Tool and method for spot-welding loose wires of frame of loudspeaker

A loudspeaker pot frame and wire loosening technology, which is applied in the direction of auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems such as the difficulty of grasping the tightness of manual pull wires, affecting the impact resistance of solder joints, and increasing the risk of customer complaints, etc., to achieve Reduce the risk of customer complaints, ensure consistency and reliability, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

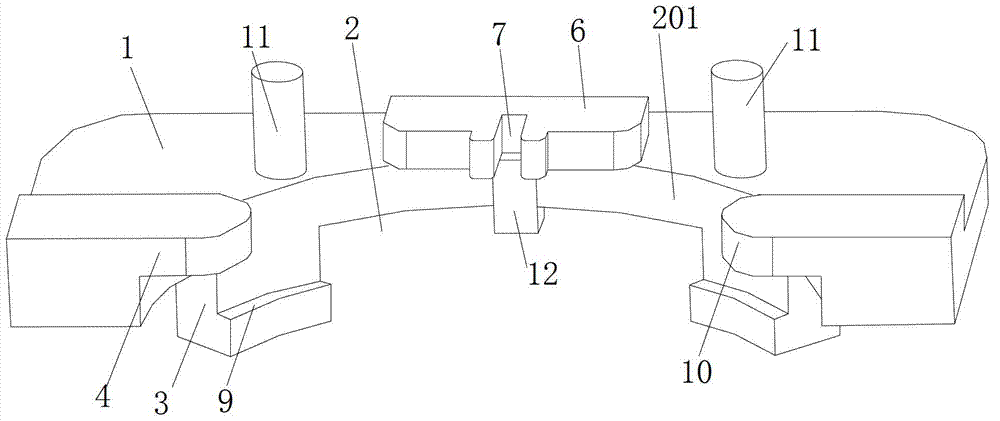

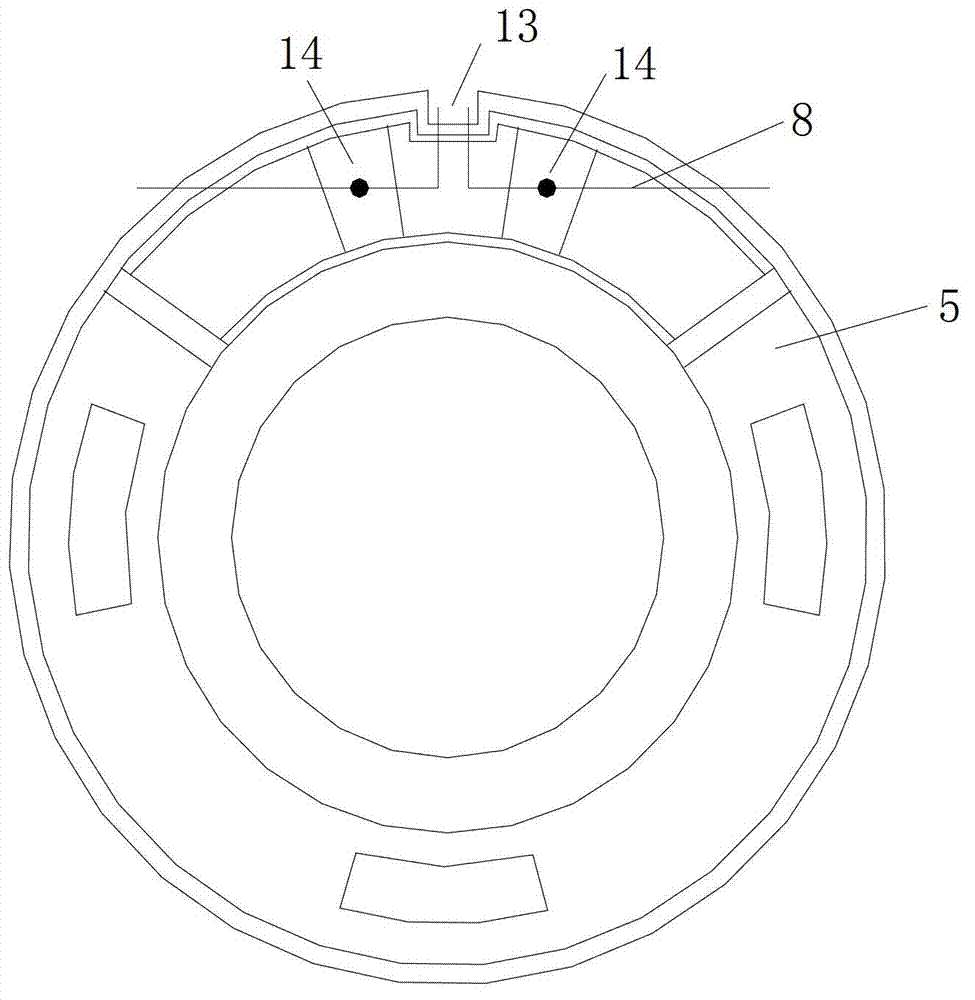

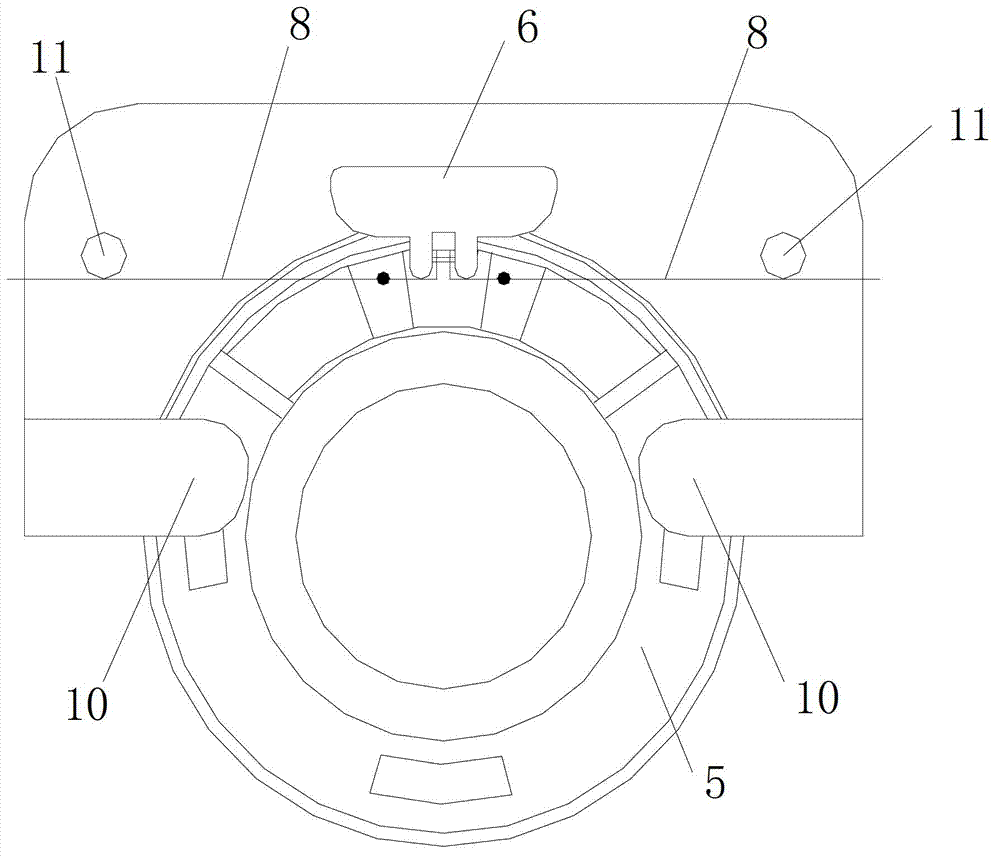

[0024] see figure 1 , 2 3. Loose wire spot welding tooling for the speaker basin frame. The tooling includes a tooling base plate 1. On one side of the tooling base plate, there is a notch 2 that is recessed toward the middle of the tooling base plate. The shape of the notch is determined according to the shape of the product, so that The shape of the notch can be square, elliptical, polygonal, etc. The notch 2 in this embodiment is an arc-shaped notch; the tooling substrate below the notch is provided with a supporting part 3, and the tooling substrate above the notch is provided with a supporting part 3. The limiting part 4 matched with each other, a limiting space is formed between the supporting part 3, the limiting part 4 and the notch wall 201, and the limiting space is used to install the speaker frame 5, which is limited after the spea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com