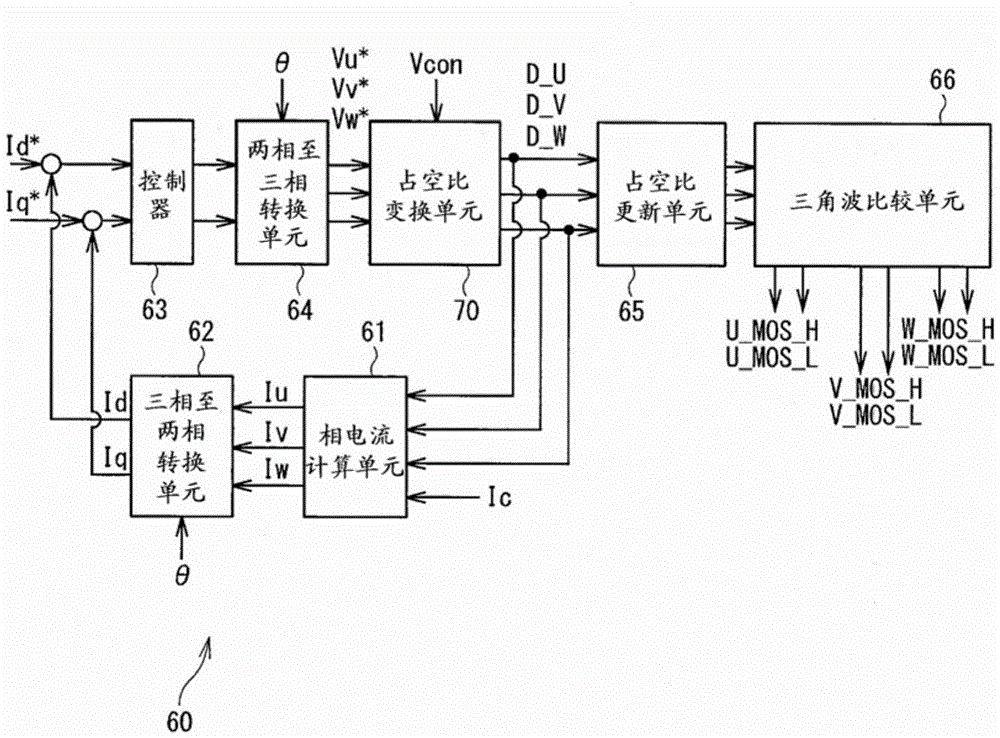

Power conversion apparatus and electric power steering apparatus having the same

ActiveCN104467494ASmall distortionReduce Current Sense ErrorsTorque ripple controlDc-ac conversion without reversalElectric power steeringPhase currents

A power conversion apparatus (2) includes: an inverter unit (20) having high and low potential-side switching elements (21-26) corresponding to each phase of a winding (15) of a rotating electrical machine (10); a current detecting unit (40); a current obtaining unit (42) obtaining a current detection value with a fixed interval sampling timing; and a control unit (60) controlling the switching elements based on a PWM reference signal and a duty instruction value. The control unit (60) includes: a phase current computing device; voltage instruction value computing devices (63, 64); and a duty computing device. The phase current computing device computes a correction current based on positive and negative side corrected current detection values. The positive-side corrected current detection value is obtained when a duty is adjusted to a positive side, and the negative-side corrected current detection value is obtained when the duty is adjusted to a negative side.

Owner:DENSO CORP

Brushed electric motor/generator

ActiveUS10284029B2Reduced torque rippleEfficient outputMagnetic circuit rotating partsMagnetic circuit stationary partsCondensed matter physicsMagnetic field

Disclosed are various embodiments for an improved generator / motor and a method of generating current, the method comprising providing a circular rotation path, generating a concentrated magnetic field around a portion of the circular rotation path; rotating a coil along the circular path and through the concentrated magnetic field; generating current within the coil as a result of the rotating, and extracting the current from the coil.

Owner:LINEAR LABS

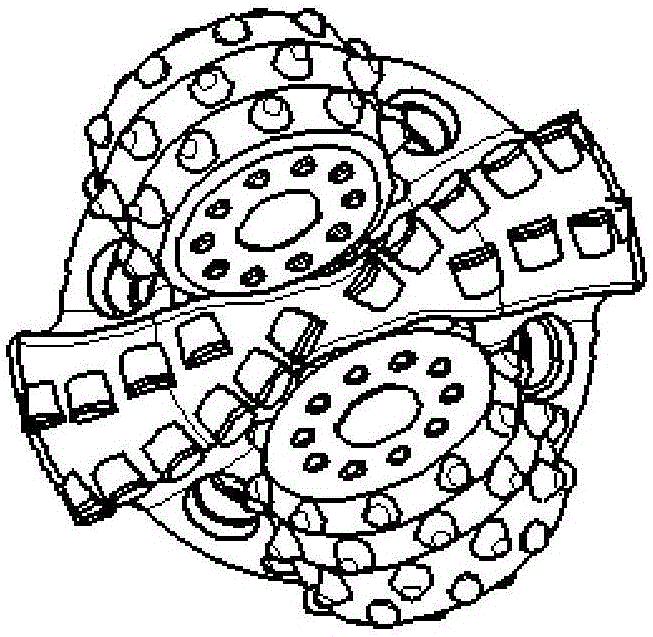

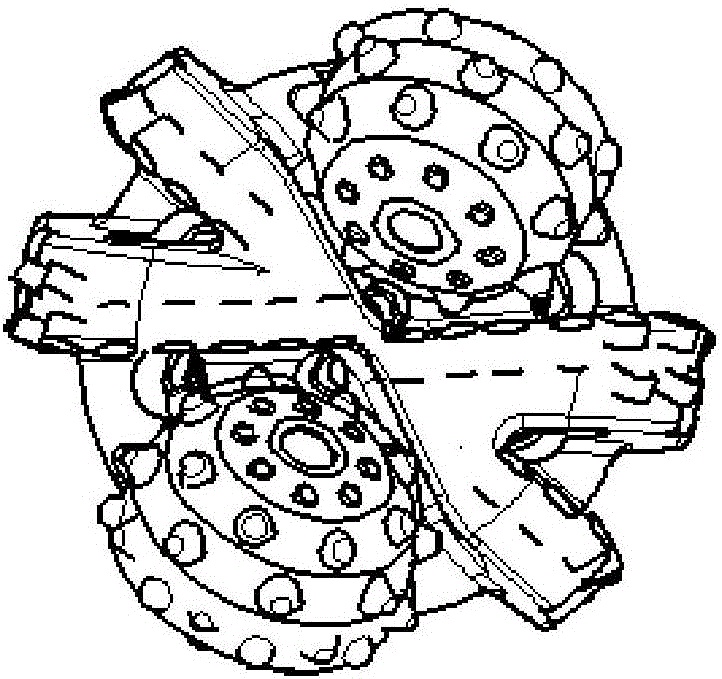

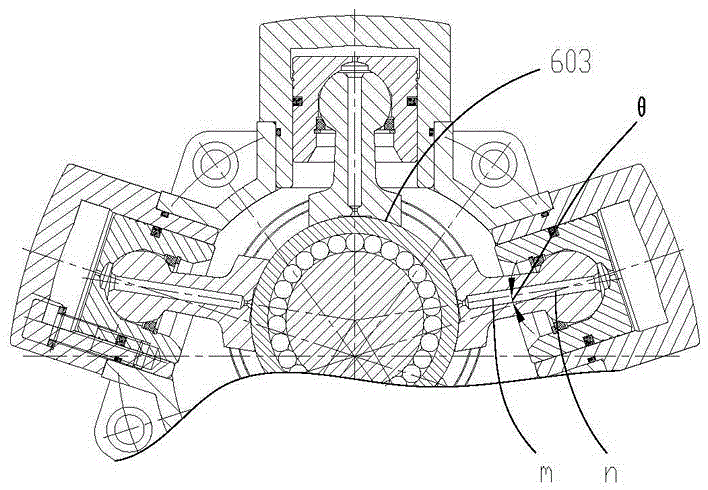

Composite drill bit

InactiveCN106121541AWide operating parameter spaceEasy to controlDrill bitsConstructionsTorsional vibrationIgneous rock

The invention relates to the technical field of petroleum drilling and well cementation, in particular to a composite drill bit which comprises a PDC drill bit body and roller cones. The roller cones are installed on the PDC drill bit body. The roller cone and PDC composite drill bit is composed of the roller cones and PDC, the advantages of roller cone drill bits and PDC drill bits are combined, the aggressivity is high, the cutting efficiency is high, the mechanical drilling speed of the composite drill bit is 2-4 times higher than the roller cone drill bits when the composite drill bit operates on poor-drillability stratums (such as igneous rock and mud and sand interbeddings containing gravels), and the mechanical drilling speed and the rotation speed are in direct proportion. When a motor is adopted by the roller cone and PDC composite drill bit for drilling, the mechanical drilling speed is increased remarkably. Another advantage is reflected in the influences of the roller cones on drill bit dynamics, compared with the conventional PDC drill bits, the torque fluctuation degree can be reduced by as much as 50%, the torsional vibration degree is lowered under the low rotation speed condition, and the whirling vibration degree is lowered under the high rotation speed condition.

Owner:TIANJIN LILIN BIT

High-performance permanent magnet servo motor

InactiveCN105099012AImprove reliabilityImprove cooling effectMagnetic circuit rotating partsMagnetic circuit stationary partsProduction ratePunching

The invention provides a high-performance permanent magnet servo motor, which comprises a stator and a rotor, wherein the stator comprises a stator core and a coil; the coil is wound on the stator core; the rotor comprises a rotor core and a permanent magnet; the permanent magnet is arranged on the periphery of the rotor core; the high-performance permanent magnet servo motor is characterized in that the stator core is formed by laminating stator punching plates; each stator punching plate is formed by splicing at least two stator tooth punching plates; the rotor core is formed by laminating rotor punching plates; a permanent magnet groove is formed in the periphery of the rotor core; and the permanent magnet is embedded into the permanent magnet groove. According to the high-performance permanent magnet servo motor, improvement of the utilization rate of a silicon steel sheet is facilitated; the offline production rate is improved; the slot space-factor can be improved; the coils in a slot are arranged regularly and densely; and heat dissipation of the coils is facilitated.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

