Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reduce rolling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

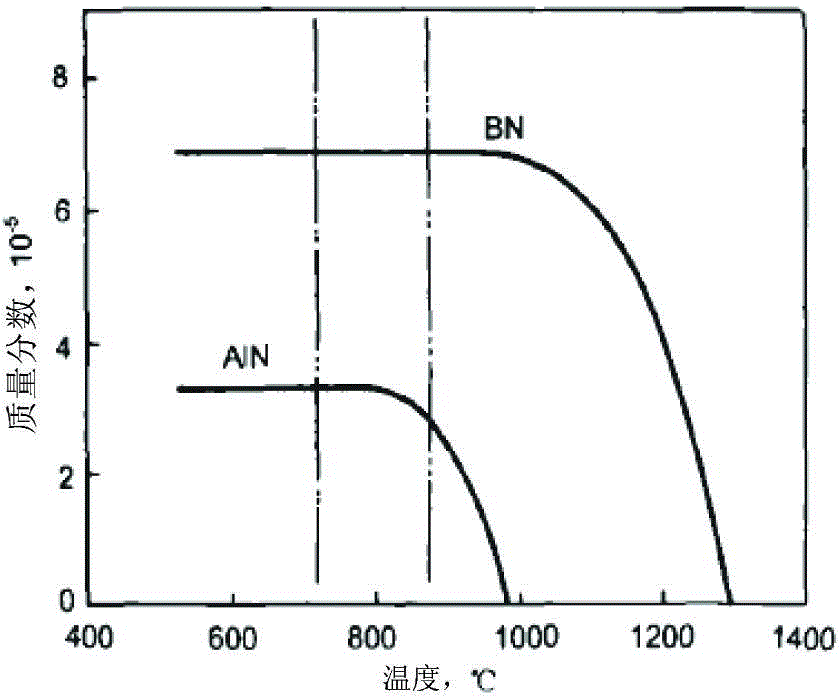

Boron-containing weather-proof thin strip steel and manufacturing method thereof

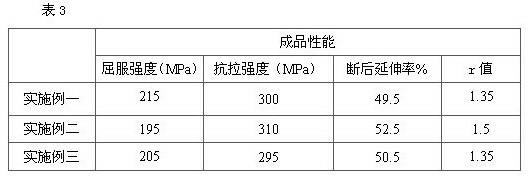

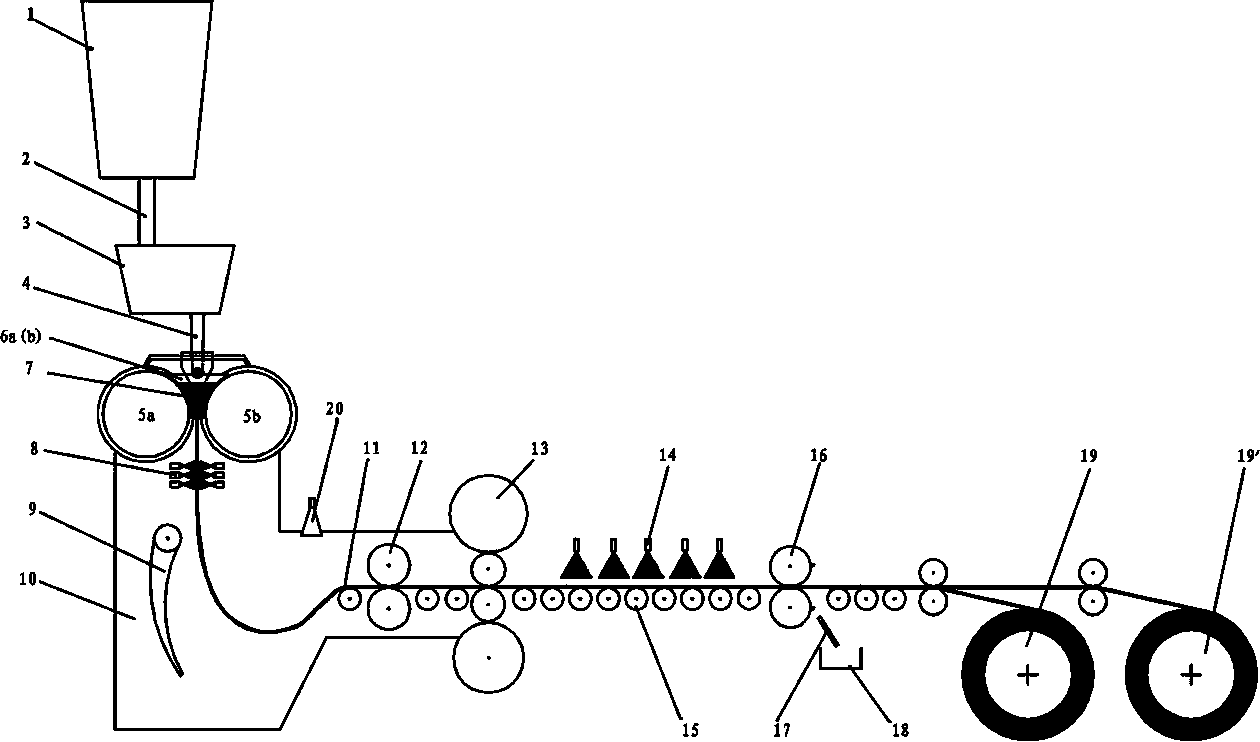

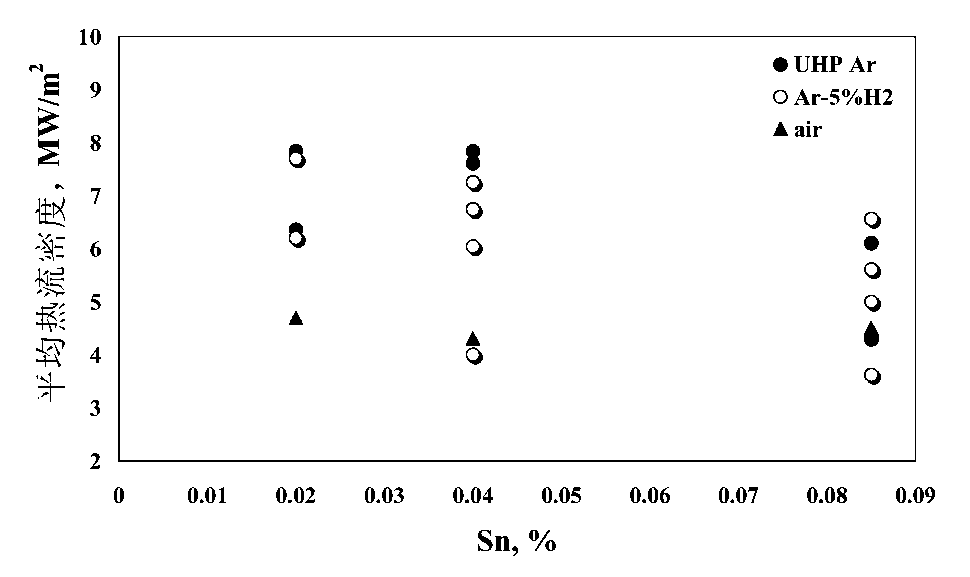

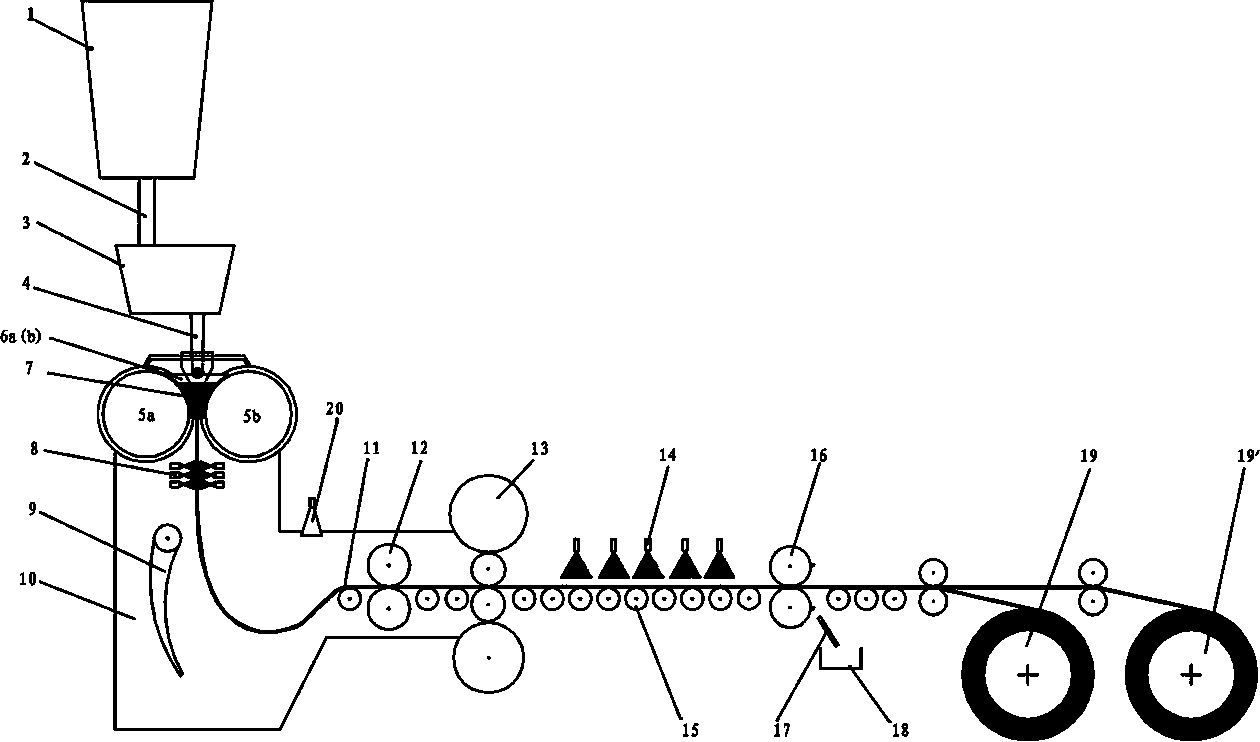

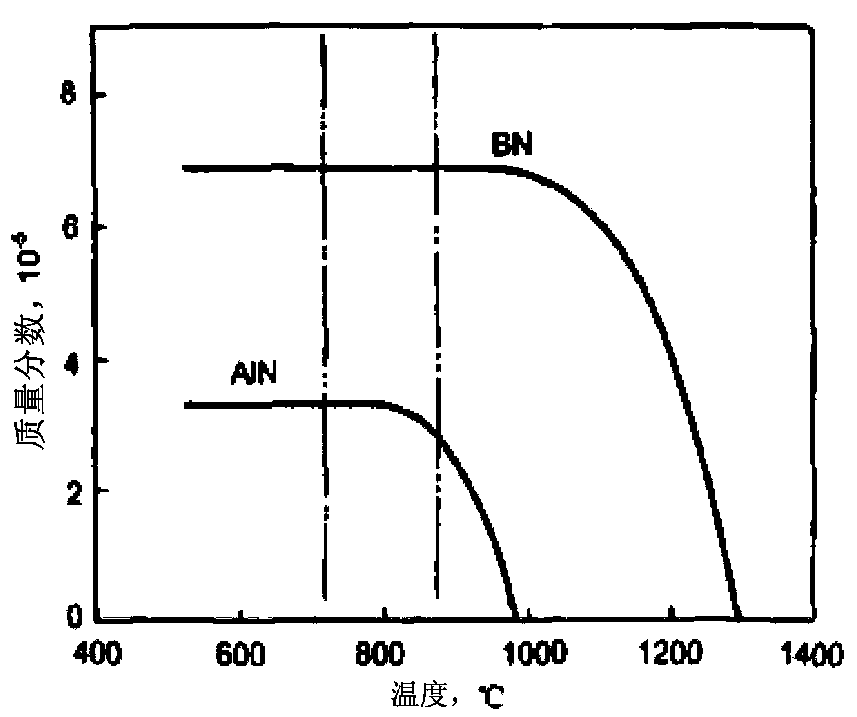

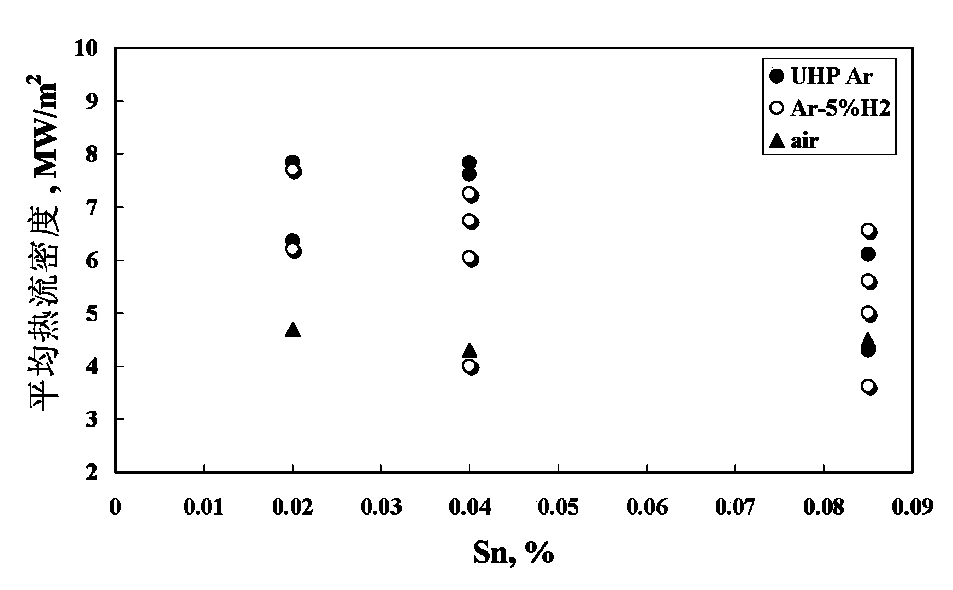

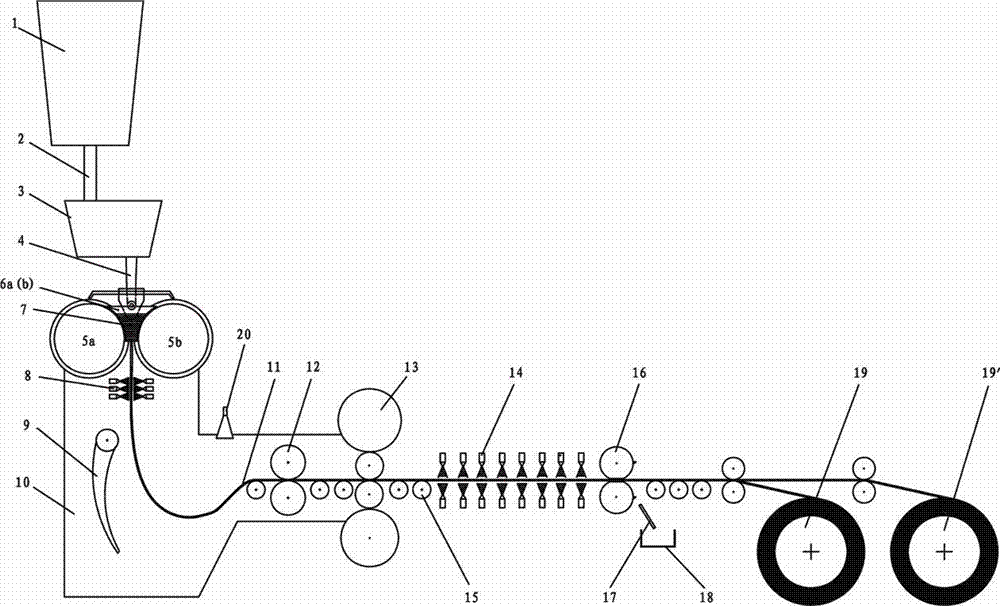

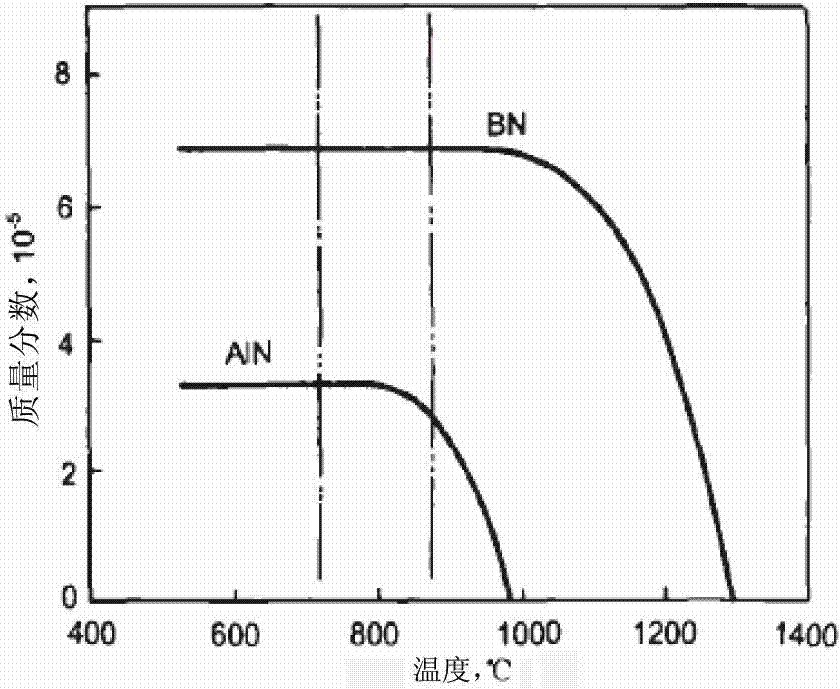

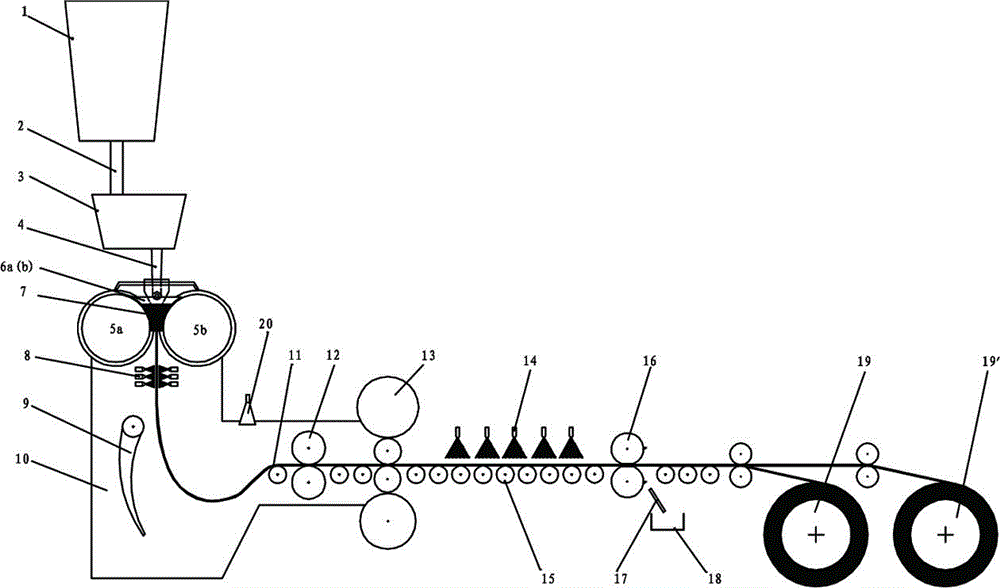

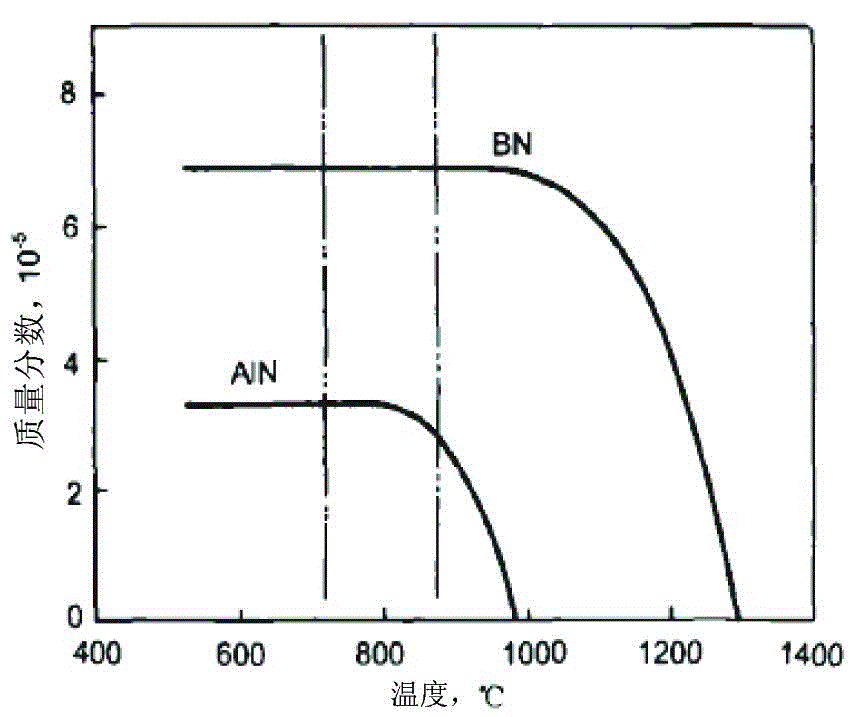

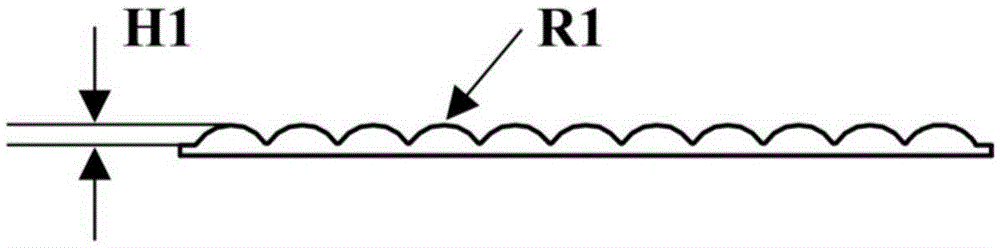

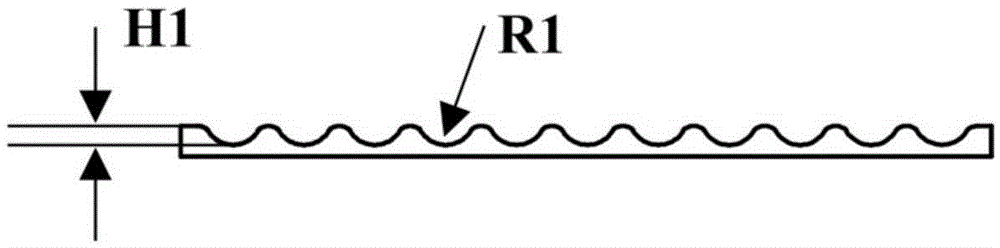

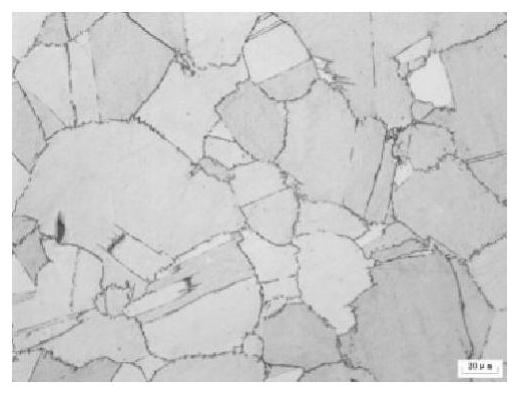

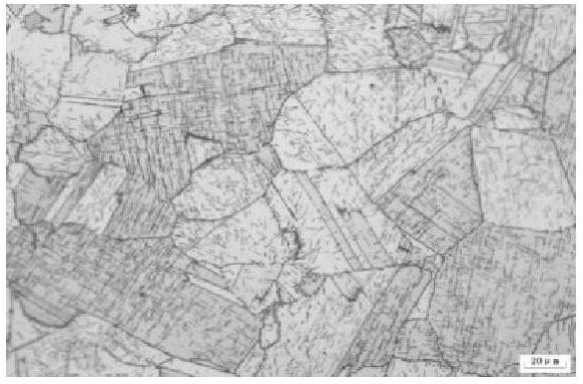

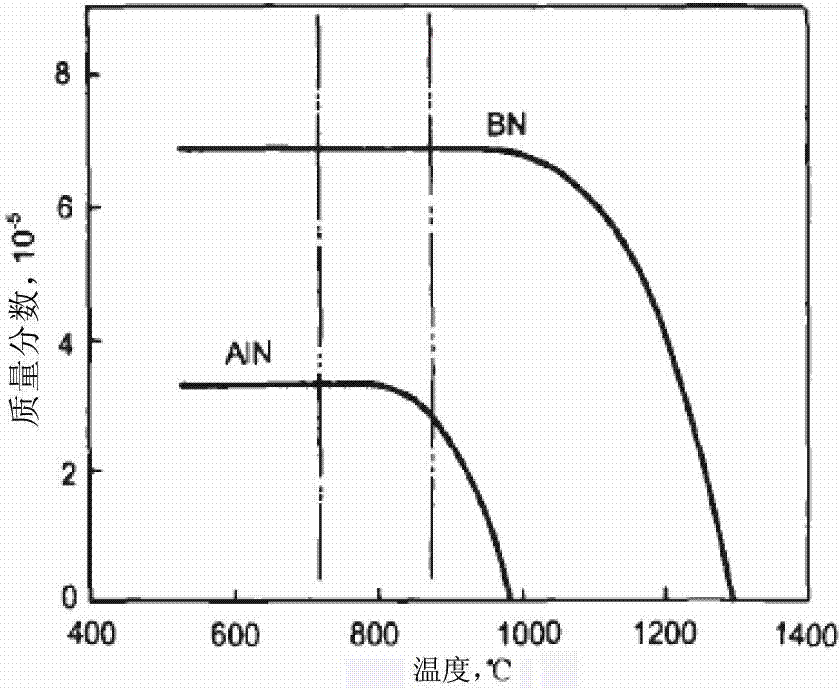

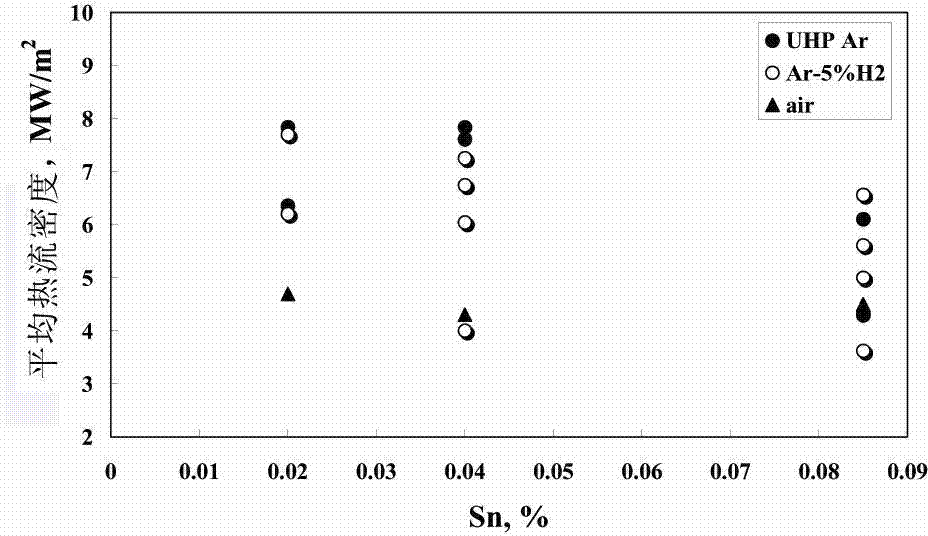

Provided are boron-containing weather-proof thin strip steel and a manufacturing method thereof. The manufacturing method comprises performing double roller thin strip continuous casting to produce boron-containing weather-proof steel; after a cast strip is processed through a crystallizing roller, adopting a mode of spraying dry ice to perform uniform strengthened cooling on the cast strip, rapidly cooling the cast strip to below 1,280 DEG C, and enabling the cooling speed to be 200-300 DEG C / s, so that precipitation of thick and large BN in the cooling mode