Method and device for optically measuring external threads

An external thread and thread technology, which is applied in the field of optical measurement of external threads, can solve problems such as inability to measure pipe threads, and achieve the effect of improving efficiency and reducing the risk of complaints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

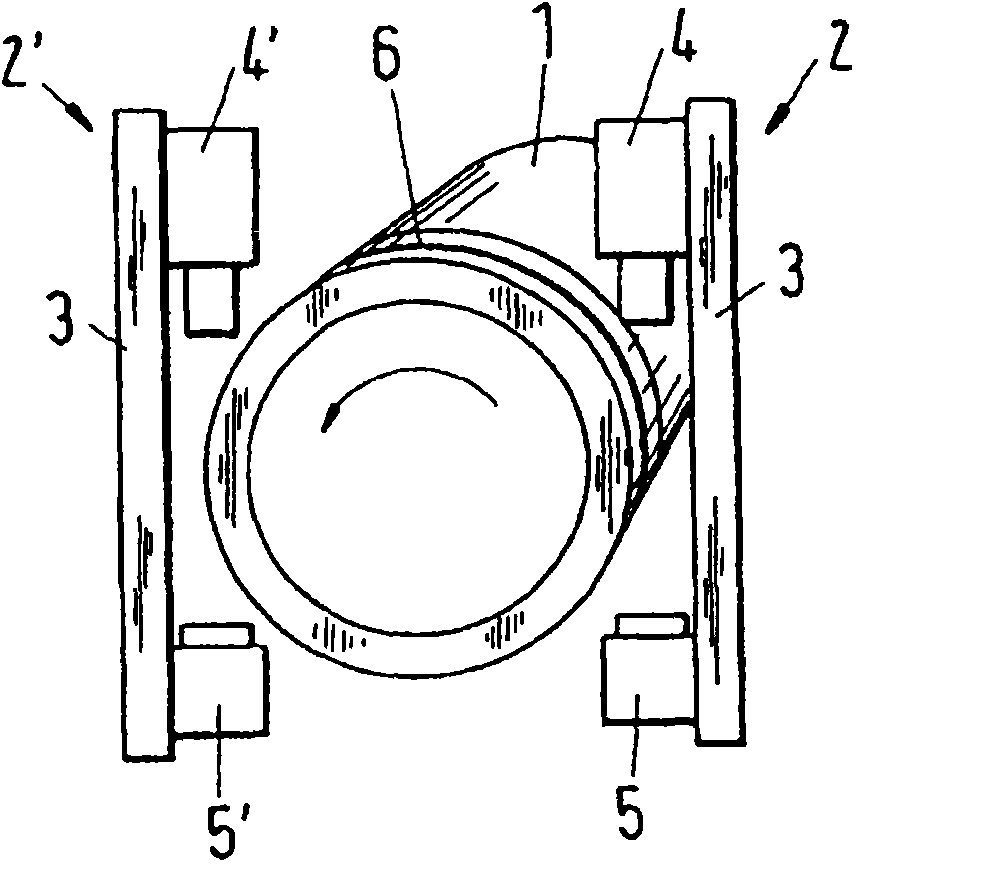

[0058] FIG. 1 a shows a schematic diagram of a device according to the invention for determining the thread profile of an external thread on a pipe.

[0059]In order to increase efficiency, ie to shorten the assay time, the device is provided with two assay units 2 which are arranged opposite to each other with respect to the tube cross section.

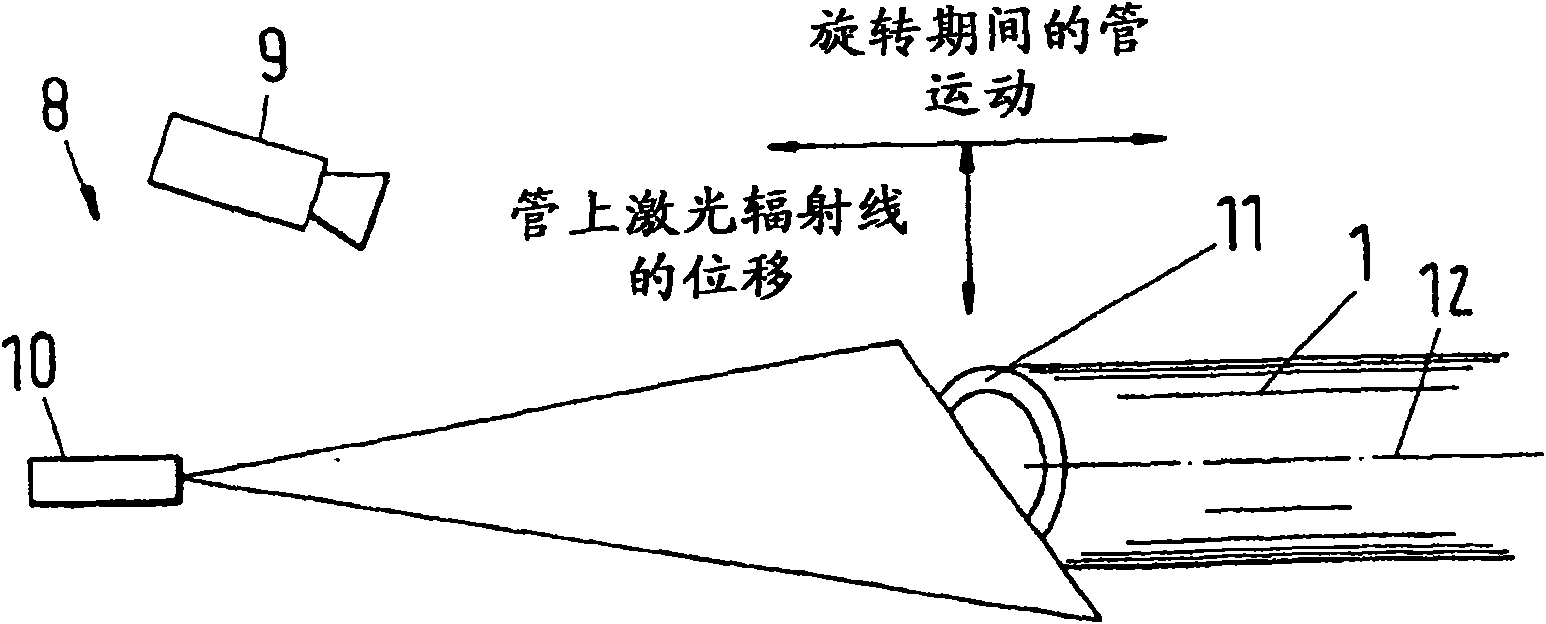

[0060] The measuring unit 2 consists of an illuminating device 5, 5' fastened to a support 3 and a camera 4, 4' which is adjusted in a backlit arrangement so that the thread 6 of the pipe 1 to be measured is illuminated tangentially to the pipe cross-section or Scanning and images of the thread profile are captured by a camera.

[0061] According to the invention, the lighting devices 5 , 5 ′ and the cameras 4 , 4 ′ are designed for telecentric light.

[0062] Subsequently, the optical signal is processed by a processing unit (not shown here) and compared with a setpoint value to be maintained.

[0063] According to the invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com