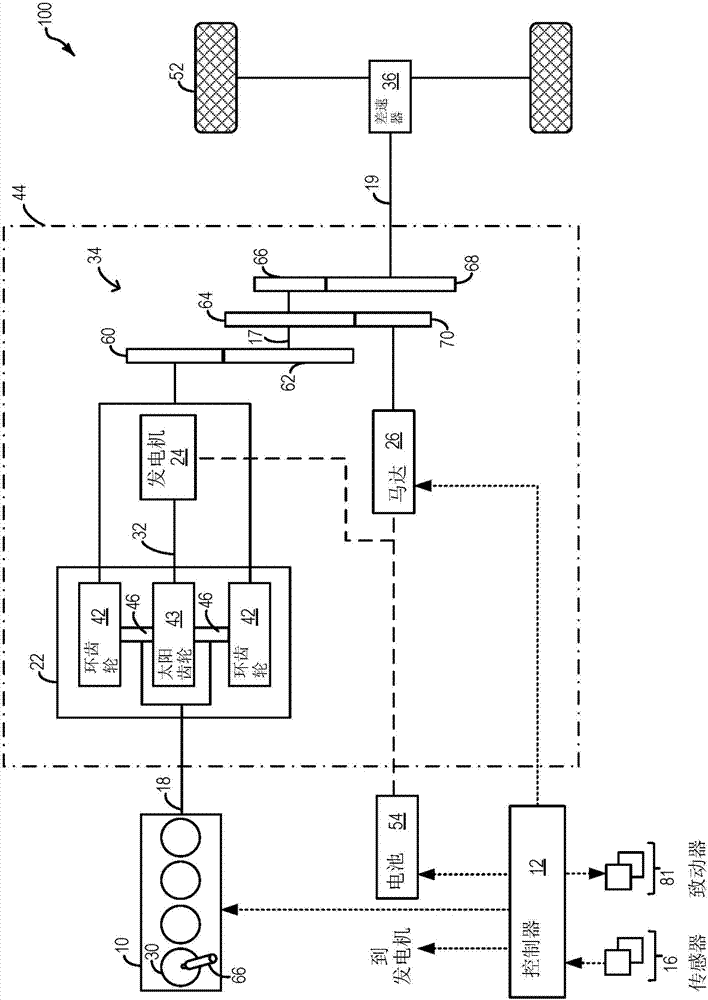

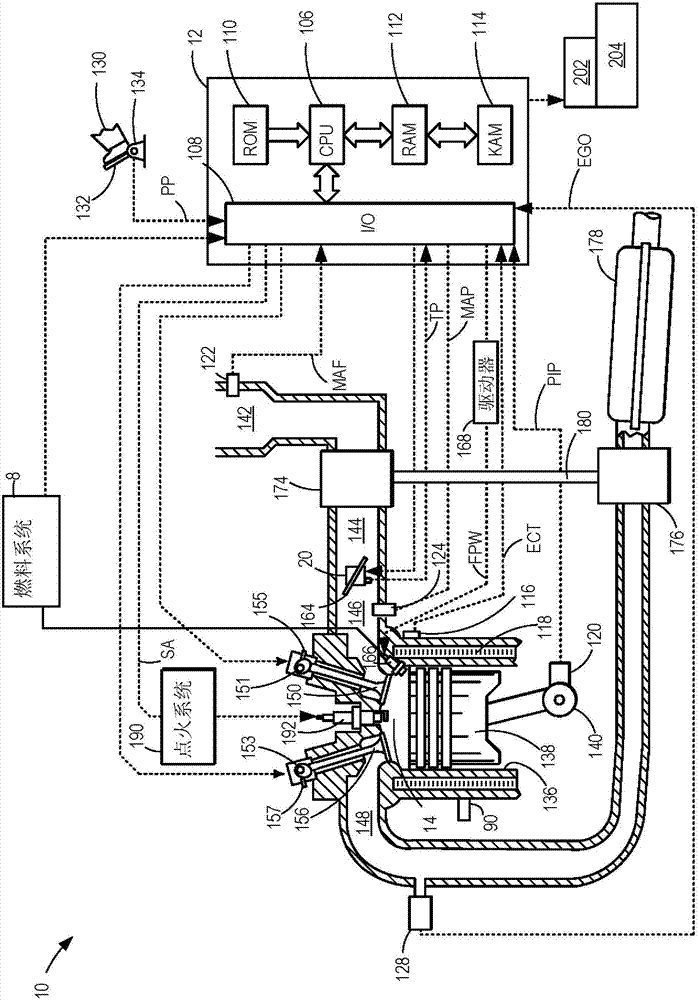

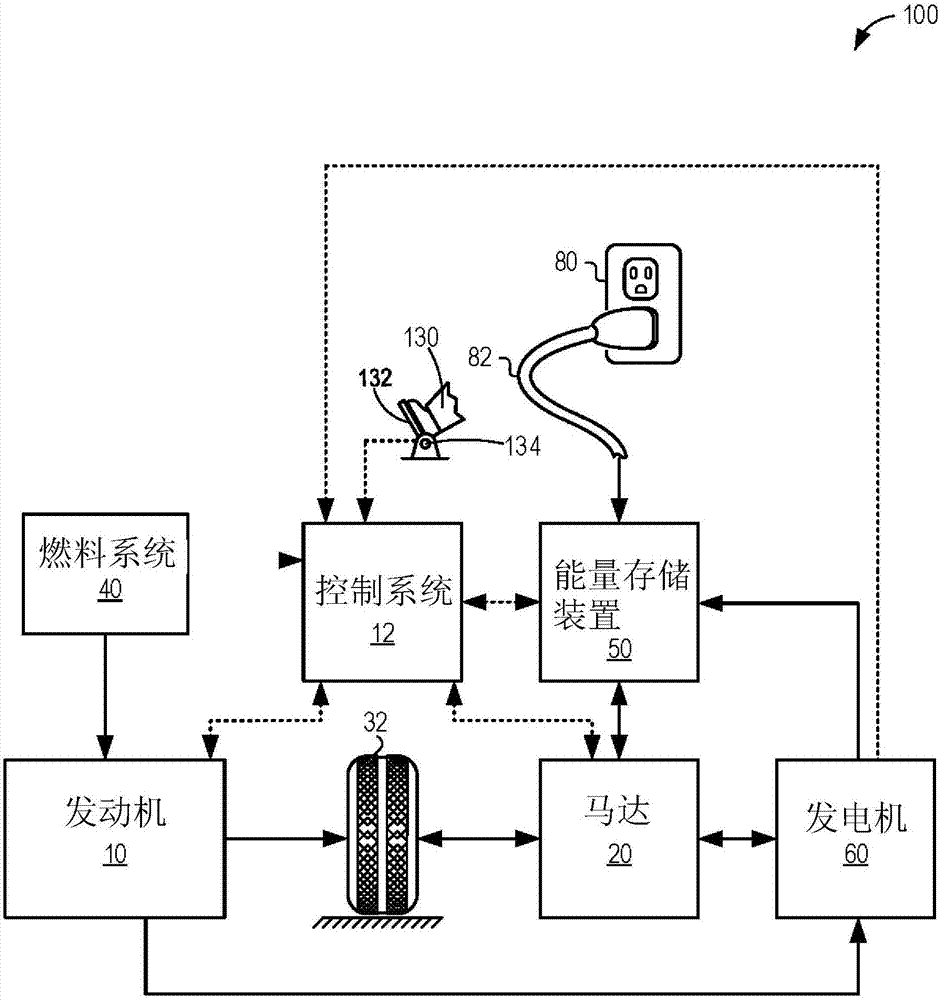

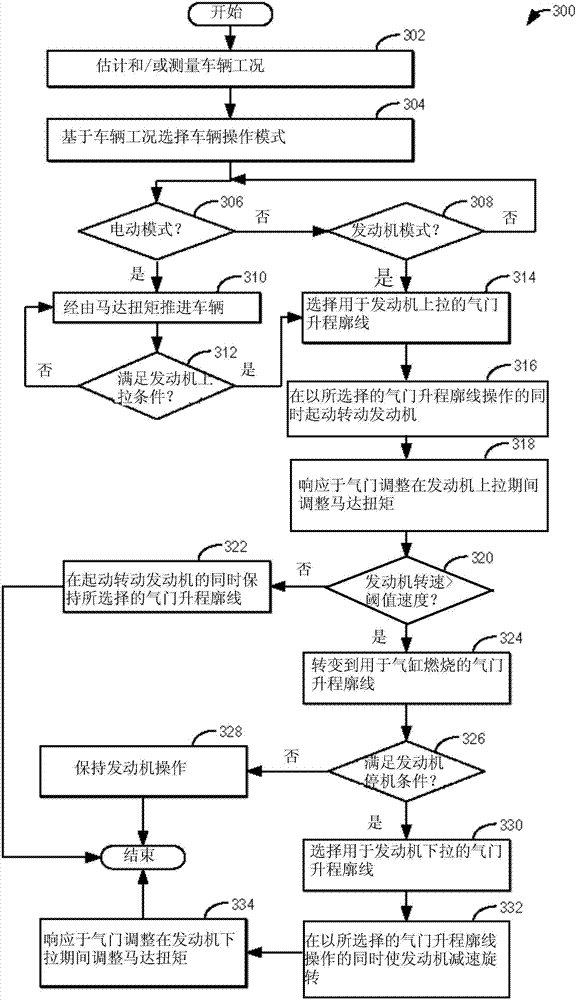

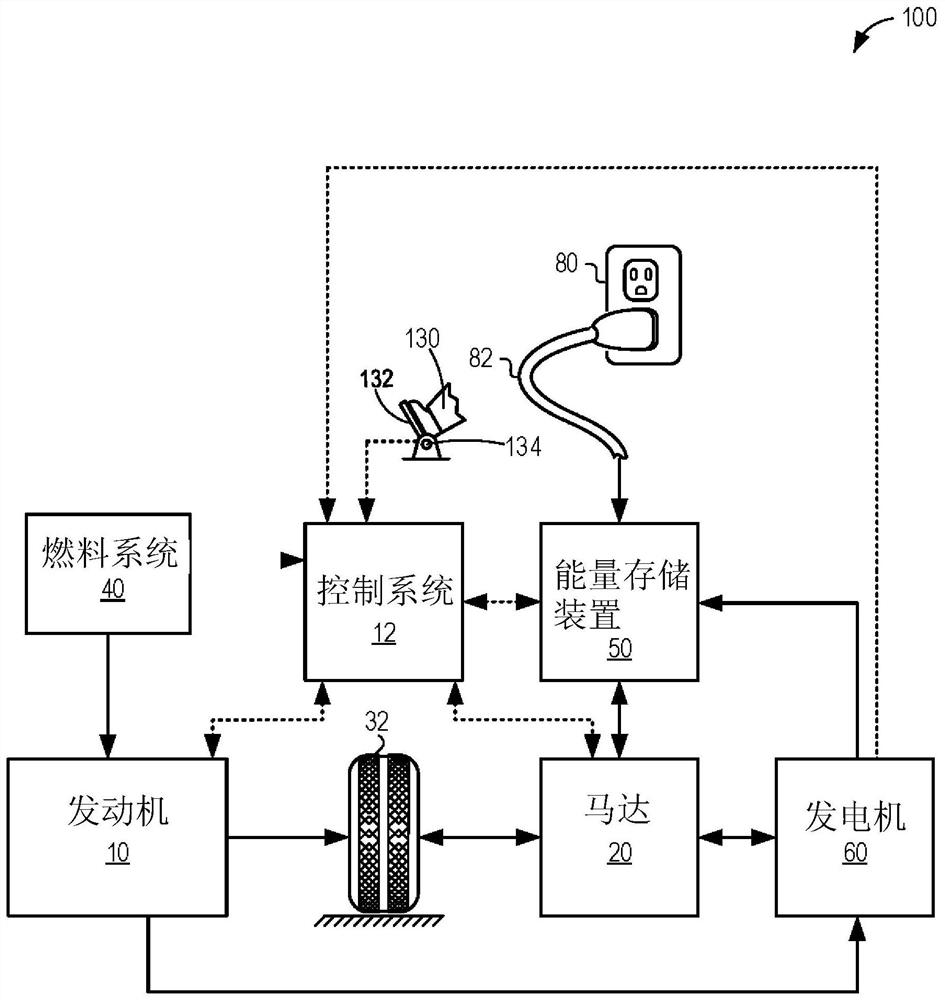

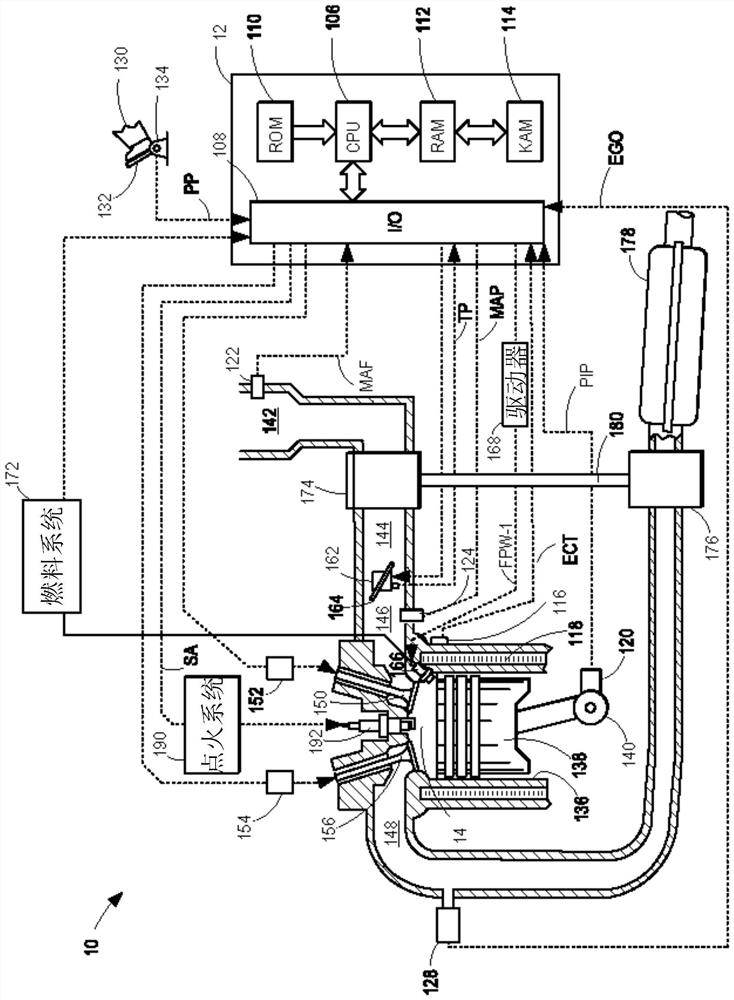

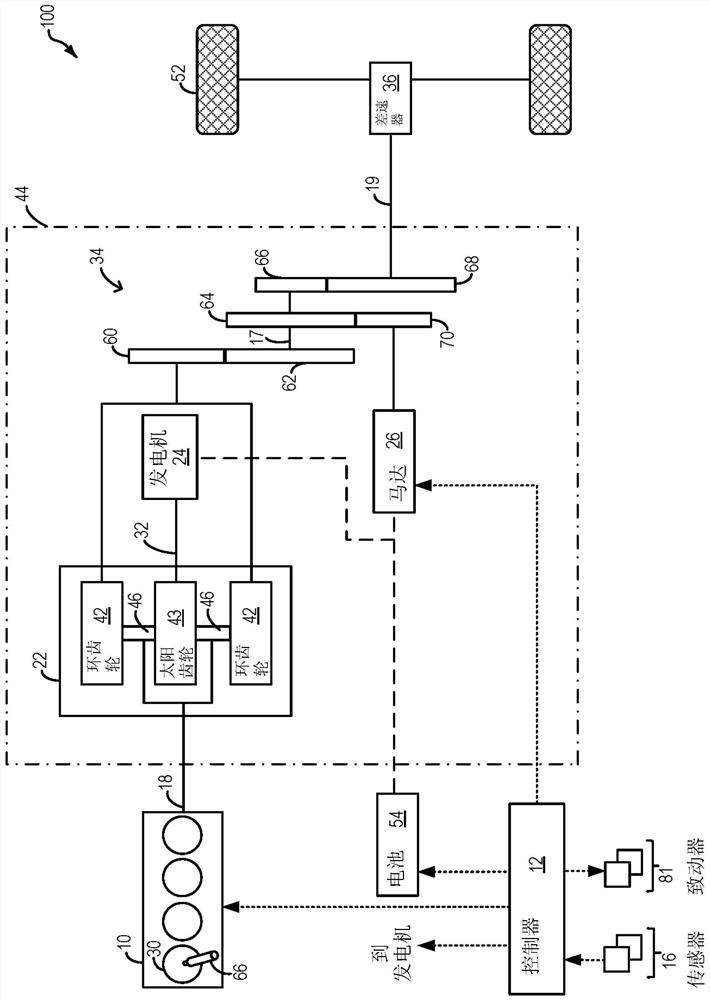

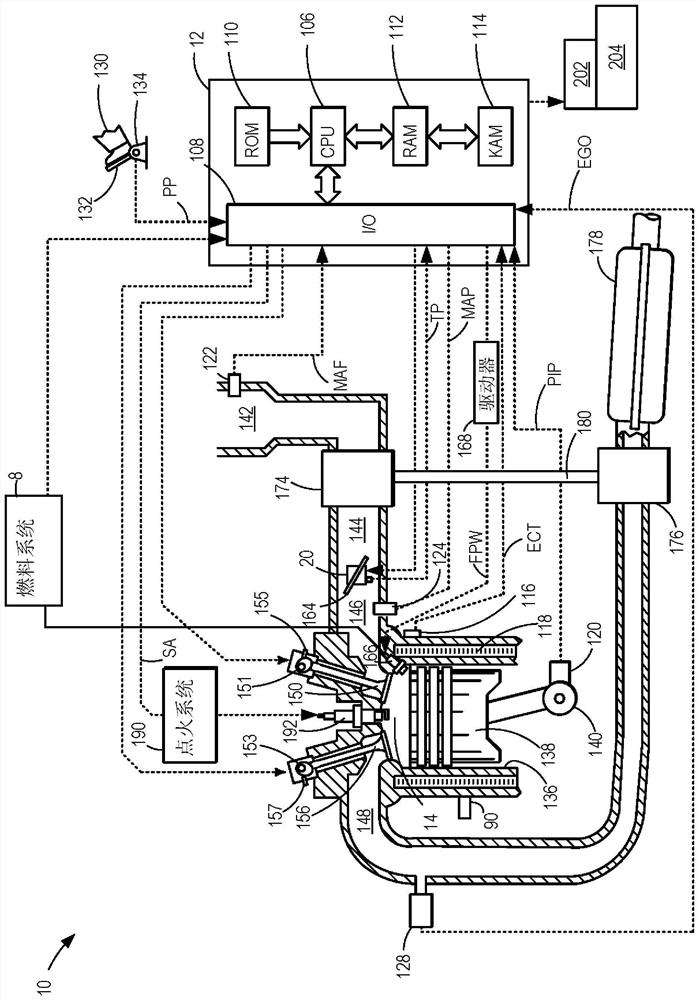

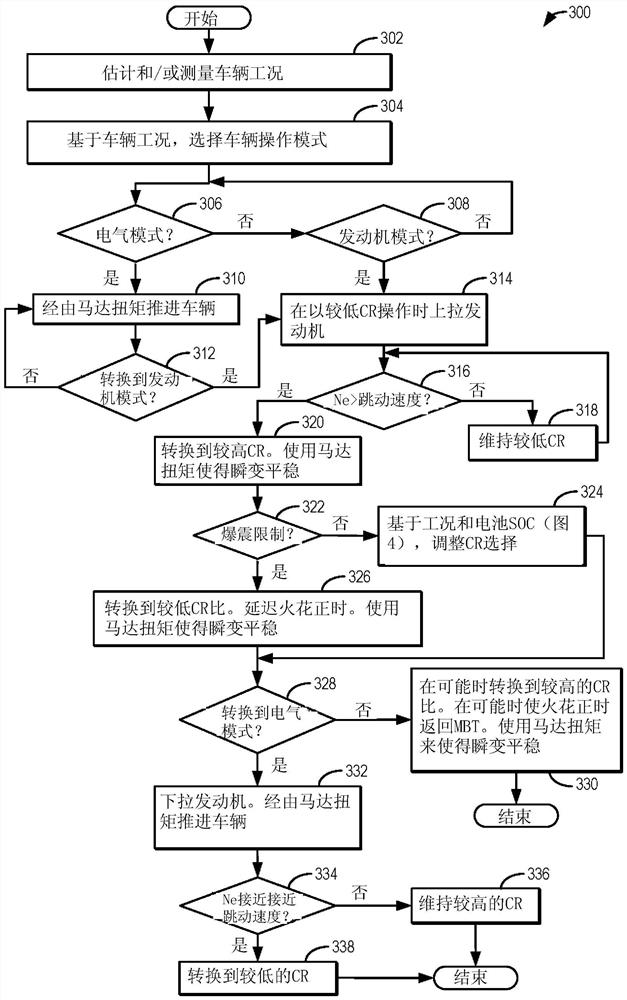

Method and system for engine control

ActiveCN107345500AMeet Torque DemandsReduce economic lossHybrid vehiclesElectrical controlLow speedHybrid vehicle

The invention relates to a method and system for engine control. Methods and systems are provided for synergizing the benefits of a variable compression ratio engine in a hybrid vehicle system. A vehicle controller may hold the engine in a lower compression ratio during engine pull-ups and pull-downs, in particular when passing through a low speed region where compression bobbles can occur. During engine operation, in response to a change in driver demand, the controller may opt to switch the compression ratio or maintain a current compression ratio while smoothing a torque deficit using motor torque, the selection based on fuel economy.

