Switch reluctance motor and vehicle power motor assembly

A technology for switched reluctance motors and stator poles, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc. The problems such as low height and unstable operation of switched reluctance motor can achieve the effect of reducing radial vibration, improving efficiency and reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

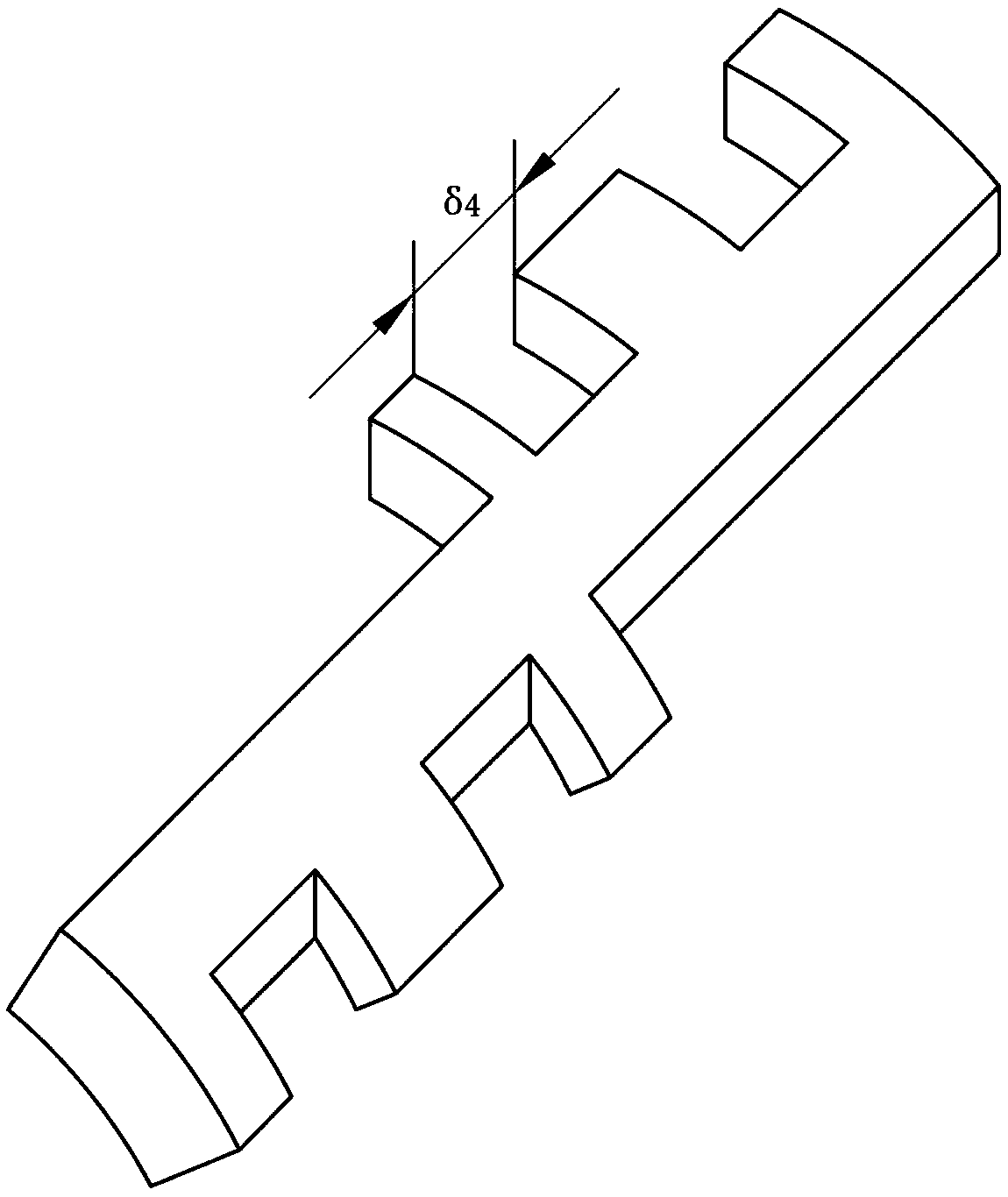

[0025] figure 1 is a schematic structural diagram of a switched reluctance motor according to an embodiment of the present invention.

[0026] refer to figure 1 , shows the structure of a switched reluctance motor according to an embodiment of the present invention. In this embodiment, the switched reluctance motor may have an inner rotor outer stator structure or an inner stator outer rotor structure. For ease of description, a switched reluctance motor with an inner rotor and outer stator structure is taken as an example below.

[0027] The switched reluctance motor may include a coaxially arranged stator 10 and a rotor 20 , the stator 10 may include a plurality of stator poles 11 uniformly distributed in the circumferential direction, and a coil (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com