A kind of preparation method of recycled gh4169 alloy cold drawn bar

A technology of GH4169 and cold-drawn rods, which is applied in the field of preparation of recycled GH4169 alloy cold-drawn rods, can solve problems such as unsatisfactory, and achieve the effects of reducing growth, reducing adjustment time, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

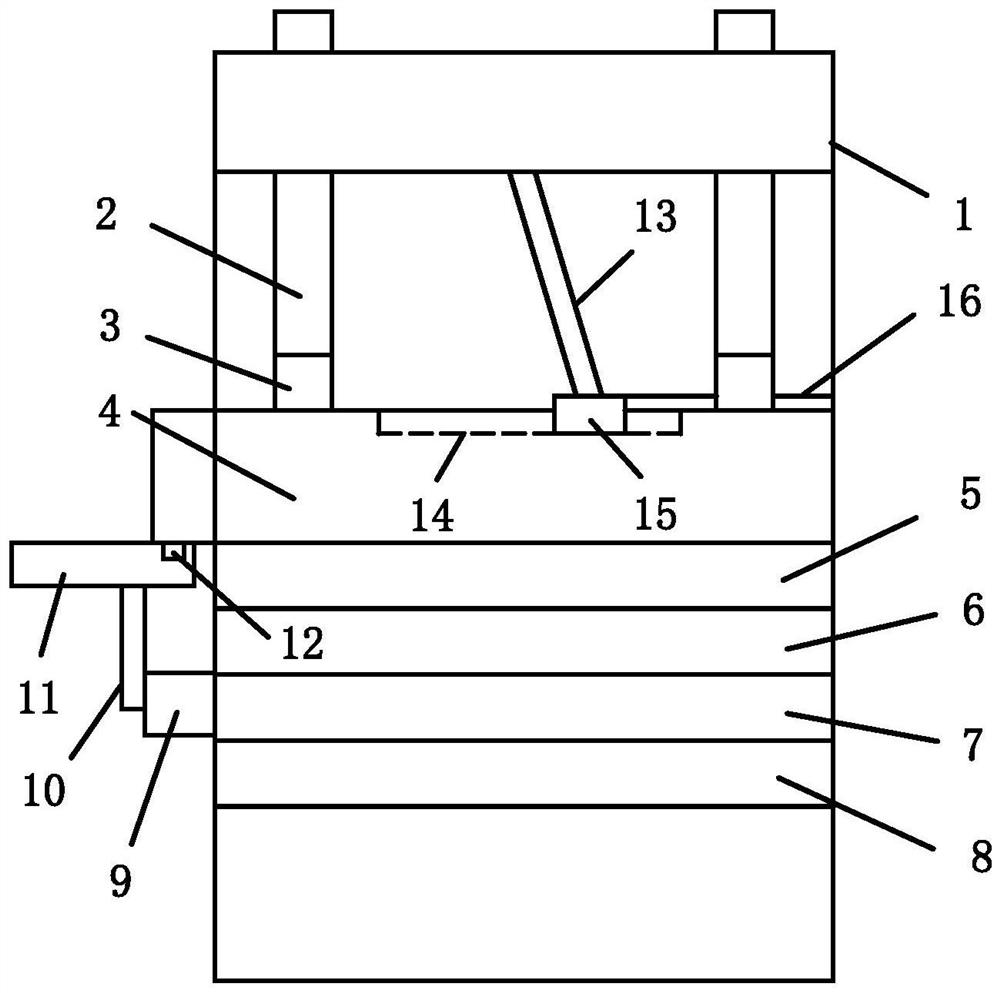

[0023] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, will not be described in detail here.

[0024] A preparation method for recycling GH4169 alloy cold-drawn rods, comprising the following steps:

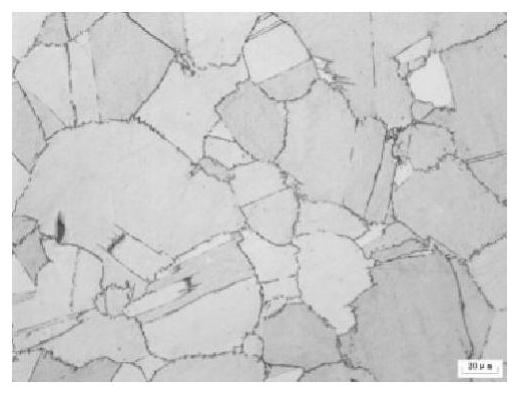

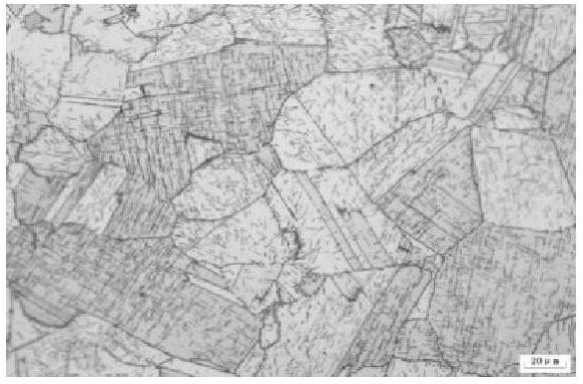

[0025] A. Use the blanking machine to roll the GH4169 alloy steel billet of Φ160mm once; the heating temperature is 1090°C, and the billet is opened to a 58mm billet; the Φ160mmGH4169 alloy steel billet contains 70% recycled materials; the surface is polished after billeting deal with;

[0026] B. Use the blanking machine to carry out secondary rolling and blanking of the steel billet processed in step A; the heating temperature is 1010°C, the rolling deformation is 75%, water cooling within 1 minute af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com