Owner:FORD GLOBAL TECH LLC

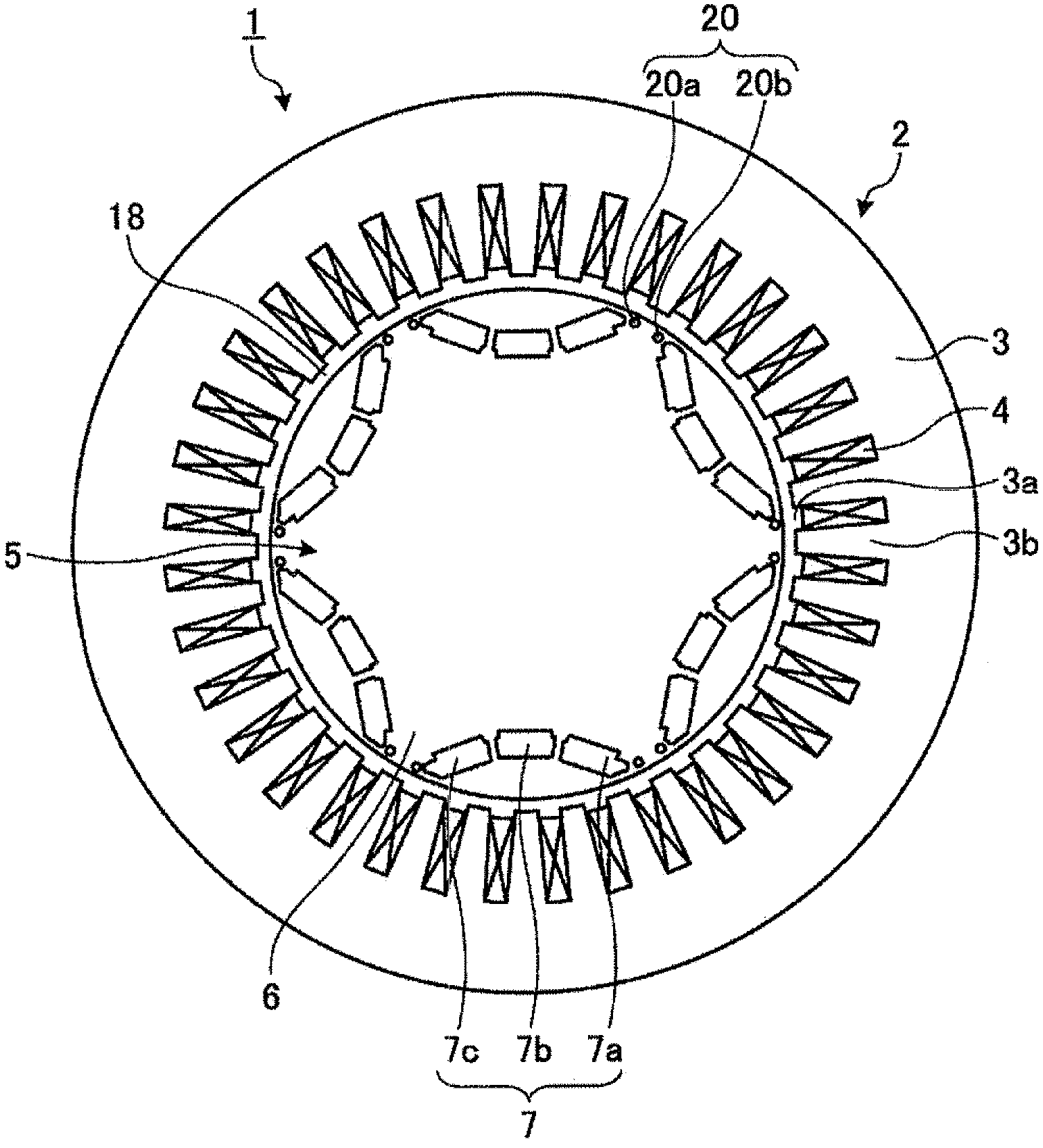

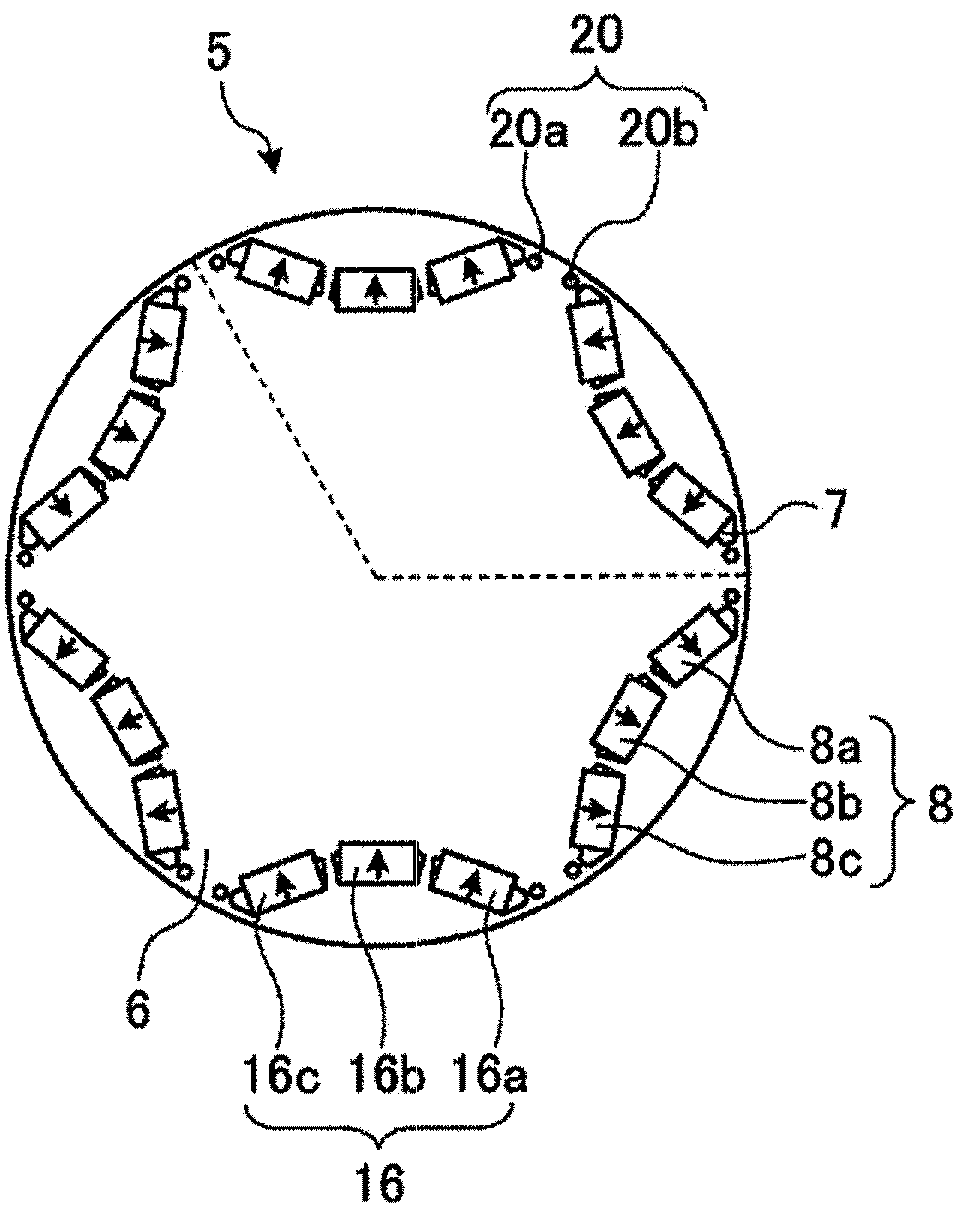

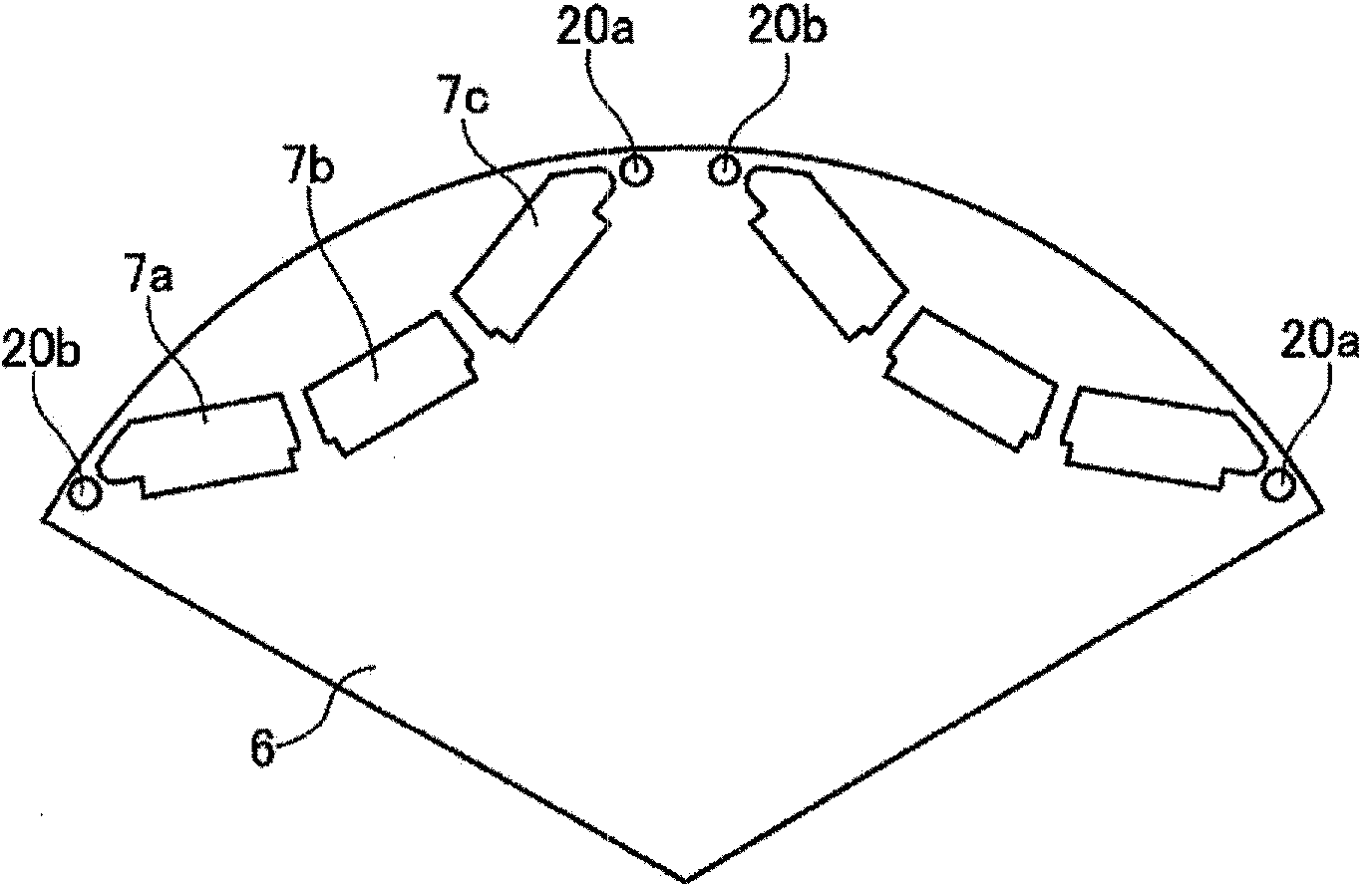

Permanent-magnet type rotating electrical machine

The purpose of the invention provides a permanent-magnet type rotating electrical machine. Magnet inserting holes (7a-7c), into which a plurality of permanent magnets are to be embedded for each pole, are formed on a rotor iron-core (6) in protrusion towards the center of the rotor, and pairs of magnetic-flux controlling holes (20a, 20b) that are symmetrical with respect to the centerline between magnetic poles are formed at inter-pole sections (22) of the rotor iron-core (6), for each of the magnetic poles. When the diameter of the magnetic-flux control holes (20a, 20b) is assumed to be d, the distance between the centers is assumed to be m, the width of the inter-pole sections (22) is assumed to be b, and the pitch between the magnetic poles is assumed to be tau, the magnetic-flux control holes (20a, 20b) are formed so that the value of m / tau, which is a value resulting from standardizing the distance between the centers (m) with the pole pitch (tau), will satisfy a relationship of 0.08 (m / tau((b-2d) / tau.

Owner:MITSUBISHI ELECTRIC CORP

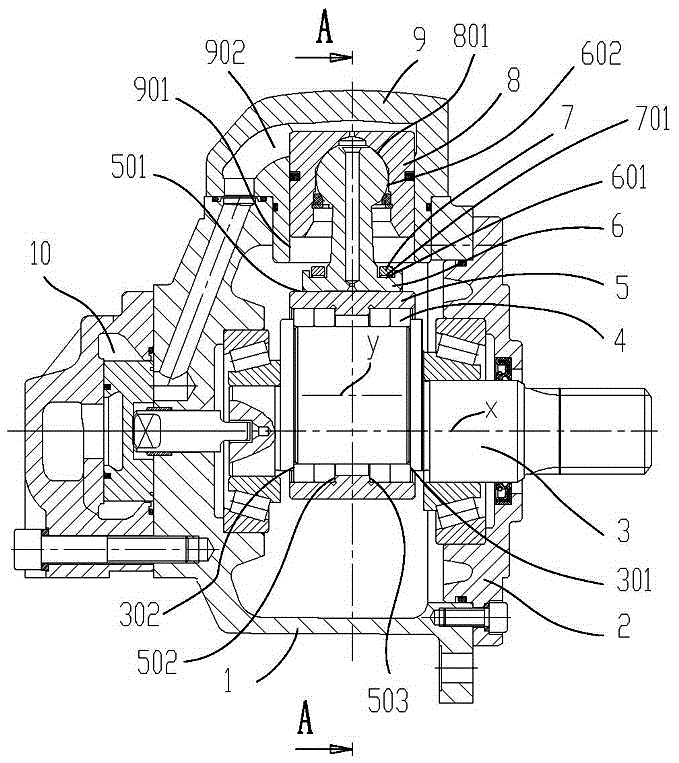

Intermediate-speed large-torque radial plunger hydraulic motor

ActiveCN105756850AEliminate lateral forceEliminates the phenomenon of oval wearPlungersTrunk pistonsHydraulic motorCylinder head

The invention relates to an intermediate-speed large-torque radial plunger hydraulic motor which comprises a casing (1), a crankshaft (2), a roller (3), a bearing bush (4), a cylinder head (5), a telescopic sleeve (6), a retainer ring (7), a hanger rod (8) and a drive shaft (10).The telescopic sleeve (6) is arranged along the radial direction of the bearing bush (4), and the upper end and the lower end of the telescopic sleeve (6) are respectively abutted against an external spherical surface (501) of the cylinder head (5) and an external spherical surface (402) of the bearing bush (4).The lower end of the telescopic sleeve (6) is closely attached to the external spherical surface (402) of the bearing bush (4) by the retainer ring (7).The upper end of the telescopic sleeve (6) is closely attached to the external spherical surface (501) of the cylinder head (5) by the hanger rod (8).Two ends of the drive shaft (10) are respectively connected with the crankshaft (2) and an oil distributing mechanism (9).The roller (3) is inserted in an inner bore (401) of the bearing bush; and the crankshaft (2) comprises an eccentric section (201).Compared with the prior art, the radial plunger hydraulic motor has the advantages of highly increased revolution speed and compact structure.

