Method for testing bright spots and rain marks of exterior wall flat-coating finish paint

A test method and exterior wall technology, applied in the preparation of test samples, optical test flaws/defects, measurement devices, etc., can solve the problems of serious rain marks on bright spots, loss of company profits, etc., to reduce profit losses and reduce customers. The risk of complaints, the effect of improving the overall assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

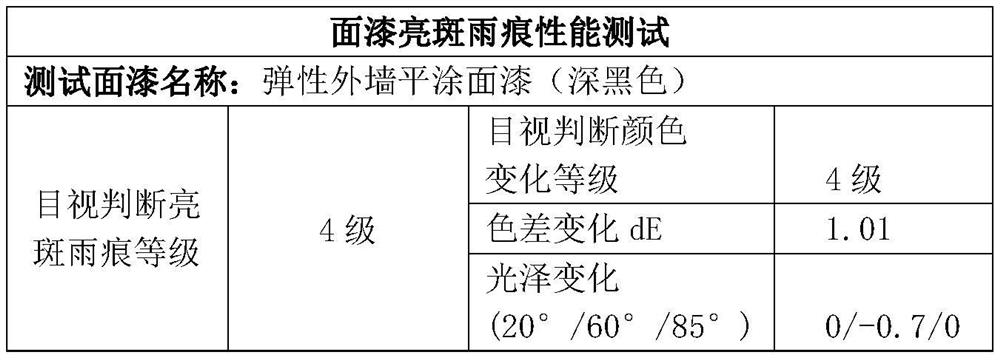

Embodiment 1

[0024] A test method for bright spots of rain marks on flat paint on exterior walls, comprising the following steps:

[0025] Step 1: Scrape a piece of fine grain on the asbestos-free cement board (430x150x4~6mm), put it in a 50°C oven and bake it for 5 hours, then take it out, then place it under constant temperature and humidity conditions for 0.5h, and then polish it with 240-grit sandpaper smooth. After grinding, continue to scrape a fine layer of putty, and the total thickness of the two layers of putty is 1mm. Then put it in a 50°C oven and bake for 8 hours, take it out, and then place it under constant temperature and humidity conditions for 0.5 hours, and then polish it with 320-grit sandpaper. The constant temperature and humidity conditions are a temperature of 21° C. and a humidity of 45%.

[0026] Step 2: On the putty layer, evenly roll coat an outer wall anti-alkali sealing primer, and the coating rate of the primer is 0.11KG / m 2 . The roller coating construct...

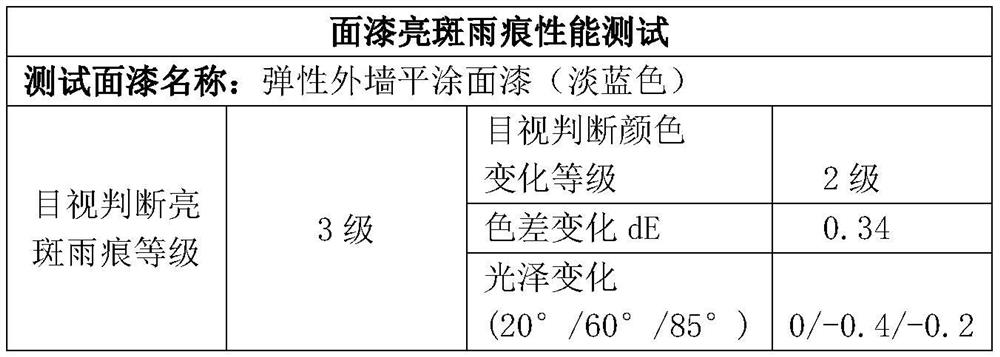

Embodiment 2

[0044] A test method for bright spots of rain marks on flat paint on exterior walls, comprising the following steps:

[0045] Step 1: Scrape a fine grain on the asbestos-free cement board (430x150x4~6mm), put it in a 55°C oven and bake it for 6 hours, take it out, then place it under constant temperature and humidity conditions for 0.8h, and then polish it with 240-grit sandpaper smooth. After grinding, continue to scrape a fine layer of putty, and the total thickness of the two putty layers is 1.5mm. Then put it into a 55°C oven and bake for 9 hours, take it out, and then place it under constant temperature and humidity conditions for 0.8 hours, and then smooth it with 320-grit sandpaper. The constant temperature and humidity conditions are a temperature of 23° C. and a humidity of 50%.

[0046] Step 2: On the putty layer, evenly roll coat an outer wall anti-alkali sealing primer, and the coating rate of the primer is 0.12KG / m 2 . The roller coating construction tool is a...

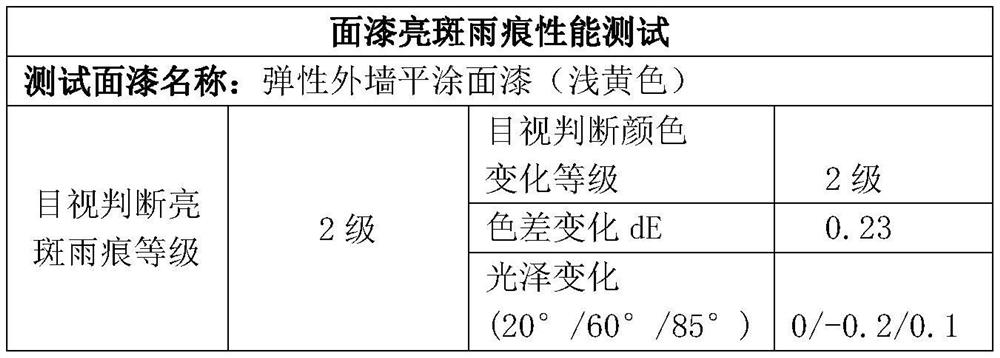

Embodiment 3

[0064] A test method for bright spots of rain marks on flat paint on exterior walls, comprising the following steps:

[0065] Step 1: Scrape a piece of fine grain on the asbestos-free cement board (430x150x4~6mm), put it in a 60°C oven and bake it for 7 hours, then take it out, then place it under constant temperature and humidity conditions for 1 hour, and then smooth it with 240-grit sandpaper . After grinding, continue to batch scrape a delicate layer, and the total thickness of the two layers of putty is 2mm. Then put it in a 60°C oven to bake for 10 hours, take it out, place it under constant temperature and humidity conditions for 1 hour, and then smooth it with 320-grit sandpaper. The constant temperature and humidity conditions are a temperature of 25° C. and a humidity of 55%.

[0066] Step 2: On the putty layer, evenly roll coat an outer wall anti-alkali sealing primer, and the coating rate of the primer is 0.13KG / m 2 . The roller coating construction tool is a 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com