Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Reduce the risk of complaints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

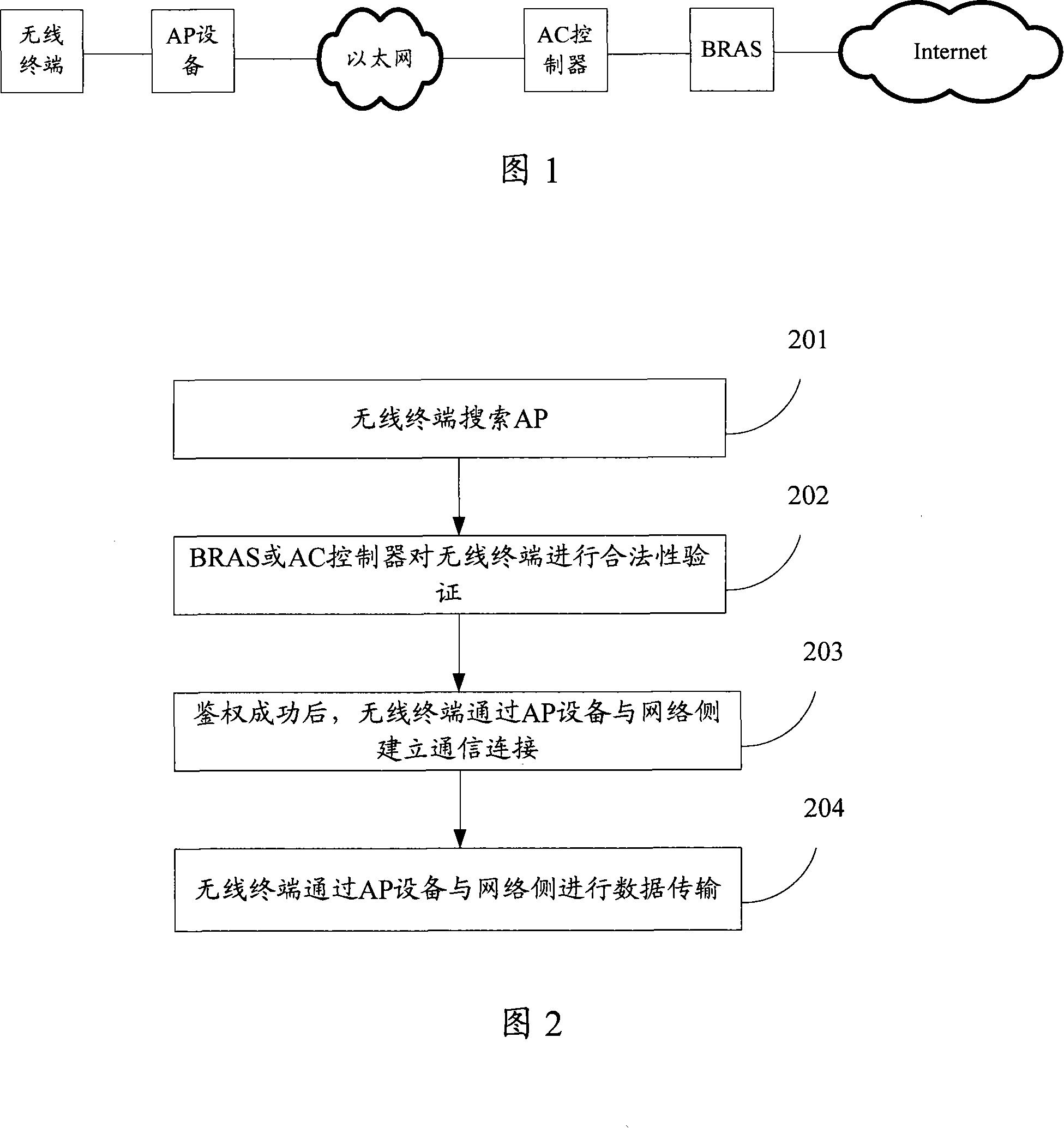

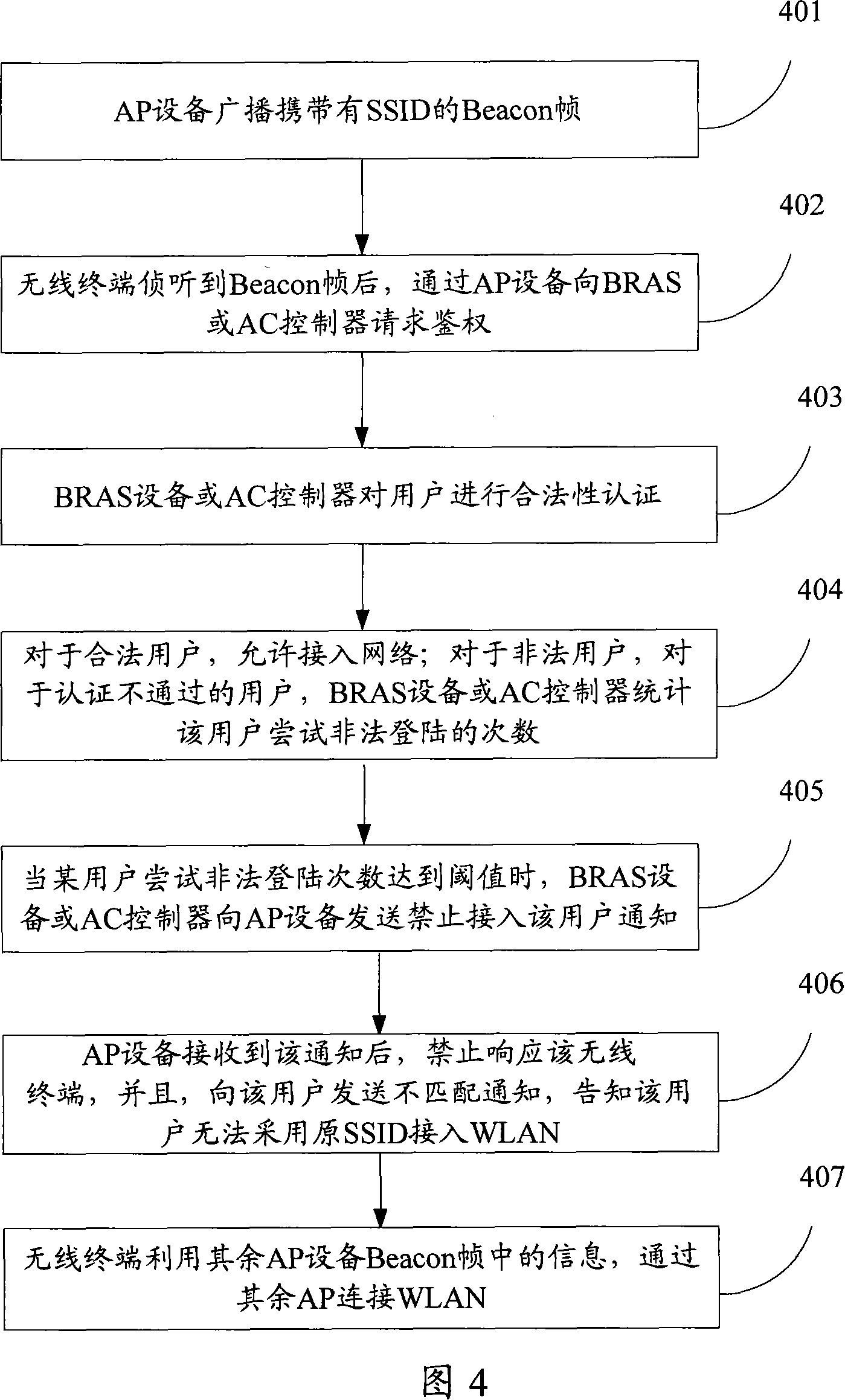

Method and device of access point equipment for preventing error access

InactiveCN101141259AImprove securityReduce the impactUser identity/authority verificationData switching by path configurationComputer science

The utility model discloses a method for guarding against the misconnection to the AP equipment. After the wireless terminal requires for the certification from the network via the AP equipment, the network will examine the validity of the wireless terminal. When the certification fails, the network equipment will record the illegal frequency of the wireless terminal's misconnection to the AP equipment. When the illegal frequency reaches the preset threshold, the network equipment will send the signal to the AP equipment for forbidding the wireless terminal access. After the signal is received by the AP equipment, the response t the wireless terminal is forbidden. The utility model can be used to effectively prevent the disabled user's access to the AP equipment. As the frequency of misconnection is arranged and dynamically adjusted, the influence to the user operation can be reduced, so as to lower the frequency of connect failure and the user's complains. As responding to the above method, the utility model also provides a device used for guarding against the misconnection to the AP equipment.

Owner:NEW H3C TECH CO LTD

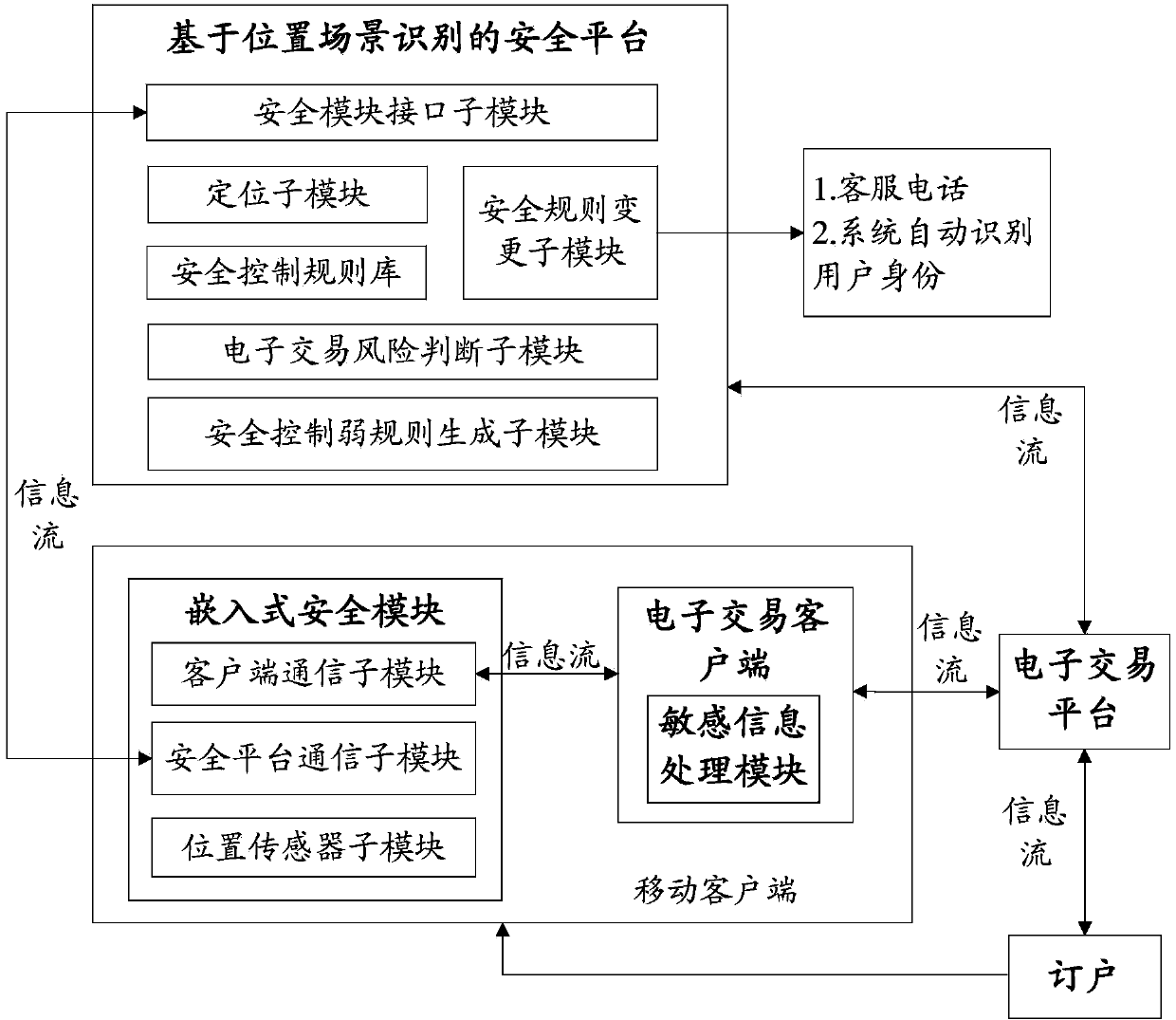

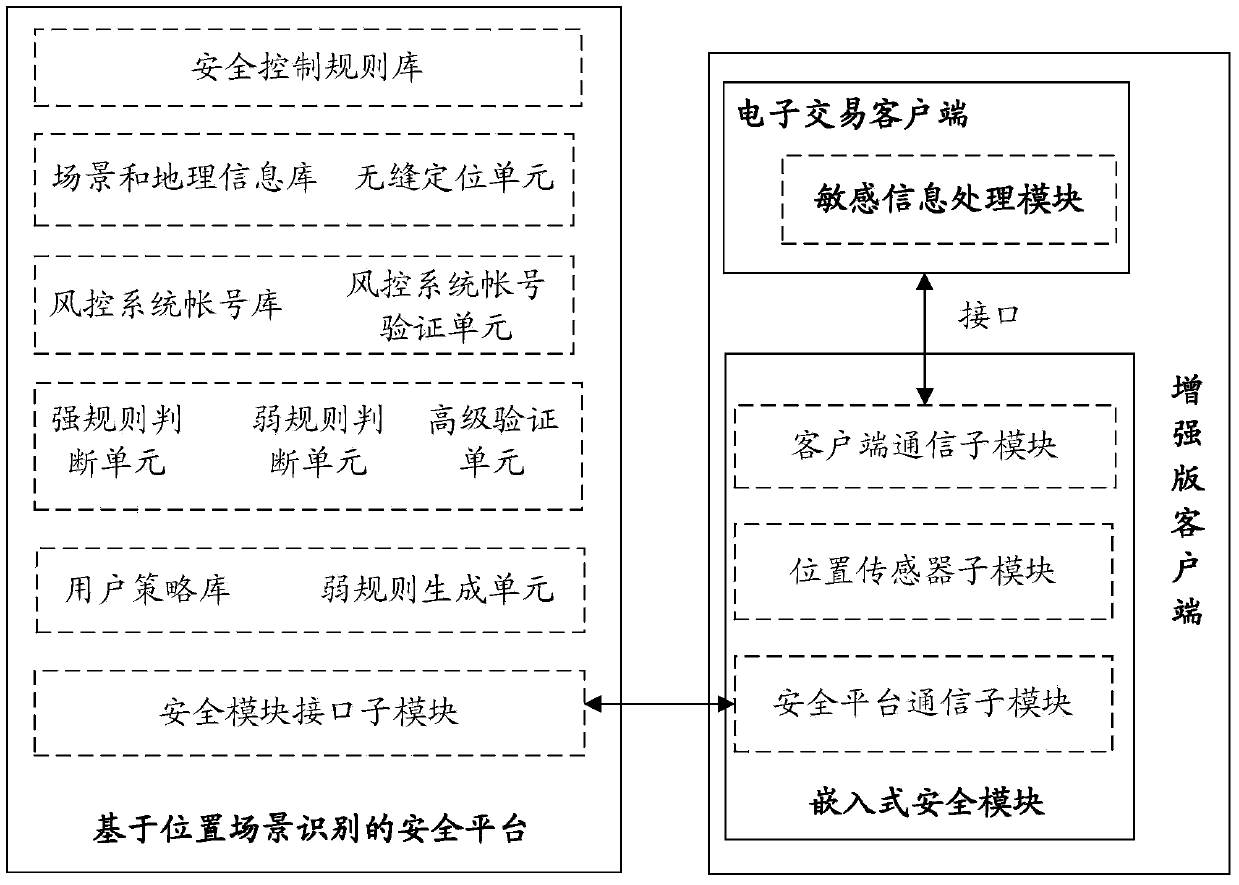

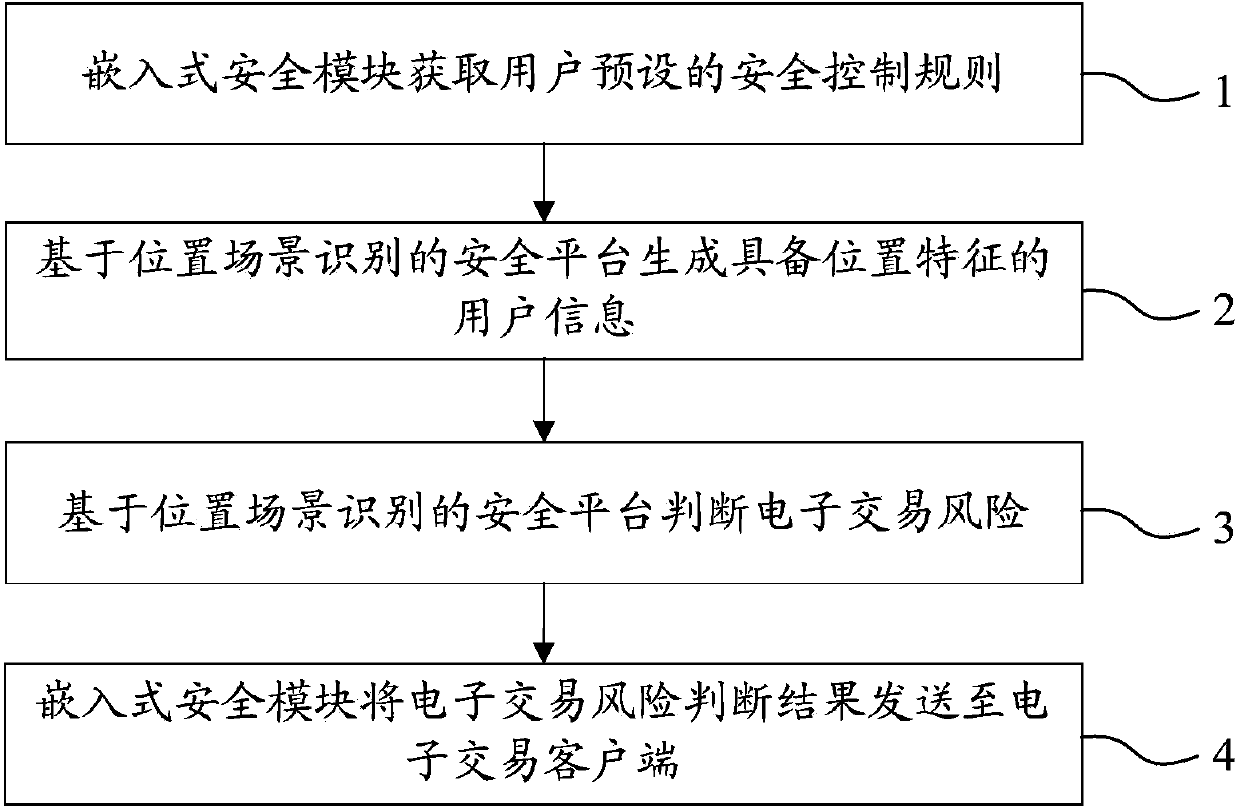

System and method for realizing electronic transaction risk control based on position scene identification

InactiveCN103745397APrevent fraudReduce personal property damageFinanceBuying/selling/leasing transactionsRisk ControlEmbedded security

The invention relates to a system for realizing electronic transaction risk control based on position scene identification. The system comprises a position scene identification-based security platform and an embedded security module, wherein the position scene identification-based security platform comprises a security interface sub-module, a positioning sub-module, a security control rule library, a security rule change sub-module, an electronic transaction risk judging sub-module and a security control weak rule generation sub-module, which are communicated with the embedded security module. The invention further relates to a method for realizing electronic transaction risk control based on position scene identification through the system. By adopting the system and the method for realizing electronic transaction risk control based on position scene identification, risk control over the electronic transactions of a user can be realized by providing positioning service and identifying a user position scene, so that the security of an electronic transaction process is enhanced, and losses caused by transaction security problems are reduced. The method is easy, convenient, and wider in application range.

Owner:YINLIAN FINANCIAL INFORMATION SERVICE BEIJING CO LTD

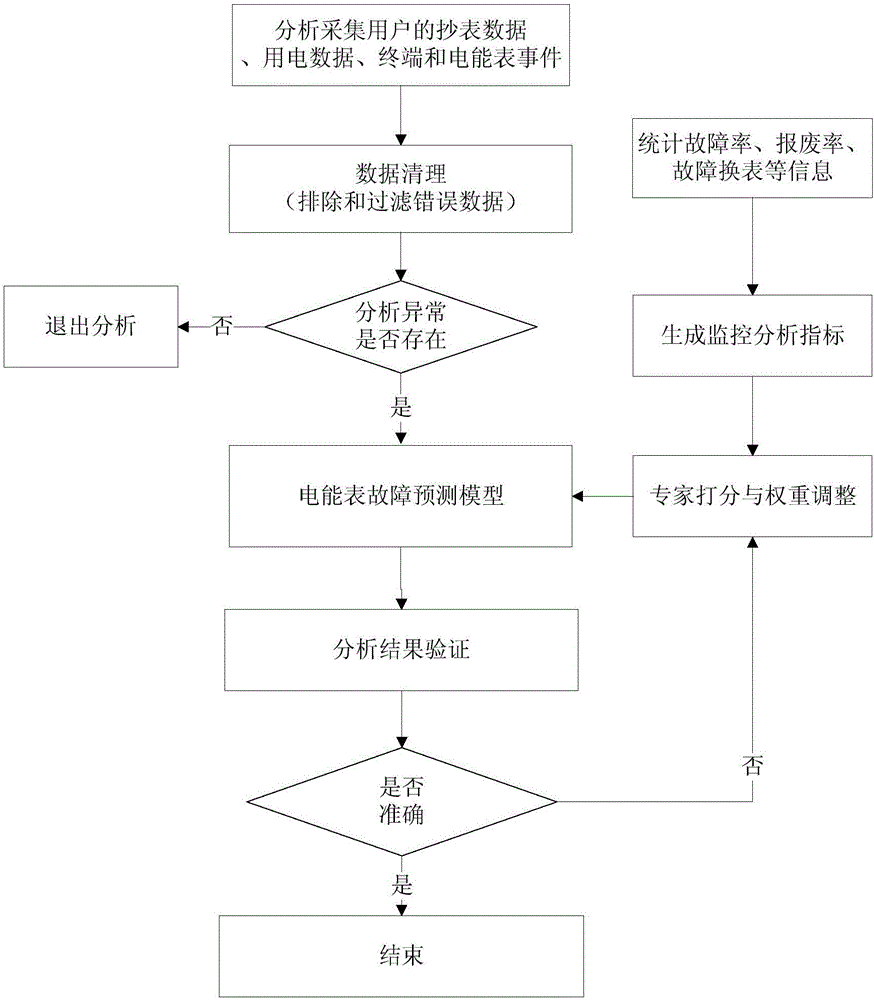

Electric energy meter fault prediction method based on decision tree algorithm

ActiveCN106154209ADiscovered in timeReduce the risk of complaintsElectrical measurementsElectricityLow voltage

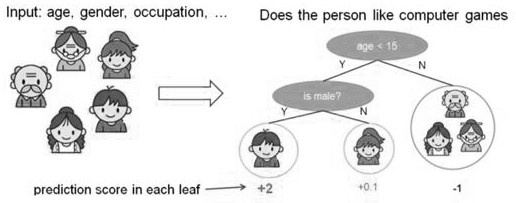

The invention discloses an electric energy meter fault prediction method based on a decision tree algorithm. The electric energy meter fault prediction method comprises the following steps: acquiring relevant data of a user by using an acquirer and eliminating wrong data; analyzing whether electric energy meters which have abnormal environments and abnormal quality exist in specific power transformer users and low-voltage users within statistical time buckets; counting whether metering and electricity utilization abnormal events which meet requirements of fault judgment exist for the special power transformer users, and counting whether metering abnormal events which meet requirements of fault judgment exist for the low-voltage users; establishing an electric energy meter fault prediction model by using the decision tree algorithm according to manufacturers corresponding to the electric energy meter and information of failed batches and on the basis of electric energy meter metering fault information of a marketing system; judging whether the result is accurate or not; if the result is accurate, finishing the process; and if the result is inaccurate, continuing judging faults. By the electric energy meter fault prediction method based on the decision tree algorithm, failed electric energy meters can be found out accurately in time, so that workload of field investigation and metering fault treatment of an examination department is reduced.