Owner:INTRA ITAL HYDRAULICS FOSHAN SHUNDE

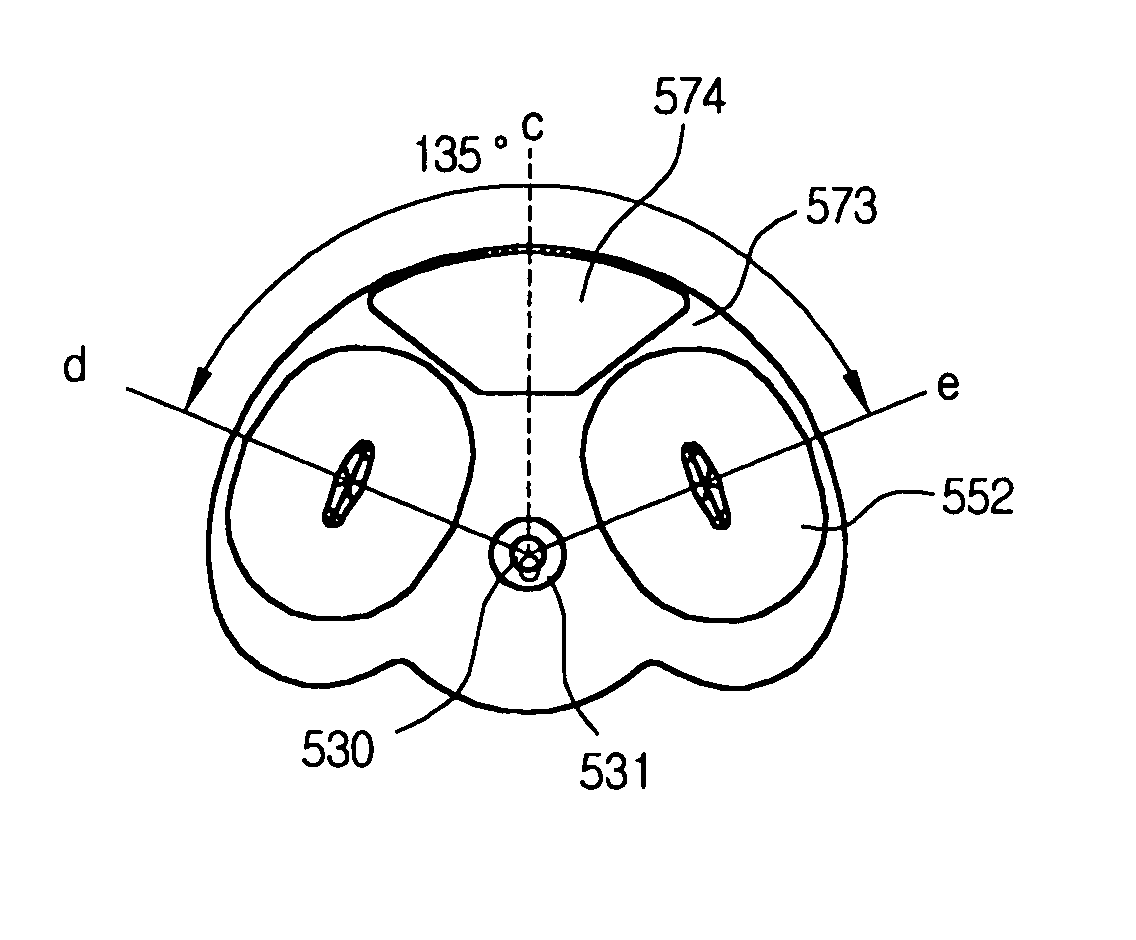

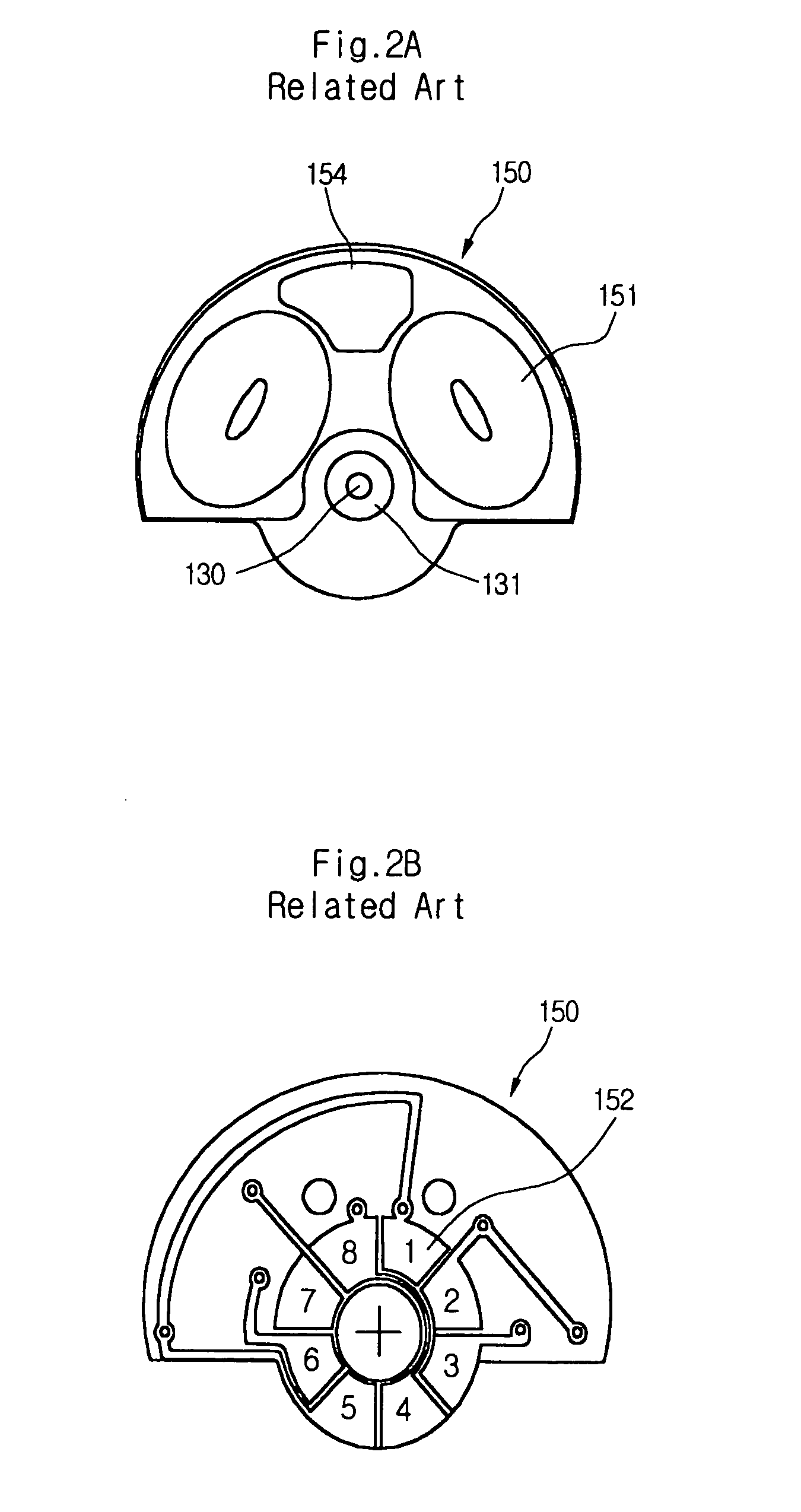

Vibration motor

ActiveUS20050264114A1Torque stabilizationReduced torque rippleMagnetic circuitSynchronous machinesElectric machineEngineering

A vibration motor includes: a lower case provided with a lower board; an upper case coupled with the lower case; a four-pole magnet provided on the lower case; a shaft supported between the lower case and the upper case; a rotor rotatably supported by the shaft with an eccentricity, in which a pair of coils is provided in the rotor at an angle ranging form 135° to 142° between centerlines thereof; a commutator formed on a bottom of the rotor with six segments; and a pair of brushes having lower parts contacted with the lower board and upper parts contacted with the segments of the commutator at an angle of 90° therebetween.

Owner:TL ELECTRONICS CO LTD

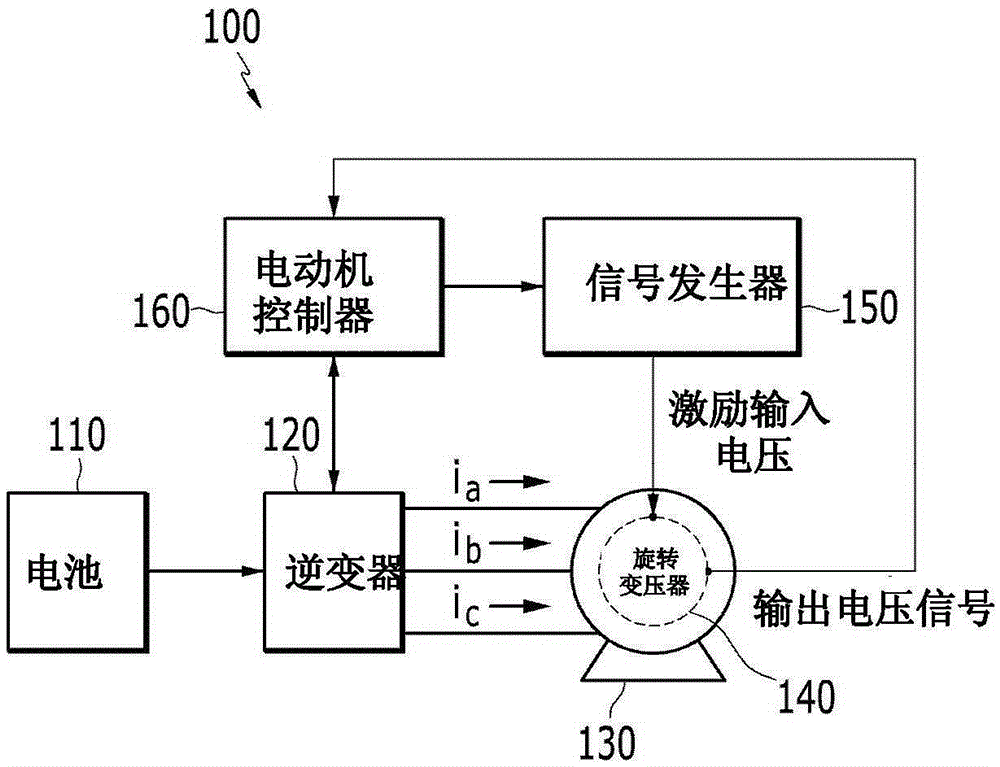

System and method for reducing speed ripple of drive motor of electric vehicle

ActiveCN106059403AImprove efficiencyReduce speed pulsationTorque ripple controlAC motor controlMicrocontrollerIntegrator

A system and method for reducing drive motor speed ripple of an electric vehicle are provided. The system includes an inverter that converts DC power supplied from a battery to AC power and supplies the AC power to the drive motor by inverter switching. A resolver is configured to detect a speed of the drive motor and a position of a rotor, a signal generator includes a microcontroller that is configured to generate a square wave signal. An integrator is configured to convert the square wave to a sine wave, and apply a sine-wave excitation input signal to the resolver. Furthermore, a motor controller is configured to adjust the frequency of the excitation input signal to prevent the inverter switching frequency of the inverter and the peaks of an output voltage signal sampled for speed calculation from overlapping.

Owner:HYUNDAI MOTOR CO LTD

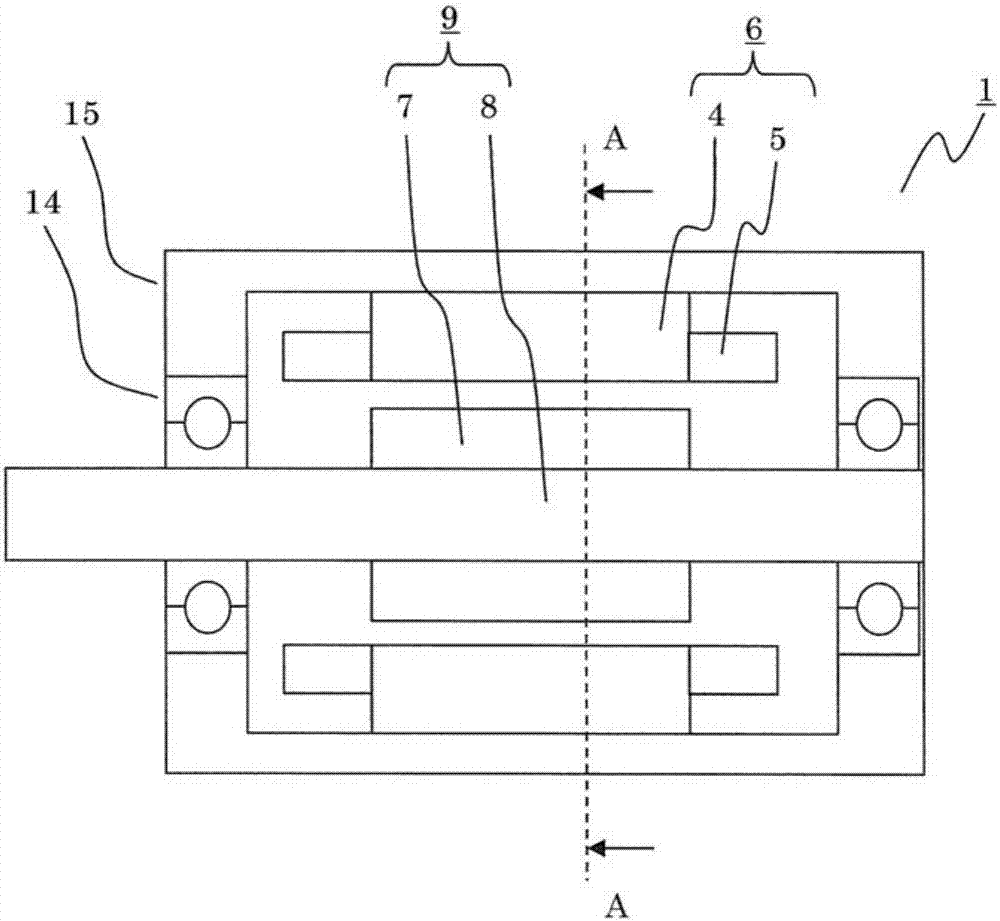

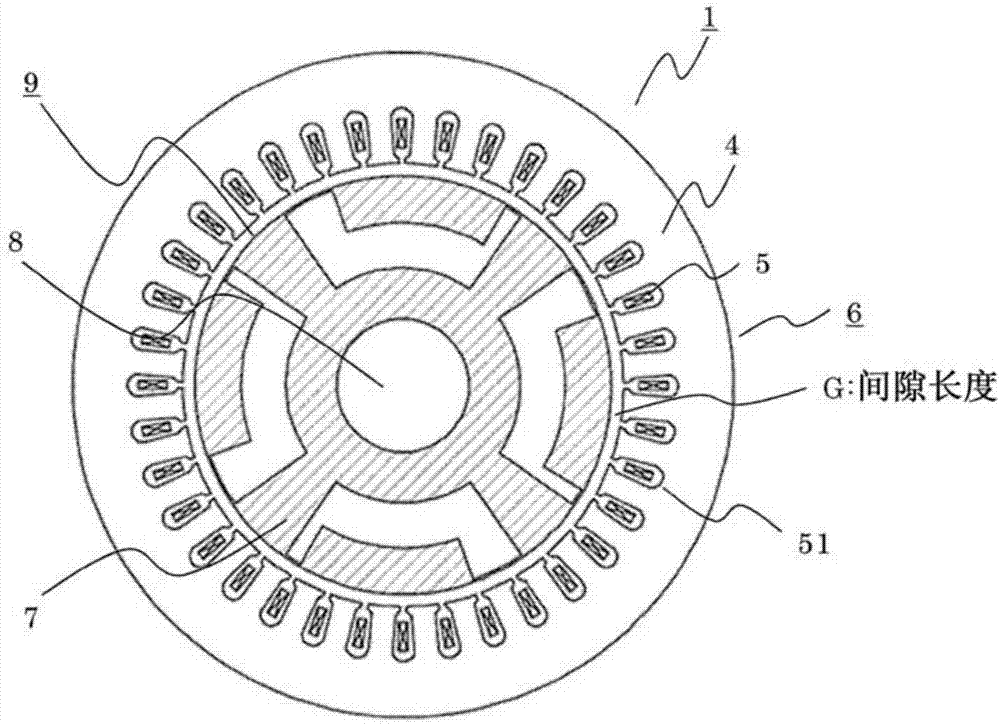

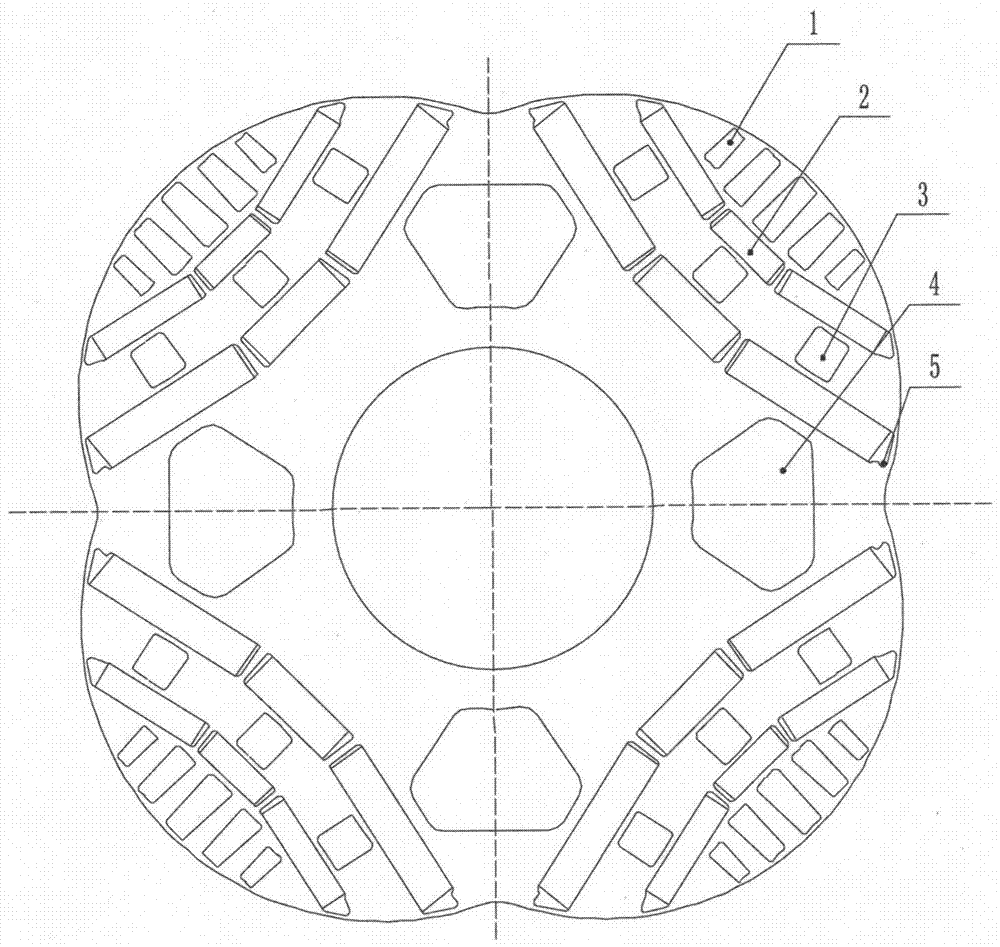

Switch reluctance motor and vehicle power motor assembly

InactiveCN108809035AImprove performanceImprove efficiencySynchronous machine detailsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesPhysics

The invention provides a switch reluctance motor and a vehicle power motor assembly. The switch reluctance motor comprises a stator and a rotor, the stator comprises multiple stator magnetic poles uniformly distributed peripherally, each stator magnetic pole comprises a first stator magnetic pole unit and a second stator magnetic pole unit, each first stator magnetic pole unit comprises a first stator magnetic pole root portion extending axially and multiple first stator magnetic pole tooth portions radially extending from the first stator magnetic pole root portion to the rotor, and each second stator magnetic pole unit comprises a second stator magnetic pole root portion extending axially and multiple second stator magnetic pole tooth portions radially extending from the second stator magnetic pole root portion to the rotor; the rotor comprises multiple rotor magnetic poles uniformly distributed peripherally, each rotor magnetic pole comprises a rotor magnetic pole root portion, multiple first rotor magnetic pole tooth portions and multiple second rotor magnetic pole tooth portions, the first rotor magnetic pole tooth portions extend peripherally from one side of the corresponding rotor magnetic pole root portion, and the second rotor magnetic pole tooth portions peripherally extend from the other side of the corresponding rotor magnetic pole root portion.

Owner:石镇德

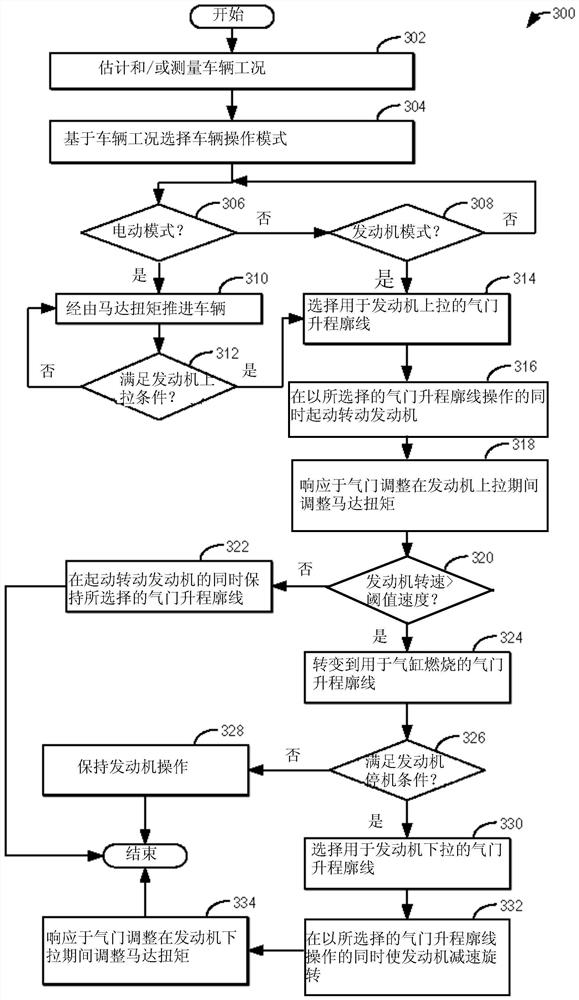

Method and system for torque control

ActiveCN107542510AReduce control complexityReduce control requirementsHybrid vehiclesValve arrangementsEngineeringDirect torque control

The application relates to methods and systems for torque control. Methods and systems are provided for reducing torque pulsations during hybrid engine shutdown and restarts. A valve actuating mechanism may be actuated to operate an engine with a selected valve lift profile during engine restart and shutdown events that is distinct from the valve lift profile applied during cylinder combustion. The selected valve lift profile reduces cylinder pressure during engine shutdown and restarts.

