High-performance permanent magnet servo motor

A permanent magnet servo motor, high-performance technology, applied in the direction of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of no-load phase sinusoidal back electromotive force, reduce Motor running performance and other issues, to achieve the effect of heat dissipation, stable motor operation, and lower temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

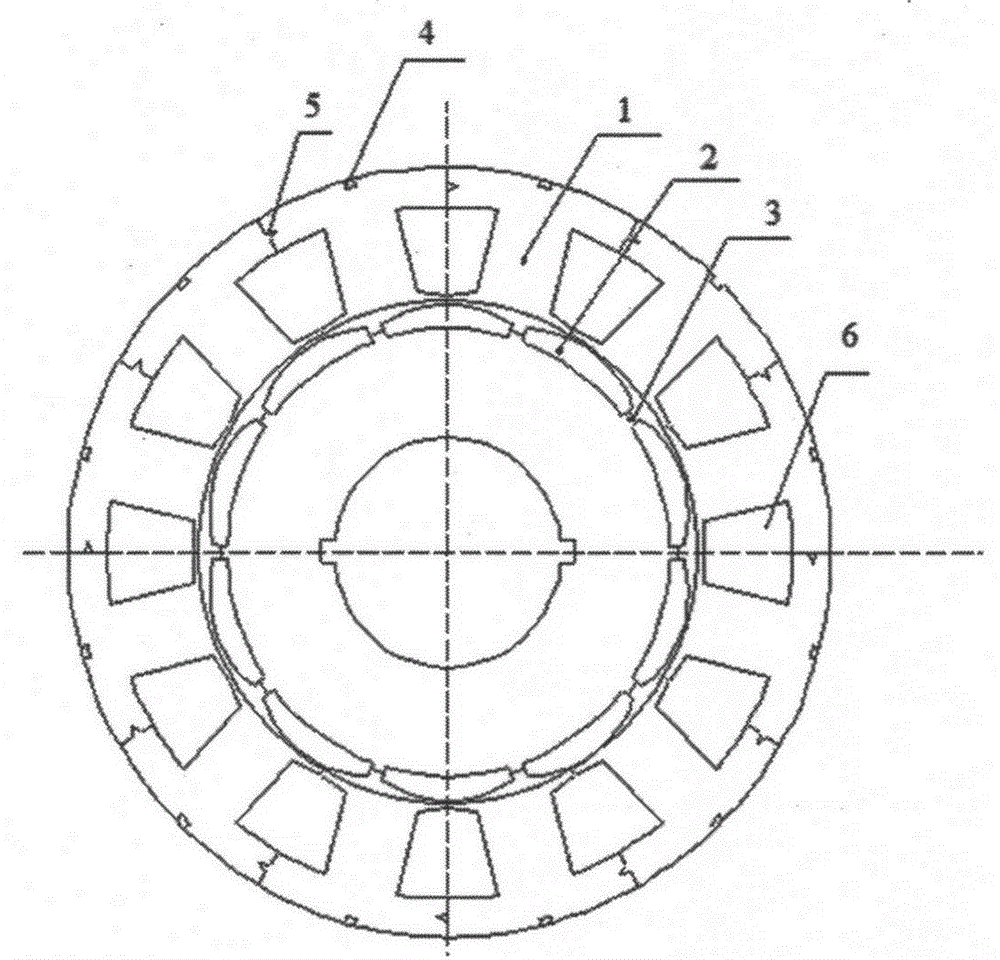

[0025] Such as figure 1 As shown, the high-performance permanent magnet servo motor of this embodiment includes a stator and a rotor, the stator includes a stator core and coils wound on the stator core, and the rotor includes a rotor core and a The permanent magnet 2 on the outer circumference, the stator iron core is formed by lamination of stator punching pieces, the stator punching piece is a split tooth structure, and is formed by splicing 12 stator tooth punching pieces 1, and the rotor The iron core is formed by lamination of rotor punching sheets, and permanent magnet slots are formed on the outer periphery of the rotor iron core. The permanent magnets 2 are in the shape of unequal thickness, and are embedded in the permanent magnet slots. The surface of the permanent magnets Glue is applied to both the permanent magnet slot and the permanent magnet slot for reinforcement. The outer sides of the rotor core and the permanent magnet 2 are provided with plastic seals, an...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the stator core has a half-open slot structure, and its opening is formed on the inner circumference of the stator core, which can effectively improve the air gap magnetic field distribution, reduce harmonic loss, and The cogging torque is greatly reduced, so that the output torque fluctuation of the permanent magnet servo motor meets the accuracy requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com