Owner:NARI TECH CO LTD +3

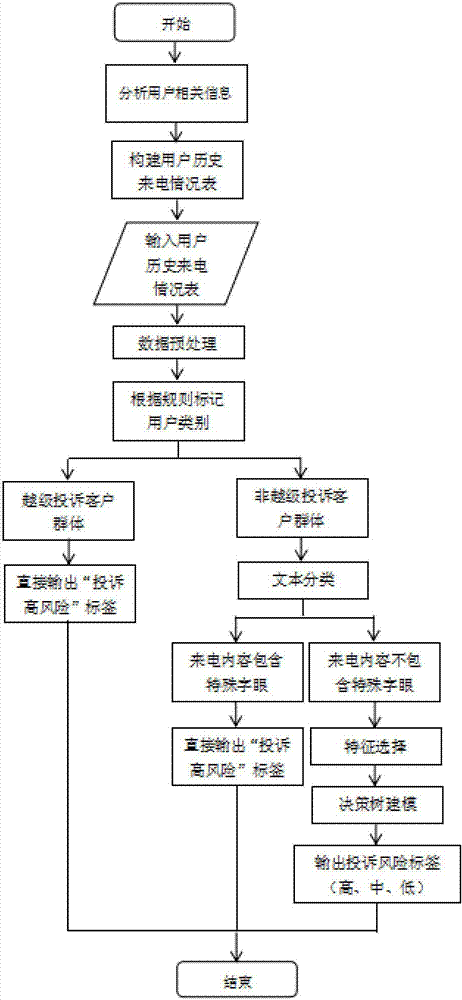

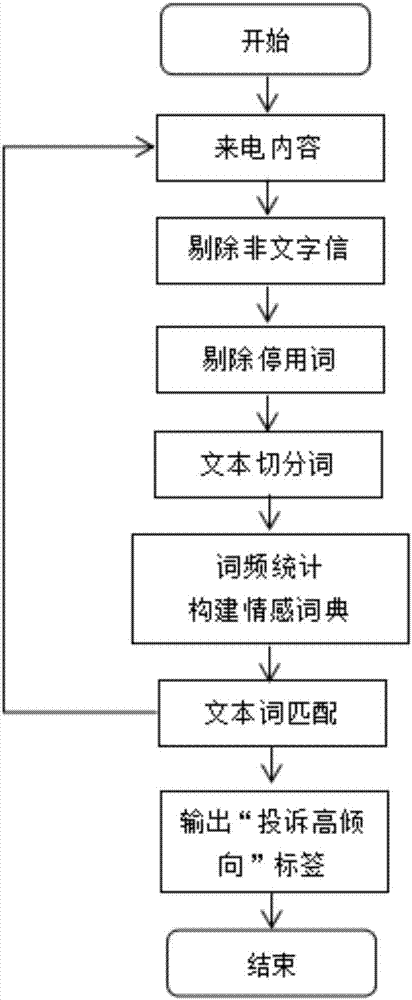

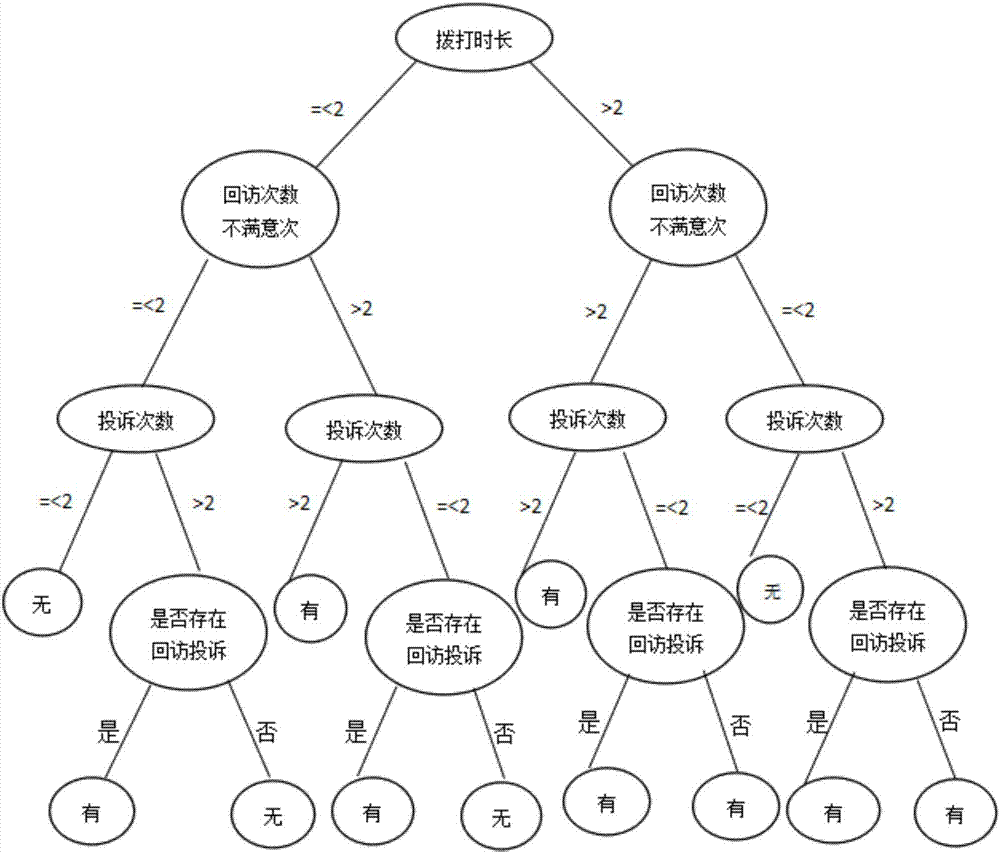

Text classification technology and decision-making tree based complaint tendency judgment method

ActiveCN107992609AReduce the risk of complaintsImprove social imageCustomer relationshipRelational databasesData setElectric power

The invention discloses a text classification technology and decision-making tree based complaint tendency judgment method. The method includes: acquiring user information from a database management system and establishing a user history call information table accordingly, wherein the user information includes user profile information and customer service order information; determining a time window for acquiring the user information; determining a prejudgment period and a feature data set used for prejudgment; determining a group range for prejudgment. With the method, complaint tendency degrees of users can be judged accurately when the users call, reference is provided for designing a strategy library and adopting different pacification and guidance strategies, and customer request information extracted from structural data is fully utilized; meanwhile, unstructured text data in call content in work orders is analyzed systematically, future complaints of the users are precast in advance according to the historical call information, complaint risk of the users can be reduced, and good social image of an electric power company is established.

Owner:GUANGDONG POWER GRID CO LTD INFORMATION CENT

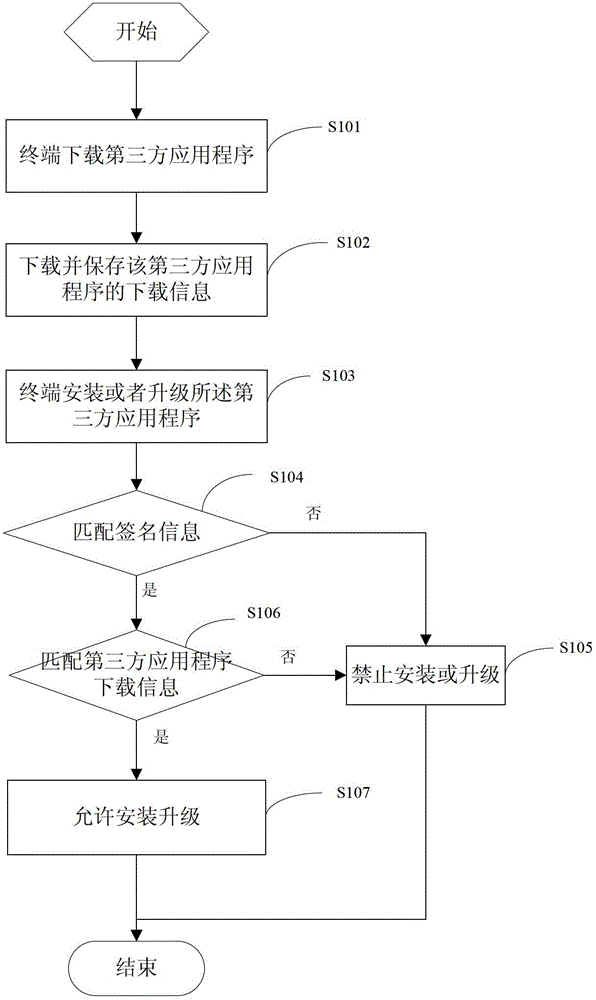

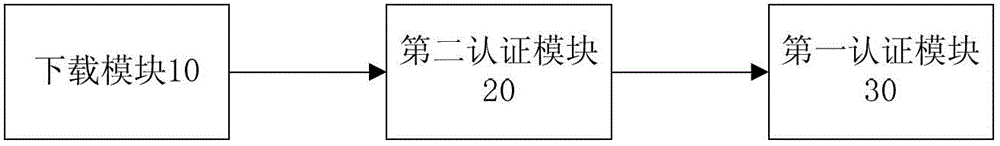

Method and system for restricting terminals from mounting or upgrading third-party application programs

ActiveCN102750491AAffect normal useAvoid unstable performanceComputer security arrangementsThird partySoftware engineering

The invention discloses a method and a system for restricting terminals from mounting or upgrading third-party application programs, wherein the method includes the following steps: downloading and saving downloading information of the third-party application programs while downloading the third-party application programs at the terminals; and matching the downloaded information with prestored and authorized information while mounting or upgrading the third-party application programs at the terminals, and allowing the third-party application programs to be mounted or updated if the information are matched. According to the method and the system for restricting the terminals from mounting or upgrading the third-party application programs, the problem of unstable terminal performances caused by the fact that users download the third-party application programs from informal channels can be solved, and the influence of some malicious third-party application programs on the normal use of users can also be avoided, so that risks of customer complaints about terminal suppliers caused by third-party application programs are reduced greatly.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

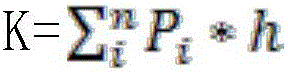

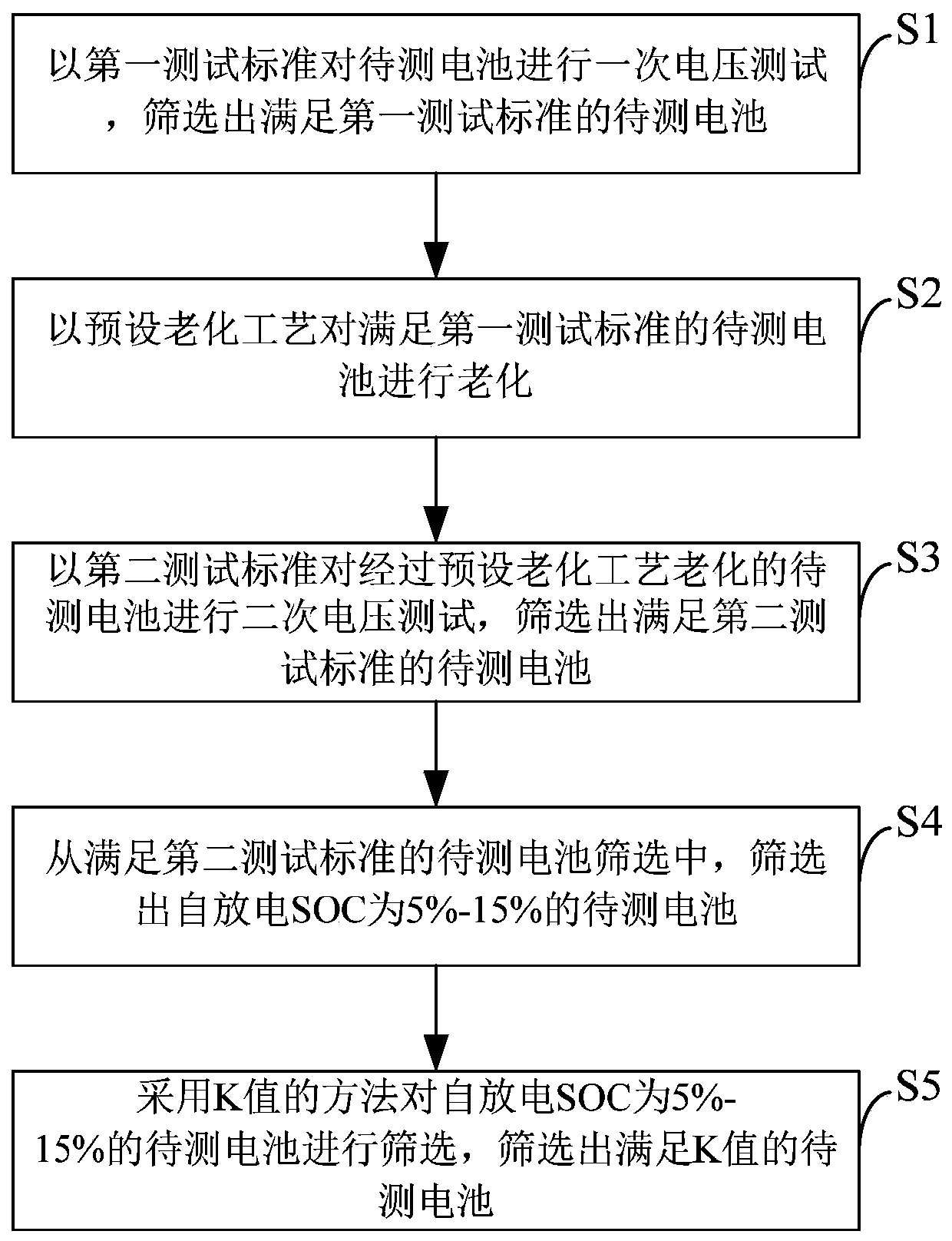

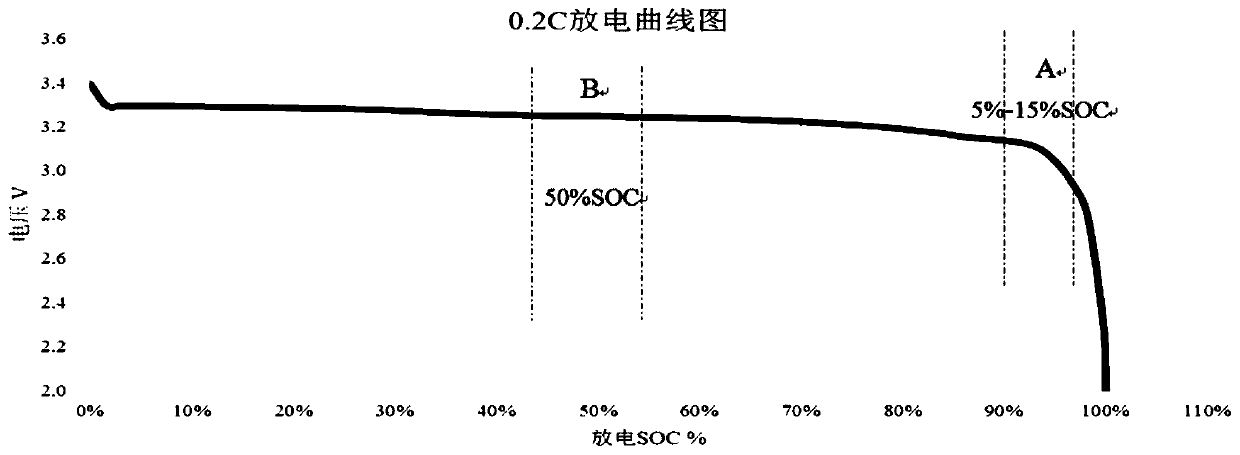

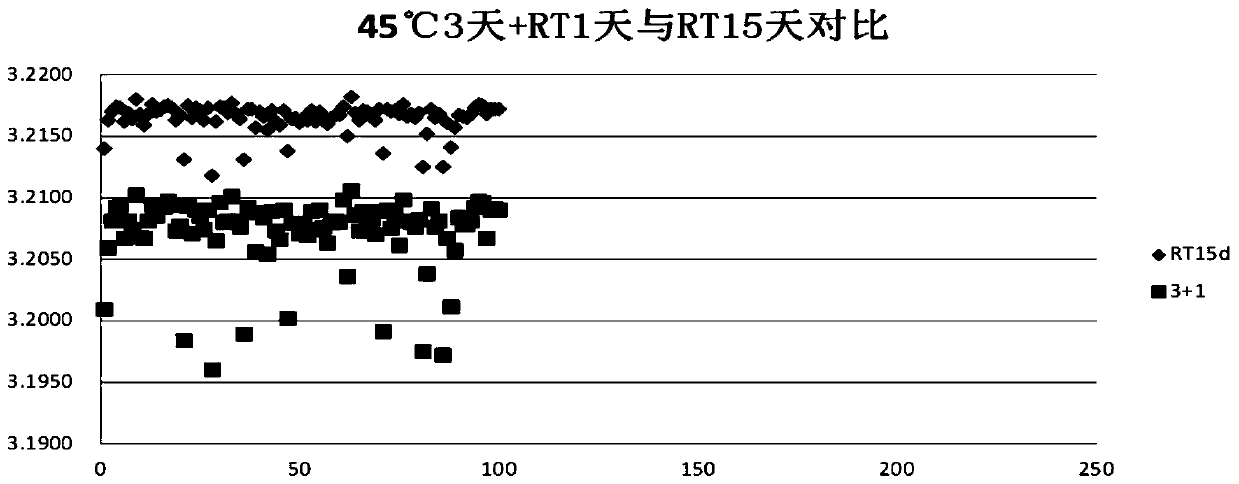

Lithium ion battery self-discharging screening method

ActiveCN108682908AShort screening cycleIncrease production capacitySecondary cells testingTest batteryVoltage

The invention relates to a lithium ion battery self-discharging screening method. The lithium ion battery self-discharging screening method comprises the following steps: S1, performing first-time voltage test on to-be-tested batteries according to a first test standard and screening out the to-be-tested batteries meeting the first test standard; S2, ageing the to-be-tested batteries meeting the first test standard by a preset ageing process; S3, performing second-time voltage test on the to-be-tested batteries aged by the preset ageing process according to a second test standard and screeningout the to-be-tested batteries meeting the second test standard; S4, screening the to-be-tested batteries meeting the second test standard and screening out the to-be-tested batteries with self-discharging SOC being 5 to 15 percent; and S5, screening the to-be-tested batteries with the self-discharging SOC being 5 to 15 percent by a K value method and screening out the to-be-tested batteries meeting the K value. By the method, the self-discharging screening cycle can be effectively shortened, the productivity is improved, the cost is further reduced, the efficiency is high and the accuracy degree is high; furthermore, the quality of products can be improved and the customer complaint risk can be reduced; meanwhile, the delivery cycle of the products can be shortened.

Owner:HUIZHOU TOPBAND ELECTRICAL TECH CO LTD

Method for intelligently adjusting online queuing priority of customer service system

InactiveCN107274893AImprove the resolution rateReduce the risk of complaintsSpecial service for subscribersSpeech recognitionChronological timeSpeech sound

The invention discloses a method for intelligently adjusting an online queuing priority of a customer service system, wherein the method relates to the field of communication technology. The method comprises the following steps of S1, acquiring a telephone number of an incoming call client, comparing the telephone number of the client with a VIP client telephone number database, detecting whether the client is a VIP client through telephone number detection, if yes, switching the client to a VIP channel, and otherwise, switching the client to a common channel; S2, broadcasting an inquiry for a handled service kind, acquiring a voice answer of the client, extracting key words in the voice answer, and determining kind of the handled service of the client; and S3, determining the priority of the client according to the kind of the handled service of the client, and adjusting position of the client in a queue. The method of the invention settles problems of high loss of some clients, customer experience reduction and loss of some potential important client caused by queuing of all clients according to a time sequence after telephone end clients select a man service.

Owner:SICHUAN XW BANK CO LTD

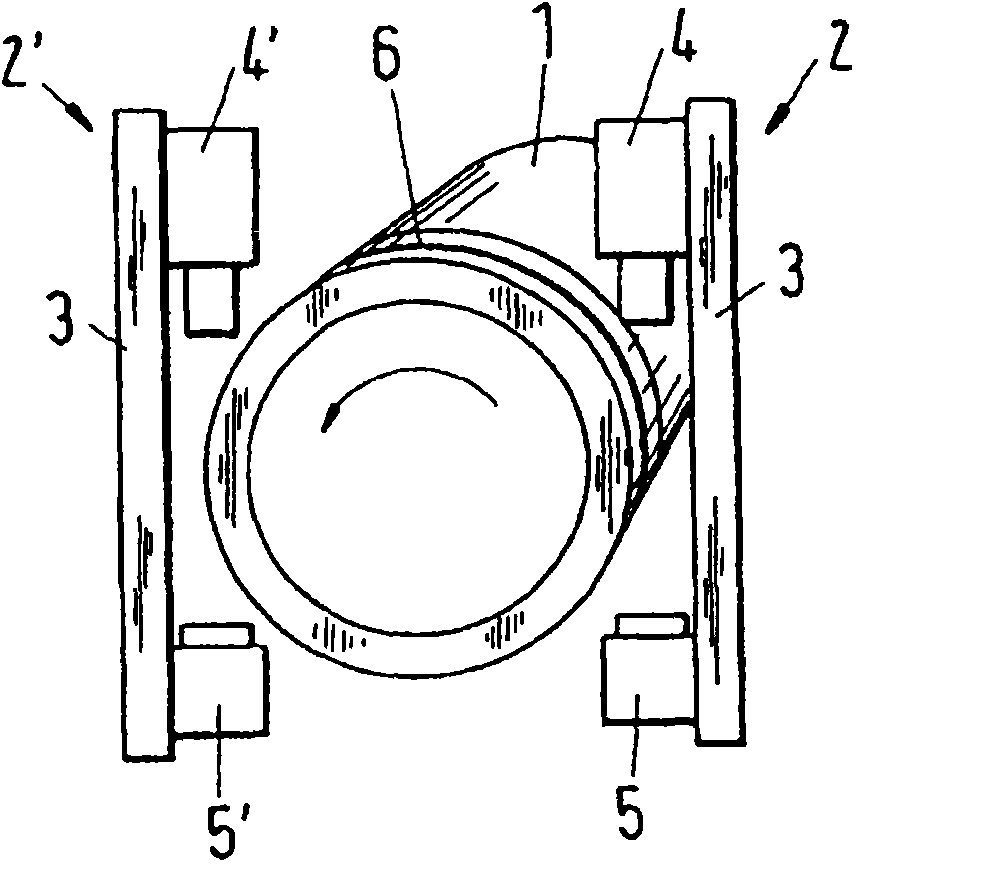

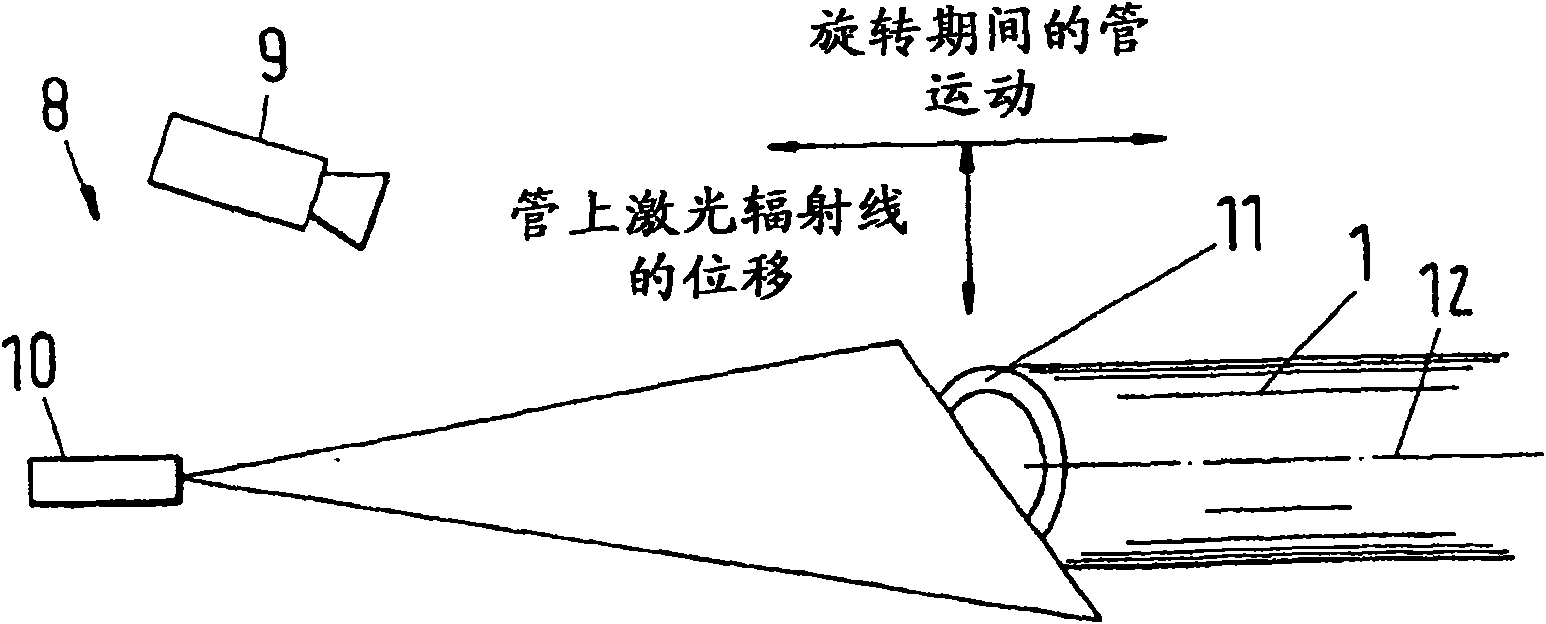

Method and device for optically measuring external threads

ActiveCN101688770ARealize the collectionFull quality inspectionUsing optical meansProduction lineImage resolution