Owner:FORD GLOBAL TECH LLC

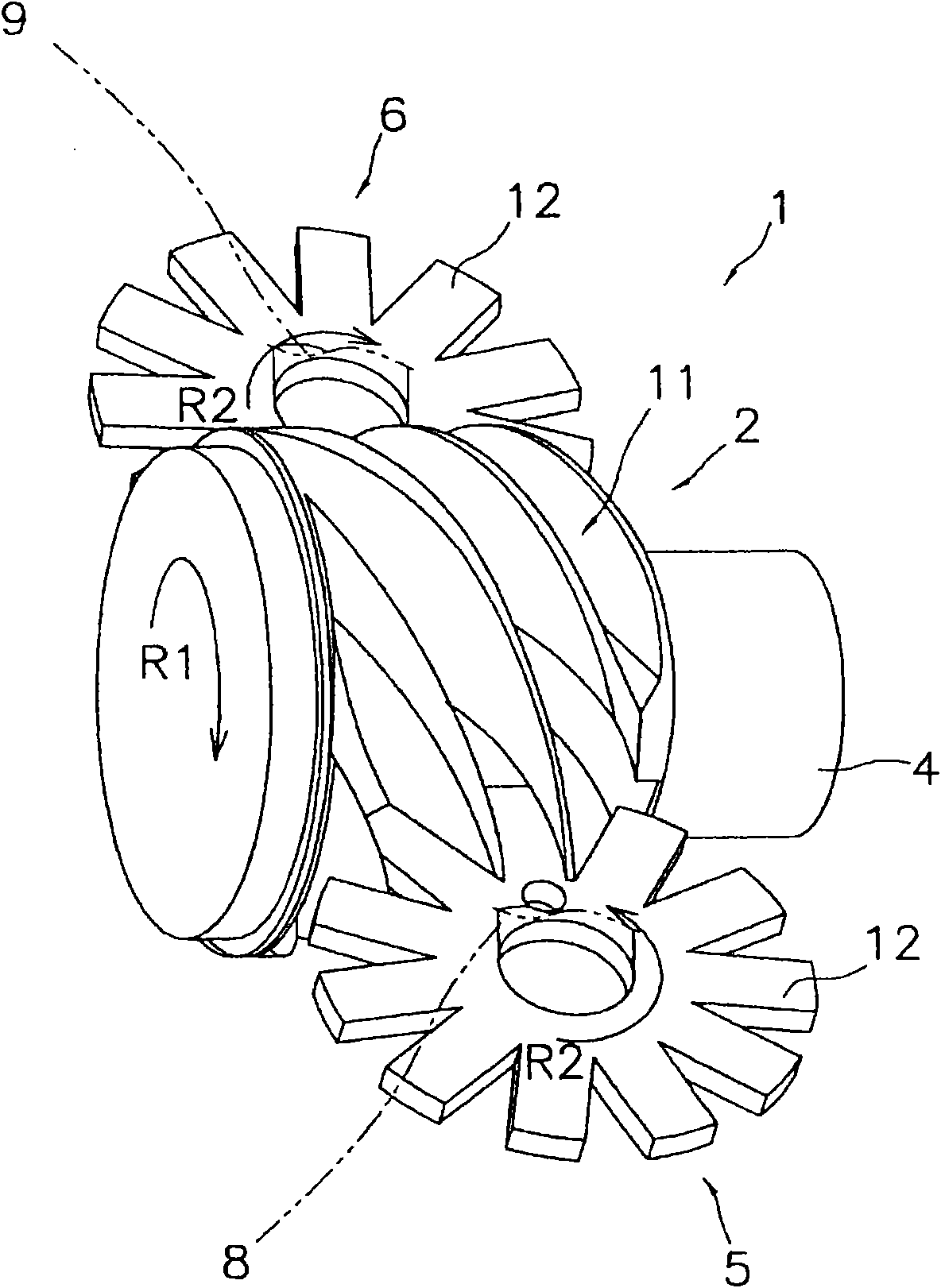

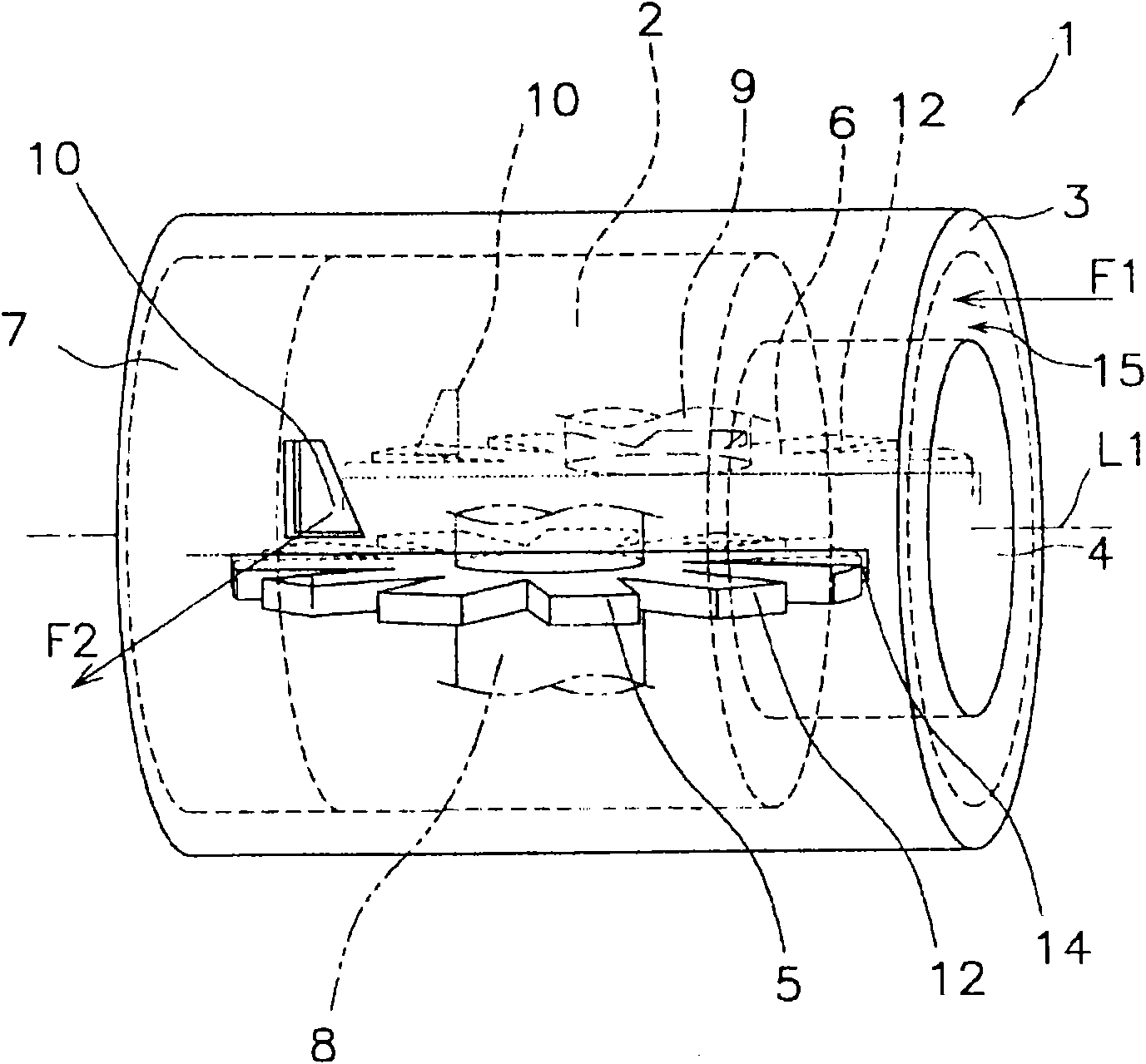

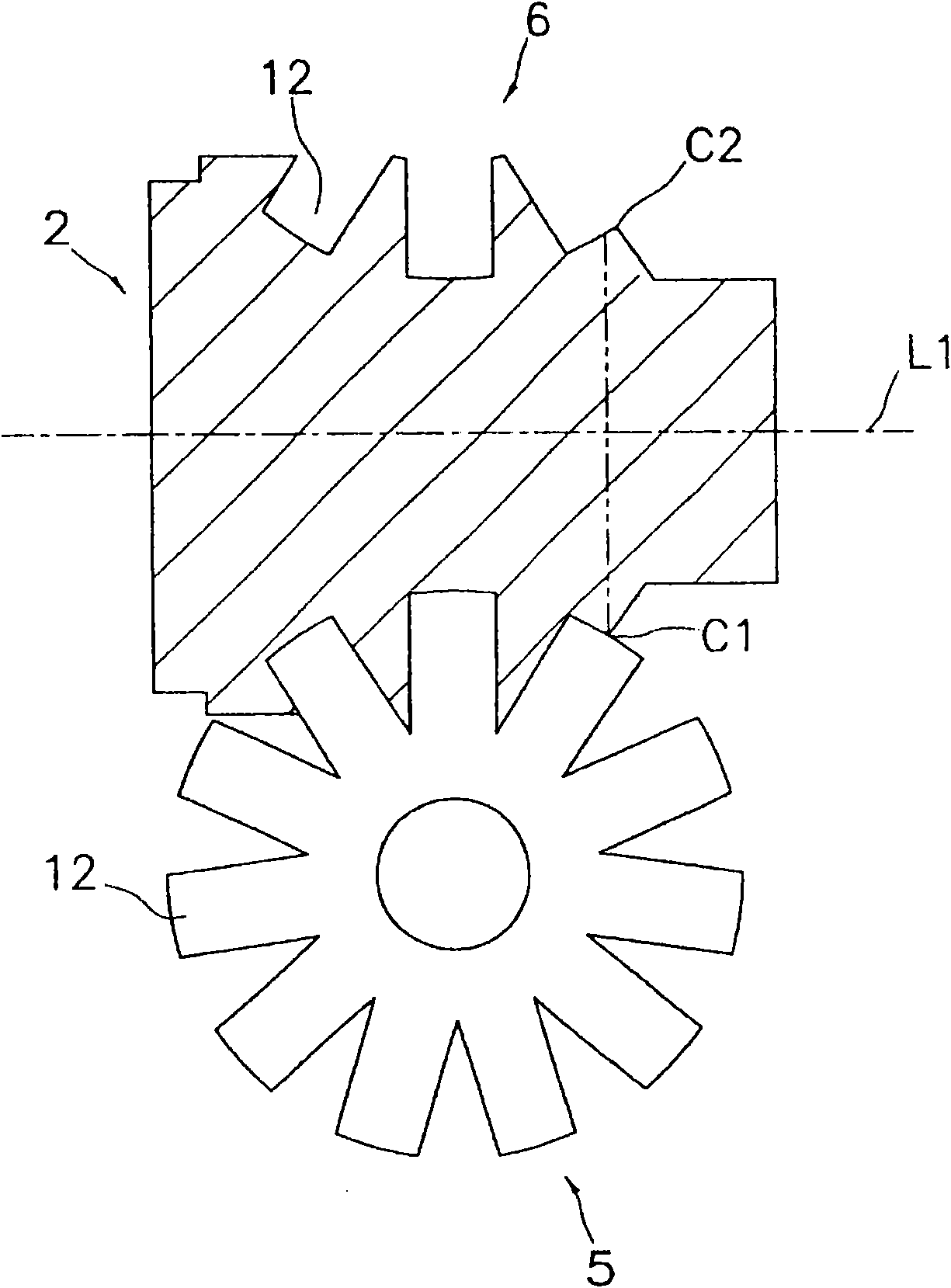

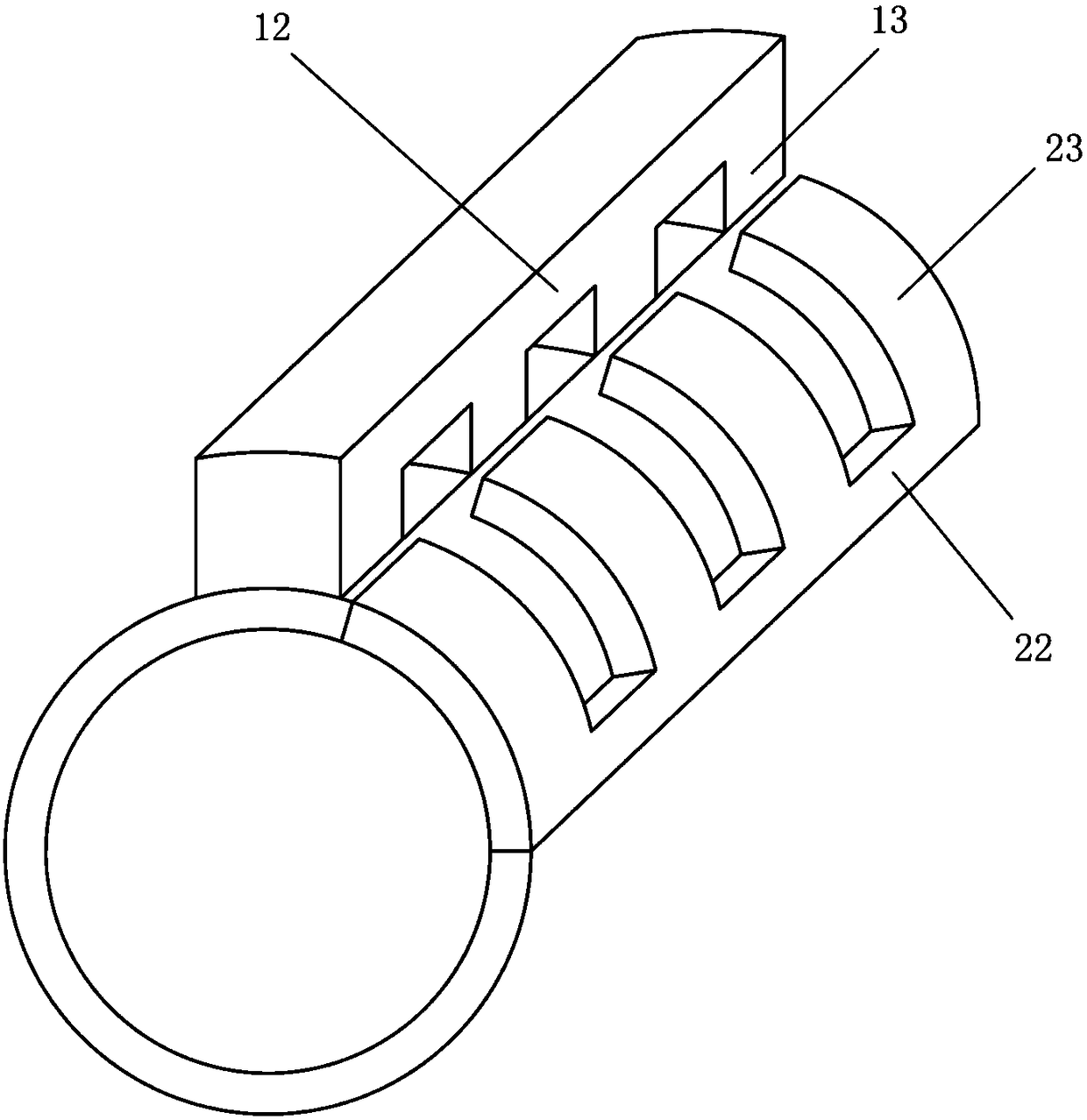

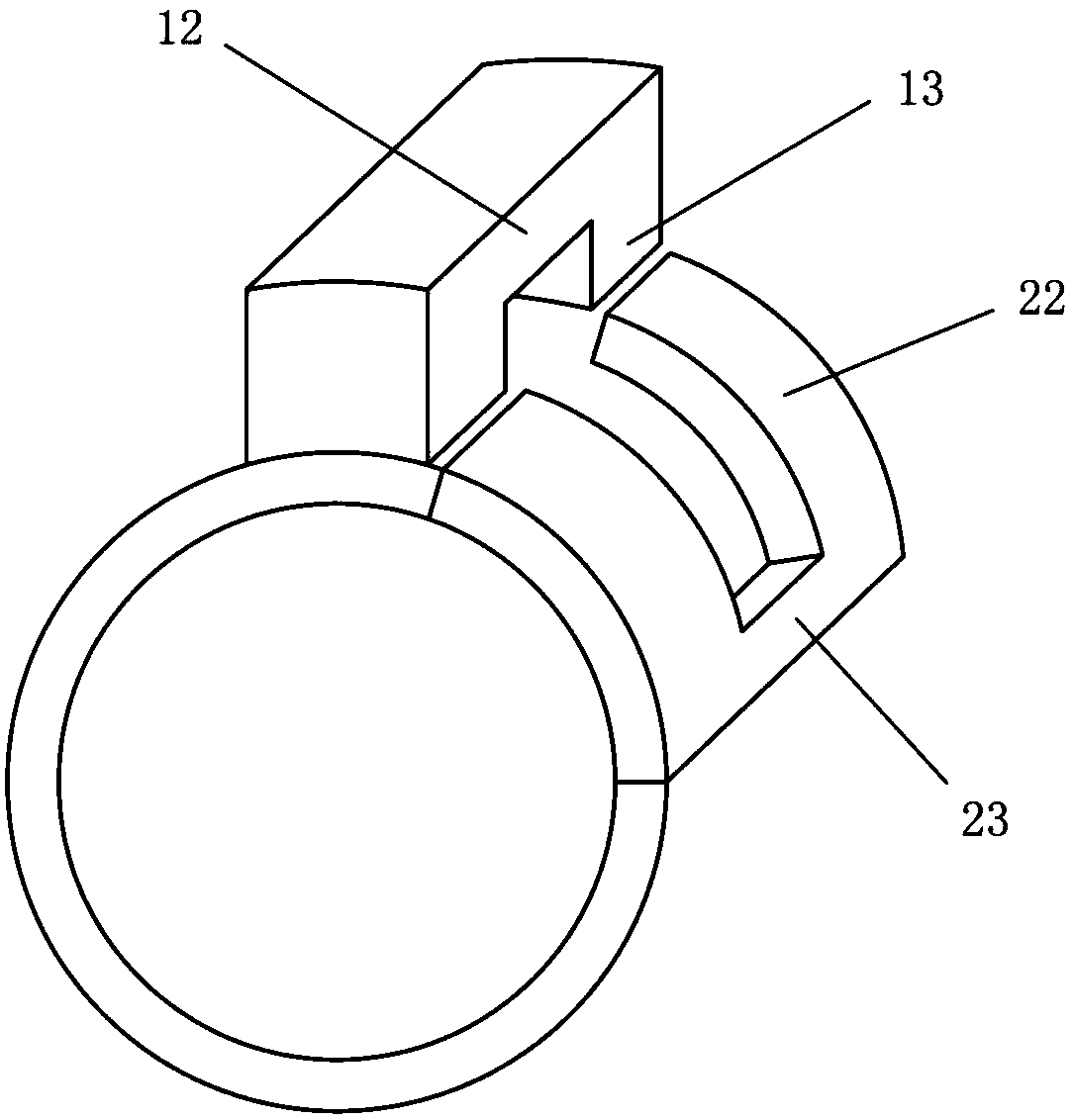

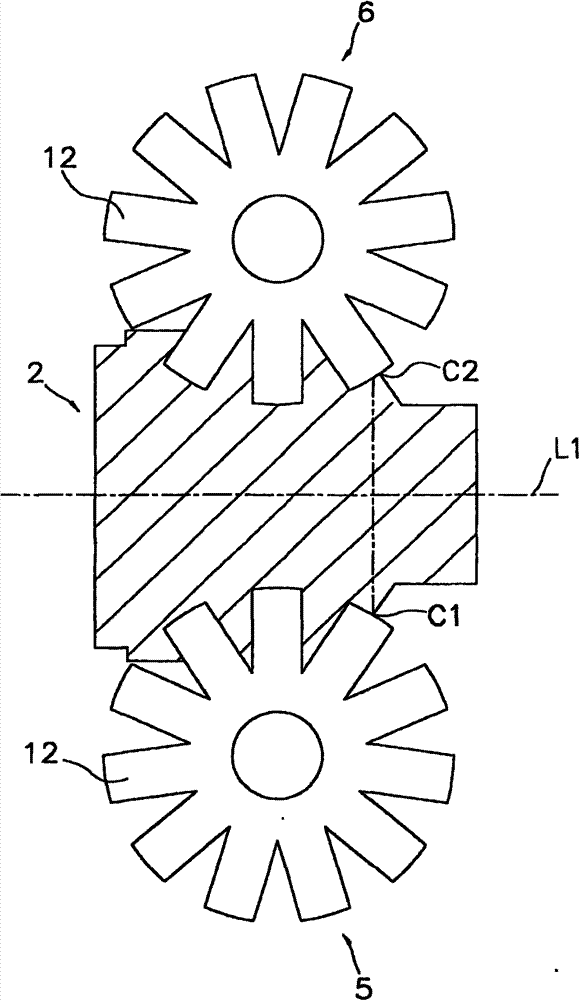

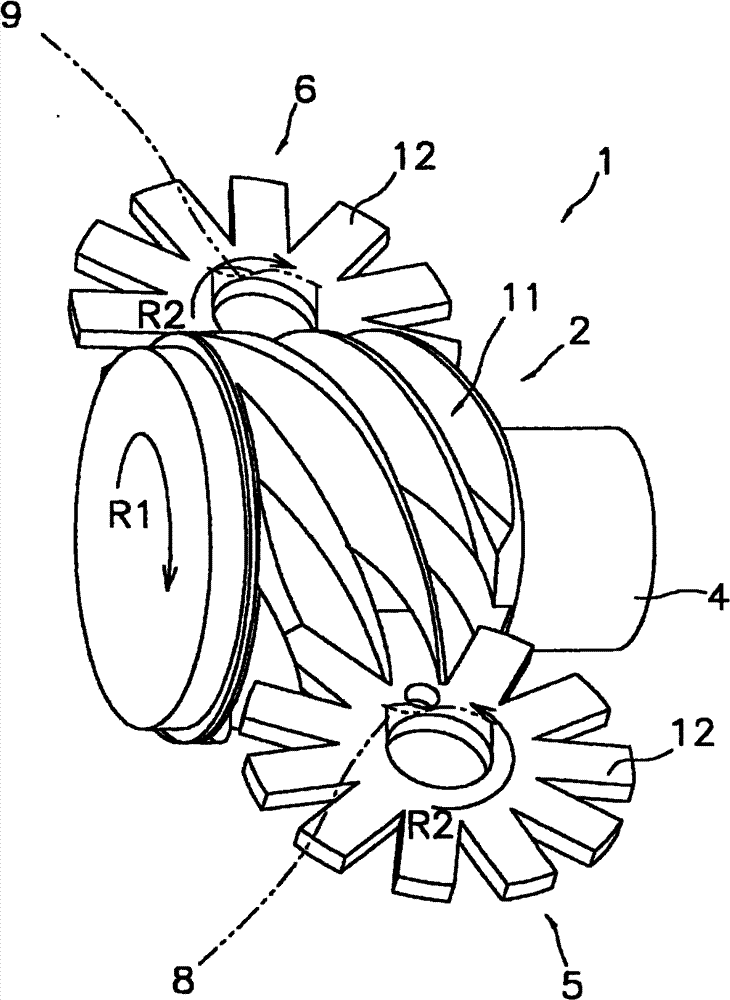

Screw compressor

ActiveCN101802410AReduce irregularitiesReduce noiseRotary piston pumpsRotary piston liquid enginesEngineeringRotary-screw compressor

A screw compressor in which noise and vibration caused by a variation in compression torque are effectively reduced. The screw compressor (1) has a first meshing body (2) and second meshing bodies (5, 6). The first meshing body (2) has helical grooves (11) around a first rotating shaft (4). The second meshing bodies (5, 6) have projections (12) or ridges formed around second rotating shafts (8, 9). At least one projection (12) or ridge of each second rotating shaft (8, 9) is placed irregularly in the circumferential direction with respect to the other projections (12) or ridges. The helical grooves (11) are arranged in the circumferential direction in the first rotating shaft (4) so as to be able to mesh with the projections (12) or ridges.

Owner:DAIKIN IND LTD

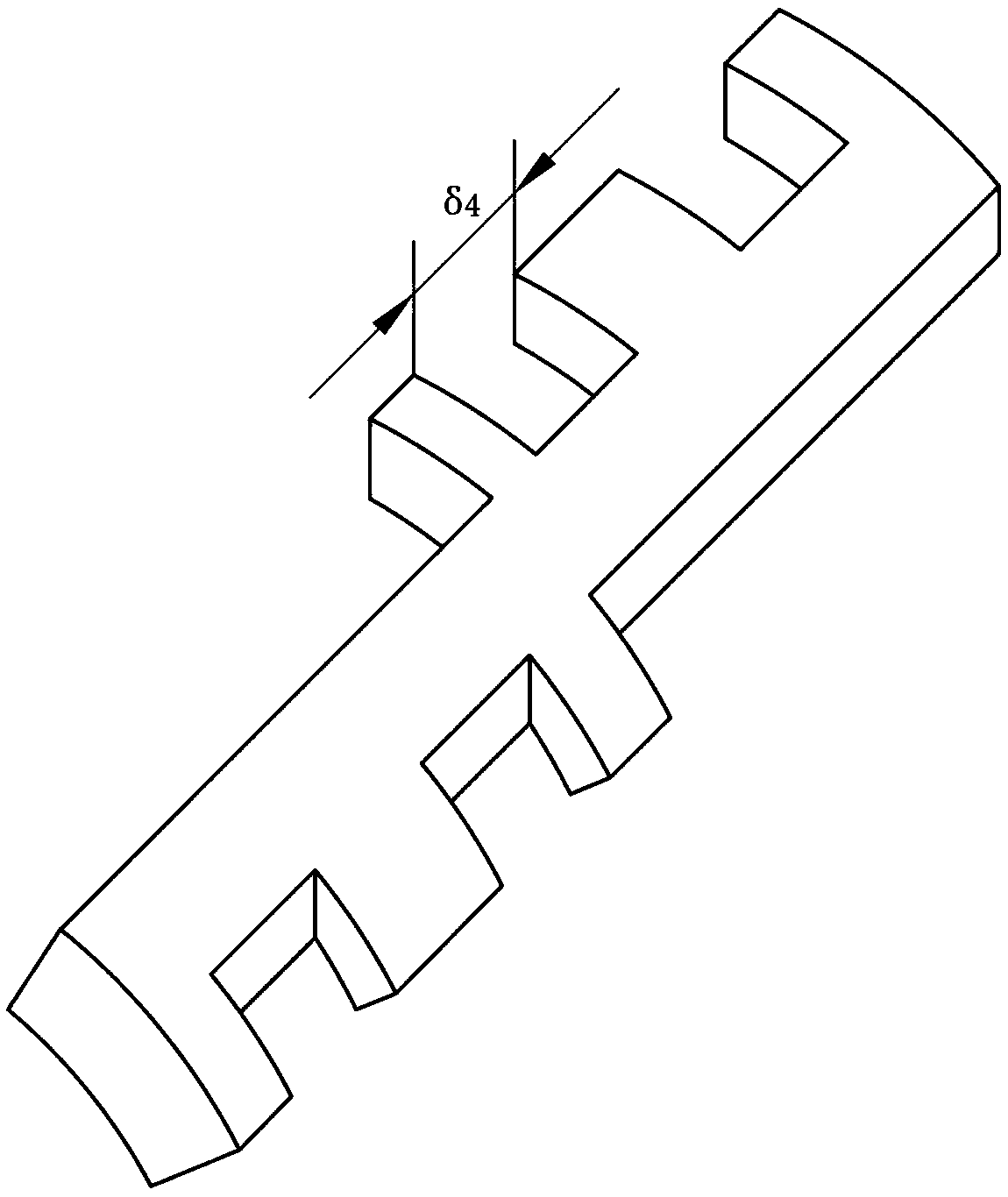

Reluctance motor, and method for manufacturing rotor core used in reluctance motor

ActiveCN107431393AReduced torque rippleMagnetic circuit rotating partsMagnetic reluctanceStructural engineering

With regard to the shape of slot end parts in a rotor core having as many flux barriers in the circumferential direction as the number of poles, the flux barriers being formed by alternately arranging one or more slits and core layers in the radial direction, the slit end parts are shaped so that deltagi and epsilongi satisfy a predetermined formula, these variables representing the spacing between the first slit end to the ith slit end on the same direction side when viewed in the circumferential direction, where mg represents the number of slot end parts, ni represents a natural number equal to or greater than 1, alpha and beta represent a number in the range of -1 / 4 to 1 / 4, q represents a natural number equal to or greater than 1, and Ns represents the number of slots.

