Method and system for engine control

An engine, engine torque technology, applied in the direction of engine control, road vehicle drive control system, machine/engine, etc., can solve problems such as jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

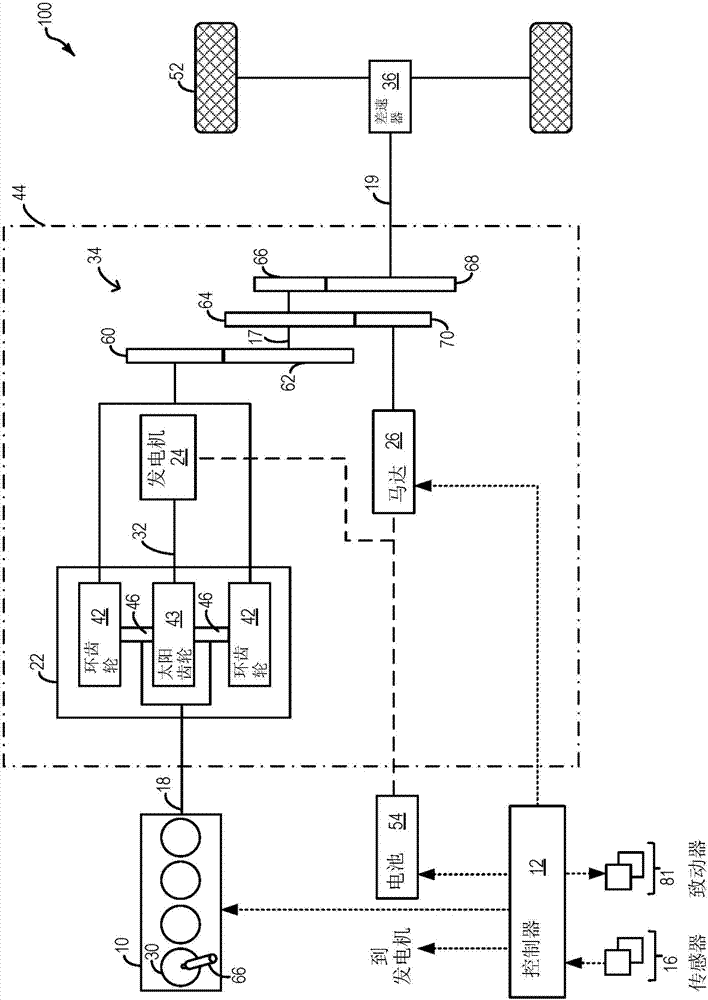

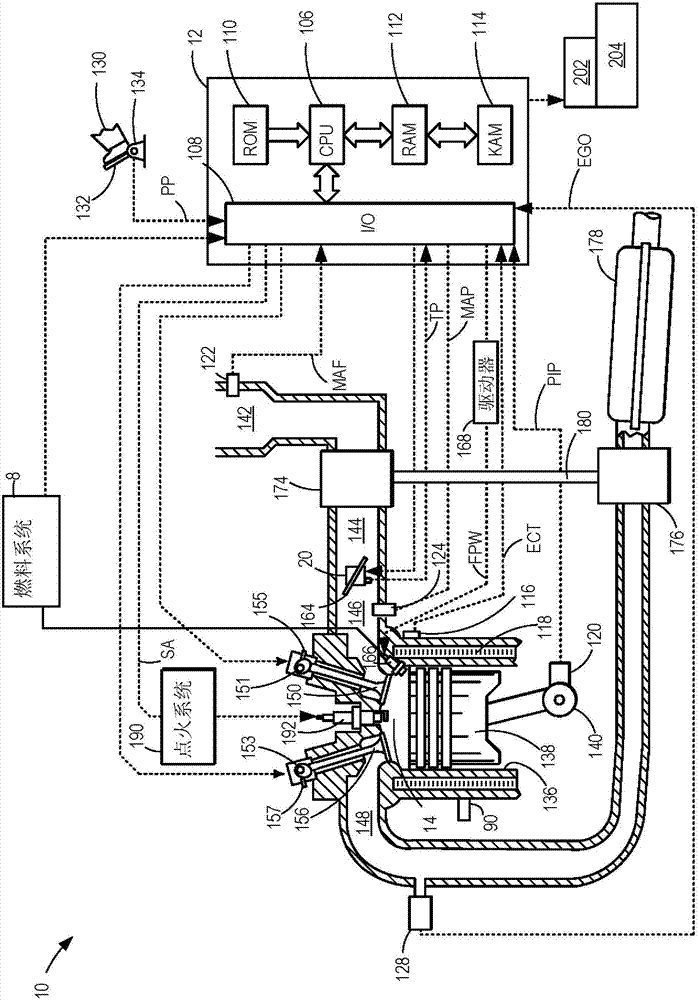

[0016] The following description relates to methods for improving hybrid vehicle systems such as figure 1 Systems and methods for fuel economy in a vehicle system. as reference figure 2 As described above, a vehicle system may include an engine configured with a variable compression ratio (VCR) mechanism capable of varying the compression ratio of the engine via mechanical adjustment. The controller can be configured to execute control routines such as image 3 example routine) to reduce the engine's compression ratio during engine pull-up and pull-down events, thereby reducing associated pumping losses and NVH. The controller can also execute routines (such as Figure 4 example routine) to choose between switching to an alternate compression ratio and maintaining the current compression ratio while using motor torque to meet demand deficits. refer to Figure 5-Figure 6 An example map is shown that may be used by a controller to select a compression ratio. Figure 7 Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com