is promoted, emergency of low-melting-point-phase B203 and precipitation of tiny AlN are avoided, and the aims of homogenizing austenite grains and reducing yield ratio are achieved; then performing austenite on-line recrystallization rolling; then performing anti-oxidizing rapid cooling to cool the strip steel undergoing hot rolling, and enabling the cooling temperature to be 80-200 DEG C / s; and enabling coiling temperature to be 500-600 DEG C. Steel with low yield ratio can be obtained through the manufacturing method, and the problems that steel produced by thin strip continuous casting are universally uneven in structure, high in yield ratio and difficult to form and cannot meet the requirements for cold rolling materials are effectively solved.

Owner:BAOSHAN IRON & STEEL CO LTD

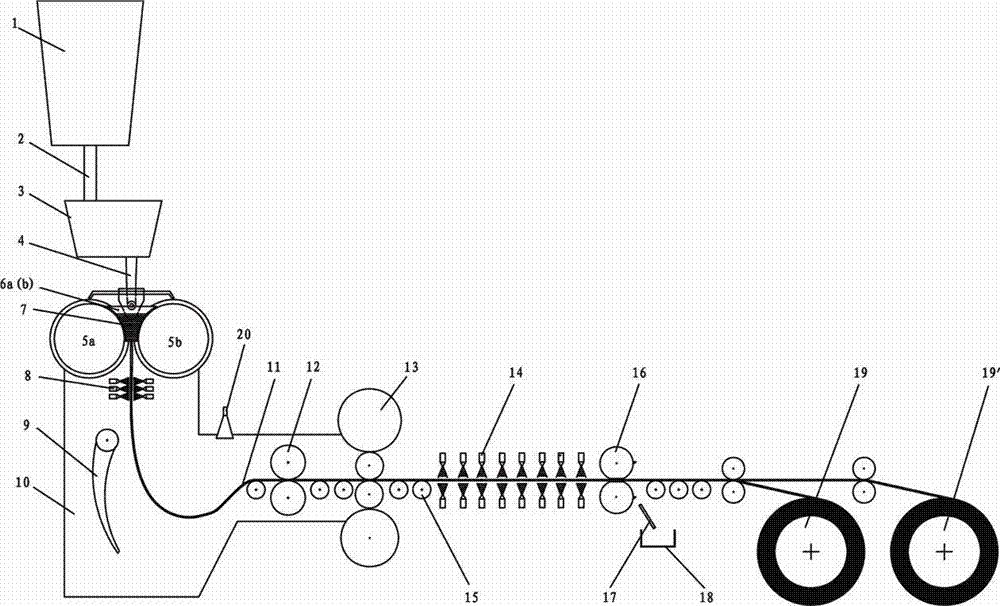

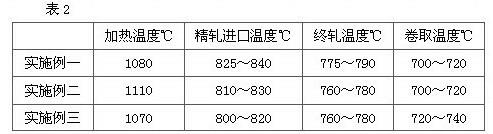

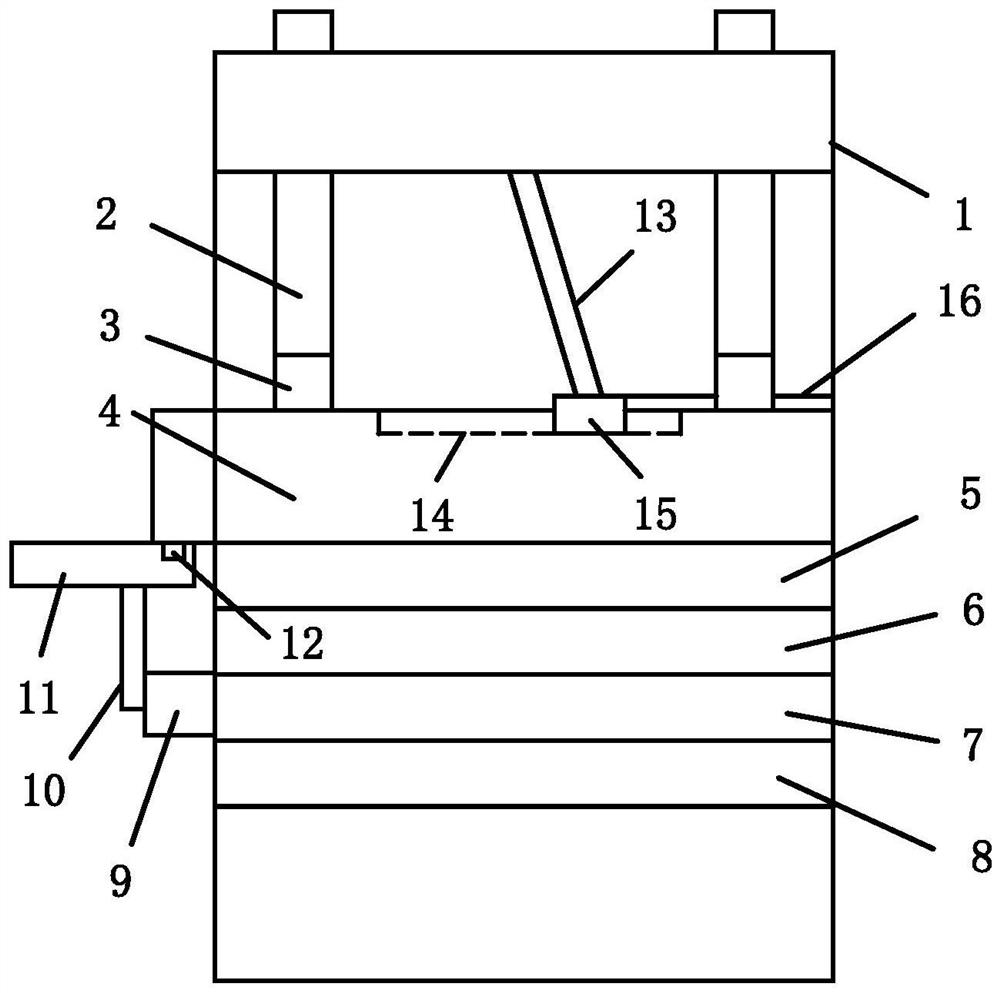

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

Large reduction rolling method for magnesium alloy

ActiveCN103962376AIncrease single pass reductionReduce rolling passesAuxillary arrangementsMetal rolling arrangementsThermal insulationManganese

The invention relates to a large reduction rolling method for magnesium alloy. According to the rolling method, a hard alloy lining plate is additionally arranged on the upper surface or the lower surface of the magnesium alloy, or two hard alloy lining plates are additionally arranged on the upper surface and the lower surface of the magnesium alloy at the same time, and the added hard alloy lining plates are rolled synchronously together with the magnesium alloy. The rolling method includes the steps that after a high temperature lubricating agent is evenly smeared on the surfaces of the lining plates and the surface of the magnesium alloy, the high temperature lubricating agent, the lining plates and the magnesium alloy are simultaneously placed into a heating box to be heated, after the temperature rises to a preset temperature, standing and thermal insulation are performed for a certain period of time, one hard alloy lining plate is placed on the upper surface or the lower surface of magnesium alloy blank, or the two hard alloy lining plates are placed on the upper surface and the lower surface of the magnesium alloy at the same time, and the hard alloy lining plates and the magnesium alloy are simultaneously fed into the position between rollers so that rolling can be completed. Through the method, the single pass reduction of the magnesium alloy can be greatly increased in the rolling process, the number of rolling passes is decreased, magnesium alloy crystalline grains are thinned, the texture is weakened, magnesium alloy plates with high strength and plasticity are prepared, and the large reduction rolling method for the magnesium alloy is also suitable for the large deformation rolling process of titanium, manganese and metal-matrix composite materials.