Owner:MITSUBISHI ELECTRIC CORP

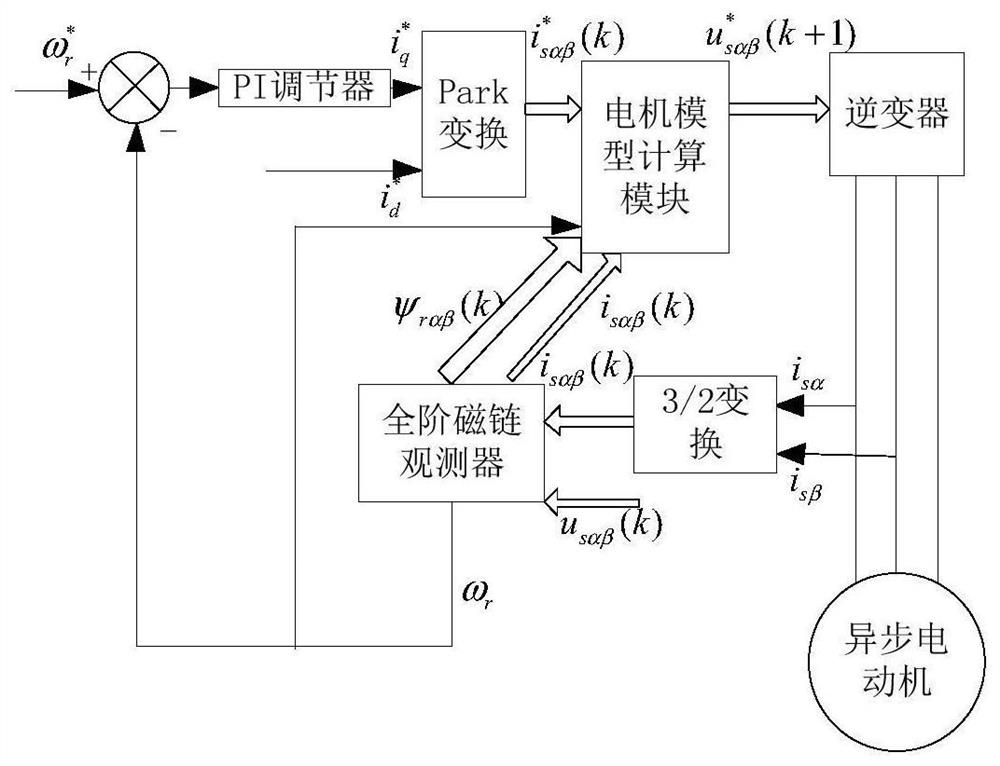

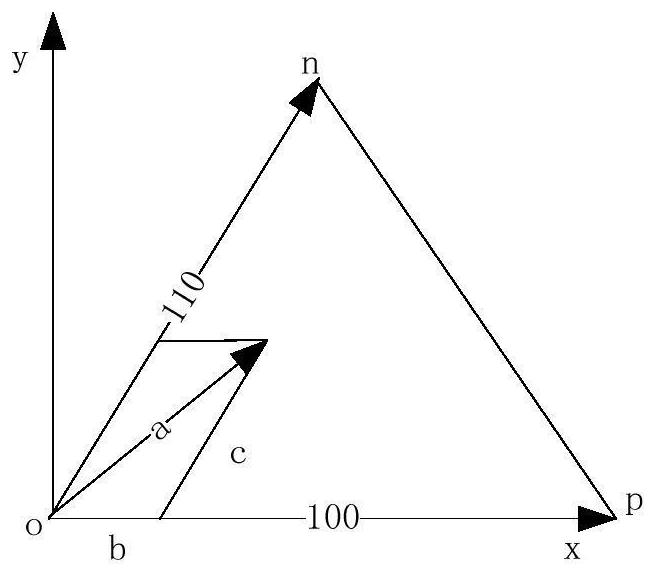

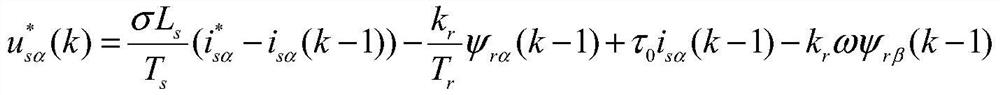

Motor model calculation, induction motor control method and device, induction motor

ActiveCN109546910BSure easyFew parametersElectronic commutation motor controlVector control systemsControl vectorControl engineering

The invention discloses an induction motor control method, device and induction motor. The motor model calculation module is used to replace the PI regulator of the current loop in the vector control and the Park inverse conversion link, and the motor model calculation module is used to replace the traditional one in predictive control. Rolling optimization module and objective function calculation module. There is neither current closed-loop PI control nor complex rolling optimization in the whole control, which can reduce the debugging time, avoid the problems of large torque ripple and high sampling frequency, and make the control more direct and effective.

Owner:SHANDONG UNIV OF SCI & TECH

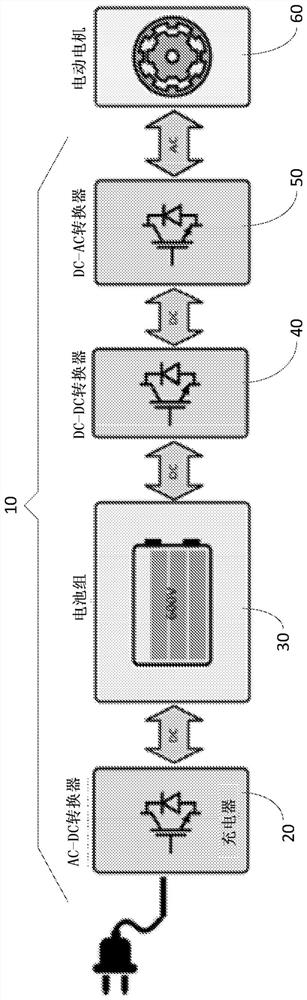

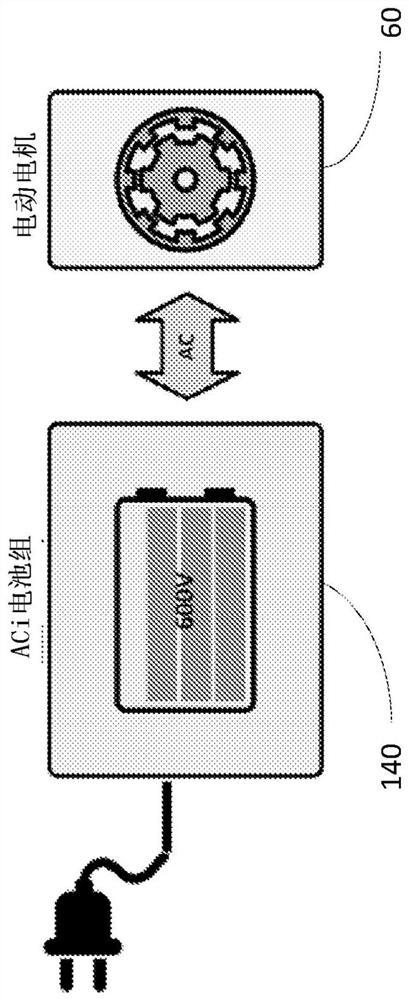

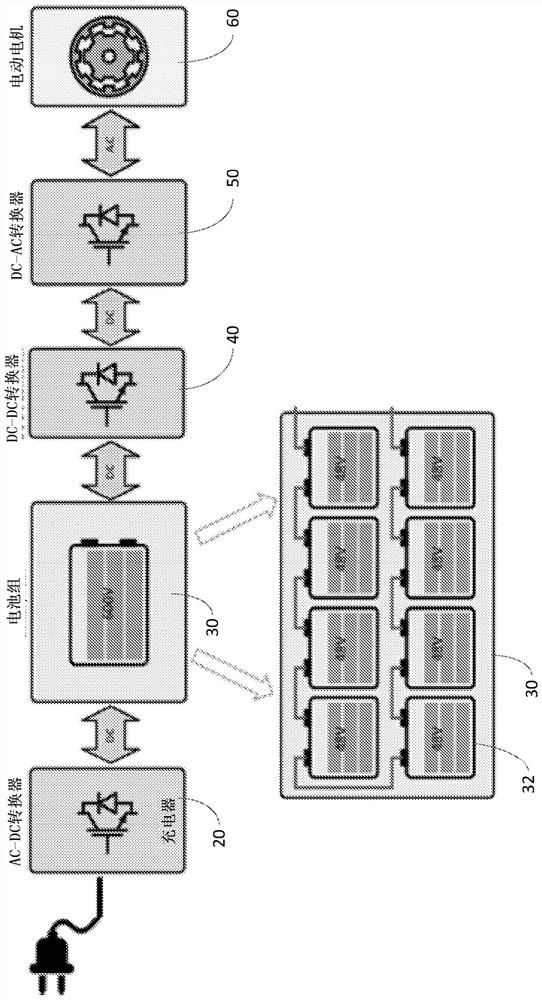

Systems and methods for power management and control

PendingCN112188969AReduce heat lossDelay agingHybrid vehiclesCircuit monitoring/indicationConvertersElectrical battery

Systems and methods directed to improved battery management, motor control, energy storage and battery charging. The systems and methods enable vehicle electrification and provides a paradigm changingplatform that enables integration of battery management, charging and motor controls with means to manage regenerative braking, traction and handling. In embodiments, systems and methods are directedto a unified modular battery pack system having a cascaded architecture comprising an integrated combination of a networked low voltage converter / controller with peer-to-peer communication capability, embedded ultra-capacitor or other secondary energy storage element, battery management system and serially connected set of individual cells as the fundamental building block.

Owner:TRI ALPHA ENERGY INC

Method and system for torque control

ActiveCN107542510BReduce control complexityReduce control requirementsHybrid vehiclesValve arrangementsThermodynamicsEngineering

Owner:FORD GLOBAL TECH LLC

Method and system for engine control

ActiveCN107345500BMeet Torque DemandsReduce economic lossHybrid vehiclesElectrical controlLow speedControl theory

The present invention relates to methods and systems for engine control. Methods and systems are provided for enhancing the benefits of variable compression ratio engines in hybrid vehicle systems. During engine pull-up and pull-down, the vehicle controller may maintain the engine at a lower compression ratio, especially when passing through low speed regions where compression bounce can occur. During engine operation, in response to changes in driver demand, the controller may choose to switch the compression ratio or maintain the current compression ratio while using motor torque to smooth undertorque, the selection being based on fuel economy.

Owner:FORD GLOBAL TECH LLC

Switched reluctance motor including U-shaped rotor magnetic pole structure

InactiveCN108448756AImprove performanceImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesReluctance motor

The invention provides a switched reluctance motor including a U-shaped rotor magnetic pole structure. The switched reluctance motor comprises a stator and a rotor, wherein the stator and the rotor are coaxially arranged. The stator comprises a number of stator magnetic poles uniformly distributed in the circumferential direction. Each stator magnetic pole comprises a stator magnetic pole root anda number of stator magnetic pole teeth extending radially from the stator magnetic pole root toward the rotor. Each stator magnetic pole is wound with a coil. The rotor comprises a number of rotor magnetic poles uniformly distributed in the circumferential direction. Each rotor magnetic pole comprises a rotor magnetic pole root and a number of rotor magnetic pole teeth extending in the circumferential direction from the same side of the rotor magnetic pole root, wherein the rotor magnetic pole teeth and the rotor magnetic pole root share the same curvature. A number of stator magnetic pole teeth and a number of rotor magnetic pole teeth are axially aligned with each other. According to the switched reluctance motor provided by the invention, radial vibration and torque ripple of the motor can be significantly reduced; noise generated by radial vibration can be reduced; and the motor efficiency is improved.

Owner:石镇德

Screw compressor

ActiveCN101802410BReduce irregularitiesReduce noiseRotary piston pumpsRotary piston liquid enginesEngineeringRotary-screw compressor

A screw compressor in which noise and vibration caused by a variation in compression torque are effectively reduced. The screw compressor (1) has a first meshing body (2) and second meshing bodies (5, 6). The first meshing body (2) has helical grooves (11) around a first rotating shaft (4). The second meshing bodies (5, 6) have projections (12) or ridges formed around second rotating shafts (8, 9). At least one projection (12) or ridge of each second rotating shaft (8, 9) is placed irregularly in the circumferential direction with respect to the other projections (12) or ridges. The helical grooves (11) are arranged in the circumferential direction in the first rotating shaft (4) so as to be able to mesh with the projections (12) or ridges.

