Method and system for torque control

A technology of valve lift and profile, applied in road vehicle drive control system, electrical control, engine control, etc., can solve problems such as large torque pulsation, achieve the effect of reducing torque pulsation, reducing NVH, and smoothing cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

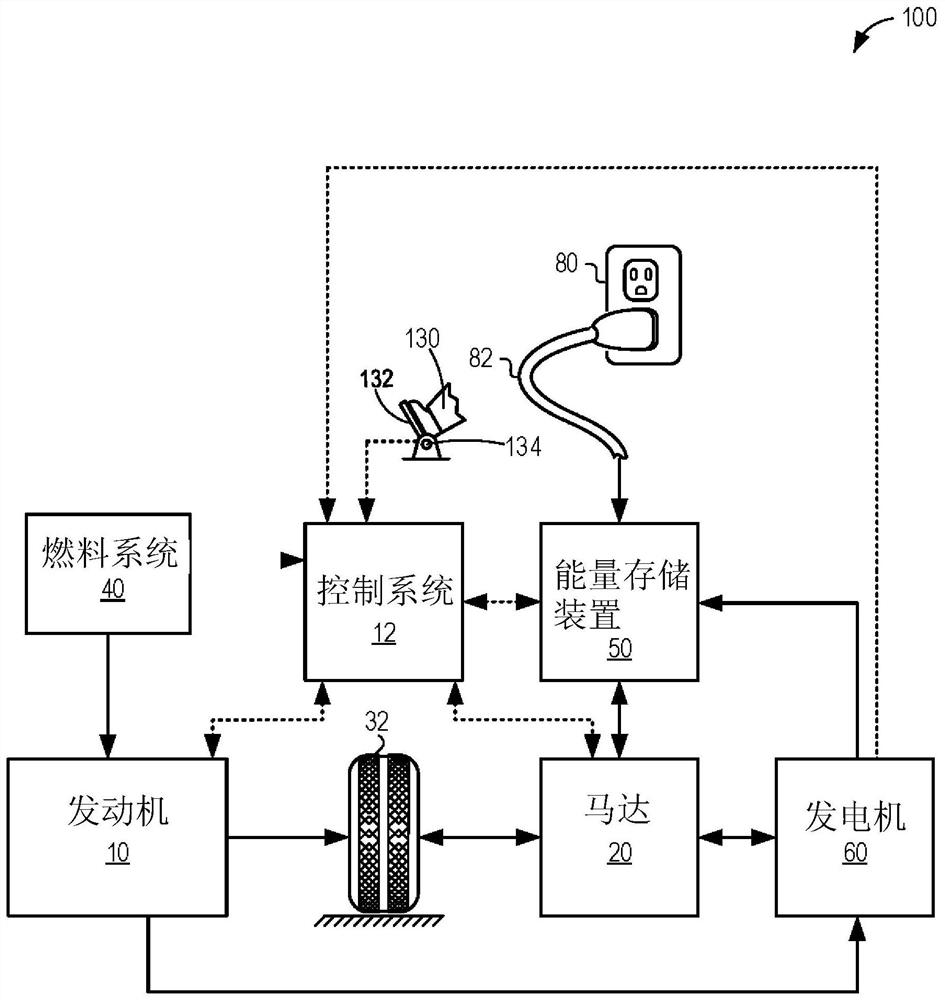

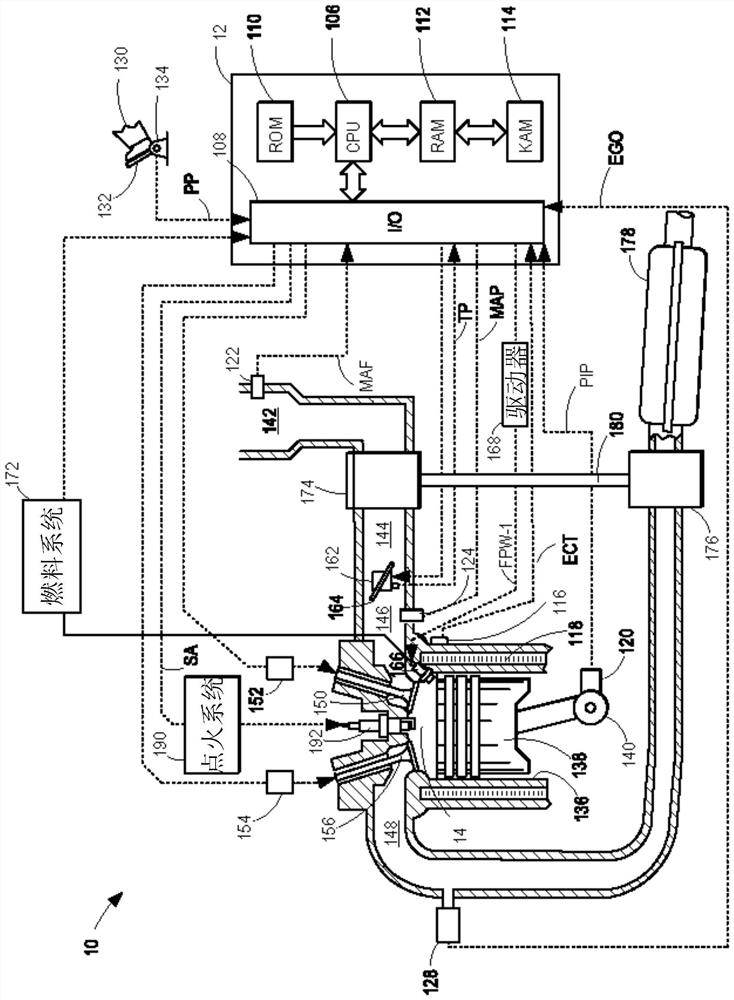

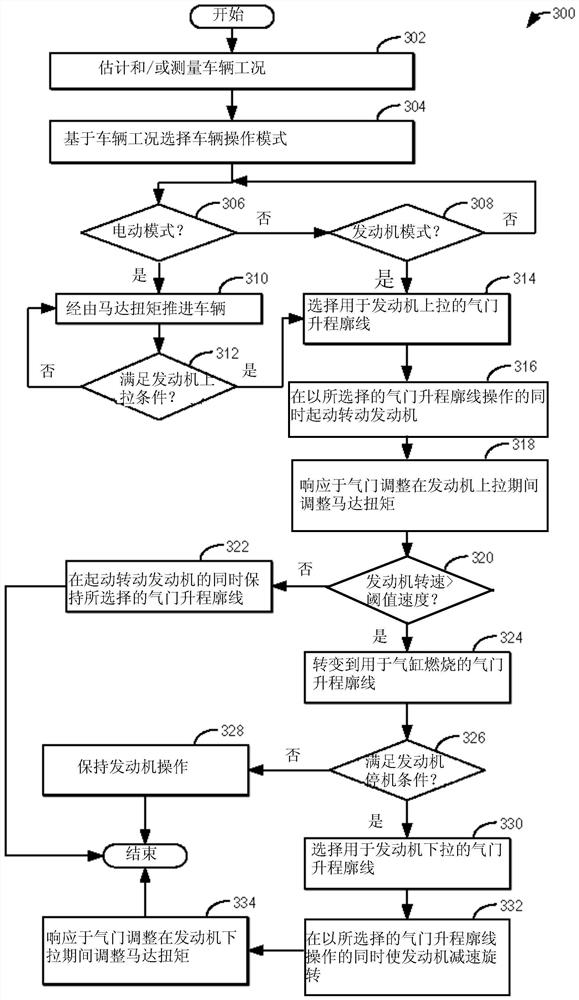

[0016] The following description is concerned with reducing hybrid vehicle systems such as figure 1 A system and method for torque ripple that occurs during engine start and stop events in a vehicle system for the vehicle. The vehicle system may include an engine configured with variable valve lift actuation, as referenced figure 2 The engine system described. The controller can be configured to execute a control program (such as image 3 example routine) to reduce engine compression pressure during engine pull-up and pull-down events, thereby reducing associated pumping losses, torque ripple, and NVH. An example valve lift profile reference that can be used by the controller to reduce cylinder Figure 4 shown. refer to Figure 5 Example valve lift adjustments during vehicle operation are shown. In this way, engine restart and shutdown torque ripple is reduced.

[0017] figure 1 An example vehicle propulsion system 100 is shown. Vehicle propulsion system 100 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com