Owner:瓦卢莱克德国有限公司

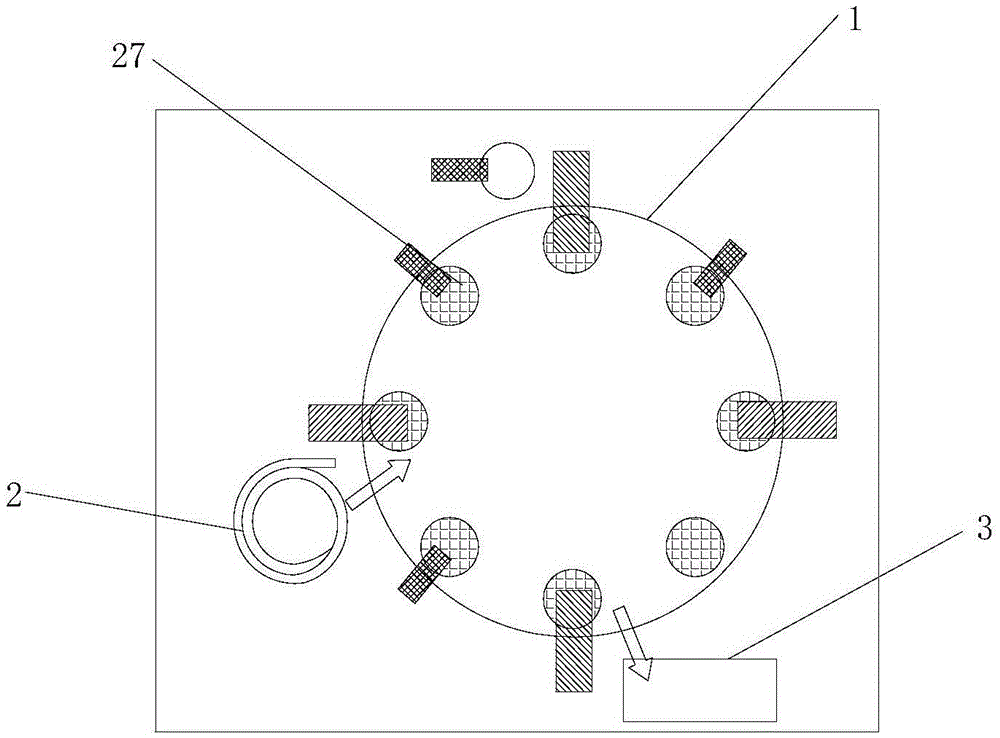

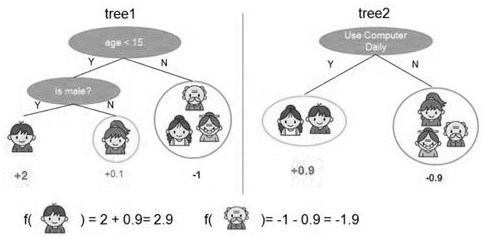

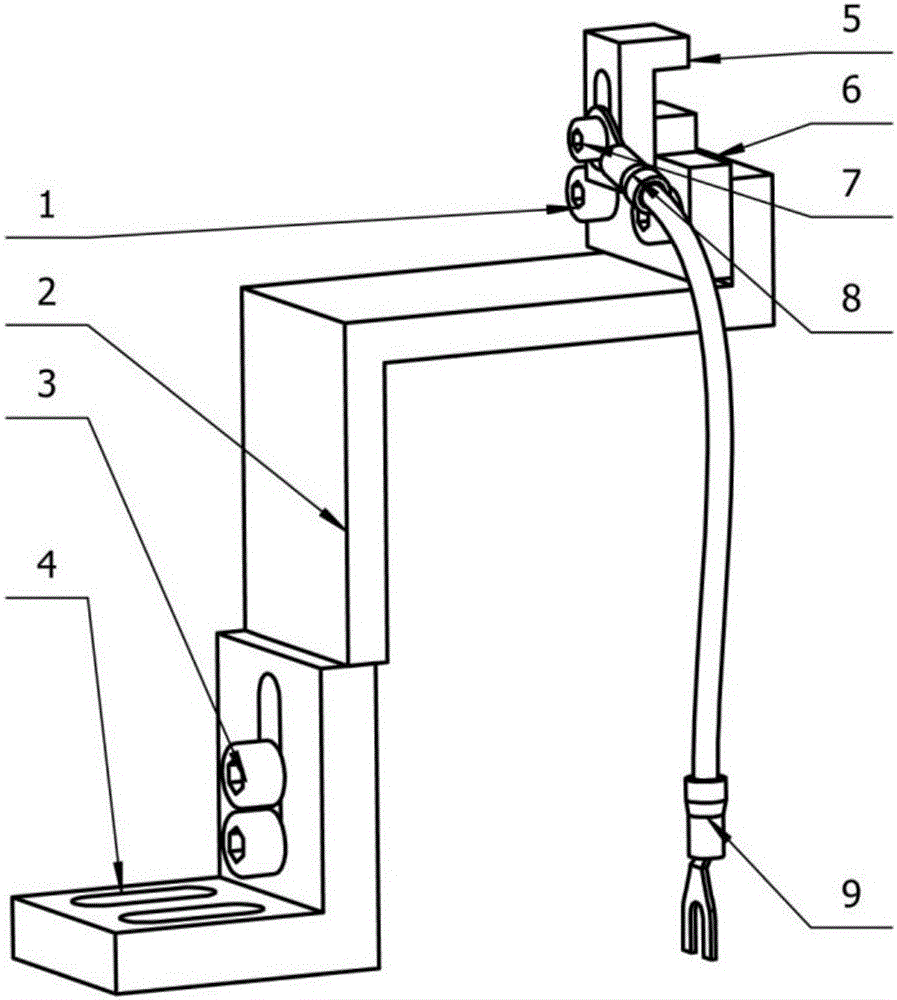

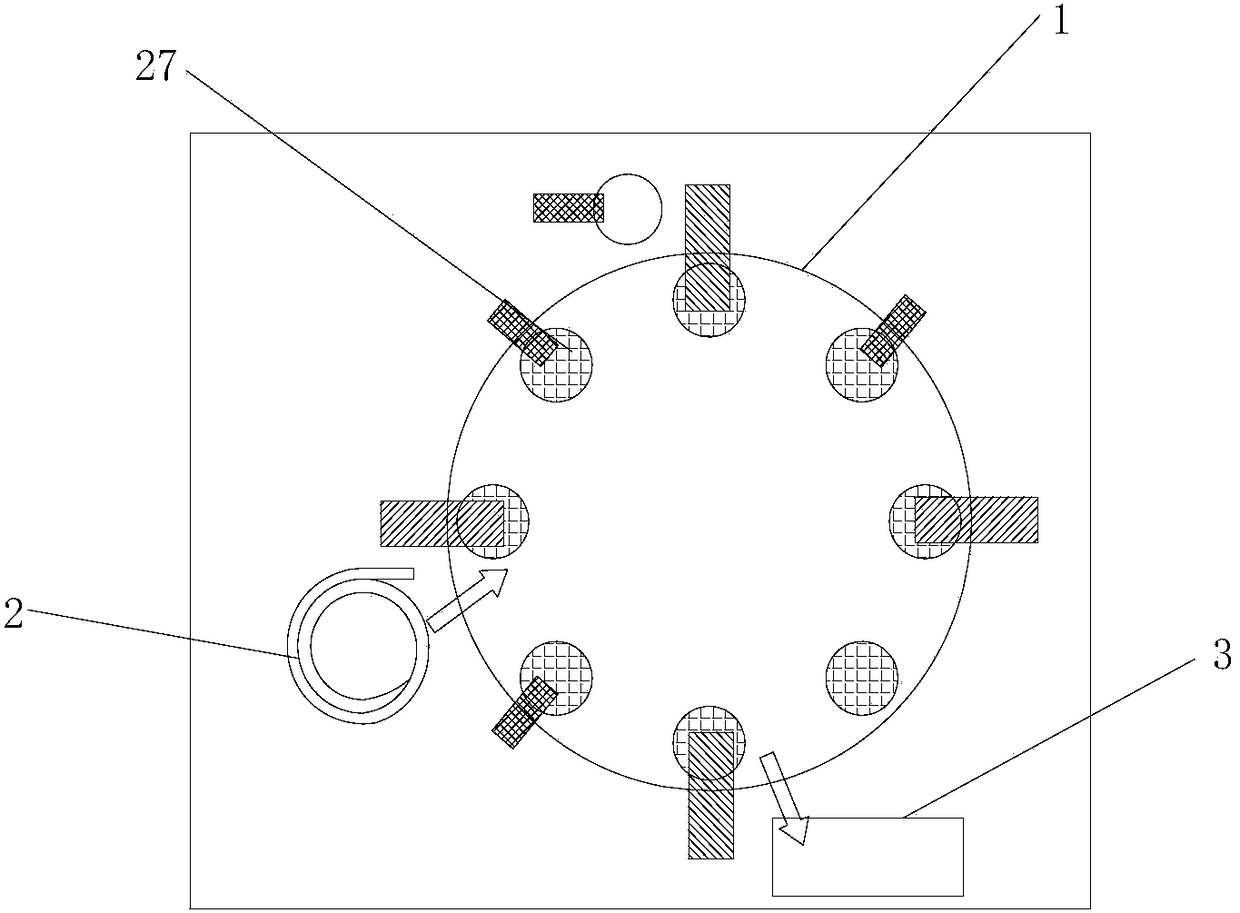

Automatic winding device

The invention relates to the technical field of coil winding devices for metal brackets, in particular to an automatic winding device. Four stations are also arranged on a rack on the peripheral edge of a turn table; a loading device, a coil winding device, a dispensing machine and an unloading device are arranged on the four stations respectively; the loading device is used for mounting a to-be-wound metal bracket on a turn plate workpiece support device; the coil winding device is used for winding a wire on the metal bracket; the dispensing machine is used for coating the coil on the metal bracket with glue; the unloading device is used for taking out the metal bracket; the loading device comprises a loading manipulator; the coil winding device comprises a winding device and a wire cutting device; and the unloading device comprises an unloading manipulator, so that the automatic winding device saves manpower, increases the production capacity, completely eradicates manual operation and avoids pre-damage to an enamelled wire.

Owner:BESTAR HLDG

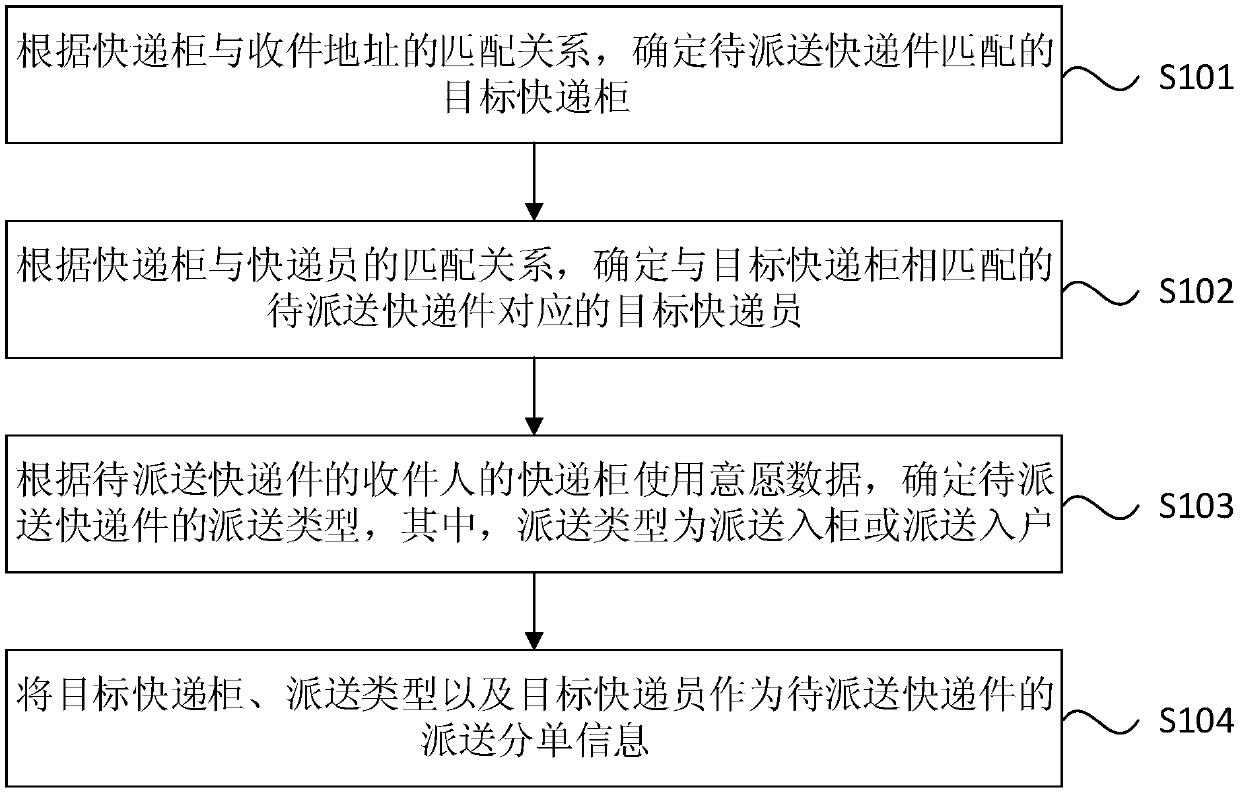

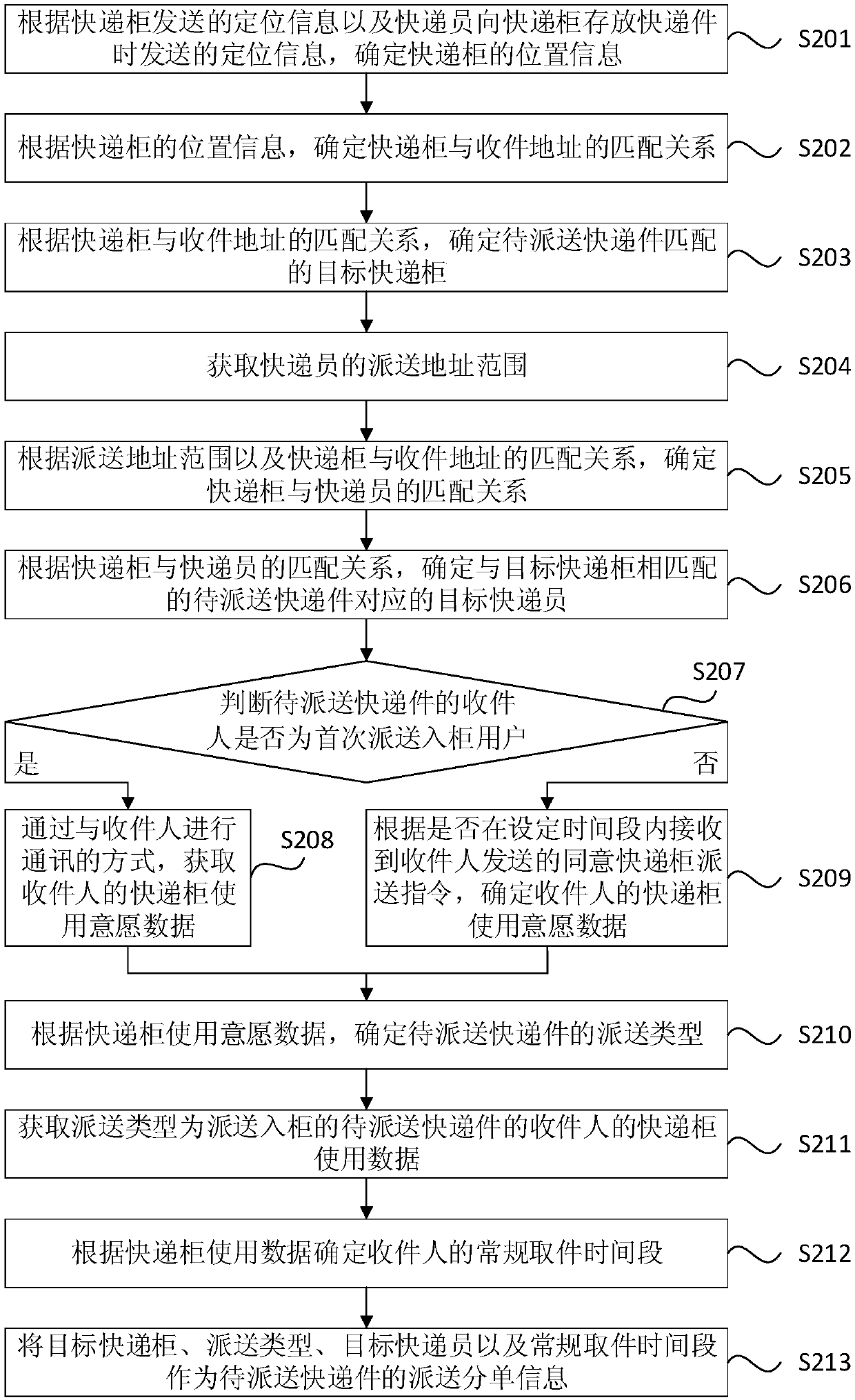

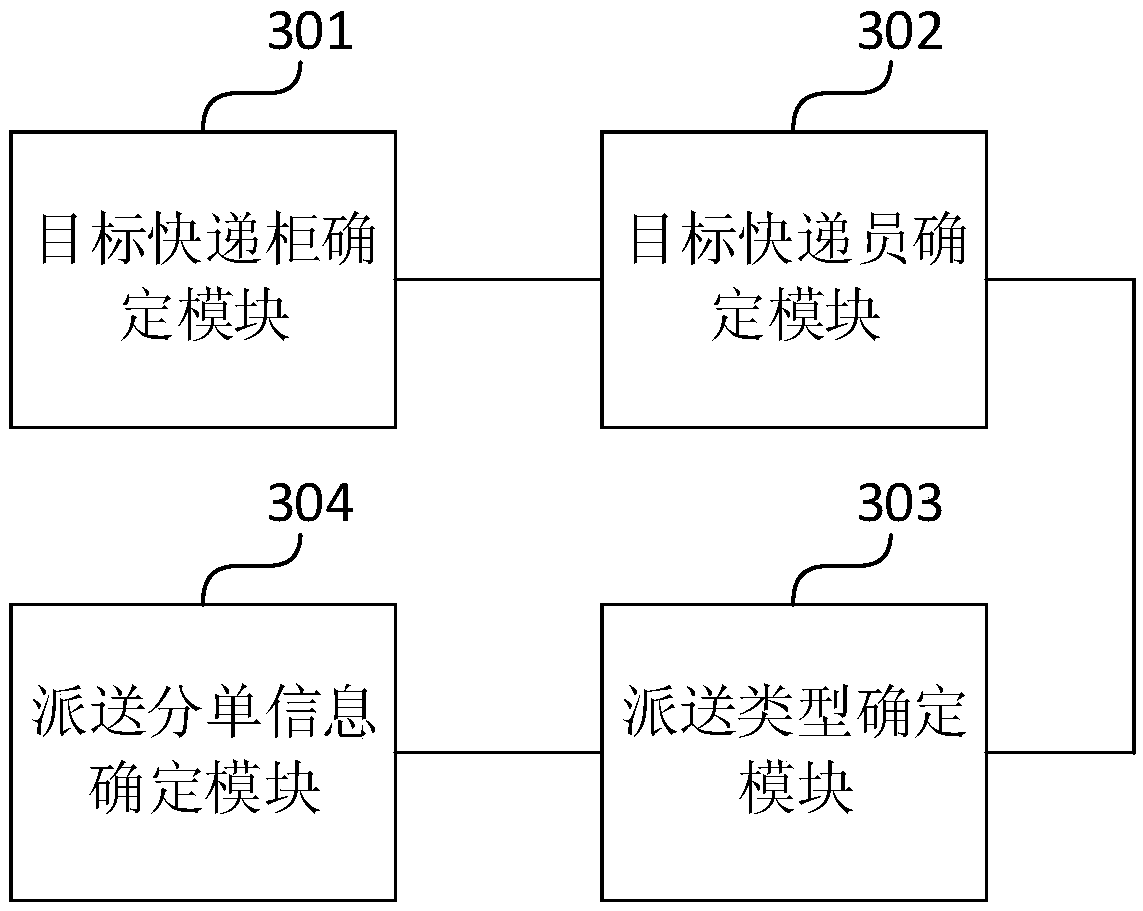

Express delivery order distribution method and device, computer equipment and storage medium

PendingCN109685416ASimplify the delivery processDecrease in turnover rateResourcesLogisticsDistribution methodComputer science

The embodiment of the invention discloses an express delivery order distribution method and device, computer equipment and a storage medium. The method comprises the following steps: determining a target express cabinet matched with a to-be-delivered express according to a matching relationship between an express cabinet and a receiving address; Determining a target courier corresponding to the to-be-delivered express according to a matching relationship between the express cabinet and the courier; Determining the delivery type of the to-be-delivered express according to the express cabinet use willingness data of the recipient of the to-be-delivered express; And taking the target express cabinet, the delivery type and the target courier as delivery order distribution information of the to-be-delivered express. According to the technical scheme provided by the embodiment of the invention, the corresponding relationship between the express item and the express cabinet and between the express item and a courier is determined in the delivery and order distribution link; Compared with the prior art, the method has the advantages that the efficiency of distributing the express items isimproved, the delivery process of the express items is simplified, the labor waste of couriers is reduced, the delivery type of the express items is determined in the distribution link of distributingthe express items, the risk that the express items remain in the express cabinet is reduced, and the turnover rate of the express cabinet grid is increased.