Owner:DAIKIN IND LTD

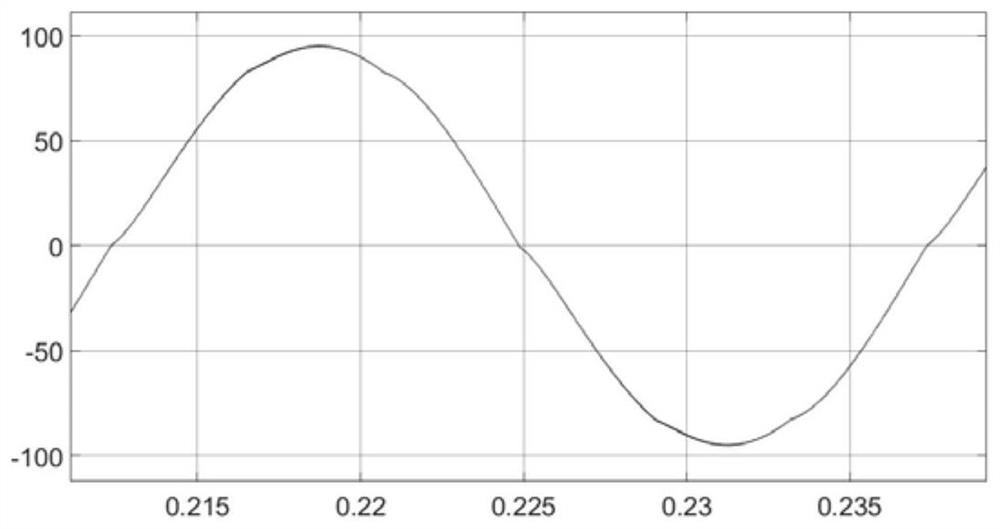

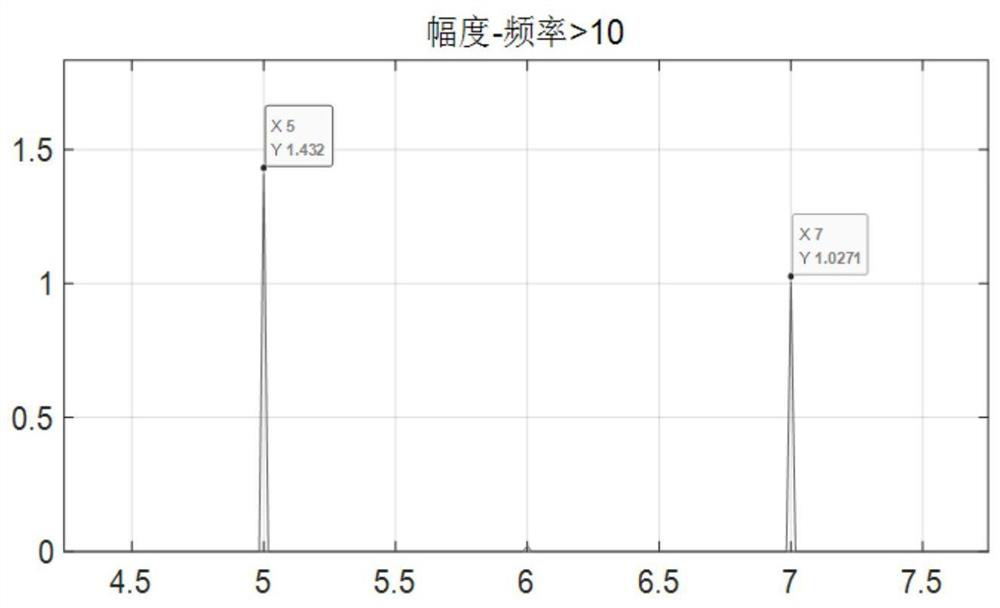

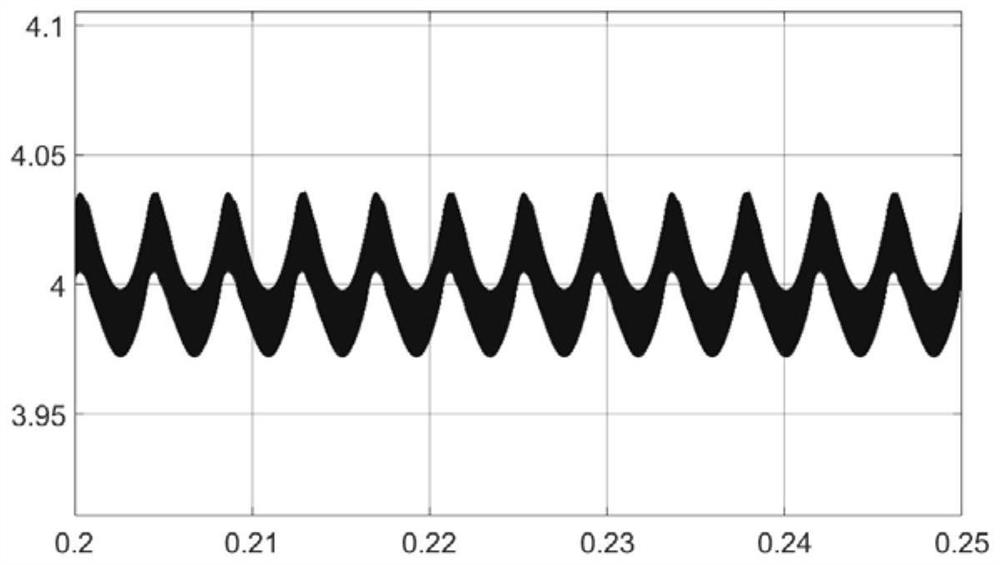

Torque pulsation compensation method based on current harmonic analysis and open-loop torque control

PendingCN114765436AAchieve compensationReduced torque rippleElectronic commutation motor controlAC motor controlElectric power steeringHarmonic analysis

The invention relates to the technical field of permanent magnet synchronous motors, in particular to a torque pulsation compensation method based on current harmonic analysis and open-loop torque control, which comprises the following steps of: calculating a-phase current, b-phase current and c-phase current, calculating phase current, substituting the phase current into a current fundamental wave and torque formula to obtain torque, converting a three-phase static coordinate system into a rotating coordinate system, and calculating the torque pulsation. 24-order torque pulsation is obtained, and the value of the 24-order torque pulsation is shown in the specification; 24-order torque pulsation is substituted into an open-loop torque control compensation formula to obtain torque harmonic waves, a torque harmonic wave formula is obtained, the torque harmonic wave formula is adopted to replace the torque harmonic waves of open-loop torque control in an original model, and a 24-order noise compensation model is established. Compared with the prior art, the torque pulsation compensation method based on current harmonic analysis and open-loop torque control is designed, compensation of torque pulsation is achieved by establishing a relation formula of current harmonics and torque harmonics and establishing a model, and therefore the torque pulsation and noise of the electric power steering system are reduced.

Owner:BOSCH HUAYU STEERING SYST CO LTD

Permanent-magnetic rotor structure of motor of shielding pump

InactiveCN108574356AImprove efficiencyReduce temperature riseMagnetic circuit rotating partsThree phase asynchronous motorMagnetic poles

A permanent-magnetic rotor structure of a motor of a shielding pump comprises arched magnetic steel, a cast aluminum winding and a shielding sleeve. The arched magnetic steel is embedded into a rotor,the rotor is provided with the cast aluminum winding, the shielding sleeve is arranged outside the rotor, and the stainless steel shielding sleeve is provided with a diversion groove. According to the permanent-magnetic rotor structure of the motor of the shielding pump, a permanent magnet synchronous motor replaces a three-phase asynchronous motor, so that the efficiency of the motor is improvedto large extent; a permanent magnet is embedded with the arched magnetic steel, so that the torque of a magnetic pole of the permanent magnet fluctuates much narrowly; and the diversion grooves are designed in the external diameter of the rotor shielding sleeve, so that the flow of a heat radiation medium between a stator and the rotor can be increased, the heat radiation condition is improved, temperature rise of the motor is reduced, and the motor performance is improved.

Owner:大连帝国屏蔽电泵有限公司

Switched reluctance motor including u-shaped rotor pole structure

InactiveCN108448756BImprove performanceImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesReluctance motor

The invention provides a switched reluctance motor including a U-shaped rotor magnetic pole structure. The switched reluctance motor comprises a stator and a rotor, wherein the stator and the rotor are coaxially arranged. The stator comprises a number of stator magnetic poles uniformly distributed in the circumferential direction. Each stator magnetic pole comprises a stator magnetic pole root anda number of stator magnetic pole teeth extending radially from the stator magnetic pole root toward the rotor. Each stator magnetic pole is wound with a coil. The rotor comprises a number of rotor magnetic poles uniformly distributed in the circumferential direction. Each rotor magnetic pole comprises a rotor magnetic pole root and a number of rotor magnetic pole teeth extending in the circumferential direction from the same side of the rotor magnetic pole root, wherein the rotor magnetic pole teeth and the rotor magnetic pole root share the same curvature. A number of stator magnetic pole teeth and a number of rotor magnetic pole teeth are axially aligned with each other. According to the switched reluctance motor provided by the invention, radial vibration and torque ripple of the motor can be significantly reduced; noise generated by radial vibration can be reduced; and the motor efficiency is improved.

Owner:石镇德

A rotor punching structure of a permanent magnet servo motor

ActiveCN104882981BImprove back EMF waveformReduce additional stray lossMagnetic circuit rotating partsPermanent magnet rotorRotor magnets

The invention provides a rotor punching structure of a permanent magnet servo motor, comprising a rotor punching body, a permanent magnet groove is arranged on the circumferential surface of the rotor punching body, and a permanent magnet is embedded in the permanent magnet groove; the rotor above the permanent magnet groove The outer diameter of the punching body is not concentric with the inner circle of the stator; the rotor punching body above the permanent magnet slot is provided with magnetic isolation holes arranged in parallel, and the rotor punching body below the permanent magnet slot is provided with an axial cooling channel. The permanent magnet slots are arranged in layers in the radial direction, a magnetic isolation slot is provided between the permanent magnet slots of adjacent layers, and a magnetic isolation bridge is provided between the magnetic isolation slots and the permanent magnet slots. The invention improves the rotor punching structure, controls the direction of the magnetic field, reduces the non-linear influence of the motor parameters caused by the coupling of the alternating and direct axis magnetic circuits, makes full use of the rotor punching space to place as many permanent magnets, and improves the demagnetization resistance of the permanent magnet servo motor capacity and overload capacity, effectively improving the performance of the permanent magnet servo motor.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

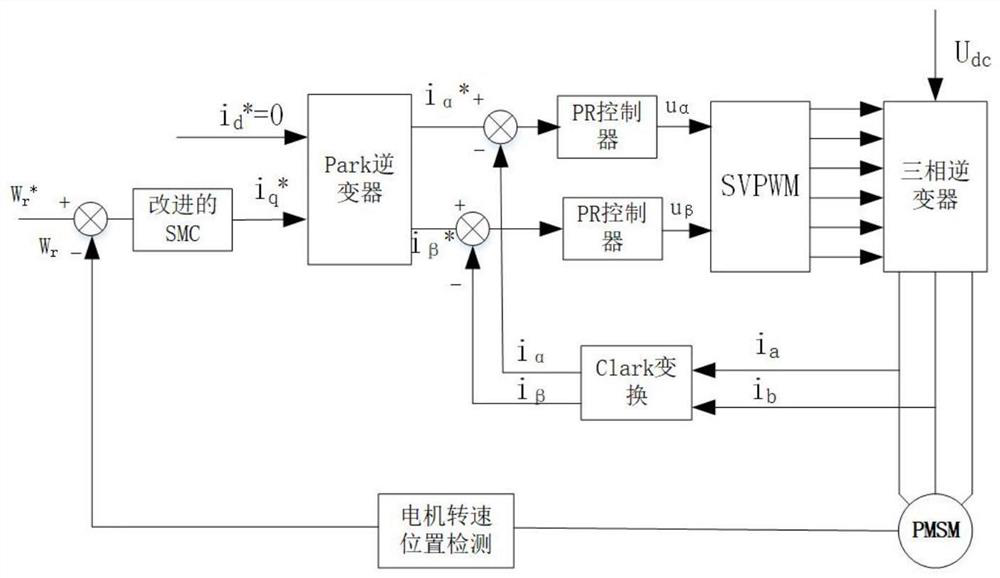

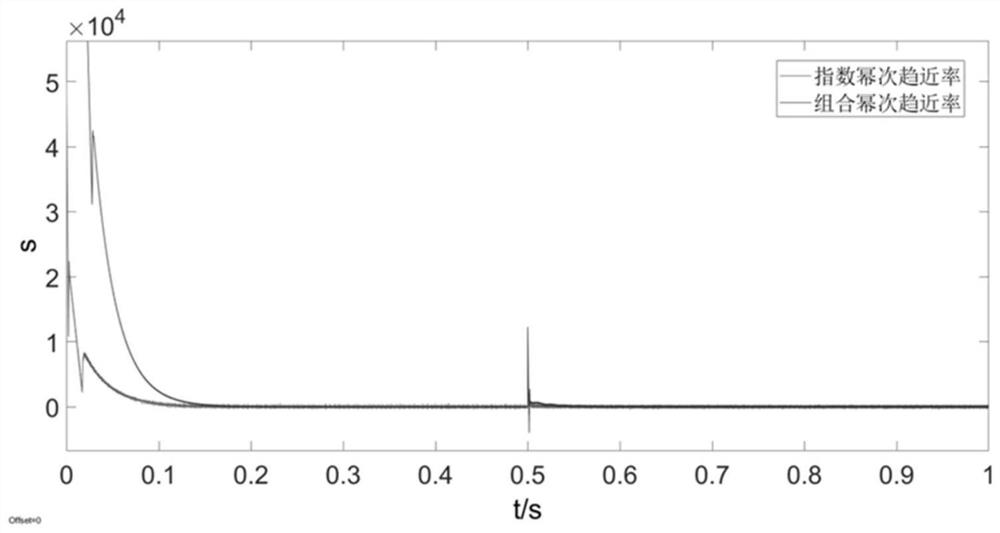

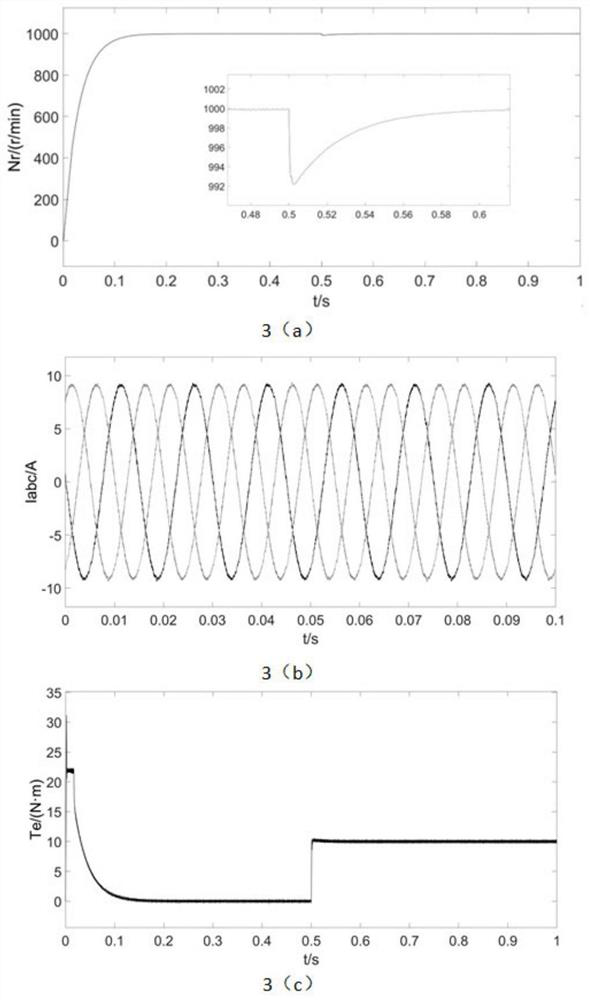

Permanent magnet synchronous motor sliding mode control method based on combined reaching law and storage medium

PendingCN113497578AOvercome the shortcomings of not being able to effectively eliminate chatteringImprove control effectElectronic commutation motor controlVector control systemsMathematical modelPermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor sliding mode control method based on a combined reaching law and a storage medium, and the sliding mode control method comprises the steps: 1, obtaining the actual rotor angular speed and rotor angle data of a permanent magnet synchronous motor; 2, establishing a mathematical model of the permanent magnet synchronous motor under a three-phase static coordinate system, and obtaining current component data under a two-phase static coordinate system; 3, obtaining voltage component data through a speed loop and a current loop; 4, obtaining inverter switching signal data through the voltage component data; 5, enabling the switching signal data to pass through a three-phase inverter, and then outputting three-phase stator voltage data; and 6, controlling the rotating speed and the torque of the permanent magnet synchronous motor by using the three-phase stator voltage data to realize the speed regulation of the motor. Compared with the prior art, the method has the advantages of being good in control effect, high in response speed, good in robustness and the like.

Owner:SHANGHAI DIANJI UNIV +1

Single-Phase Permanent Magnet Synchronous Motor and Dust Collector

PendingUS20220368181A1Small sizeLight weightMagnetic circuit rotating partsSynchronous motorsElectric machinePermanent magnet synchronous motor

A single-phase permanent magnet synchronous motor and dust collector. The single-phase permanent magnet synchronous motor includes a plurality of stator teeth, the plurality of stator teeth include at least: a first-type and second-type stator tooth; the first-type and second-type stator teeth enclose an annular working cavity for accommodating a rotor part, where the size of a central angle corresponding to a first contour line of an end face of the first-type stator tooth facing the rotor part is different from the size of a central angle corresponding to a second contour line of an end face of the second-type stator tooth facing the rotor part The motor has a significantly reduced cogging torque, a greatly reduced torque ripple, and an obviously increased motor output torque. The single-phase permanent magnet synchronous motor is small in size, light in weight, simple in structure, convenient for large-scale manufacture and low in manufacturing cost.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com