Owner:JILIN UNIV

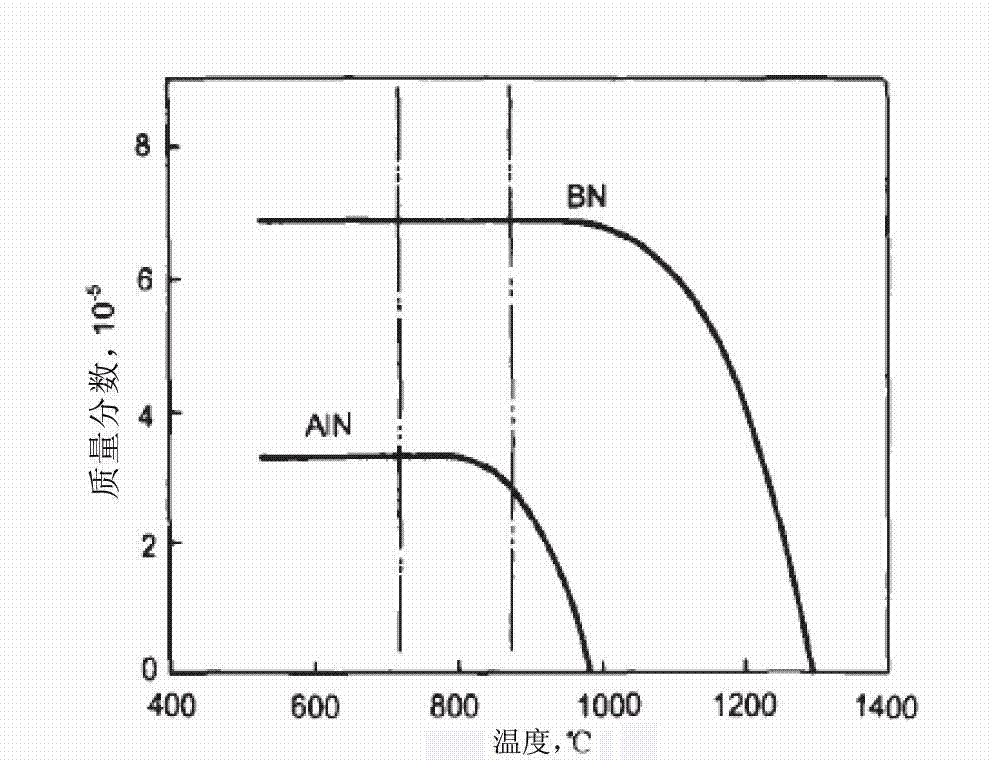

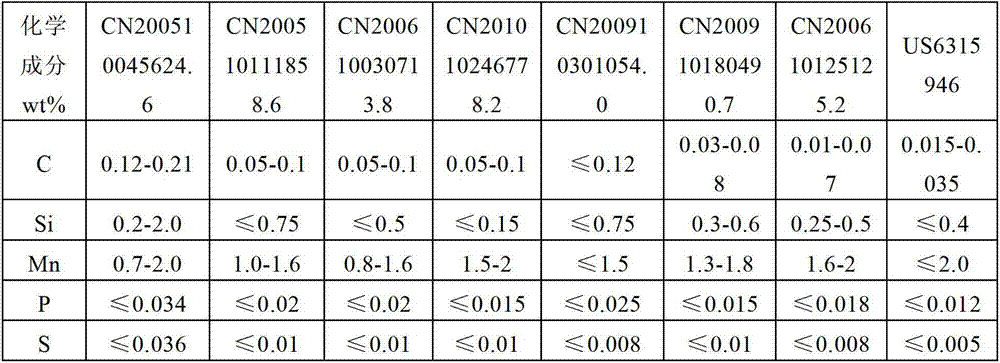

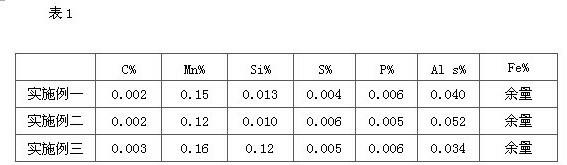

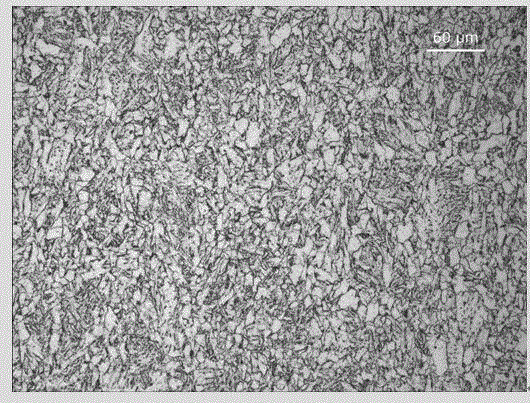

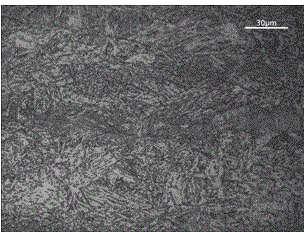

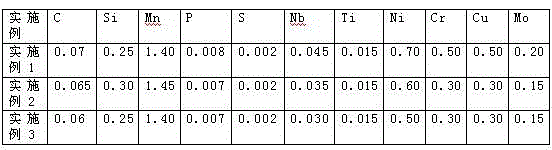

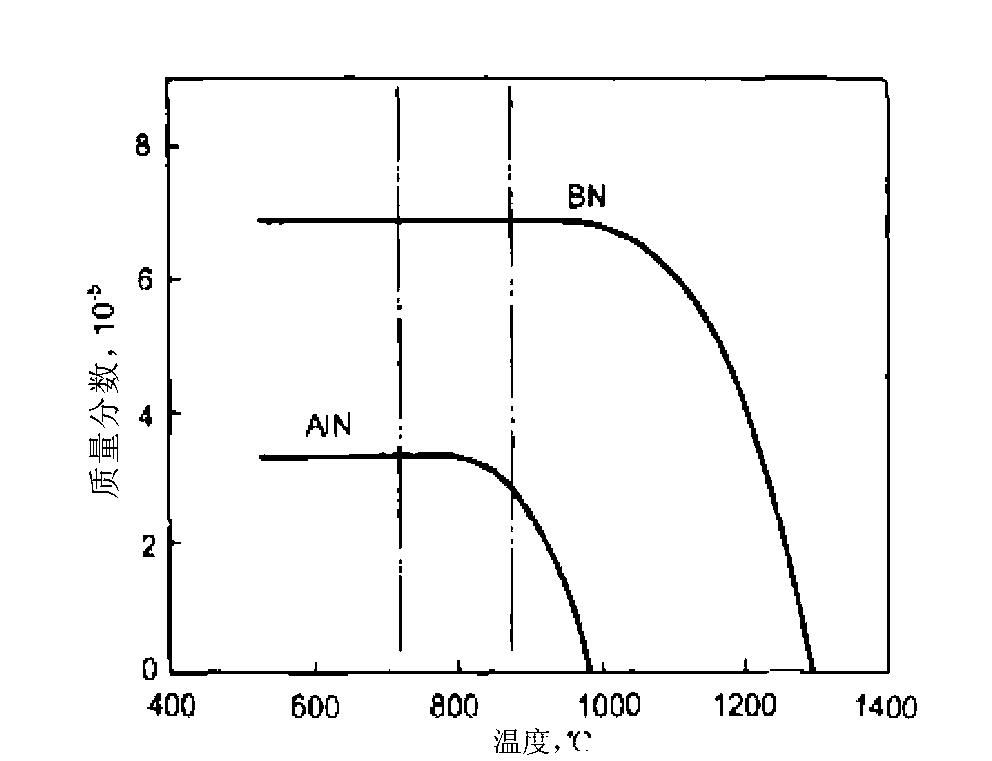

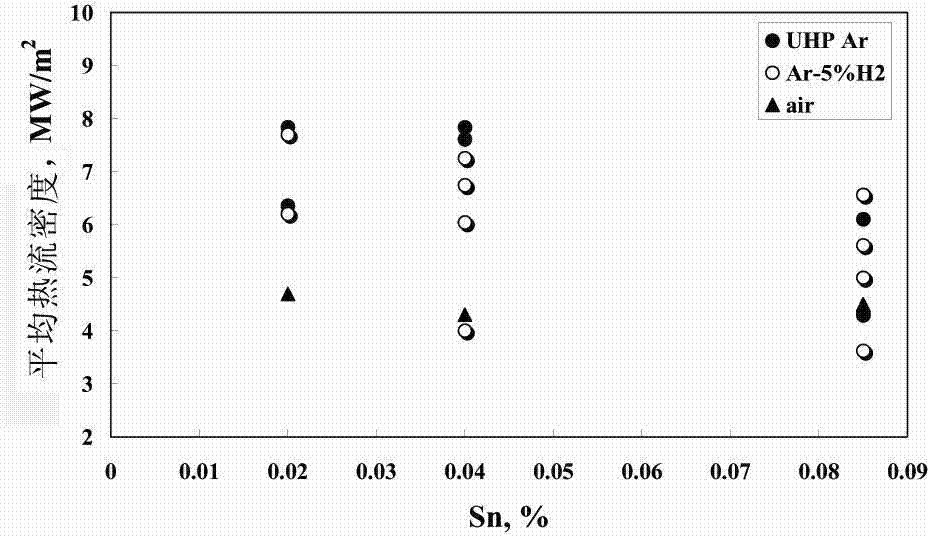

High-strength thin strip steel for cold forming and manufacturing method thereof

ActiveCN103667895ATo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideHigh pressure

The invention relates to high-strength thin strip steel for cold forming and a manufacturing method thereof. The manufacturing method comprises the following steps: performing uniform enhanced cooling on a cast strip by adopting a high-pressure dry ice spraying way after the cast strip is discharged from a crystallization roller, thus rapidly cooling the cast strip to below 1280 DEG C, wherein the cooling rate is 200-300 DEG C / s, and by adopting the cooling way of the strip steel after boron treatment, the precipitation of coarse BN (boron nitride) can be promoted, the appearance of low-melting point phase B2O3 and the precipitation of fine AlN can be prevented and the purposes of uniformizing austenite grains and reducing yield ratio are achieved; then performing austenite online recrystallization rolling; cooling the strip steel after hot rolling by atomization cooling, wherein the cooling rate of atomization cooling is 10-70 DEG C / s; coiling at the temperature of 650-750 DEG C. Through the manufacturing method provided by the invention, the high-strength thin strip steel for cold forming of an automobile, which has relatively low yield ratio and excellent stamping performance, can be obtained. The high-strength hot-rolled thin strip steel for cold forming, which is produced by the method, can be directly used for replacing cold-rolled steel with the hot-rolled steel, cancel a cold rolling process step and greatly reduce production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