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

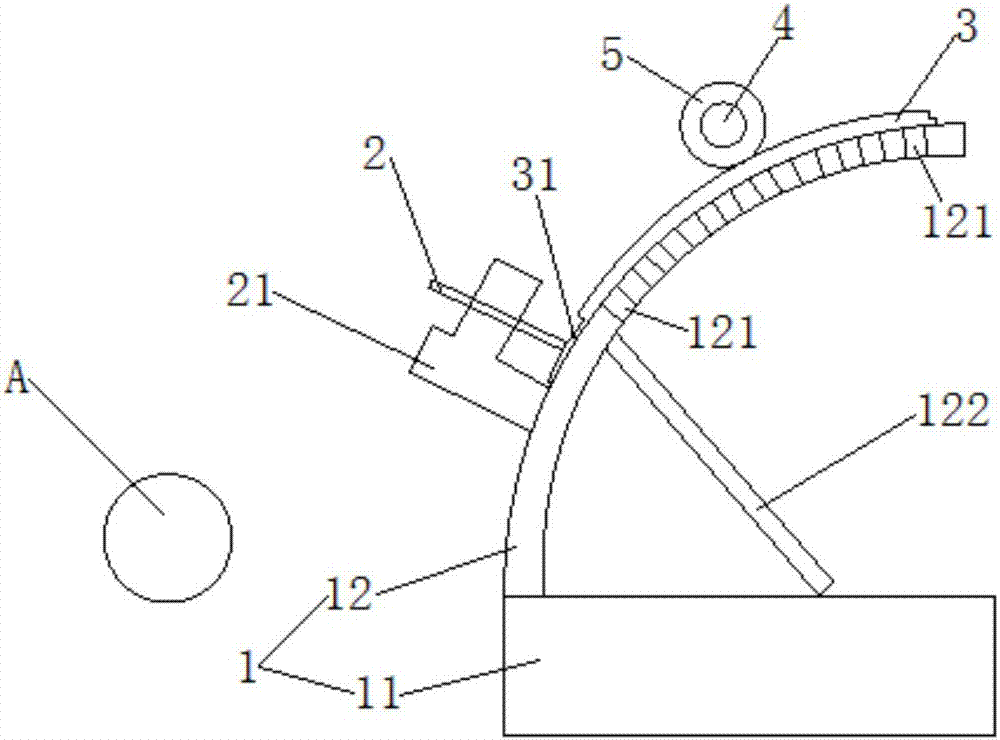

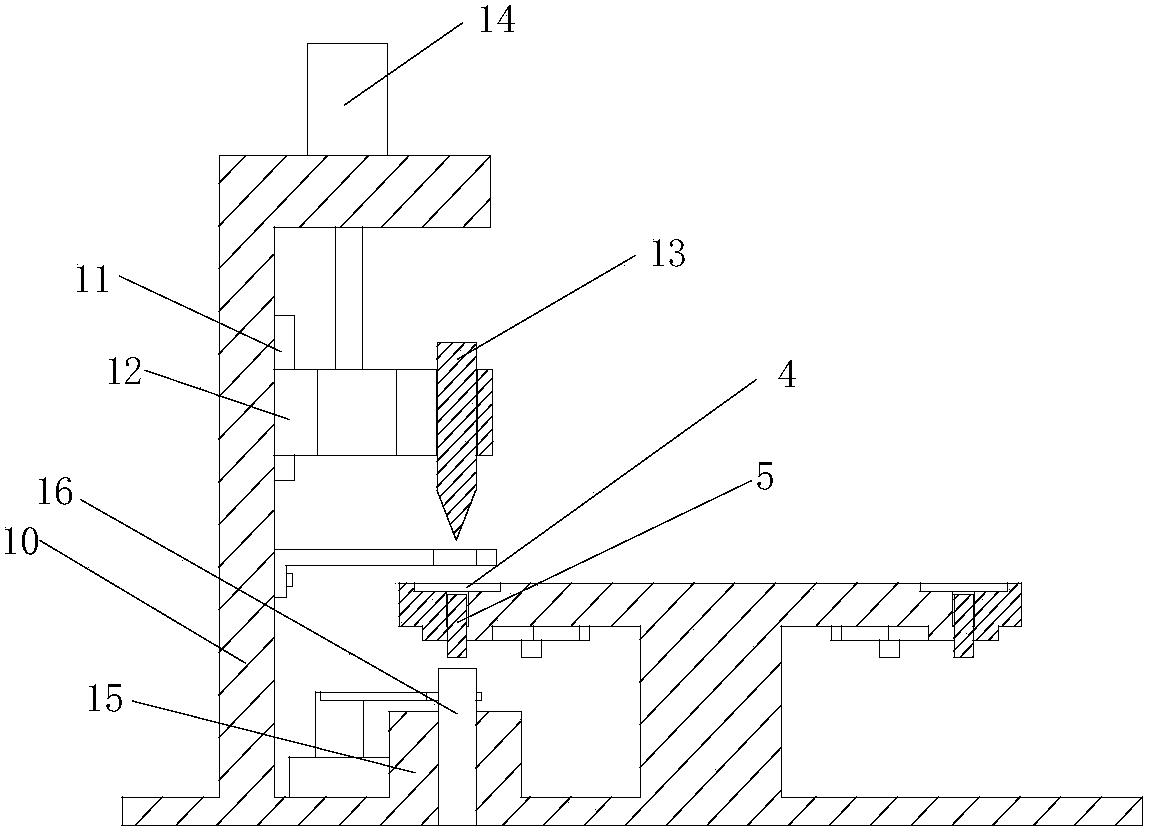

Automatic membrane spot welding machine

ActiveCN105618918AQuality assuranceMaintain consistencyWelding/soldering/cutting articlesMetal working apparatusEngineeringSpot welding

The invention relates to the technical field of membrane machines, in particular to an automatic membrane spot welding machine. Circulation tools comprise containing grooves formed in a rotating plate, and copper cores are arranged in the containing grooves; a membrane placement device comprises a base with an insertion hole, a T-shaped membrane tool is arranged in the insertion hole, and a motor is arranged in the insertion hole in the bottom end of the membrane tool; the drive end of the motor makes contact with a membrane at the bottom end of the membrane tool; a spot welding device comprises a first support arranged on a work table, a sliding rail vertically arranged at the top end of the first support, a sliding block arranged on the sliding rail and a top electrode installed on the sliding block; a first air cylinder pushing the sliding block to be lifted is arranged at the top end of the first support; a supporting column is arranged at the part, below the top electrode, of the work table and is provided with a bottom electrode capable of being lifted. The automatic membrane spot welding machine can accurately guarantee the quality of vibration membranes, keep the uniformity and the reliability of the vibration membranes, avoid the phenomenon that mass slices and the membranes are not concentric in production and improve the stability of products.

Owner:BESTAR HLDG

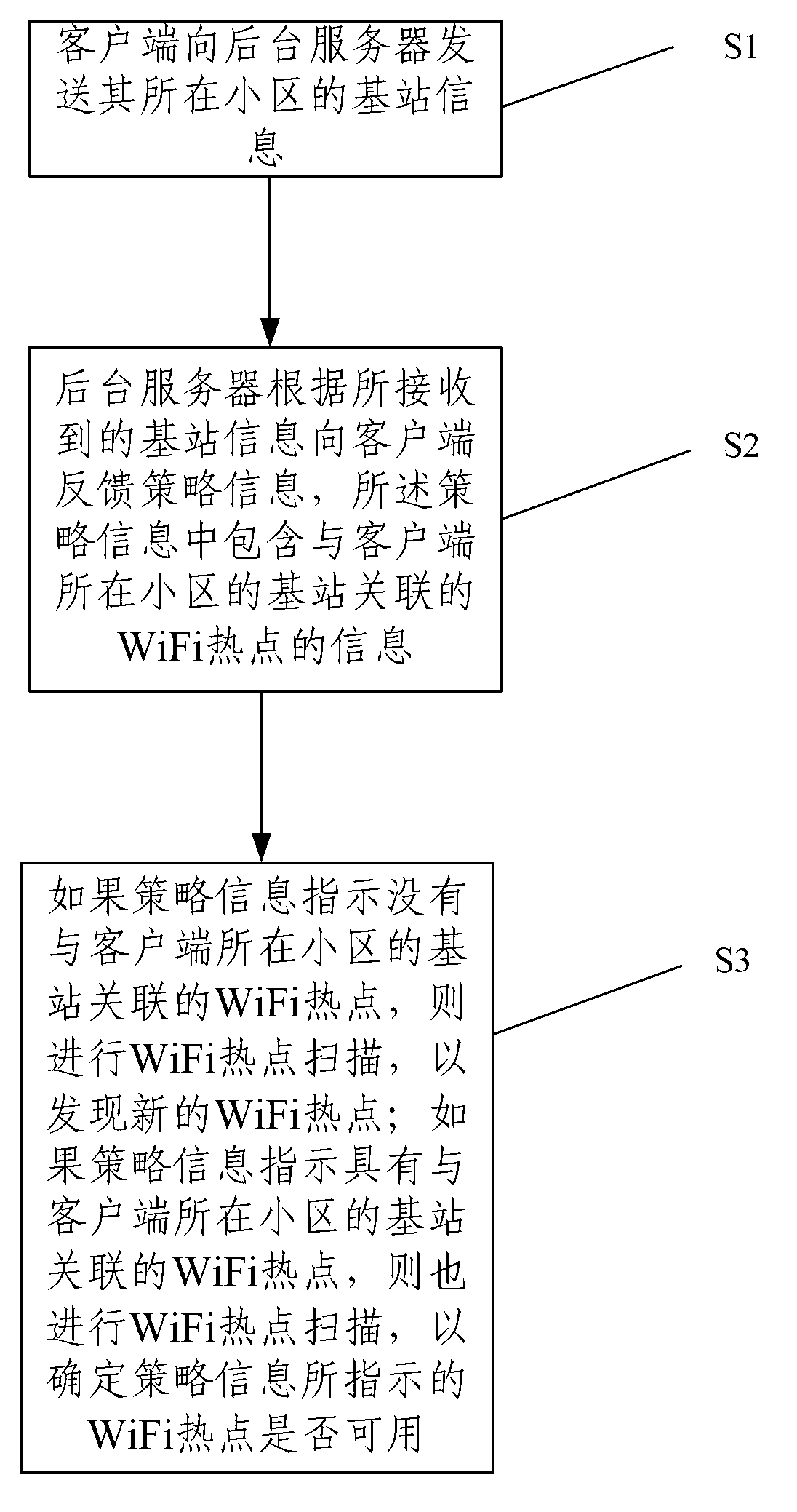

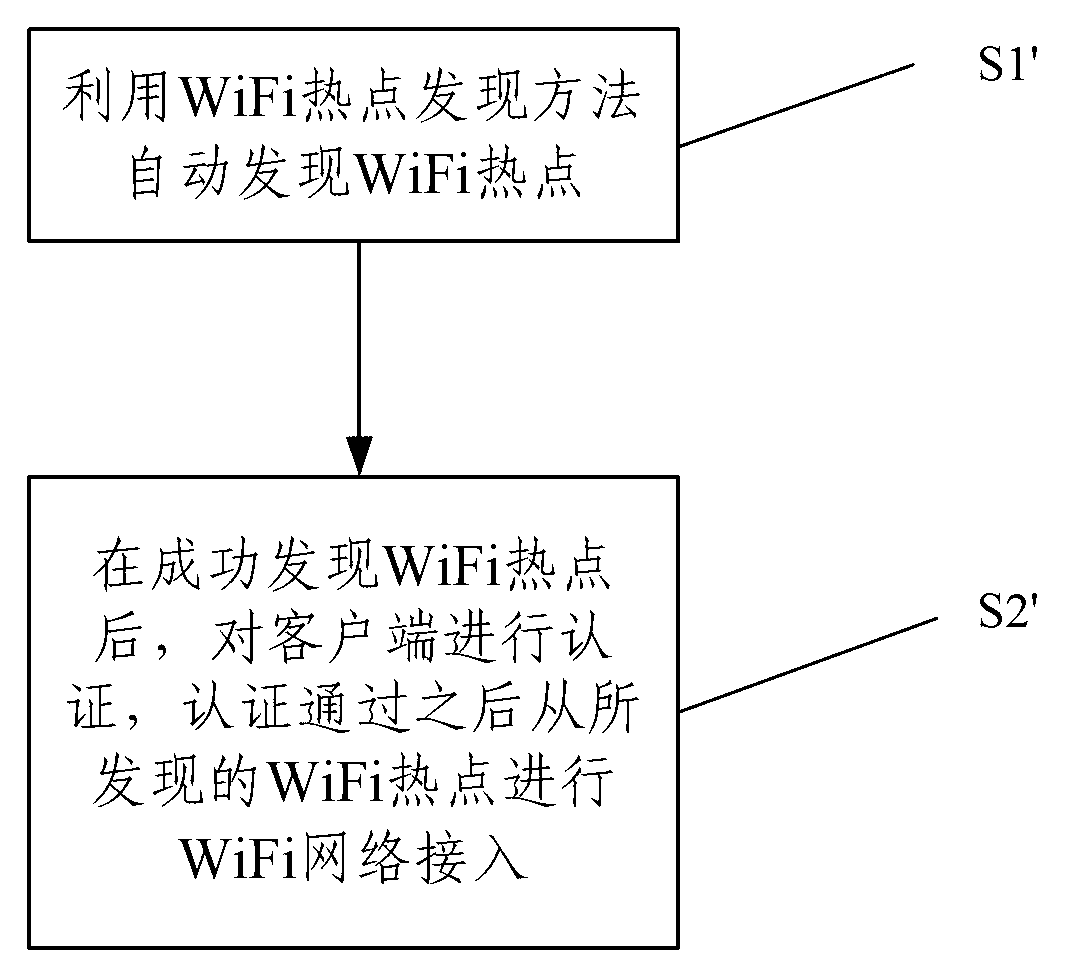

Wireless fidelity (WiFi) hotspot finding method and network switching method

The invention relates to the technical field of wireless communication, and discloses a wireless fidelity (WiFi) hotspot finding method and a network switching method. Reliable guarantee is supplied to physical quality of a wireless local area network (WLAN) by judging whether a cell base station where a client is positioned is covered by a WiFi hotspot signal and judging whether the cell base station meets a switching condition; and therefore, the risk of complaints of users caused by mis-judgment of information is reduced.

Owner:BEIJING YINGJIN ZHIFANG TECH

Fabrication method of selective gold deposition plate

ActiveCN105813393AReduce defective rateReduce the risk of complaintsPrinted circuit manufactureScreen printingEconomic benefits

A fabrication method of a selective gold deposition plate comprises the following steps of (1) providing gold deposition plates, wherein each gold deposition plate is provided with a gold deposition region and a non-gold deposition region; (2) pasting a dry film, wherein the dry film is pasted on the non-gold deposition region of the gold deposition plate; (3) exposing, wherein the dry film covering the non-gold deposition region is exposed; (4) printing an ink, wherein a layer of ink is printed on the dry film by a silk-screen printing mode; (5) depositing gold, wherein a gold plating layer is formed on the gold deposition region; (6) removing the ink; (7) removing the dry film; and (8) carrying out OSP processing. Before a gold deposition process, a layer of ink covers the dry film, the gold deposition resistant effect is improved, the gold proportion on a copper surface of the non-gold deposition region can be reduced to 2%, the reject ratio of the gold deposition plate and the customer complaint risk are greatly reduced, the gold dosage for production of a printed circuit board (PCB) is saved, the production cost is saved, and the economic benefit of an enterprise is improved.

Owner:DONGGUAN MEADVILLE CIRCUITS

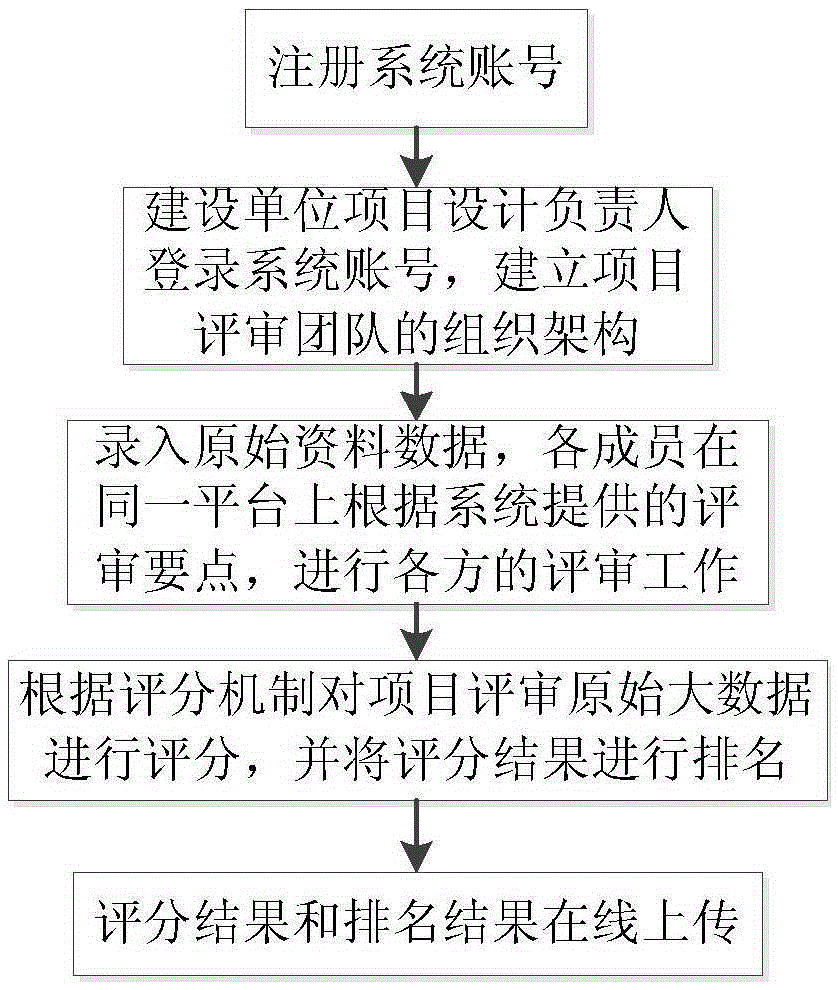

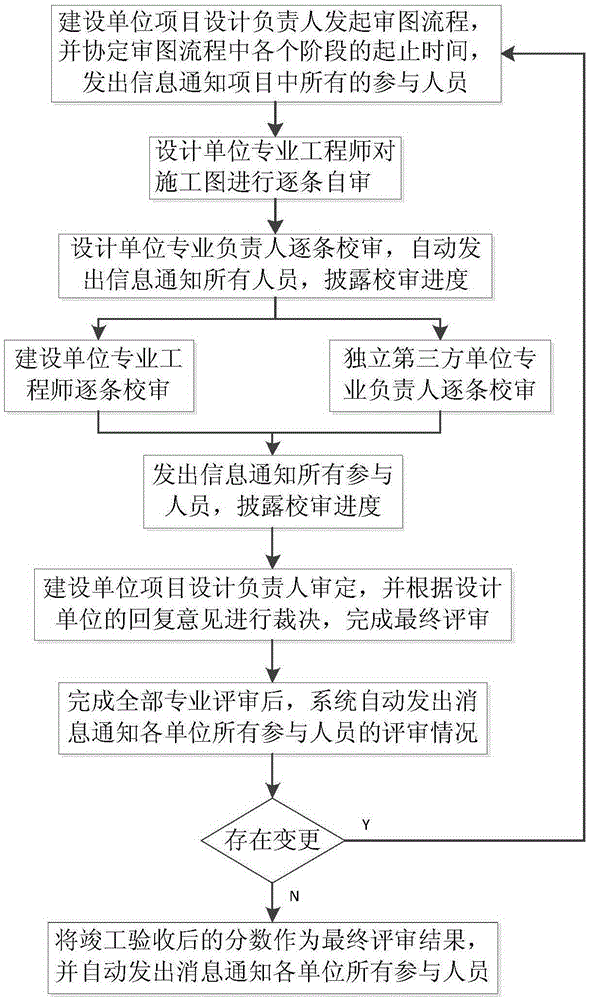

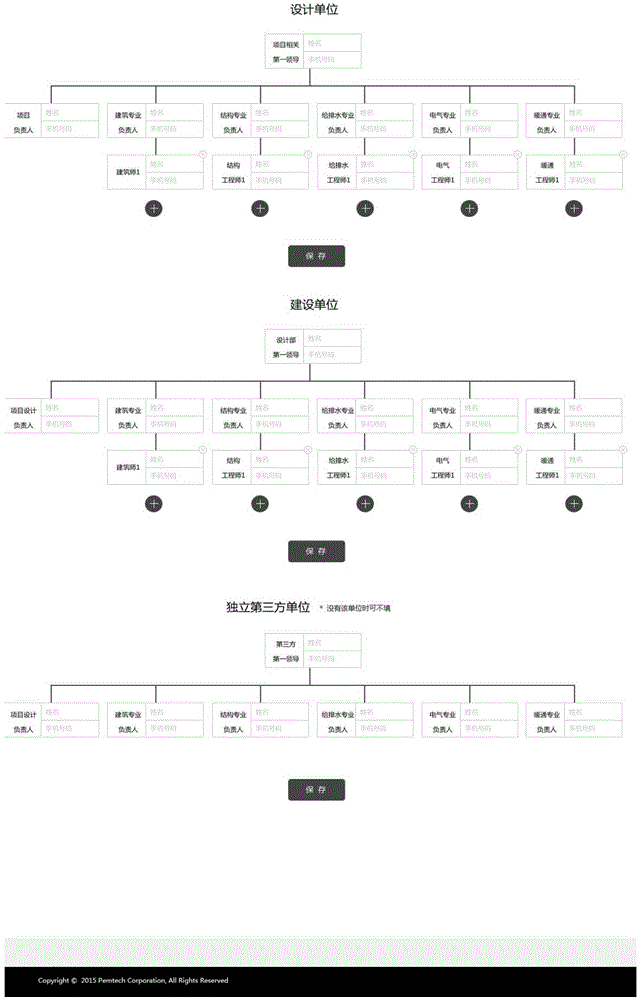

PEM project evaluation management system and control method thereof

InactiveCN105427042AReduce the risk of complaintsImprove the sense of responsibilityResourcesTerminal serverSource material

The invention discloses a PEM project evaluation management system and a control method thereof. The system comprises a management terminal server, a peripheral terminal server and a communication system, wherein a source material database, an evaluation standard database, an evaluation staff database, a scoring mechanism database, a scoring system, a ranking system, a file system and an information searching system are arranged in the management terminal server; after working drawings are evaluated and scored, scores of designers and design organizations and a ranking list are published, the designers and the design organizations are evaluated by construction units through a search engine and data, and pressure of project design defects is directly transmitted to each designer. The PEM project evaluation management system has the advantages that evaluation of the project design working drawings can be objectively and accurately completed on line, and working condition of the designers and the design units are objectively evaluated by scores and ranking, thus solving six problems in the construction industry.

Owner:毛文筠

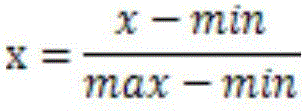

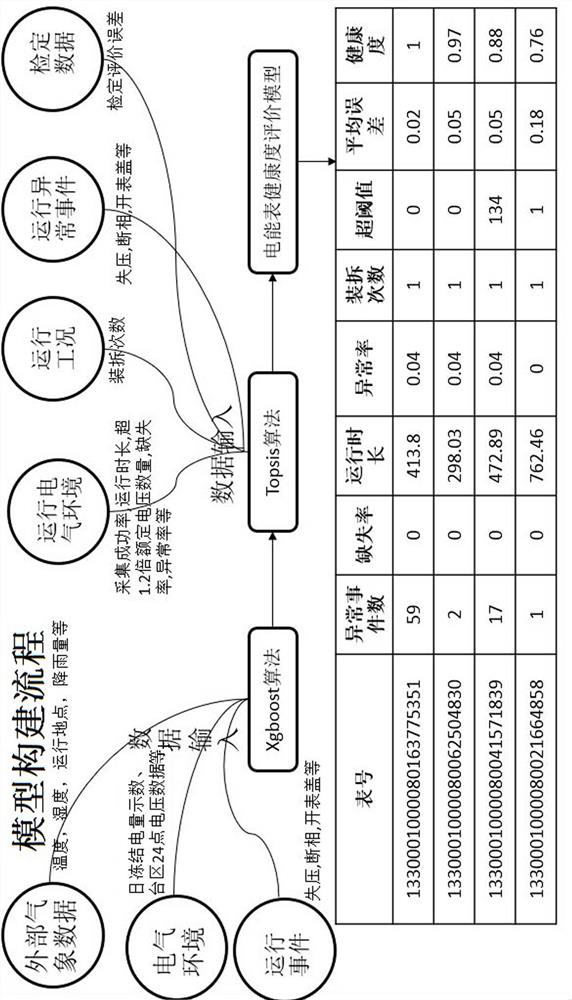

Health evaluation method based on full-life-cycle data of electric energy meter

PendingCN111738573AReduce the risk of complaintsImprove satisfactionDigital data information retrievalEnsemble learningFeature screeningReliability engineering

The invention relates to a health evaluation method based on full-life-cycle data of an electric energy meter. According to full-life-cycle data of the electric energy meter, the electric energy meterserves as a node, data requirements are integrated, data cleaning and feature screening are completed, fault factors and feature attributes of the electric energy meter are extracted through a data mining algorithm, health scoring is conducted on the electric energy meter through a comprehensive evaluation algorithm, and health grades are divided. The method is deeply ploughed in the power industry based on a big data concept, power grid internal data and external environment data are fused, influence analysis is performed on health-related factors of the electric energy meter, an electric energy meter fault prediction model is constructed, the operation state of the electric energy meter is evaluated according to the mounting and dismounting times, the event reporting times, the acquisition success rate, the acquisition electric quantity abnormality rate, the operation duration, the first inspection error and other dimension data of the electric energy meter, a health evaluation system of the electric energy meter is established, and the health degree of the operation state of the electric energy meter is given.

