Rolling method for high-strength coiled screw

A high-strength, screw-on technology, used in temperature control, metal rolling, rolling force/roll gap control, etc., can solve the problems of low production efficiency, environmental pollution, and high cost, and achieve high production efficiency and environmental pollution. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

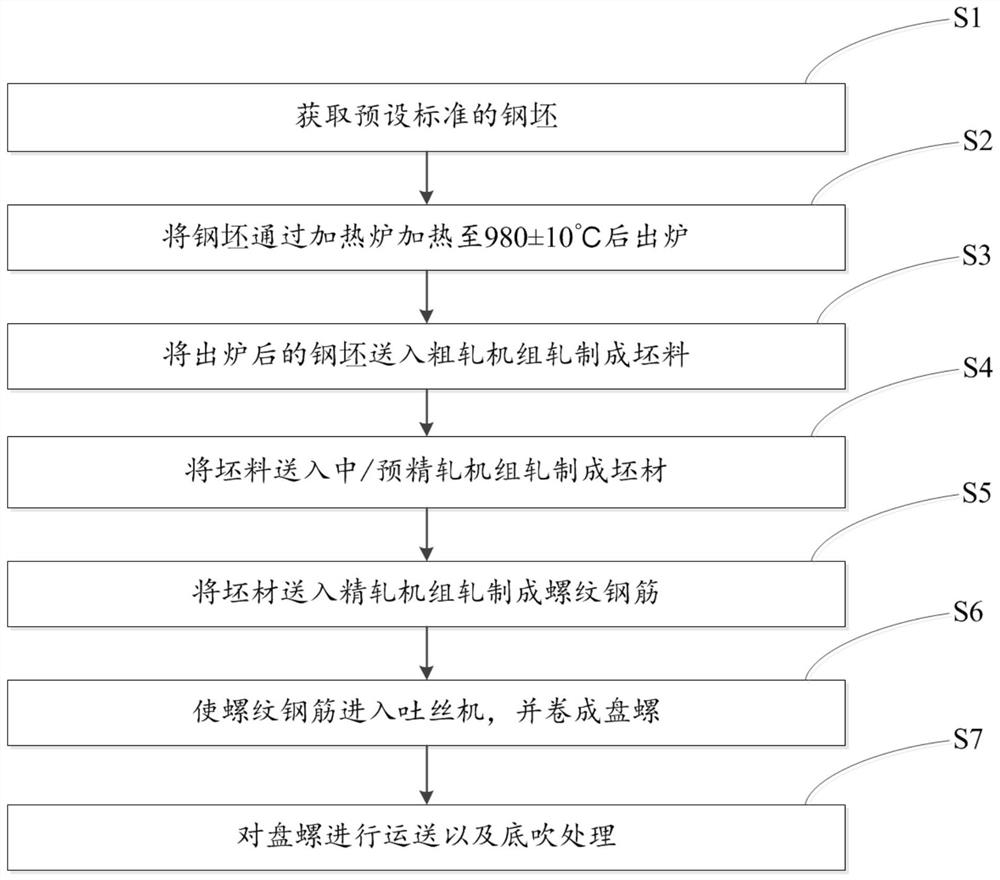

Image

Examples

Embodiment 1

[0052] A billet of preset standard is obtained through continuous casting of molten steel, and the billet of preset standard is 170×170mm 2 billet, heating the billet in a heating furnace to raise the temperature of the billet, and taking the billet out of the furnace when the temperature of the billet is 980±10°C;

[0053] The steel slab after being heated and released from the furnace is sent to the rough rolling mill to be rolled into a billet according to pass types K28, K27, K26, K25, K24 and K23. K28, K27, K26, K25, K24 and K23 stands are controlled, so that when the billet is rolled by the rough rolling group, the rolling force of the rolling mill in the rough rolling group is increased, and the rolling temperature is reduced, The relationship between the two is to increase the rolling force by 15% for each stand of the rolling mill and reduce the rolling temperature by 30-40°C.

[0054] After the billet passes through the rough rolling unit, a section of water cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com