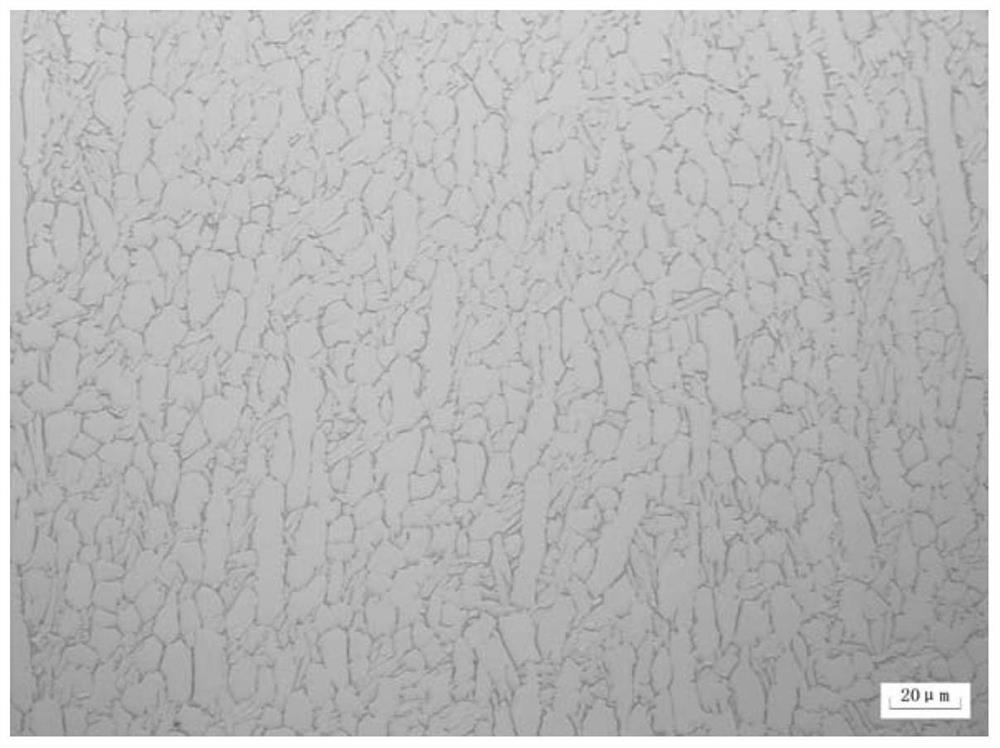

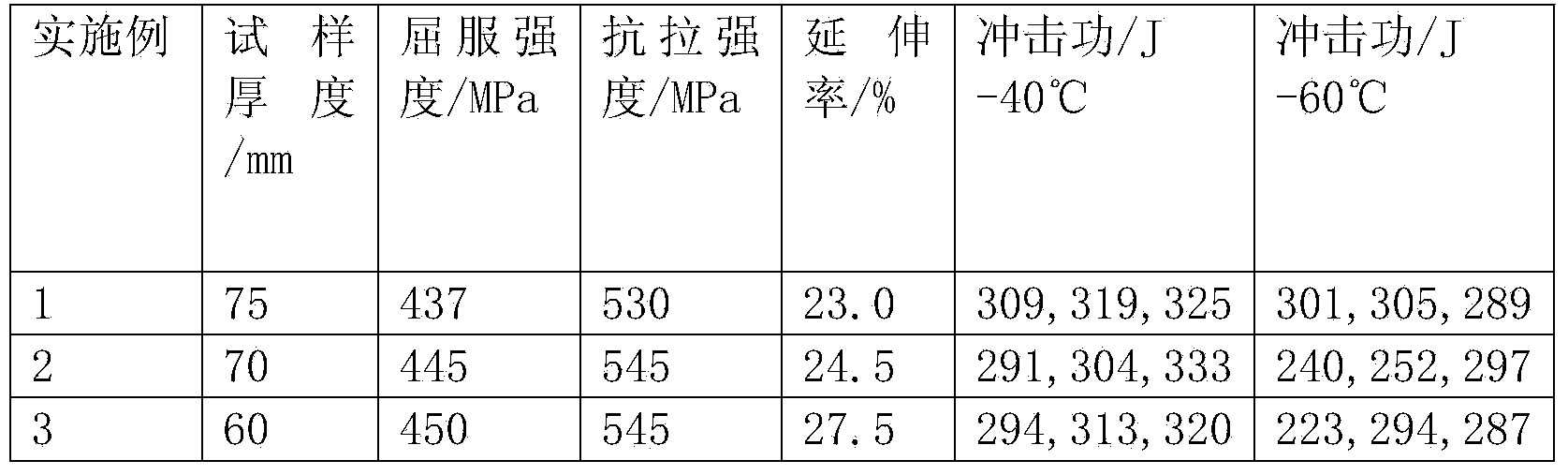

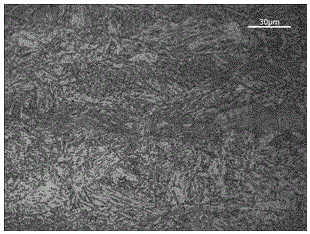

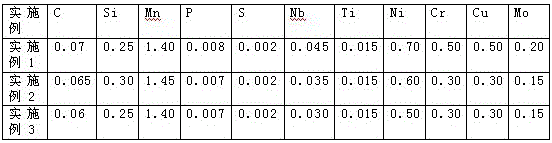

355MPa thick steel plate with low-temperature toughness and preparation method thereof

The invention belongs to the technical field of steel material production, and particularly relates to a 355MPa thick steel plate with low-temperature toughness and a preparation method thereof. The 355MPa thick steel plate with the low-temperature toughness is composed of the following components according weight percent: 0.04 to 0.14% of C, 0.2 to 0.5% of Si, 1.0 to 1.6% of Mn, less than 0.018% of P, less than 0.005% of S, 0.015 to 0.045% of Nb, 0.02 to 0.05% of V, 0.008 to 0.020% of Ti, and the balance of Fe and inevitable impurities. The thick steel plate has good low-temperature (-60 DEG C) impact toughness, and additionally, high strength, high toughness and good welding performance of the thick steel plate are achieved in the condition of the low-carbon content by adopting the preparation method.

Owner:SHANDONG IRON & STEEL CO LTD

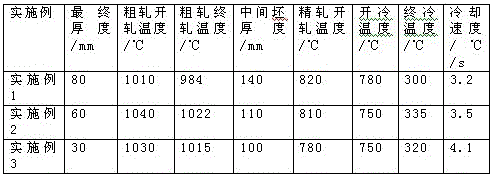

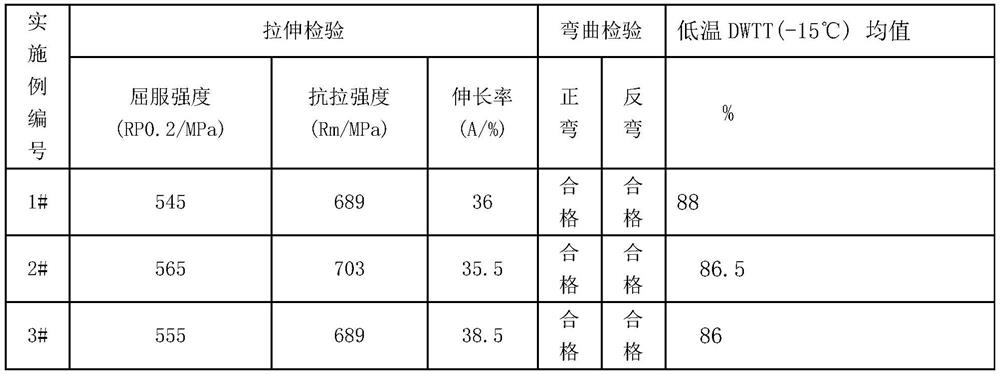

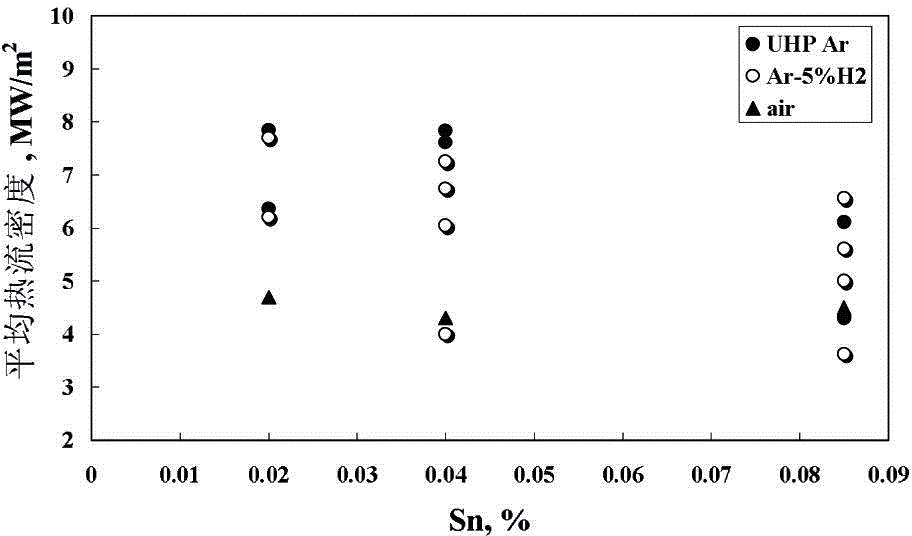

550 MPa-grade low-compression-ratio high-toughness steel plate for ocean engineering platform and production method

The invention belongs to the technical field of steel materials, and relates to a 550 MPa-grade low-compression-ratio high-toughness steel plate for an ocean engineering platform and a production method, in particular to a steel plate with high strength and toughness under conditions of the low carbon content and the low compression ratio for ocean engineering and the production method. The steel plate comprises chemical components in percentage by weight as follows: 0.04-0.10% of C, 0.2-0.4% of Si, 1.0-1.5% of Mn, smaller than 0.010% of P, smaller than 0.003% of S, 0.5-0.8% of Ni, 0.2-0.5% of Cu, 0.30-0.80% of Cr, 0.1-0.3% of Mo, 0.02-0.05% of Nb, 0.010-0.025% of Ti and the balance of Fe and inevitable impurities. The alloy C is low in content, and welding is easy. Under the condition that the thickness of a casting blank is only 250 mm, the content of the C, the P and the S is controlled strictly, the temperature is decreased and then increased, the TMCP process is optimized, the rolling temperature is decreased, the reduction at rough rolling and finish rolling stages is distributed reasonably, the cooling process and the tempering heat treatment temperature are optimized, and steel can have high strength and high low-temperature toughness under the condition of the low compression ratio (the minimum is only 3.125:1).

Owner:SHANDONG IRON & STEEL CO LTD

Thin strip steel for thin-wall oil drum and manufacturing method of thin strip steel

ActiveCN102796943ATo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideYield ratio

The invention discloses a thin strip steel for a thin-wall oil drum and a manufacturing method of the thin strip steel. Double-roll thin strip continuous production is adopted; a dry ice spray mode is adopted after a cast strip is discharged from a crystallization roll; uniform enhanced cooling is performed on the cast strip; the cast strip is quickly cooled to be below 1,280 DEG C; the cooling rate is 200-300 DEG C / s; in such a cooling mode, separation of coarse BN (Boron Nitride) can be promoted and low-melting-point phase B2O3 and fine AlN (Aluminum Nitride) separation are prevented to fulfill the aims of uniformizing austenite crystal grains and reducing the yield ratio; and then austenite is recrystallized and rolled on line, and the strip steel which is subjected to hot rolling is cooled through anti-oxidation quick cooling, wherein the cooling rate is 80-200 DEG C / s and the coiling temperature is 500-600 DEG C. Through the invention, the thin strip steel for the thin-wall oil drum with low yield ratio and superior impact performance can be obtained. According to the thin strip steel for the thin-wall oil drum produced by the method, the hot thin strip steel can be directly used in place of a cold one, a cold rolling step is removed, and the production cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel strip for thin-wall oil bucket and manufacturing method thereof

The invention discloses a steel strip for a thin-wall oil bucket and a manufacturing method thereof. The manufacturing method comprises the following steps: casting a crystal roller from a cast strip by using a thin strip casting process, subsequently uniformly reinforcing and cooling the cast strip in a mode that dry ice is sprayed at a high pressure, and rapidly cooling the cast strip to be less than 1,280 DEG C, wherein the cooling velocity is 200-300 DEG C / s; when the steel strip is subjected to boron treatment in such a mode, large boron nitride separation is prompted, occurrence of low-melting-point phase B2O3 and separation of fine AlN are prevented, and the purposes of uniformly austenite grains and reducing the yield ratio are achieved; subsequently performing on-line recrystallization and rolling on the austenite; subsequently atomizing and cooling so as to cool down the hot-rolled steel strip; finally coiling the steel strip. By adopting the manufacturing method, the thin-wall with low yield ratio and excellent stamping property for the thin-wall oil bucket is manufactured. The hot-rolled steel strip for the thin-wall oil bucket can be used in hotness instead of coldness, and a cold-rolling procedure is omitted, so that the production cost is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of preparing high strength magnesium sheet alloy