Owner:国网河北省电力有限公司营销服务中心 +2

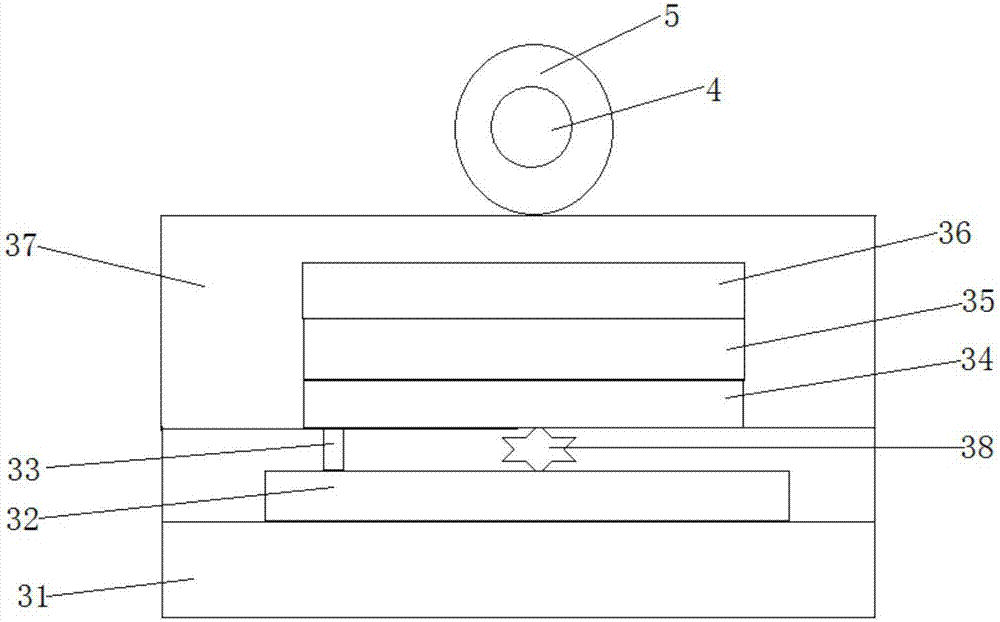

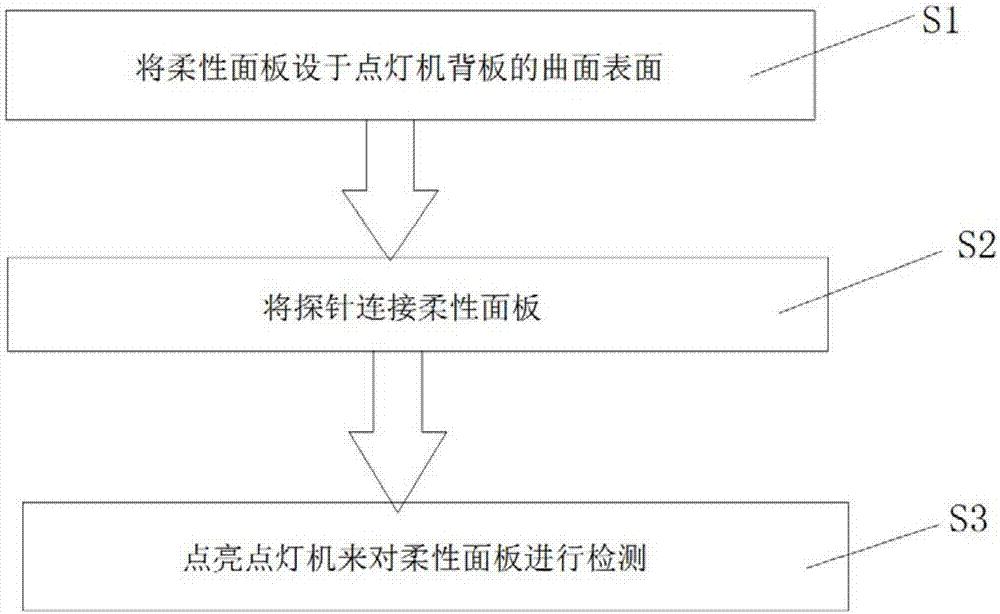

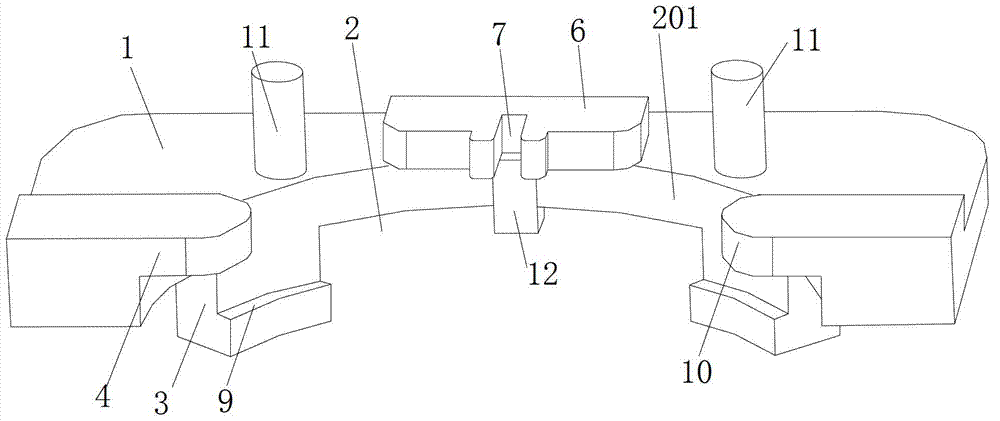

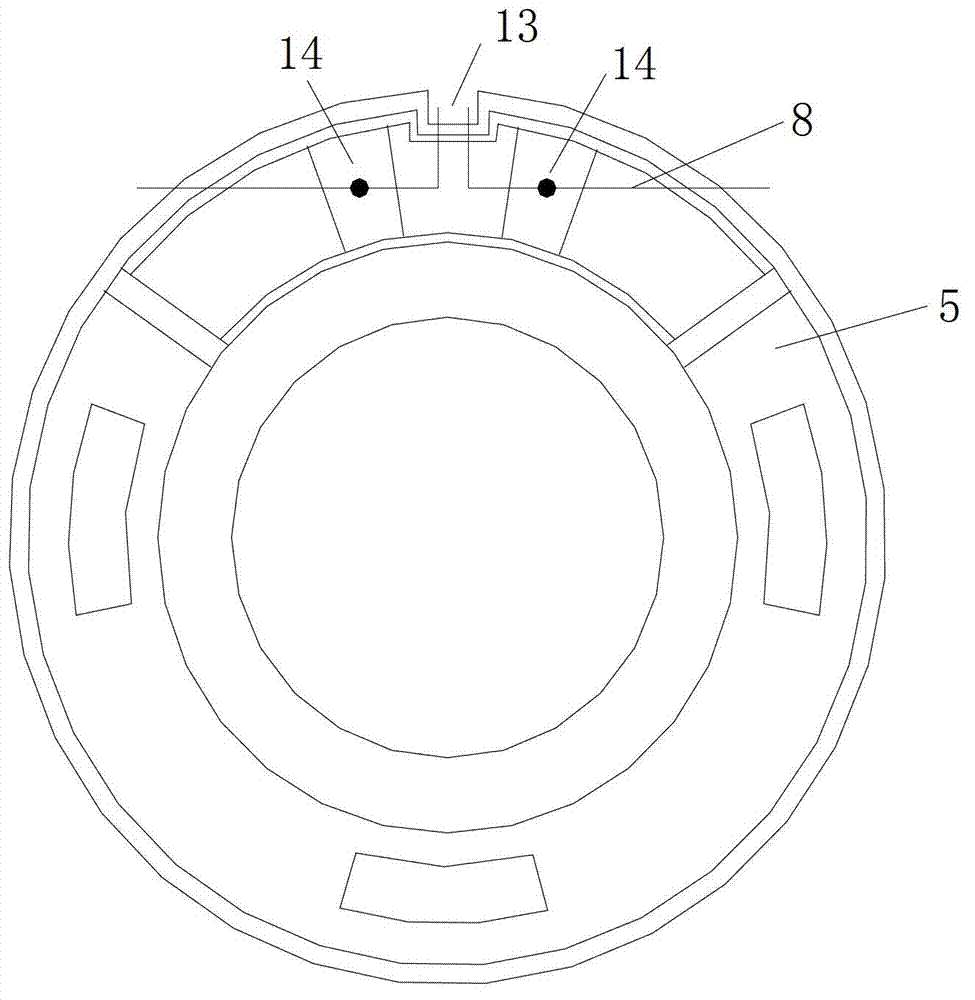

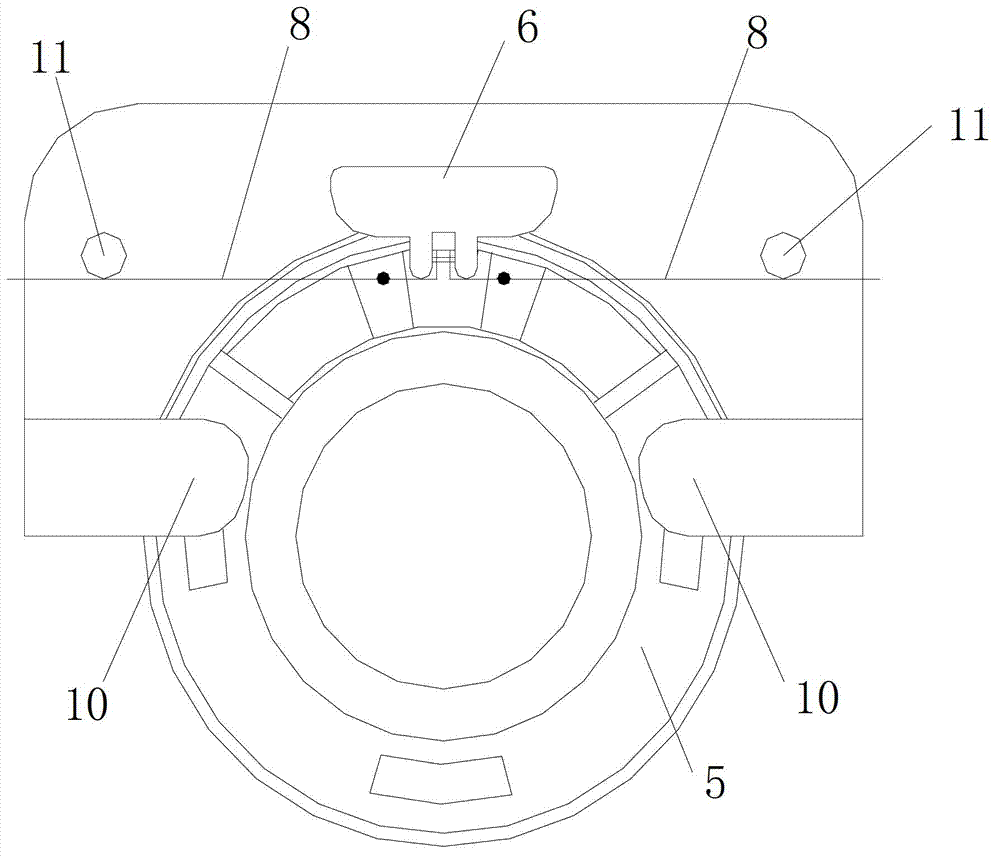

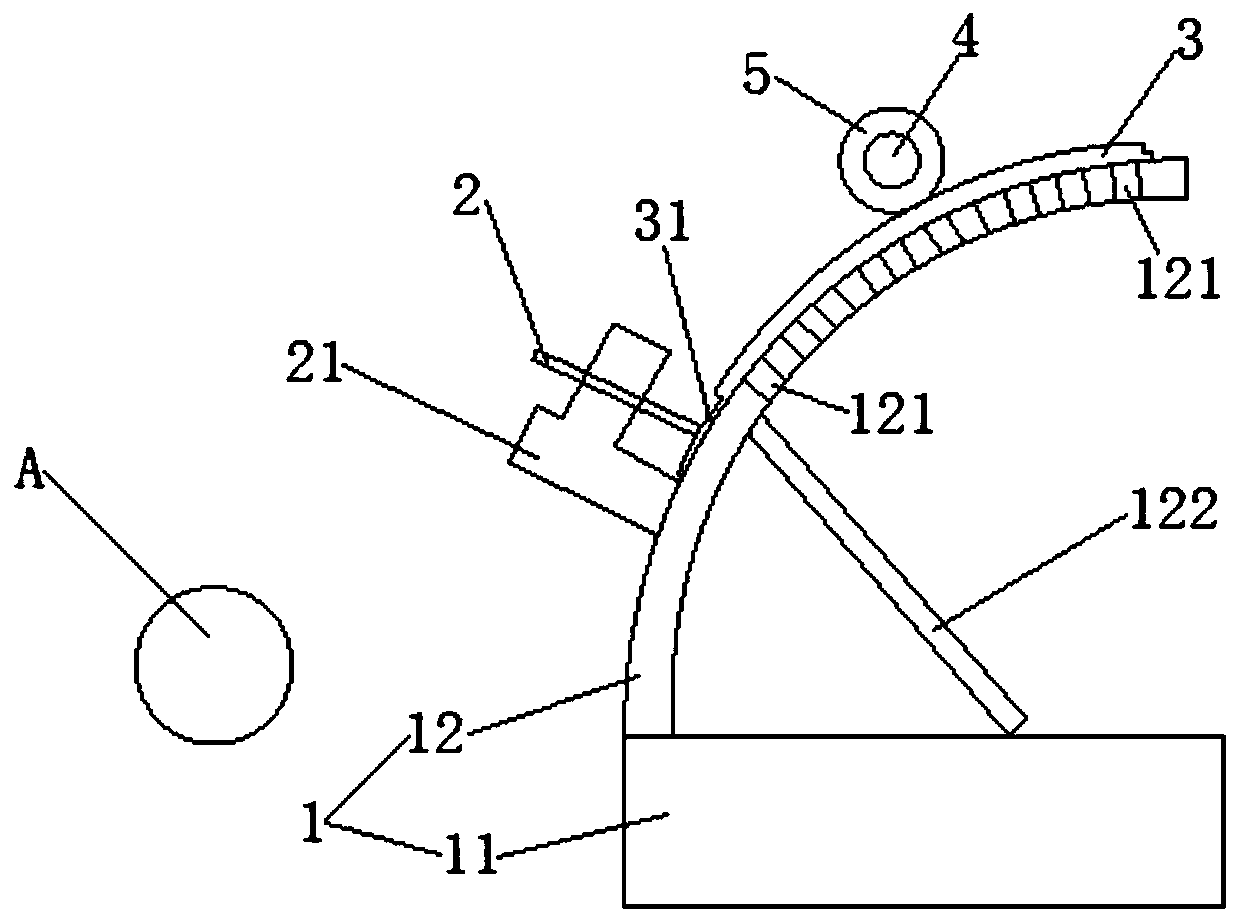

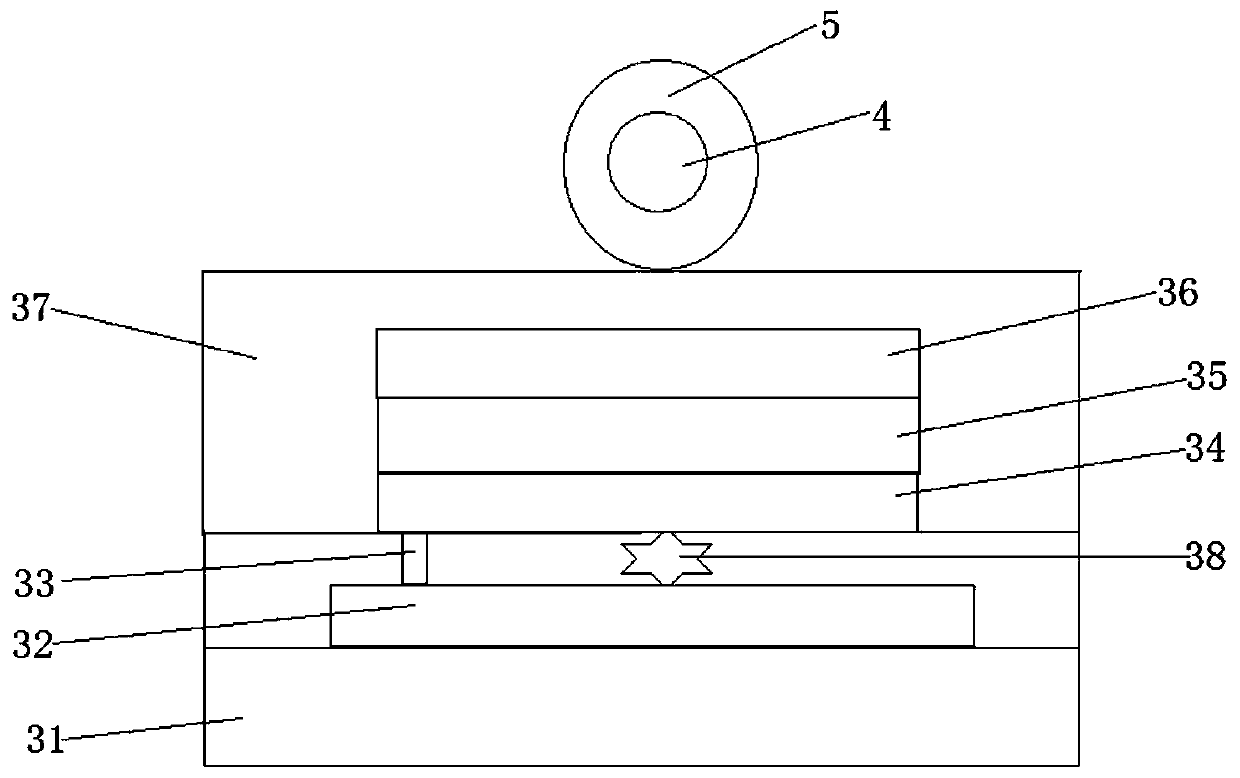

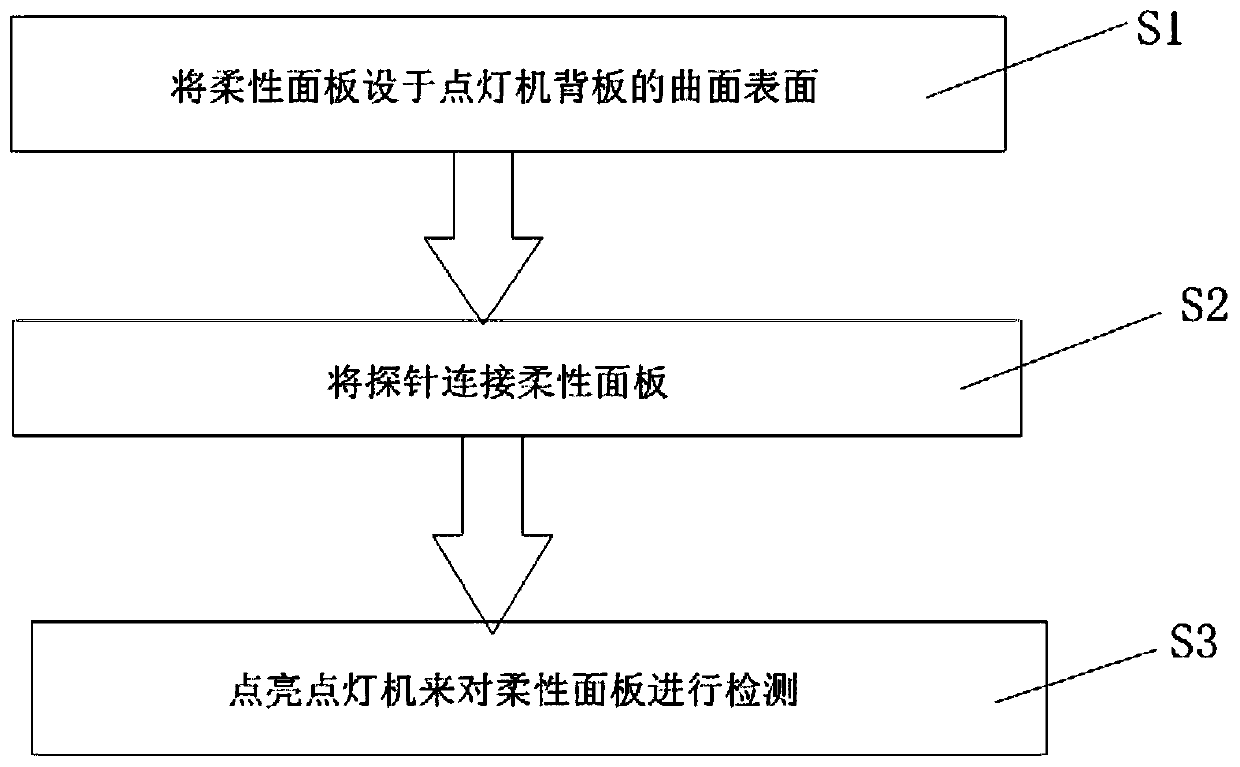

Detection device and detection method for flexible panel

ActiveCN106872485ASimple structureAccurate detectionOptically investigating flaws/contaminationEngineeringBackplane

The invention discloses a detection device of a flexible panel. The detection device comprises a light-on tester and a probe, wherein the light-on tester comprises a light-on tester body and a curved-shaped light-on tester back plate; the light-on tester body is connected with one side surface of the light-on tester back plate; the surface, away from the light-on tester, of the light-on tester back plate is a curved surface for arranging the to-be-detected flexible panel; the probe is arranged on the light-on tester, and is used for connecting the to-be-detected flexible panel and the light-on tester back plate. The detection device disclosed by the invention has the advantages that the structure is simple, the defective product in the flexible panel can be accurately detected, the poor dot / line in the module detection or terminal client detection process is avoided, the waste of a polarizing plate is effectively avoided, and the risk of customer complaint is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

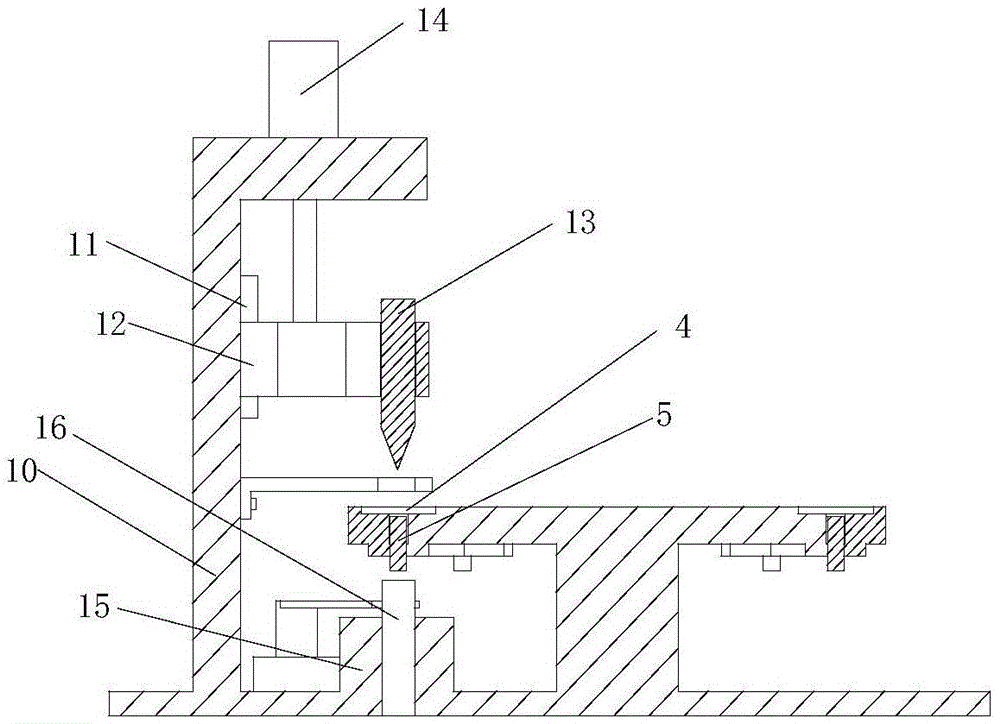

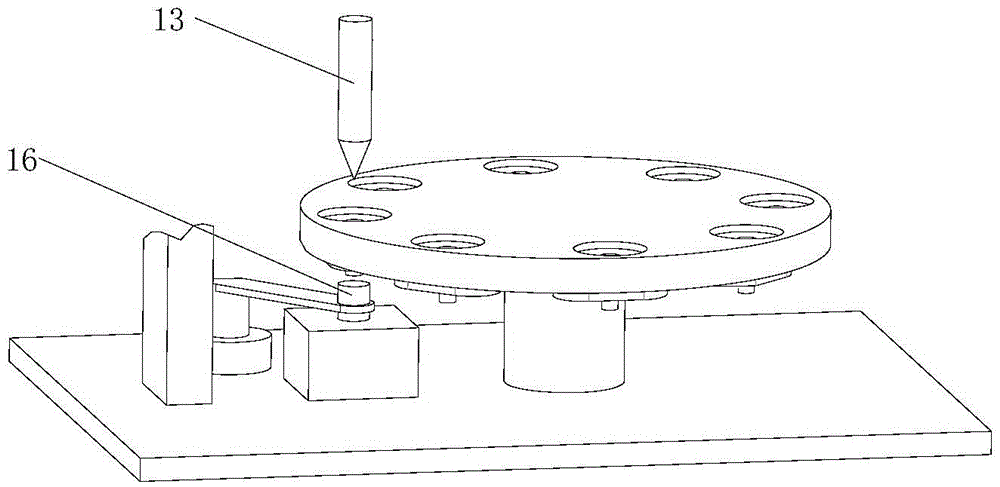

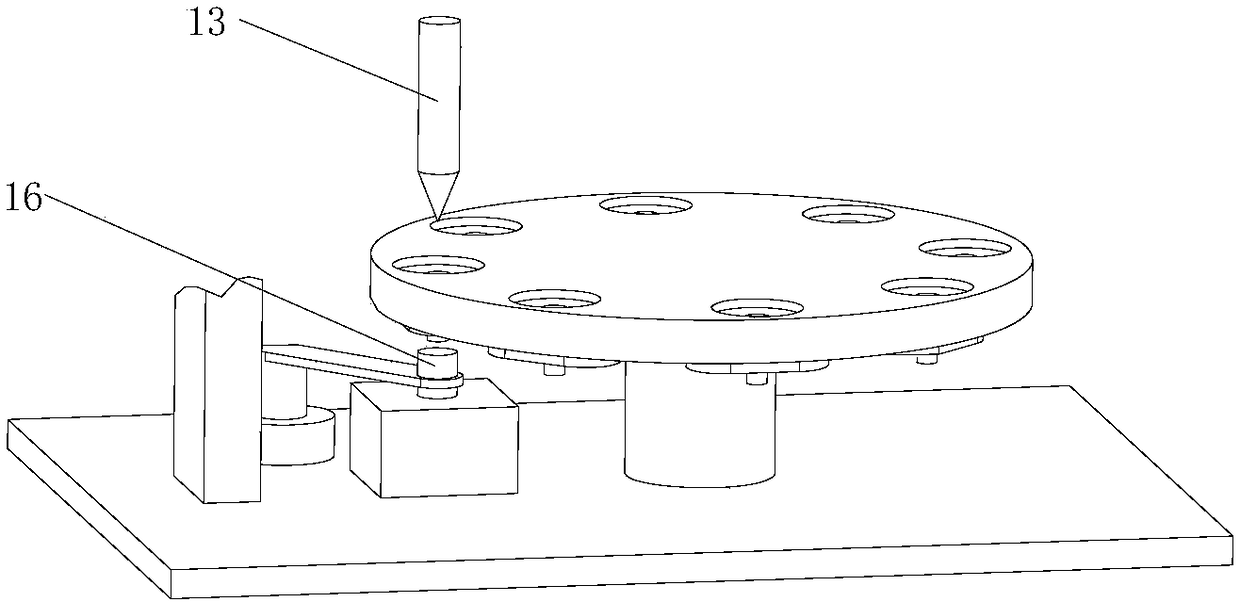

Tool and method for spot-welding loose wires of frame of loudspeaker

ActiveCN102825409AEnsure consistencyGuaranteed reliabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a tool and a method for spot-welding loose wires of a frame of a loudspeaker. The tool comprises a tool base plate; a notch which is sunk towards the middle of the tool base plate is arranged on one side of the tool base plate; a supporting portion is arranged on the tool base plate and is positioned below the notch; a limiting portion which is matched with the supporting portion is arranged on the tool base plate and above the notch; limiting space is formed among the supporting portion, the limiting portion and the wall of the notch; a wire crossing block is arranged on the upper end surface of the tool base plate and is positioned on one side of the center of the wall of the notch; one end of the wire crossing block extends to the middle of the notch; and a wire crossing groove opening is arranged at the extending end of the wire crossing block. Wires welded by the tool and the method are loose, and the phenomenon that the wires are pulled manually, are quite tight and even can be broken is avoided. In addition, because the wires cannot be tight, the anti-impact ability of welding points of the wires is increased, the quality of products is improved, and risks of customer complaint are reduced.

Owner:BESTAR HLDG

Parcel processing method and apparatus based on smart cabinet, server and readable medium

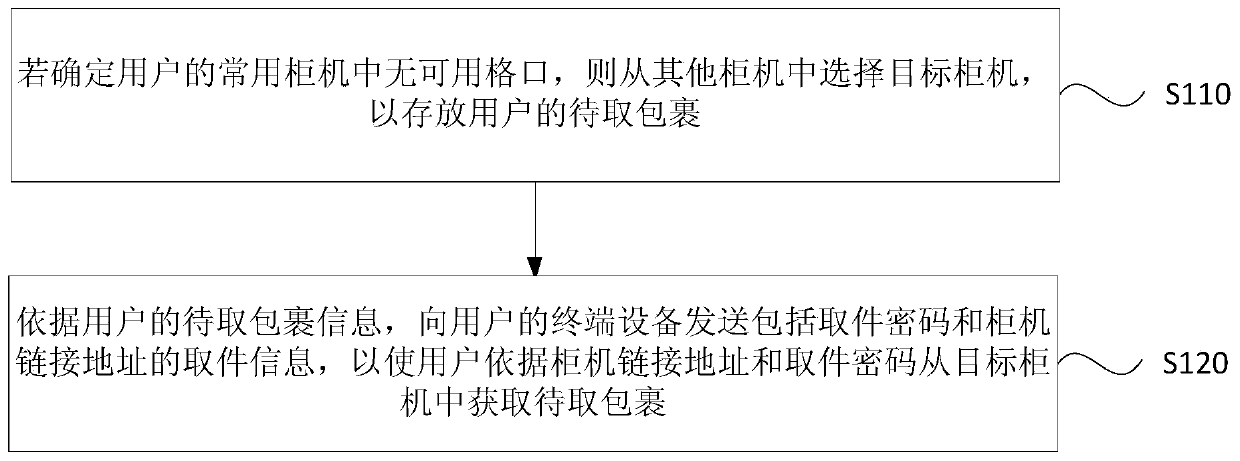

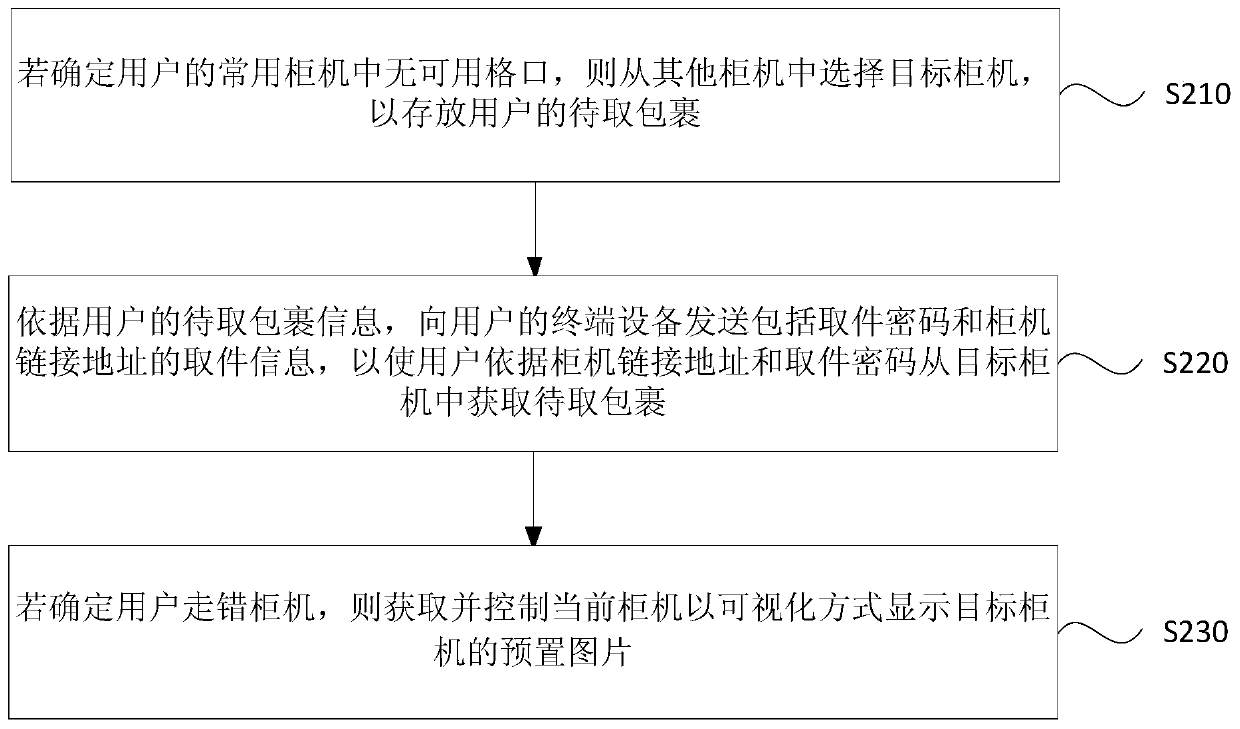

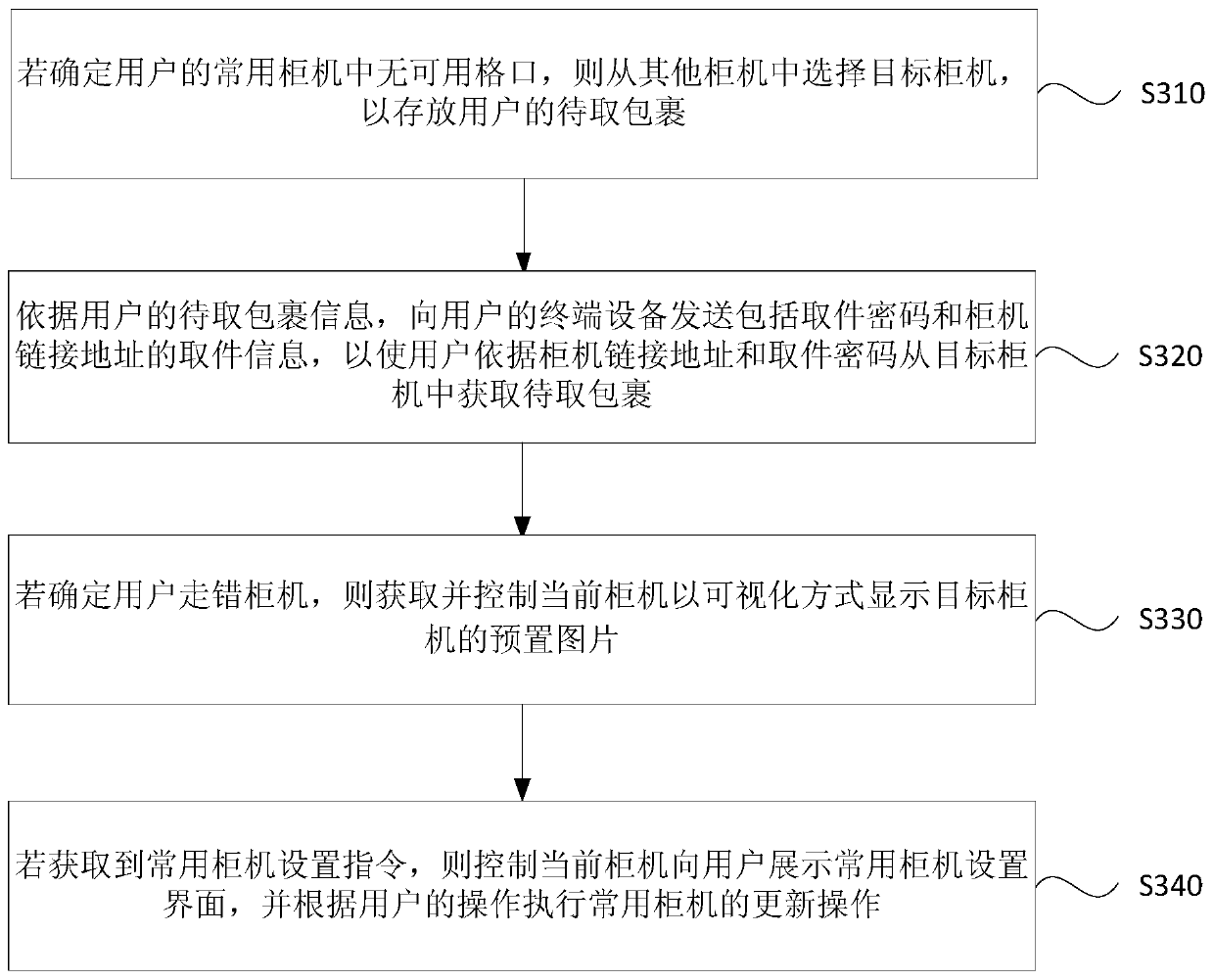

InactiveCN110164057AImprove experienceReduce the risk of complaintsNavigational calculation instrumentsApparatus for meter-controlled dispensingPasswordTerminal equipment

The embodiment of the invention discloses a parcel processing method and apparatus based on a smart cabinet, a server and a readable medium. The method comprises the steps of: if it is determined thatthere is no available grid in a common cabinet of a user, selecting a target cabinet from other cabinets to store a parcel to be picked up of the user; and sending pickup information comprising a pickup password and a cabinet linkage address to a terminal device of the user according to the information of the parcel to be picked up of the user, so that the user obtains the parcel to be picked upfrom the target cabinet according to the cabinet linkage address and the pickup password, wherein the cabinet linkage address is generated according to navigation information of the target cabinet anda preset picture of the target cabinet. By adopting the technical scheme provided by the embodiment of the invention, the probability that the user walks to a wrong cabinet can be reduced, thereby improving the user experience.

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

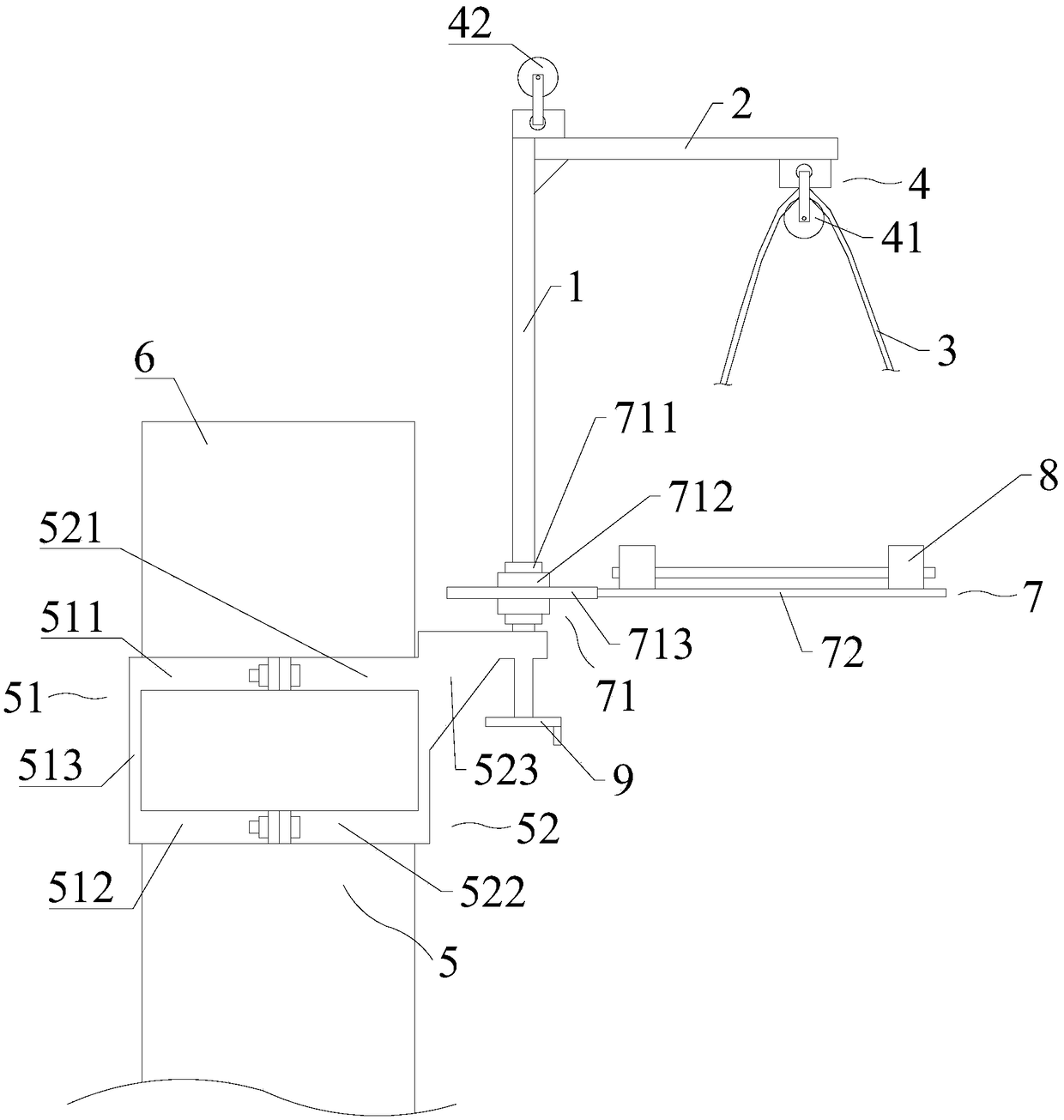

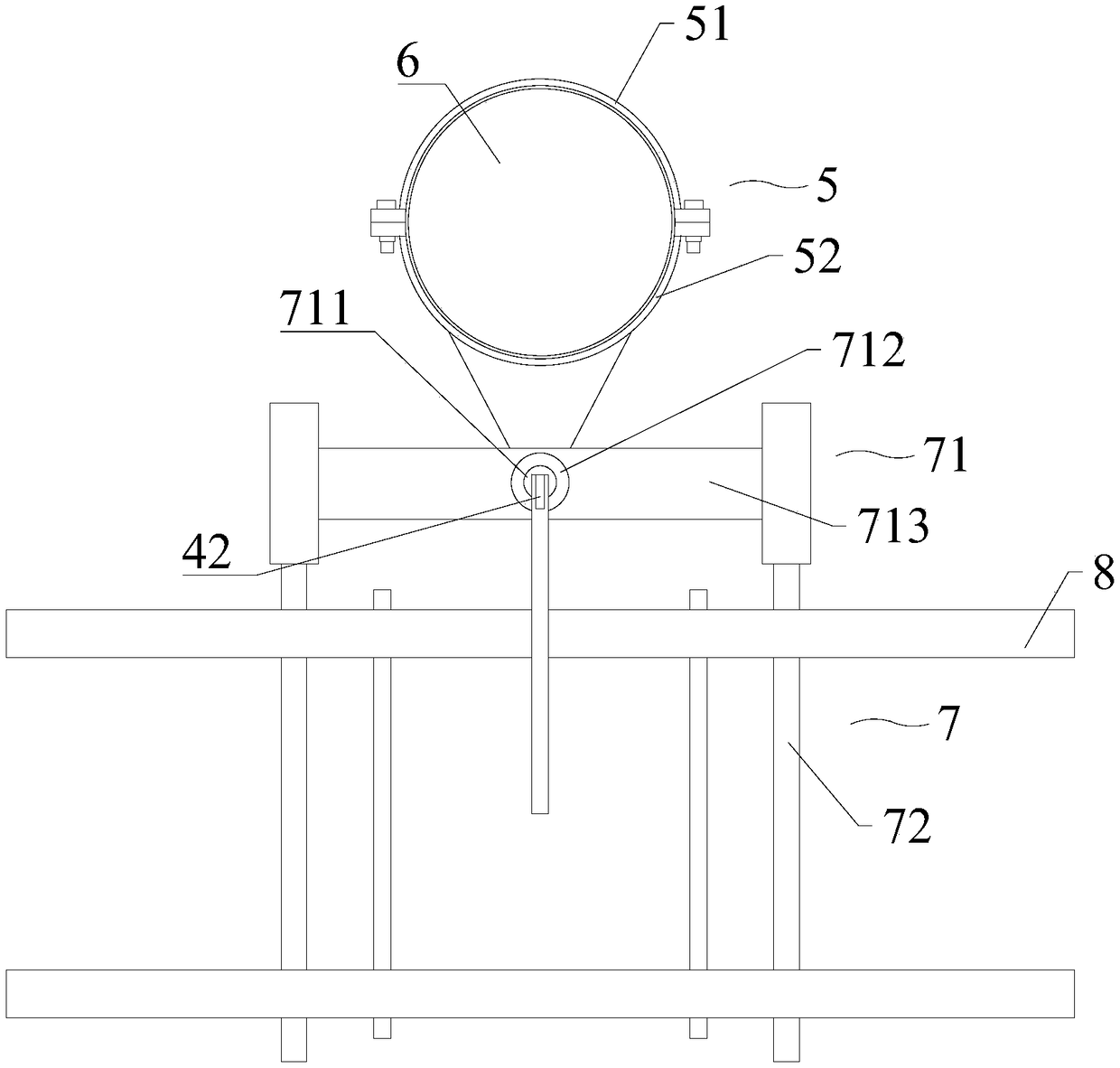

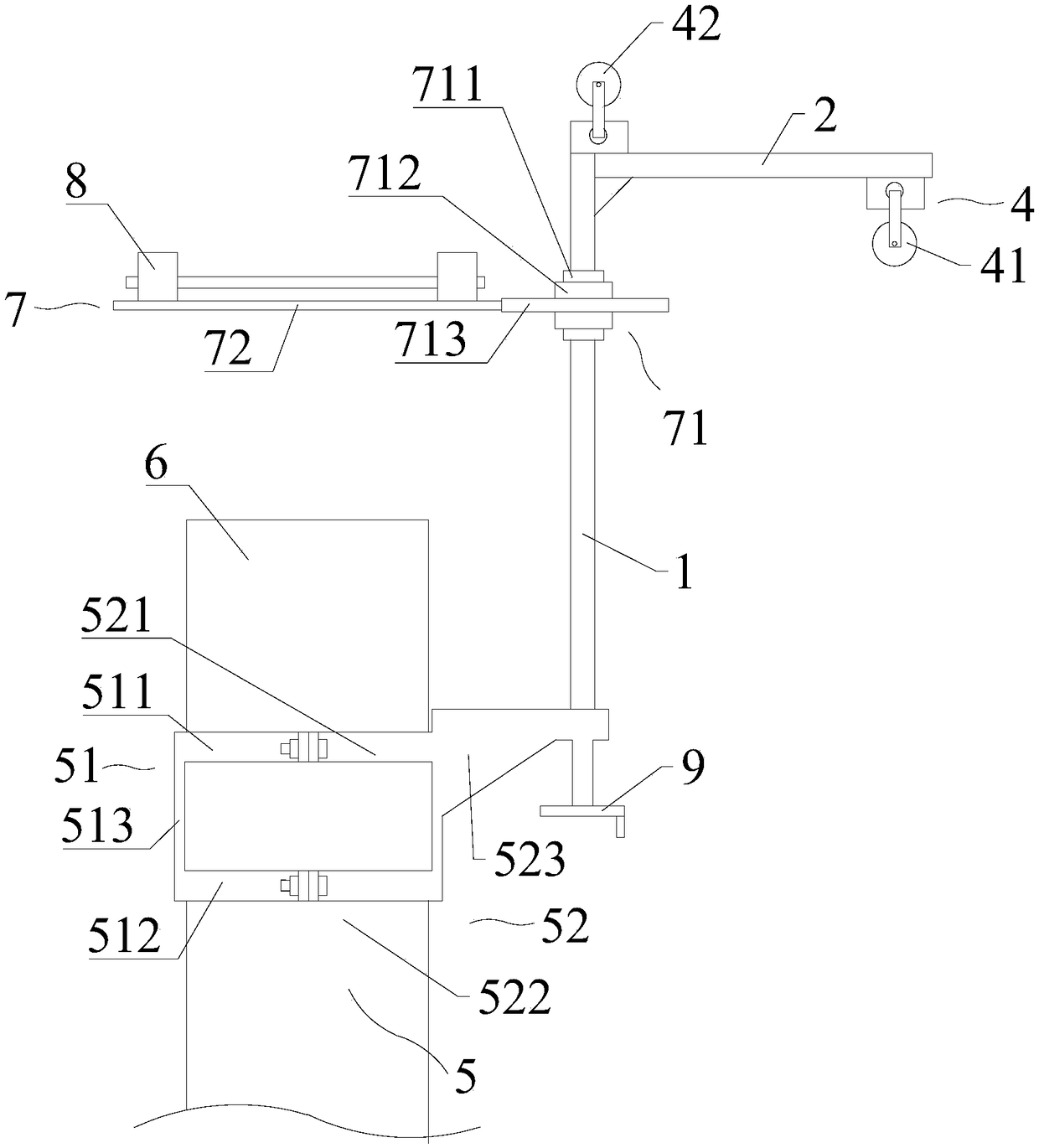

Overall installation device and method for power double cross arm assembly

ActiveCN108999458AChange the installation methodRealize process reengineeringTowersEngineeringUltimate tensile strength

The invention provides an overall installation device for a power double cross arm assembly. The device comprises a longitudinal strut, a transverse strut vertically disposed at an upper portion of the longitudinal strut, a holt hoop iron which is rotatably disposed at a lower portion of the longitudinal strut and is used for fixedly connecting with wire poles, and a bracket which is disposed between the transverse strut and the holt hoop iron, is in rotation lifting up and down connection with the longitudinal strut along the length direction of the longitudinal strut and is used for supporting double cross arms and taking the double cross arm assembly to move up and down, wherein a hanging member for hanging a traction rope is disposed on the transverse strut. The invention further provides an overall installation method for the power double cross arm assembly. The device is advantaged in that technical problems of long power-off time and large construction intensity of workers of the wire poles existing in the cross-arm installation technology in the prior art are solved.