InactiveCN101229619AGrain sizeImprove mechanical propertiesTemperature control deviceFurnace typesHigh intensityIngot

The invention relates to technique for processing magnesium alloy, in particular to a method for preparing magnesium alloy planks with high strength and solves the problems that the rolling of the magnesium alloy planks is relatively difficult; the yield of the planks is low, etc. The rolling techniques of spray forming and deposited blank-rolling are used for preparing the high-strength magnesium alloy planks; oxygen with 0.01-0.03MPa is slowly injected into an atomization chamber after the completion of the atomization; over-spray powder of the magnesium alloy is then treated with passivation; then, deposited magnesium alloy ingots are directly and hotly rolled so as to prepare the magnesium alloy crystal grains with small size, even texture and relatively high mechanical property; the mechanical property of the magnesium alloy crystal grains can be further improved by the alloy treatment followed by the alloy rolling. Compared with the traditional preparation technique of the magnesium alloy planks, the technique of the invention has simple process and relatively low temperature of the alloy rolling, and can be applied to preparation of diversified magnesium alloy planks with the high strength.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Warm-rolling manufacture method for magnesium or magnesium alloy sheet

ActiveCN101653778AGuaranteed flatnessRealize continuous productionRoll force/gap control deviceTemperature control deviceIngotHot rolled

The invention discloses a warm-rolling manufacture method for a magnesium or magnesium alloy sheet and relates to a manufacture method of a sheet. The invention solves the problem of low yield of themagnesium and magnesium alloy sheet produced by the prior hot-rolling process of the magnesium and magnesium alloy sheet. The method comprises the following steps: hot-rolling a magnesium or magnesiumalloy casting ingot to manufacture a sheet blank with thickness of 4mm; then rolling the sheet blank for four or five steps and gradually reducing the rolling temperature to obtain the magnesium or magnesium alloy sheet. The method has high yield more than 70 percent and can realize the continuous production of the magnesium and magnesium alloy sheet.

Owner:HARBIN INST OF TECH

Low-cost titanium alloy short-process rolling process

ActiveCN112517633AReduce composition segregationEliminate performance differencesFurnace typesWork heating devicesIngot castingTitanium alloy

The invention relates to a low-cost titanium alloy short-process rolling process. The low-cost titanium alloy short-process rolling process comprises the following steps of: 1, heating a slab ingot smelted by an electron beam cold bed furnace to a temperature above a phase transformation point, carrying out first fire rolling, and carrying out water cooling to obtain a first hot-rolled plate blank; 2, conducting second fire hot rolling to obtain a second hot rolled plate blank; 3, carrying out intermediate recrystallization annealing treatment; 4, conducting third hot rolling to obtain a thirdhot-rolled plate blank; and 5, conducting finished product annealing treatment to obtain the titanium alloy plate blank with the thickness ranging from 4 mm to 12 mm. The low-cost titanium alloy short-process rolling process has the advantages that the operation is easy; the process is stable and controllable; and the slab ingot obtained through an electron beam cold bed furnace smelting method is directly subjected to hot rolling, so that the ingot casting blank making heating number is avoided, the cost is reduced, and meanwhile, the related index requirements of the titanium alloy are met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Low-alloyed high-performance superplastic magnesium alloy and preparation method thereof

The invention provides a low-alloyed high-performance superplastic magnesium alloy and a preparation method thereof. The chemical components of the low-alloyed high-performance superplastic magnesiumalloy comprises, by mass, 0.5-2.5% of zinc, 0.05-1.0% of argentum, 0.05-1.0% of calcium, 0.05-1.0% of zirconium and the balance magnesium. The gross of mass percent of the chemical components of alloyelements except magnesium is less than 3%. The preparation method for the low-alloyed high-performance superplastic magnesium alloy comprises four steps of gradient-temperature smelting, accurate andrapid solidifying, rolling technology and recrystallization treatment. According to the low-alloyed high-performance superplastic magnesium alloy and the preparation method thereof, a traditional superplastic magnesium alloy design principle is broken through; through combination of a multi-element small-amount alloy component design principle, an accurate and rapid solidifying method and the rolling technology, the superplastic magnesium alloy which is characterized by having low-alloyed high performance and being short in process and low in cost and the preparation method thereof are acquired; the tensile strength of larger than 300 MPa can be acquired by the alloy with components optimized; the elongation rate is larger than 15%; room-temperature performance is outstanding; and in addition, the alloy with components optimized has superplasticity, the elongation rate at the temperature of 300 DEG C is 300%, and the elongation rate at the temperature of 250 DEG C is 250%.

Owner:JILIN UNIV

Controlled rolling method implemented by stably controlling low-temperature toughness of large-wall-thickness pipeline steel

The invention discloses a controlled rolling method implemented by stably controlling the low-temperature toughness of large-wall-thickness pipeline steel, which belongs to the technical field of low-carbon micro-alloyed steel production. Rolling is divided into two stages, i.e. rough rolling and finish rolling, after the penultimate-pass rolling of the rough rolling is completed, when the temperature of a steel billet is reduced to 975-990 DEG C, the finish-pass rolling of the rough rolling is performed, and the finish-pass rolling is replaced with a rapid and consecutive two-pass rolling mode, the deformation rates of the two passes are respectively controlled at 16-21%, and the time interval of the two passes is controlled at 4-8s so as to ensure that the superimposed deformation ratio of the two passes reaches 32-42%; and a situation that the percentage pass reduction of the two-stage rolling process is arranged in an approximately normal distribution mode is required to be ensured. The controlled rolling method has the advantages that by using the method, the good low-temperature toughness of large-wall-thickness pipeline steel can be stably controlled; charpy impact toughness: when the temperature is minus 20 DEG C, the charpy impact energy of a V-shaped notched specimen, of which the core part in the thickness direction is 10*10*55 mmV, of a steel plate is greater than or equal to 354J; and drop weight toughness: when the temperature is minus 15 DEG C, the drop weight shear area of an all-wall-thickness specimen is greater than or equal to 85%.

Owner:SHOUGANG CORPORATION

Rolling preparation method for high-silicon electrical steel thin strip

ActiveCN105598164ABright and smooth surfaceReduce orderMetal rolling arrangementsElectrical steelMetallic materials

The invention mainly belongs to the field of metal material preparation and machining and particularly relates to a rolling preparation method for a high-silicon electrical steel thin strip. The method comprises the steps of firstly, taking a high-silicon electrical steel casting blank heated in a furnace as the raw material, so that a high-silicon electrical steel plate slab is prepared and obtained, then conducting warm rolling on the high-silicon electrical steel plate slab in a stepwise-cooling mode, so that a high-silicon electrical steel warm-rolled strip is obtained, and conducting low temperature annealing and cold rolling on the high-silicon electrical steel warm-rolled strip, so that the high-silicon electrical steel thin strip is prepared and obtained. According to the rolling preparation method for the high-silicon electrical steel thin strip, warm rolling in a stepwise-cooling mode is adopted, the accumulated maximum warm rolling deflection is not influenced, meanwhile, the rolling temperature can be lowered, and a better toughening and plasticizing effect is obtained; after warm rolling is completed, annealing is conducted in the proper condition, residual tension of sides of the high-silicon electrical steel warm-rolled strip is effectively lowered, meanwhile, restoration of the ordered structure is avoided, and the cold rolling yield is raised.

Owner:UNIV OF SCI & TECH BEIJING

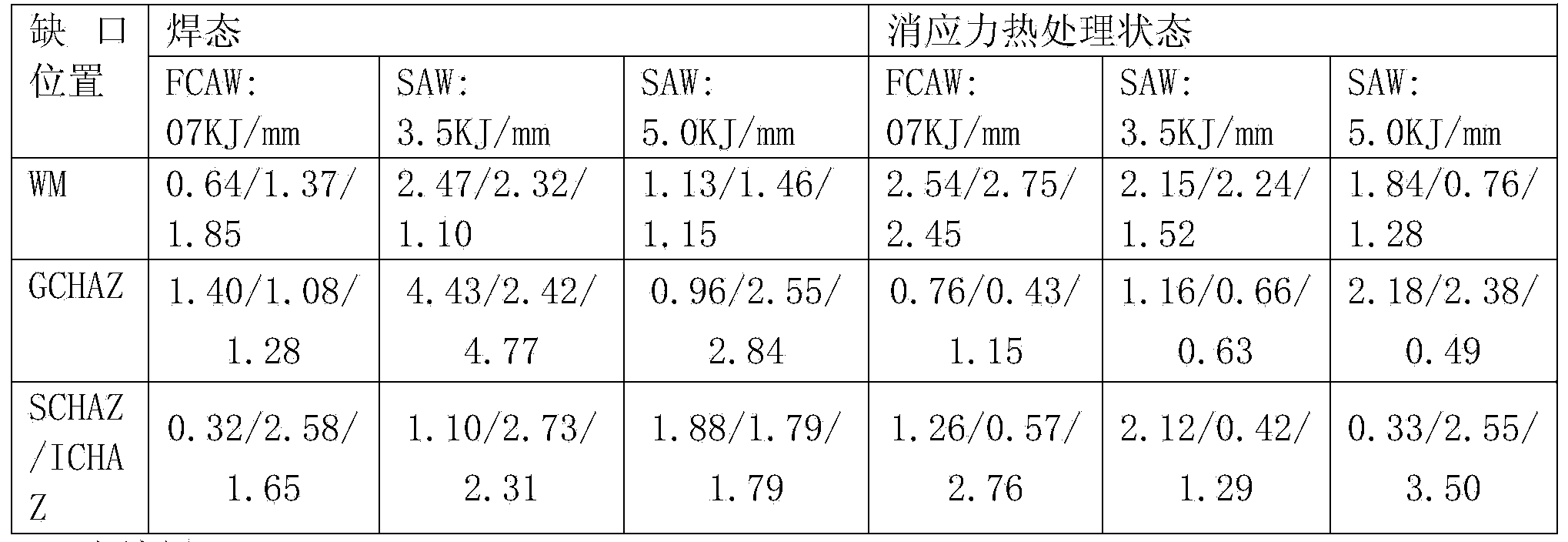

50-75 mm-thick 355MPa-grade fracture toughness protecting steel and production method thereof

InactiveCN104264050AAchieve recrystallization refinementGuaranteed low temperature impact performanceHigh fractureCrack tip opening displacement

The invention belongs to the technical field of steel and iron material production and particularly relates to 50-75 mm-thick 355MPa-grade fracture toughness protecting steel and a production method thereof. The 50-75 mm-thick 355MPa-grade fracture toughness protecting steel comprises the following chemical components in percentage by weight: 0.04-0.13 percent of C, 0.2-0.5 percent of Si, 1.0-1.6 percent of Mn, less than 0.018 percent of P, less than 0.005 percent of S, 0.3-0.7 percent of Ni, 0.02-0.05 percent of Nb, 0.02-0.04 percent of V, 0.08-0.020 percent of Ti and the balance of Fe and inevitable impurities. The 50-75 mm-thick 355MPa-grade fracture toughness protecting steel and the production method thereof have the benefits that the fracture toughness protecting steel is low in cost, is easy to weld and can reach 75 mm thickness under the condition of realizing 355MPa-grade high toughness of the steel; the CTOD (Crack Tip Opening Displacement) characteristic value of a welded joint at a temperature of 10 DEG C blew zero can be ensured, and the fracture toughness protecting steel with high strength, high toughness and high fracture toughness is realized under the condition of low carbon content.