Owner:STATE GRID CORP OF CHINA +1

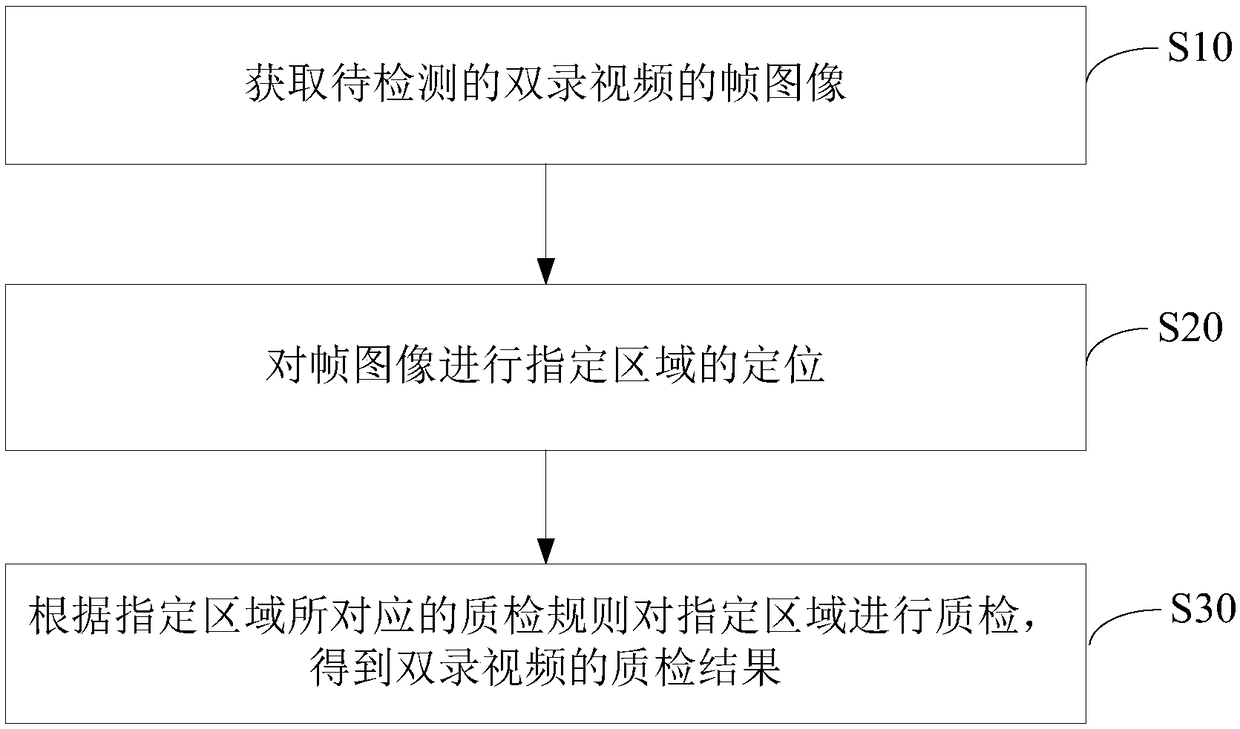

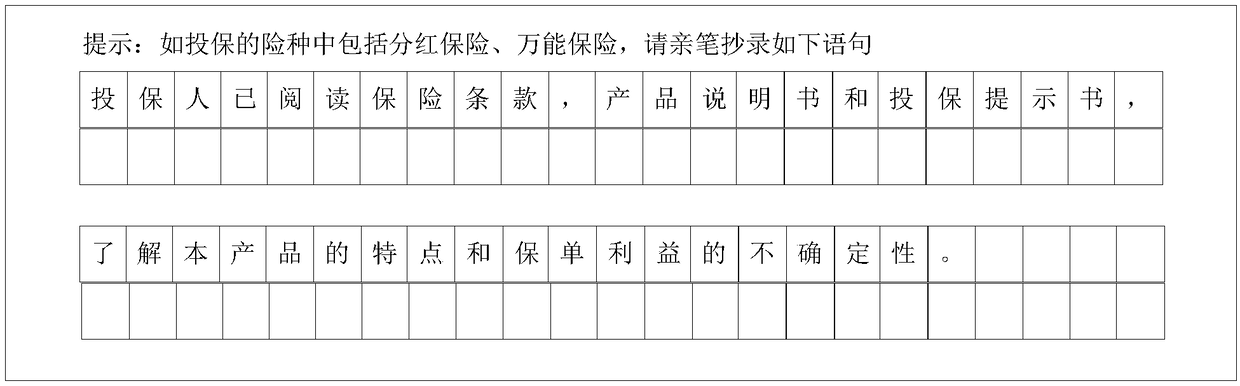

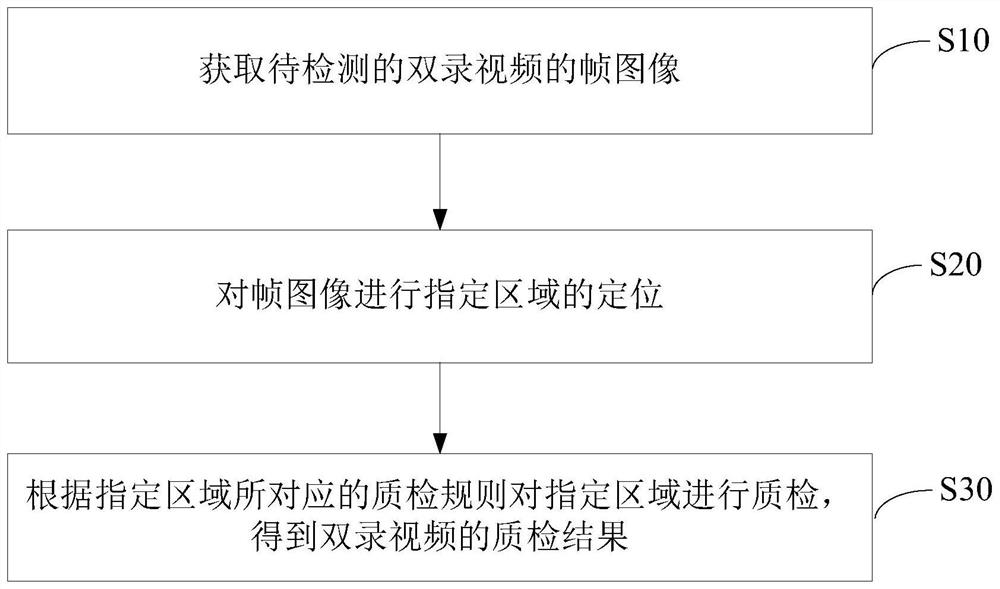

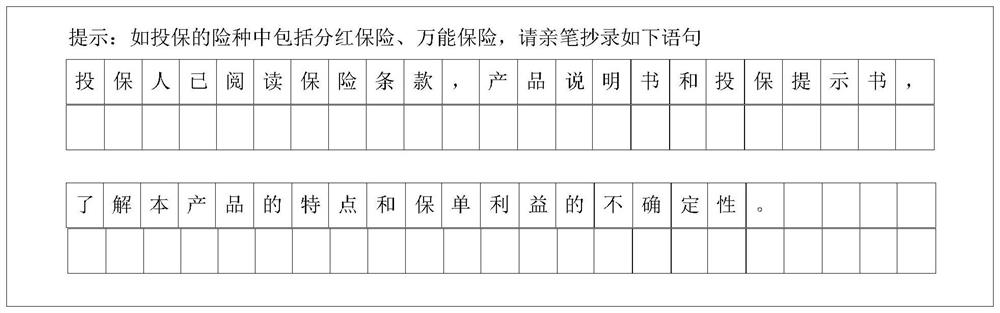

Double-recording video quality inspection method anddevice, medium and electronic device

ActiveCN109360205ARealize automated quality inspectionProtection of rights and interestsImage enhancementImage analysisVideo qualityAutonomation

The invention provides a double-recording video quality inspection method and device, a medium and an electronic device. The method comprises the following steps: obtaining a frame image of the double-recording video to be detected; positioning the designated area of the frame image; according to the quality inspection rules corresponding to the designated area, obtaining the quality inspection results of the dual-recording video. Based on the invention, the designated area and the quality inspection rule can be set according to the specific risk point, the automatic quality inspection of thedouble-recorded video can be realized, the complaint risk caused by the illegal operation can be reduced, and the customer rights and interests can be protected to the maximum extent.

Owner:TAIKANG LIFE INSURANCE CO LTD

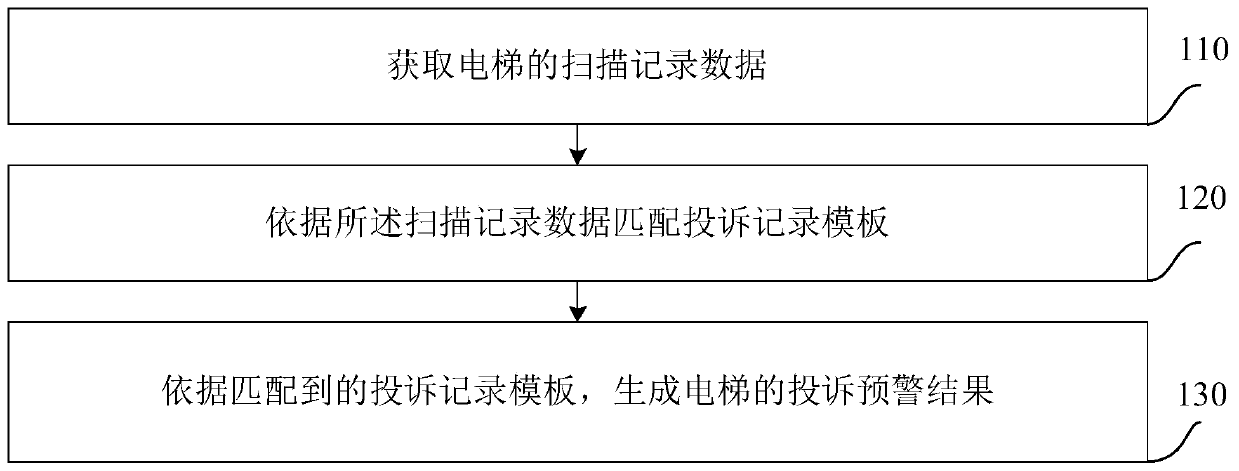

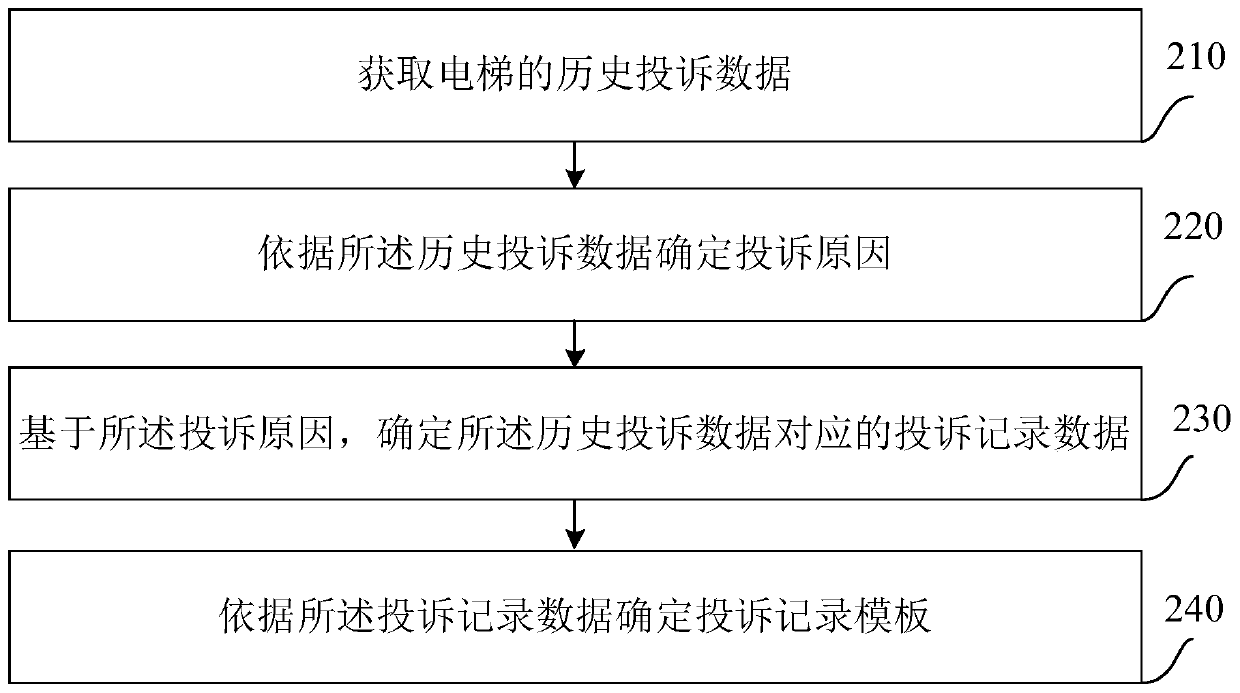

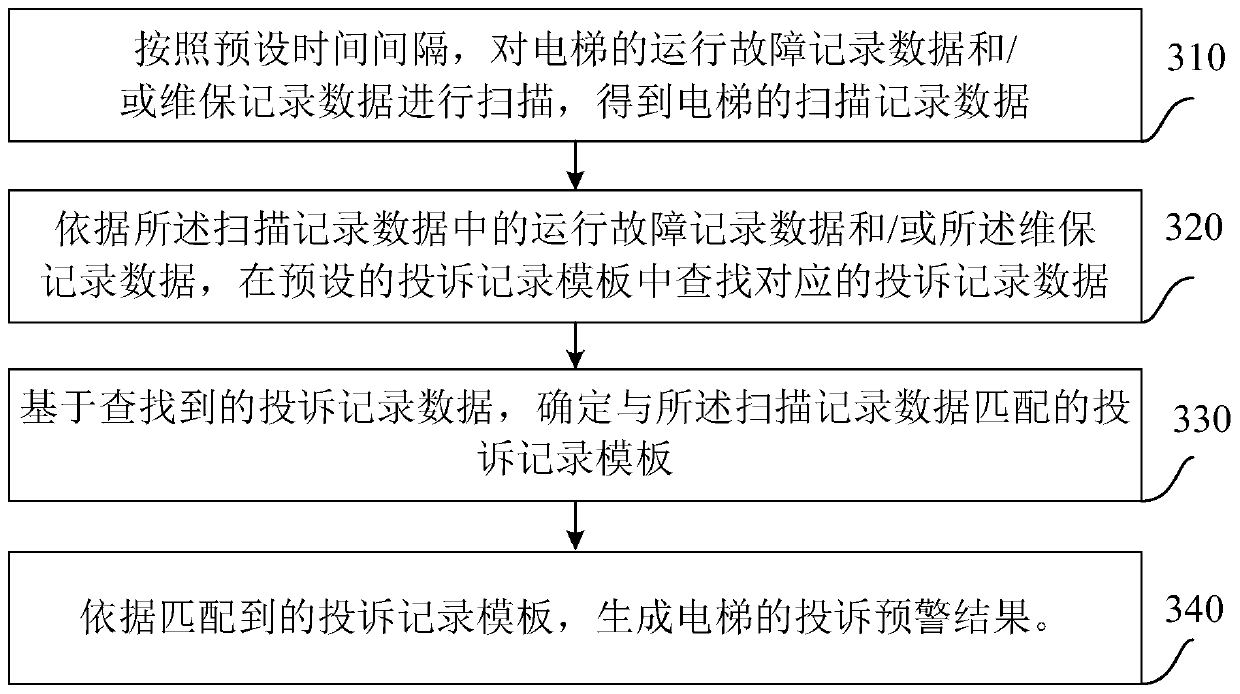

Elevator complaint early warning method and device, equipment and medium

ActiveCN110713088AReduce the risk of complaintsAppease in timeElevatorsEngineeringReliability engineering

The embodiment of the invention discloses an elevator complaint early warning method and device, equipment and a medium, and relates to the technical field of elevators. The elevator complaint early warning method comprises the following steps that scanning record data of an elevator is acquired; a complaint record template is matched according to the scanning record data; and a complaint early warning result of the elevator is generated according to the matched complaint record template. According to the embodiment of the invention, the complaint early warning result of the elevator is generated by matching the complaint record template corresponding to the scanning record data, so that the complaint problem that the elevator may appear can be early warned, and the elevator complaint riskis reduced.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

Antipole detecting device used on aluminum electrolytic capacitor bushing machine

ActiveCN105785218AReduce the risk of complaintsImprove reliabilityCapacitor testingCapacitor manufactureEngineeringCapacitor

The invention provides an antipole detecting device used on an aluminum electrolytic capacitor bushing machine. An electrode block is fixedly mounted on an insulated panel. The insulated panel is fixedly mounted on a mounting base through a mounting bracket. The mounting base is fixedly mounted on the tabletop of the bushing machine. The detecting end of the electrode block right faces a transmission path in which cathode of a capacitor on a transmission line of the bushing machine. The distance between the end surface of the detecting end of the electrode block and the cathode of the capacitor is smaller than the difference between the length of an anode guide pin and a cathode guide pin of the capacitor. Through adding the antipole detecting device on the bushing machine, the position of the electrode block is ingeniously designed in the device, and furthermore a characteristic that the anode guide pin is longer than the cathode guide pin of the capacitor is utilized. The antipole detecting device has advantages of stable performance, high detection accuracy and high reliability. Furthermore the antipole detecting device is arranged for detecting before bushing, thereby reducing client complaint risk and additional cost increases such as bushing material cost and bush stripping labor cost caused by bushing on antipole products.

Owner:GUANGXI JIGUANG ELECTRONICS TECH CO LTD

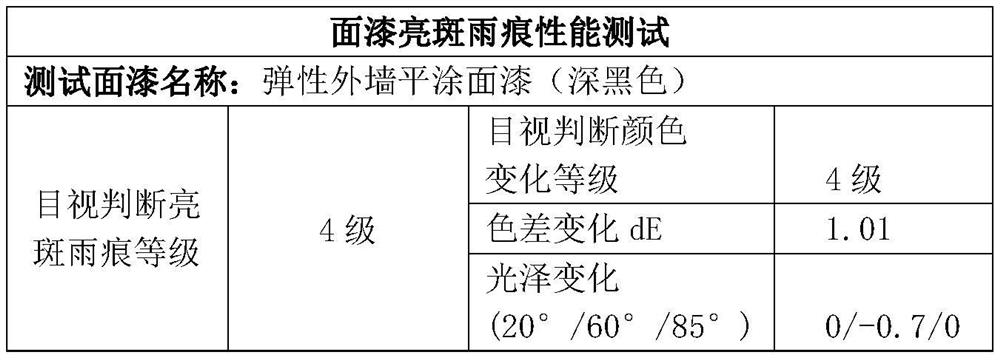

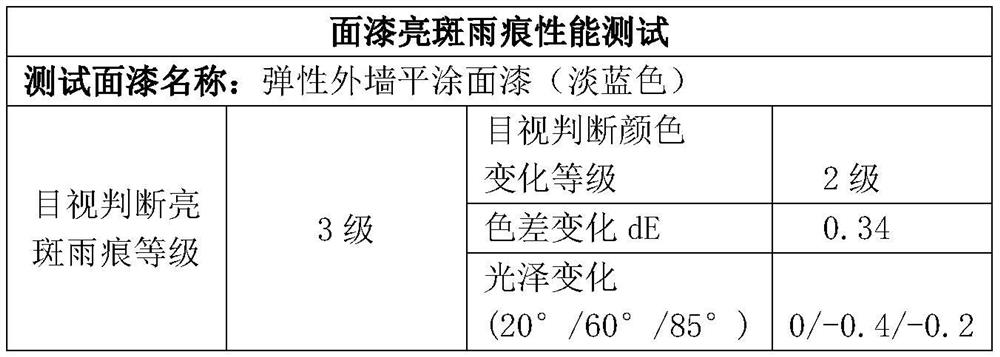

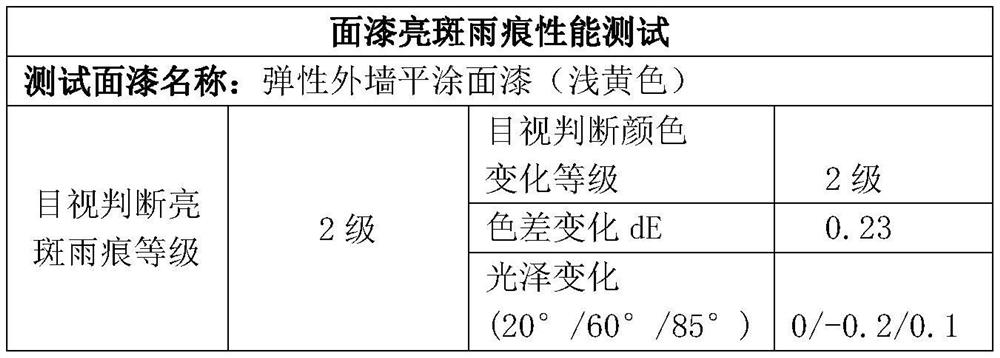

Method for testing bright spots and rain marks of exterior wall flat-coating finish paint

PendingCN112285115AQuick testReduce the risk of complaintsCovering/liningsPreparing sample for investigationTap waterCement board

The invention discloses a method for testing bright spots and rain marks of exterior wall flat-coating finish paint. The method comprises the following steps: scraping fine particles on an asbestos-free cement board, baking, and polishing to be smooth; coating a putty layer with an alkali-resistant seal primer in a rolling manner, and baking; rolling and coating a primer layer with a finish paintto be tested, and baking to obtain a to-be-tested plate; taking the to-be-tested plate, measuring 15-20ml of tap water by using a pipette, and enabling the tap water to naturally fall onto the test plate; standing for 4-6h under the conditions of constant temperature and constant humidity, and preliminarily and visually judging the grade of bright spots and rain marks; and taking the to-be-testedplate, washing the to-be-tested plate with tap water, placing the to-be-tested plate for 8-10h under the conditions of constant temperature and constant humidity after washing is completed, visually judging the color change grade, and then performing data testing with a colorimeter and a gloss meter. According to the method, the bright spot and rain mark performance of the exterior wall flat-coating finish product can be simply and quickly obtained, the optimal design of a product formula is facilitated, and customer complaints are reduced.

Owner:YANGZHOU POLYTECHNIC INST

Automatic Spot Welding Diaphragm Machine

ActiveCN105618918BQuality assuranceMaintain consistencyWelding/soldering/cutting articlesMetal working apparatusCopperSpot welding

Owner:BESTAR HLDG

Double recording video quality inspection method, device, medium and electronic equipment

ActiveCN109360205BRealize automated quality inspectionProtection of rights and interestsImage enhancementImage analysisEngineeringVideo quality

The present invention provides a dual-record video quality inspection method, device, medium and electronic equipment, the method comprising: acquiring a frame image of a dual-record video to be detected; locating a designated area of the frame image; The quality inspection rule conducts quality inspection on the designated area, and obtains the quality inspection result of the double-recorded video. Based on the present invention, designated areas and quality inspection rules can be set based on specific risk points to realize automatic quality inspection of double-recorded videos, reduce the risk of complaints caused by illegal operations, and maximize the protection of customer rights.

Owner:TAIKANG LIFE INSURANCE CO LTD

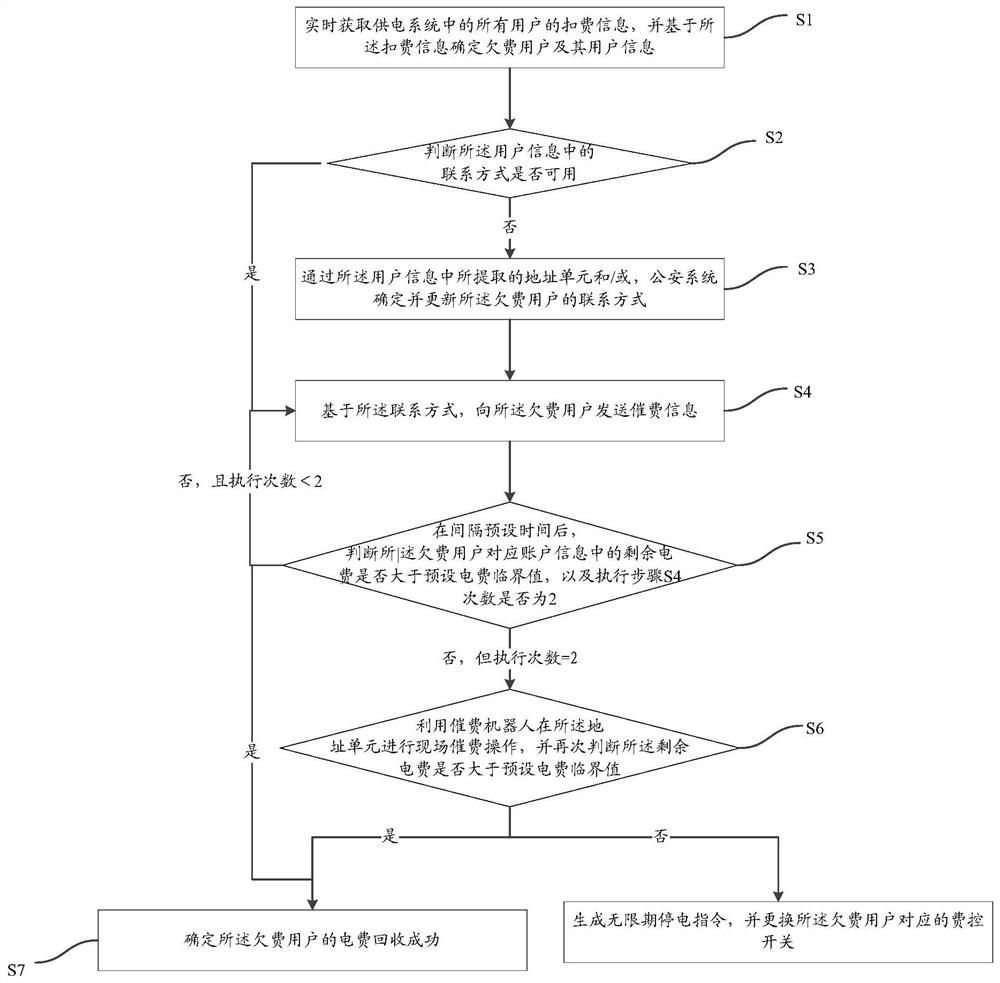

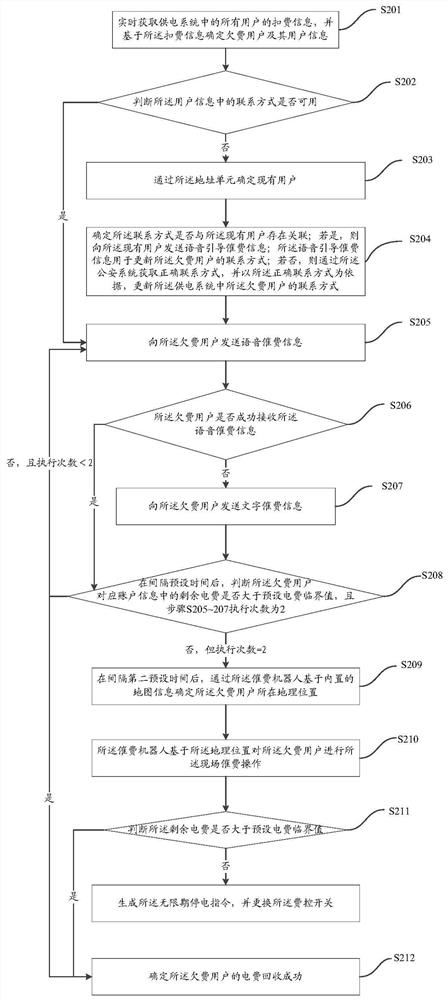

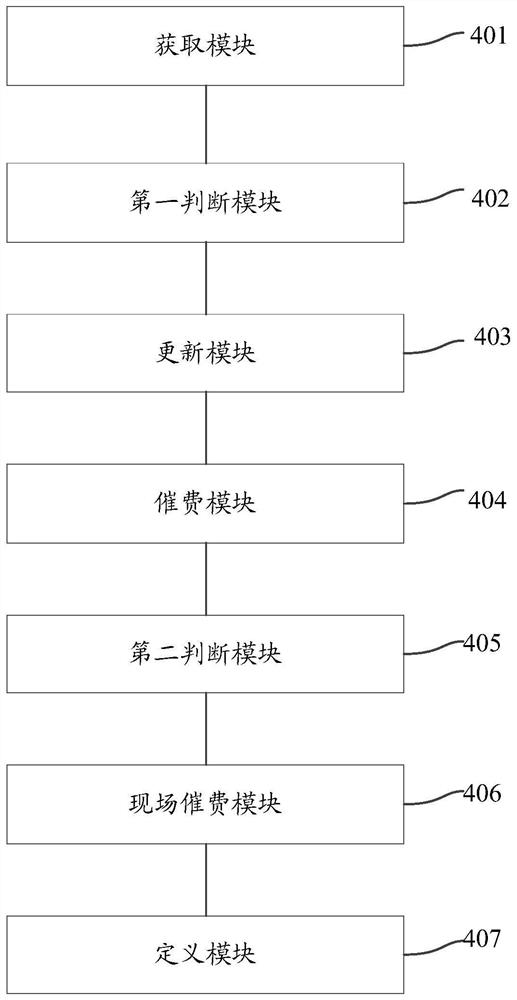

Automatic electricity charge recovery method and device

PendingCN113554431AReduce the risk of complaintsImprove recycling efficiencyEnergy industryCredit schemesAutomotive engineeringElectricity cost

The invention discloses an automatic electric charge recovery method and device, and the method aims at the defects of an existing electric charge recovery method, and achieves the real-time collection of user arrearage information through adding an automatic butt joint power supply system, obtains a correct contact way through butt joint with the big data of a public security system, and increases the flow of an intelligent on-site charge urging robot. Therefore, the labor cost of a power supply enterprise in an electric charge recovery link is reduced, the complaint risk of a user is reduced, and the electric charge recovery efficiency is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

A detection device and detection method for a flexible panel

ActiveCN106872485BSimple structureAccurate detectionOptically investigating flaws/contaminationEngineeringMechanical engineering

The invention discloses a detection device of a flexible panel. The detection device comprises a light-on tester and a probe, wherein the light-on tester comprises a light-on tester body and a curved-shaped light-on tester back plate; the light-on tester body is connected with one side surface of the light-on tester back plate; the surface, away from the light-on tester, of the light-on tester back plate is a curved surface for arranging the to-be-detected flexible panel; the probe is arranged on the light-on tester, and is used for connecting the to-be-detected flexible panel and the light-on tester back plate. The detection device disclosed by the invention has the advantages that the structure is simple, the defective product in the flexible panel can be accurately detected, the poor dot / line in the module detection or terminal client detection process is avoided, the waste of a polarizing plate is effectively avoided, and the risk of customer complaint is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

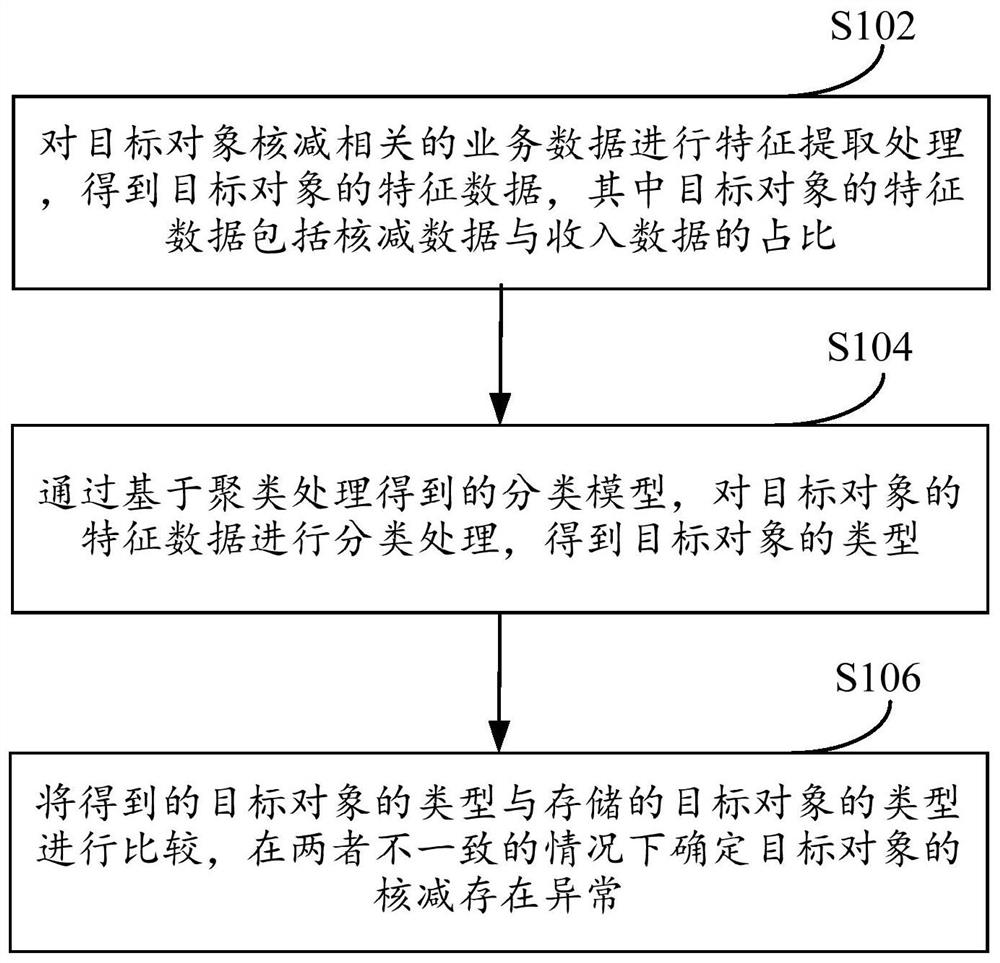

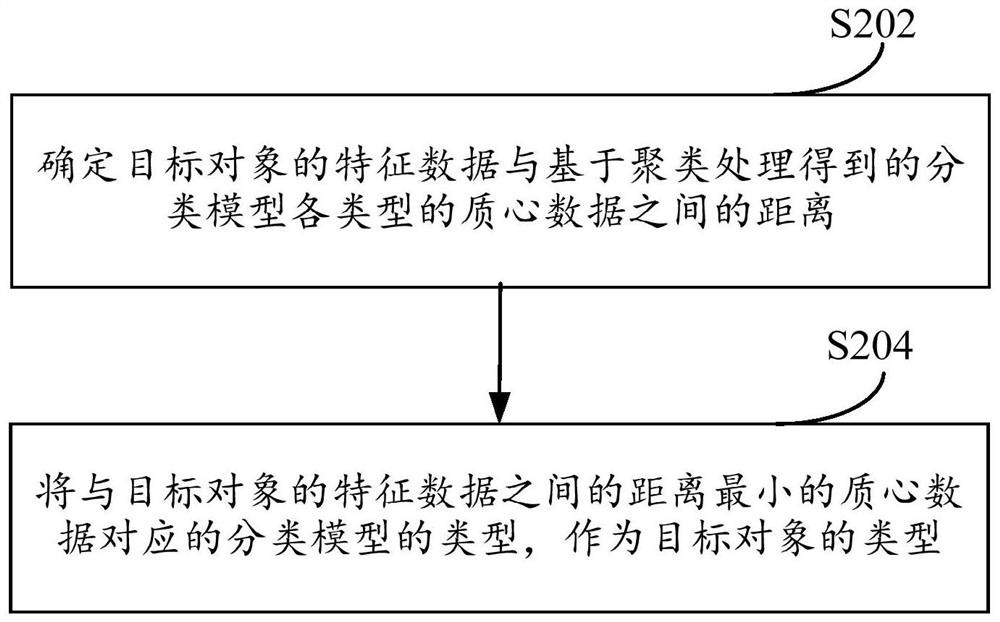

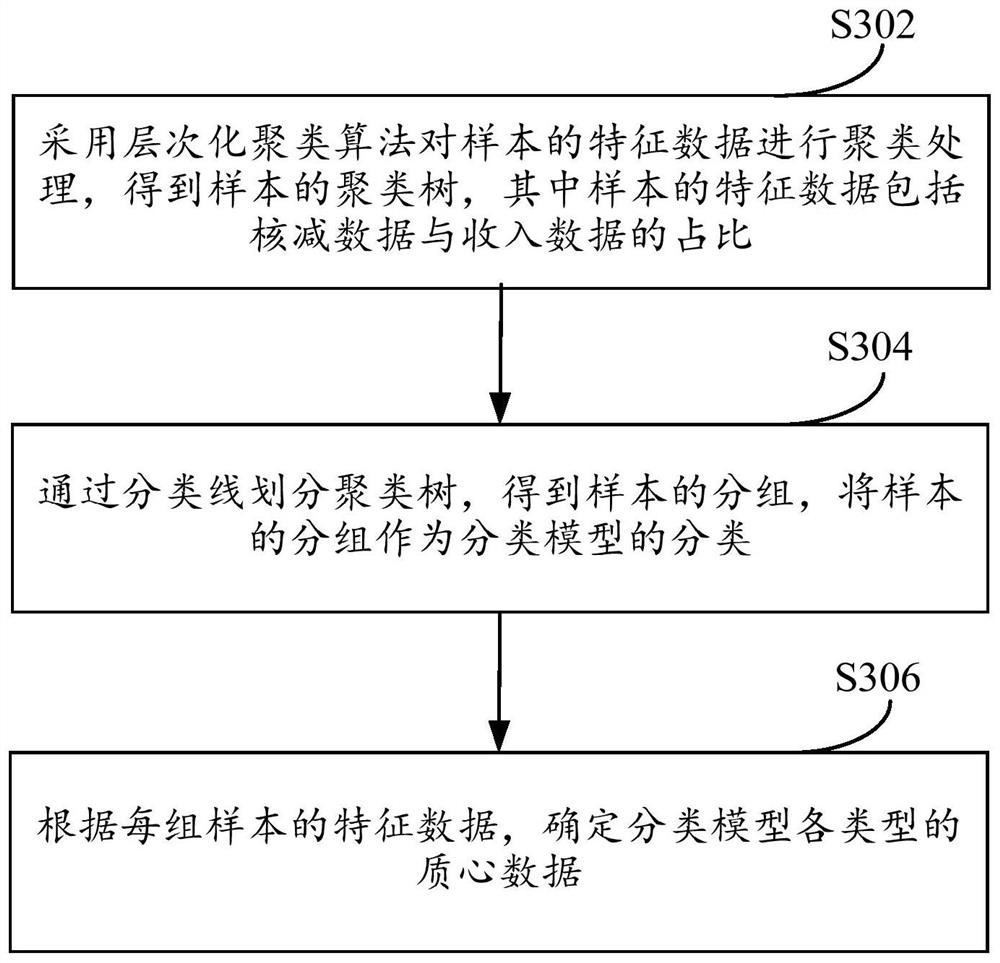

Certificate subtraction monitoring method and device, electronic equipment and computer readable storage medium

PendingCN114579628AEnsure consistencyGuaranteed accuracyFinanceNuclear energy generationFeature extractionEngineering

The embodiment of the invention provides a subtraction monitoring method and device, electronic equipment and a computer readable storage medium, and the method comprises the steps: carrying out the feature extraction processing of business data related to the subtraction of a target object, obtaining the feature data of the target object, and storing the feature data of the target object; the feature data of the target object comprises a ratio of subtraction data to revenue data; performing classification processing on the feature data of the target object through a classification model obtained based on clustering processing to obtain the type of the target object; and comparing the obtained type of the target object with the stored type of the target object, and when the obtained type of the target object is inconsistent with the stored type of the target object, determining that the subtraction of the target object is abnormal. According to the embodiment of the invention, the abnormal problem existing in the reduction check data can be found in time, the consistency and accuracy of the reduction check data are ensured, and settlement loss and complaint upgrade events are avoided.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD +1

A screening method for lithium-ion battery self-discharge

ActiveCN108682908BReduce the risk of complaintsShorten self-discharge screening cycleSecondary cells testingTest batteryProcess engineering

The invention relates to a lithium ion battery self-discharging screening method. The lithium ion battery self-discharging screening method comprises the following steps: S1, performing first-time voltage test on to-be-tested batteries according to a first test standard and screening out the to-be-tested batteries meeting the first test standard; S2, ageing the to-be-tested batteries meeting the first test standard by a preset ageing process; S3, performing second-time voltage test on the to-be-tested batteries aged by the preset ageing process according to a second test standard and screeningout the to-be-tested batteries meeting the second test standard; S4, screening the to-be-tested batteries meeting the second test standard and screening out the to-be-tested batteries with self-discharging SOC being 5 to 15 percent; and S5, screening the to-be-tested batteries with the self-discharging SOC being 5 to 15 percent by a K value method and screening out the to-be-tested batteries meeting the K value. By the method, the self-discharging screening cycle can be effectively shortened, the productivity is improved, the cost is further reduced, the efficiency is high and the accuracy degree is high; furthermore, the quality of products can be improved and the customer complaint risk can be reduced; meanwhile, the delivery cycle of the products can be shortened.

Owner:HUIZHOU TOPBAND ELECTRICAL TECH CO LTD

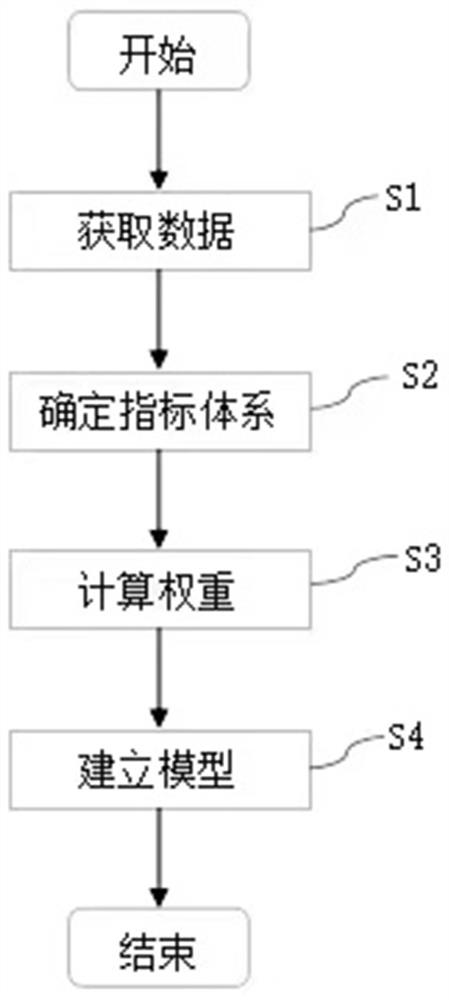

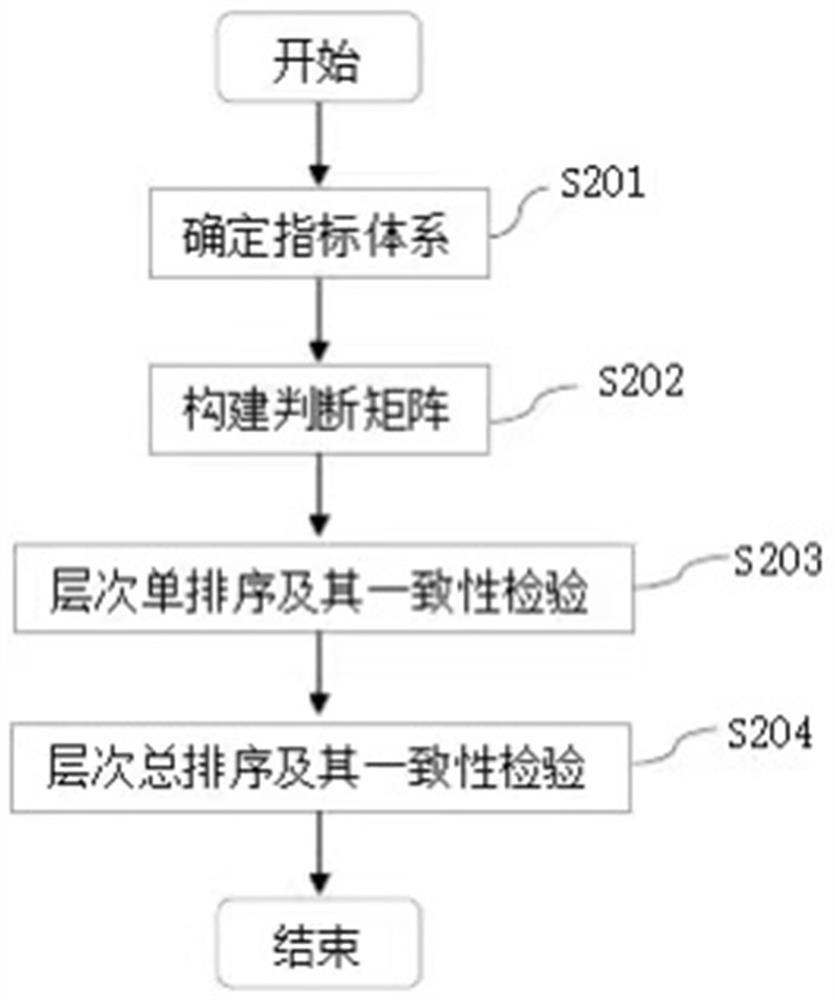

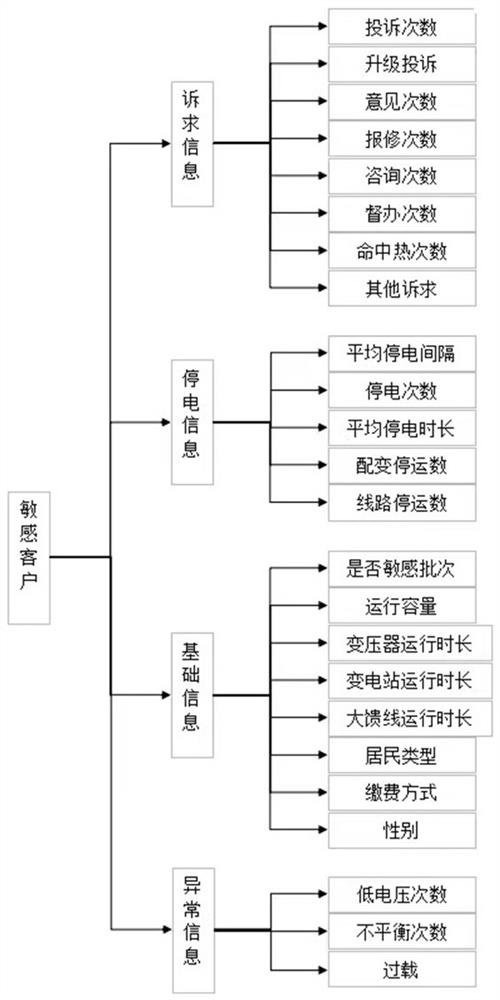

AHP-based power failure customer sensitivity grade discrimination method

PendingCN114611952AImprove satisfactionReduce the risk of complaintsResourcesSpecial data processing applicationsLinear modelEvaluation system

The invention discloses an AHP-based power failure customer sensitivity grade discrimination method. The method comprises the following steps: S1, obtaining data; s2, determining an indication system; s3, calculating a weight; and S4, establishing a model: in the step S1, customer power failure related index data is extracted from a power supply service command system and a marketing system of an electric power company, and in the step S2, a multi-index comprehensive evaluation system comprising three layers, namely a target layer, a first-level index layer and a second-level index layer is constructed. In the step S3, the weight of each index is calculated from bottom to top according to an analytic hierarchy process and a 9-quantile scale method, and in the step S4, a linear model is established according to the weights calculated by the analytic hierarchy process and the 9-quantile scale method, and a customer power failure sensitivity grade model is constructed; according to the AHP-based power failure customer sensitivity level judgment method, the active service awareness and the working efficiency of basic-level workers can be improved, power supply service management can be continuously optimized, the satisfaction degree of users can be improved, and the customer complaint risk can be reduced.

Owner:郑州格蒂电力智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com