Owner:SHANDONG IRON & STEEL CO LTD

Method for improving thick-specification L555M level pipeline steel DWTT property

The invention relates to the technical field of pipeline steel pipe production, in particular to a method for improving the thick-specification L555M level pipeline steel DWTT property. The method comprises the steps that firstly, the heating temperature is limited at 1200 to 1250 DEG C, the temperature of a soaking zone is limited at 1190 to 1230 DEG C, the heating main time is limited at 270 to330 minutes, the high-temperature segment time is limited at 120 to 180 minutes, and it is ensured that the tapping temperature is above 1200 DEG C; secondly, the transverse-longitudinal rolling manner is adopted in rough rolling, transverse rolling is carried out for four to six passes, longitudinal rolling is carried out 2 to 4 passes, the initial rolling temperature is not lower than 1150 DEG C, after transverse rolling, after the temperature is 1040 to 1080 DEG C, longitudinal rolling is carried out, meanwhile, it is ensured that the longitudinal rolling accumulative reduction rate is above 55%, the longitudinal rolling single-pass reduction rate is limited as 20%, and the intermediate blank thickness is 80 to 90 mm; thirdly, the initial rolling temperature is 780 to 850 DEG C, the finish rolling and final rolling temperature is 750 to 800 DEG C, and after rolling, the water inlet temperature is 790 to 810 DEG C; and fourthly, the controlled cooling mode is adopted, the water feeding amount is 400 to 500 m<3> / h, the water discharging amount is 1300 to 1400 m<3> / h, 12 to 15 sets are initially rolled, the water ratio is 1 / 3, the cooling speed is 10 to 20 DEG C / s, and it is ensured that the return red temperature is 420 to 480 DEG C. The thick-specification L555M level low-temperature DWTT property is improved, and the property yield is improved.

Owner:ANGANG STEEL CO LTD

Method for manufacturing difficult-to-deform tin-bismuth alloy pre-formed soldering lug

ActiveCN109513747AImprove deformationGuaranteed normal processingMetal rolling arrangementsLow speedMaterial Crack

The invention discloses a method for manufacturing a difficult-to-deform tin-bismuth alloy pre-formed soldering lug. The method is characterized in that a core process adopts a two-section type temperature-regulating variable-speed and turning calendaring process, namely low-temperature high-speed large-rolling-reduction rough rolling and high-temperature low-speed small-rolling-reduction fine rolling; a temperature, speed and a rolling direction in a calendaring process are controlled, and other processes comprising low-temperature smelting, residual stress relief hot-levelling, rolling, cutting and the like are combined, so that high-efficiency manufacturing for the difficult-to-deform tin-bismuth alloy pre-formed soldering lug is realized. The manufacturing process for the pre-formed soldering lug can effectively solve the problems that a tin-bismuth alloy with intrinsic brittleness and difficult-to-deform characteristic easily generates material crack and the like in a large-deformation-amount processing process, and total deformation amount of the alloy can be 98% or more. The process is simple in flow, can greatly improve production efficiency of a tin-bismuth pre-formed lug,and reduces production energy consumption.

Owner:SHENZHEN XINGHONGTAI TIN +1

A 550mpa grade low compression ratio high toughness ocean engineering platform steel plate and production method

The invention belongs to the technical field of steel materials, and relates to a 550 MPa-grade low-compression-ratio high-toughness steel plate for an ocean engineering platform and a production method, in particular to a steel plate with high strength and toughness under conditions of the low carbon content and the low compression ratio for ocean engineering and the production method. The steel plate comprises chemical components in percentage by weight as follows: 0.04-0.10% of C, 0.2-0.4% of Si, 1.0-1.5% of Mn, smaller than 0.010% of P, smaller than 0.003% of S, 0.5-0.8% of Ni, 0.2-0.5% of Cu, 0.30-0.80% of Cr, 0.1-0.3% of Mo, 0.02-0.05% of Nb, 0.010-0.025% of Ti and the balance of Fe and inevitable impurities. The alloy C is low in content, and welding is easy. Under the condition that the thickness of a casting blank is only 250 mm, the content of the C, the P and the S is controlled strictly, the temperature is decreased and then increased, the TMCP process is optimized, the rolling temperature is decreased, the reduction at rough rolling and finish rolling stages is distributed reasonably, the cooling process and the tempering heat treatment temperature are optimized, and steel can have high strength and high low-temperature toughness under the condition of the low compression ratio (the minimum is only 3.125:1).

Owner:SHANDONG IRON & STEEL CO LTD

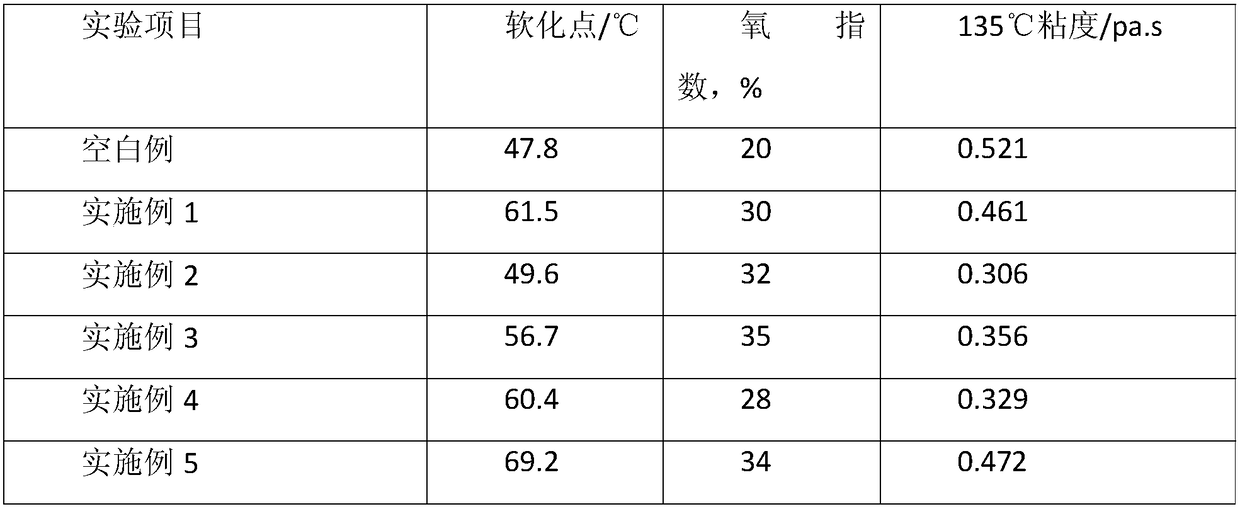

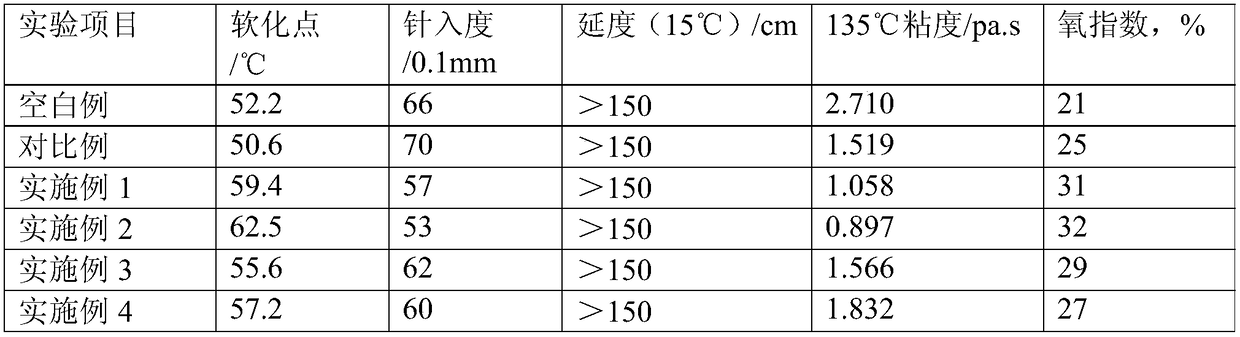

Asphalt flame-retardant viscosity reducer and preparation method thereof

The invention relates to an asphalt flame-retardant viscosity reducer and a preparation method thereof. The asphalt flame-retardant viscosity reducer comprises the following substances in parts by mass: 0.5-3 parts of a flame-retardant additive, 1-15 parts of a smoke-suppression additive and 2-4 parts of a fatty acid. The asphalt flame-retardant viscosity reducer has a flame-retardant effect and can effectively reduce the asphalt viscosity, so that the asphalt flame-retardant viscosity reducer is capable of reducing mixing, laying and rolling temperatures of an asphalt mixture, reducing the construction temperature, reducing emission of harmful gas such as asphalt flue gas and smoke dust and the like during the construction, solving the problems of environment pollution, large energy consumption, asphalt ageing decline, etc., and protecting the health of constructors. At the same time, the softening point of the asphalt is relatively high, so that the high-temperature stability of theasphalt can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

Method for improving low-temperature DWTT performance of X70M pipeline steel

ActiveCN113118209AHeating evenlyReduce rolling temperatureTemperature control deviceWork cooling devicesSteel tubeAutomatic control

The invention relates to the technical field of pipeline steel pipe production, in particular to a method for improving the low-temperature DWTT performance of X70M pipeline steel. The method comprises the steps that (1) the heating time and the high-temperature section temperature are limited; (2) rough rolling is conducted in a transverse-longitudinal rolling mode; (3) for a blank smaller than or equal to 250 mm, the thickness of an intermediate blank is 3.0-3.3 times of the thickness of a finished product, and for a blank larger than 250-300 mm, the thickness of the intermediate blank is 4.2-4.5 times of the thickness of the finished product; for the blank smaller than or equal to 250 mm, the number of longitudinal rolling loaded passes is controlled to be 2-4, and the pass reduction rate is larger than or equal to 15%; for the blank larger than 250-300 mm, the number of longitudinal rolling loaded passes is controlled to be 3-5, and the pass reduction rate is larger than or equal to 20%; (4) in the finish rolling stage, the initial rolling temperature ranges from 840 DEG C to 880 DEG C, and the finish rolling temperature ranges from 780 DEG C to 820 DEG C; (5) a semi-automatic controlled cooling mode is adopted, the water feeding amount is 200-500 m<3> / h, and the water discharging amount is 1000-1500 m<3> / h; and (6) one-pass straightening is adopted in the straightening stage. The low-temperature DWTT performance of the X70M pipeline steel is improved, and the performance qualification rate is increased; and performance differences caused by the fact that blanks with different thickness specifications are used for rolling pipeline steel with the same thickness specification without considering the influence of the thickness of the intermediate blank are avoided.

Owner:ANGANG STEEL CO LTD

Flame-retardant low-viscosity rubber asphalt and preparation method thereof

ActiveCN108659554AHigh softening pointGood swelling effectBuilding insulationsRubberized asphaltPetroleum

The invention belongs to the technical field of petroleum asphalt, and particularly relates to flame-retardant low-viscosity rubber asphalt and a preparation method thereof. The flame-retardant low-viscosity rubber asphalt is prepared from the following raw materials in parts by mass: 100 parts of matrix asphalt, 0.5-3 parts of rubber powder, 0.5-10 parts of chlorinated paraffin, 1-10 parts of a swelling agent, 0.5-3 parts of polyethylene, and 1-5 parts of stearic acid substances. The flame-retardant low-viscosity rubber asphalt and preparation method provided by the invention effectively reduce a flame-retardant oxygen index of rubber asphalt and mixing, paving and rolling temperature of a mixture, and overcome the problems of environmental pollution, large energy consumption and asphaltaging; and the preparation method provided by the invention is simple and easy to implement and realize.

Owner:CHINA PETROLEUM & CHEM CORP

A rolling preparation method of high-silicon electrical steel thin strip

ActiveCN105598164BFlat surfaceReduce orderMetal rolling arrangementsMaterials preparationSheet steel

Owner:UNIV OF SCI & TECH BEIJING

A method for manufacturing high-strength thin strip steel for cold forming

ActiveCN103667895BTo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideYield ratio

The invention relates to high-strength thin strip steel for cold forming and a manufacturing method thereof. The manufacturing method comprises the following steps: performing uniform enhanced cooling on a cast strip by adopting a high-pressure dry ice spraying way after the cast strip is discharged from a crystallization roller, thus rapidly cooling the cast strip to below 1280 DEG C, wherein the cooling rate is 200-300 DEG C / s, and by adopting the cooling way of the strip steel after boron treatment, the precipitation of coarse BN (boron nitride) can be promoted, the appearance of low-melting point phase B2O3 and the precipitation of fine AlN can be prevented and the purposes of uniformizing austenite grains and reducing yield ratio are achieved; then performing austenite online recrystallization rolling; cooling the strip steel after hot rolling by atomization cooling, wherein the cooling rate of atomization cooling is 10-70 DEG C / s; coiling at the temperature of 650-750 DEG C. Through the manufacturing method provided by the invention, the high-strength thin strip steel for cold forming of an automobile, which has relatively low yield ratio and excellent stamping performance, can be obtained. The high-strength hot-rolled thin strip steel for cold forming, which is produced by the method, can be directly used for replacing cold-rolled steel with the hot-rolled steel, cancel a cold rolling process step and greatly reduce production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength thin band steel for cold forming and manufacturing method thereof

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin strip steel for thin-walled oil barrel and manufacturing method thereof

The invention discloses a steel strip for a thin-wall oil bucket and a manufacturing method thereof. The manufacturing method comprises the following steps: casting a crystal roller from a cast strip by using a thin strip casting process, subsequently uniformly reinforcing and cooling the cast strip in a mode that dry ice is sprayed at a high pressure, and rapidly cooling the cast strip to be less than 1,280 DEG C, wherein the cooling velocity is 200-300 DEG C / s; when the steel strip is subjected to boron treatment in such a mode, large boron nitride separation is prompted, occurrence of low-melting-point phase B2O3 and separation of fine AlN are prevented, and the purposes of uniformly austenite grains and reducing the yield ratio are achieved; subsequently performing on-line recrystallization and rolling on the austenite; subsequently atomizing and cooling so as to cool down the hot-rolled steel strip; finally coiling the steel strip. By adopting the manufacturing method, the thin-wall with low yield ratio and excellent stamping property for the thin-wall oil bucket is manufactured. The hot-rolled steel strip for the thin-wall oil bucket can be used in hotness instead of coldness, and a cold-rolling procedure is omitted, so that the production cost is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

A large reduction rolling method of magnesium alloy

ActiveCN103962376BSimple processReliable workmanshipAuxillary arrangementsMetal rolling arrangementsThermal insulationManganese

The invention relates to a large reduction rolling method for magnesium alloy. According to the rolling method, a hard alloy lining plate is additionally arranged on the upper surface or the lower surface of the magnesium alloy, or two hard alloy lining plates are additionally arranged on the upper surface and the lower surface of the magnesium alloy at the same time, and the added hard alloy lining plates are rolled synchronously together with the magnesium alloy. The rolling method includes the steps that after a high temperature lubricating agent is evenly smeared on the surfaces of the lining plates and the surface of the magnesium alloy, the high temperature lubricating agent, the lining plates and the magnesium alloy are simultaneously placed into a heating box to be heated, after the temperature rises to a preset temperature, standing and thermal insulation are performed for a certain period of time, one hard alloy lining plate is placed on the upper surface or the lower surface of magnesium alloy blank, or the two hard alloy lining plates are placed on the upper surface and the lower surface of the magnesium alloy at the same time, and the hard alloy lining plates and the magnesium alloy are simultaneously fed into the position between rollers so that rolling can be completed. Through the method, the single pass reduction of the magnesium alloy can be greatly increased in the rolling process, the number of rolling passes is decreased, magnesium alloy crystalline grains are thinned, the texture is weakened, magnesium alloy plates with high strength and plasticity are prepared, and the large reduction rolling method for the magnesium alloy is also suitable for the large deformation rolling process of titanium, manganese and metal-matrix composite materials.

Owner:JILIN UNIV

A kind of preparation method of recycled gh4169 alloy cold drawn bar

The invention discloses a preparation method for recycling GH4169 alloy cold-drawn rods, which comprises the following steps: A. using a billet cutting machine to perform rolling and billeting of a Φ160mm GH4169 alloy steel rolling billet; B. using a billet cutting machine to The steel slab treated in step A is subjected to secondary rolling; C, solution annealing; D, surface polishing treatment after solution; E, cold drawing. The invention can improve the deficiencies of the prior art and improve the strength performance of the material.

Owner:AVIC SHANGDA METAL REGENERATION TECH

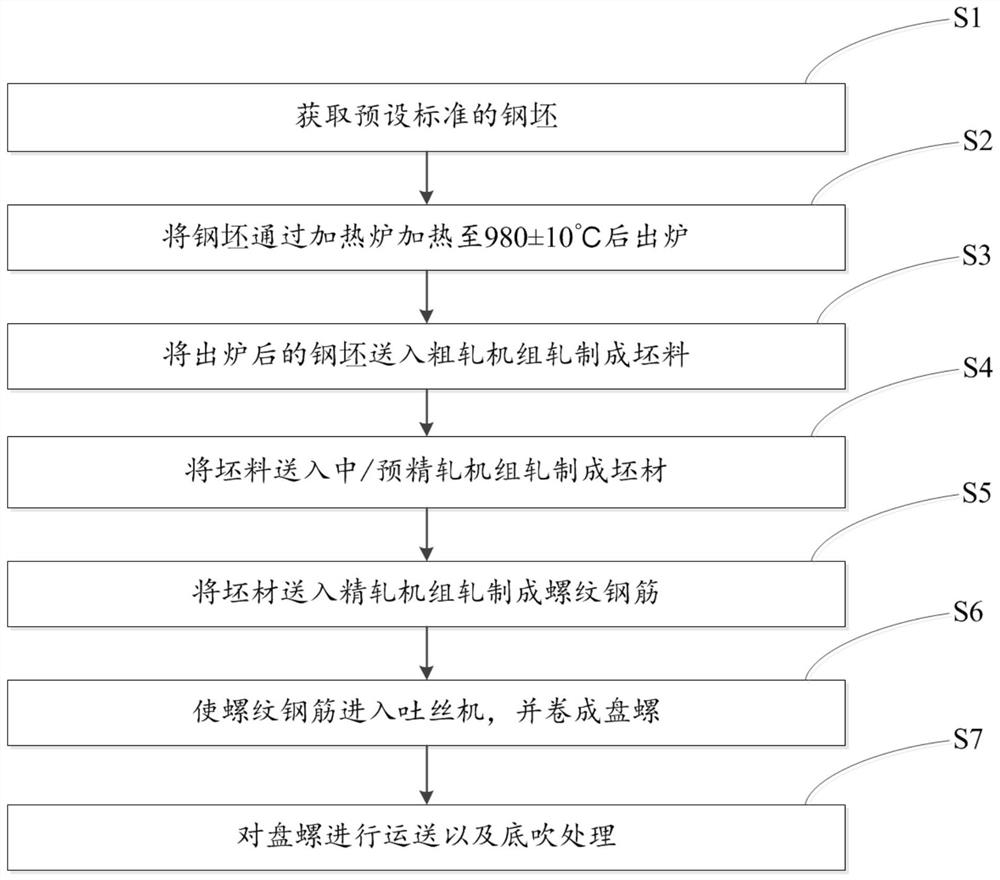

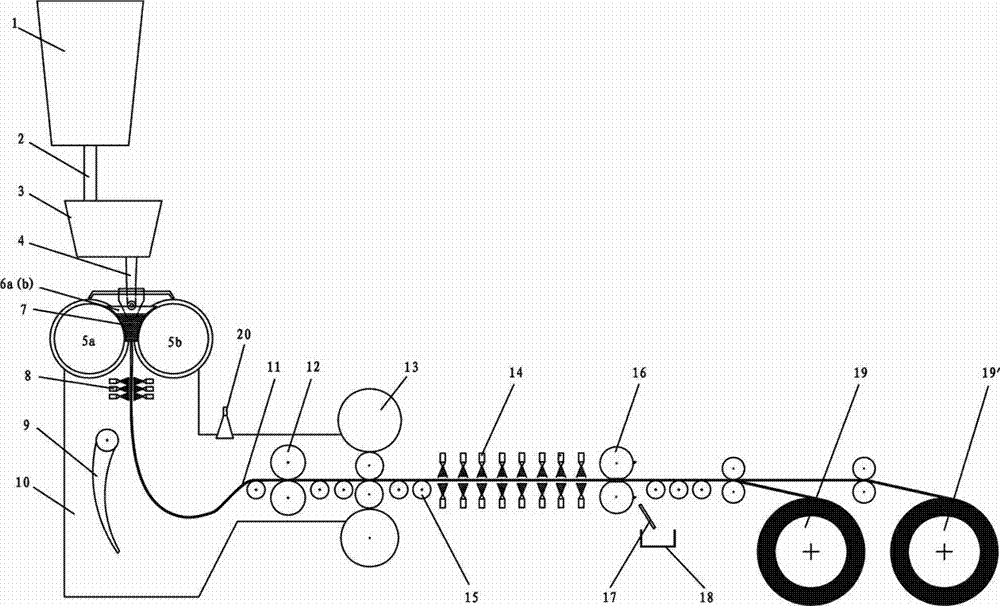

Rolling method for high-strength coiled screw

PendingCN112547796AHigh strengthLow costRoll force/gap control deviceTemperature control deviceEngineeringUltimate tensile strength

The invention provides a rolling method for a high-strength coiled screw. The rolling method comprises the steps that billet steel is heated to (980+ / -10) DEG C; the billet steel is fed into a roughing mill set to be rolled into a billet, the rolling force of mills in the roughing mill set is increased, and the rolling temperature is reduced; the temperature of the billet is controlled to be 980-990 DEG C after the billet passes through the roughing mill set; the billet is fed into a medium / pre-finishing mill set to be rolled into a blank, the temperature of the blank after rolling is controlled to be (990+ / -10) DEG C, and the temperature of the blank is adjusted to be (860+ / -10) DEG C; the blank is fed into the finishing mill set to be rolled into twisted steel, and the rolling temperature of a tail rack of the finishing mill set is adjusted to be (950+ / -10) DEG C; the temperature of the twisted steel rolled from the tail rack of the finishing mill set is adjusted to be (860+ / -10) DEGC; and the twisted steel discharged from a laying head is rolled into the coiled screw, the temperature is adjusted to (930+ / -10) DEG C, and the coiled screw is conveyed to a roller way to be subjected to bottom blowing. By means of the rolling method, the cost is low, the environment is not polluted,the production efficiency is high, and the steel strength of the coiled screw can be improved.

Owner:冷水江钢铁有限责任公司

A method for preparing a hard-to-deform tin-bismuth alloy solder preform

ActiveCN109513747BImprove deformationGuaranteed normal processingMetal rolling arrangementsMaterial CrackAlloy

The invention discloses a method for manufacturing a difficult-to-deform tin-bismuth alloy pre-formed soldering lug. The method is characterized in that a core process adopts a two-section type temperature-regulating variable-speed and turning calendaring process, namely low-temperature high-speed large-rolling-reduction rough rolling and high-temperature low-speed small-rolling-reduction fine rolling; a temperature, speed and a rolling direction in a calendaring process are controlled, and other processes comprising low-temperature smelting, residual stress relief hot-levelling, rolling, cutting and the like are combined, so that high-efficiency manufacturing for the difficult-to-deform tin-bismuth alloy pre-formed soldering lug is realized. The manufacturing process for the pre-formed soldering lug can effectively solve the problems that a tin-bismuth alloy with intrinsic brittleness and difficult-to-deform characteristic easily generates material crack and the like in a large-deformation-amount processing process, and total deformation amount of the alloy can be 98% or more. The process is simple in flow, can greatly improve production efficiency of a tin-bismuth pre-formed lug,and reduces production energy consumption.

Owner:SHENZHEN XINGHONGTAI TIN +1

Thin strip steel for thin-wall oil drum and manufacturing method of thin strip steel

ActiveCN102796943BTo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com