Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce outbound volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

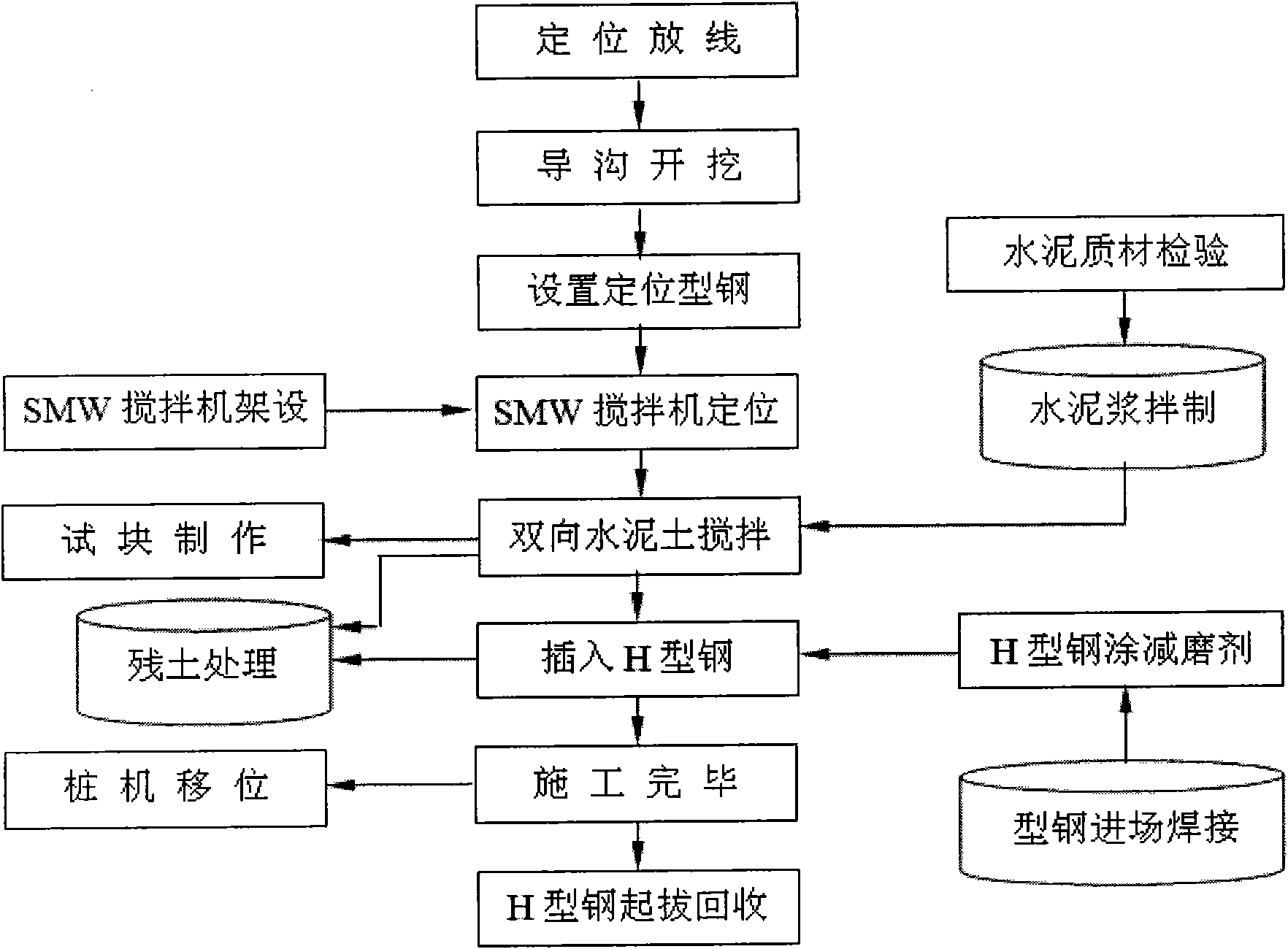

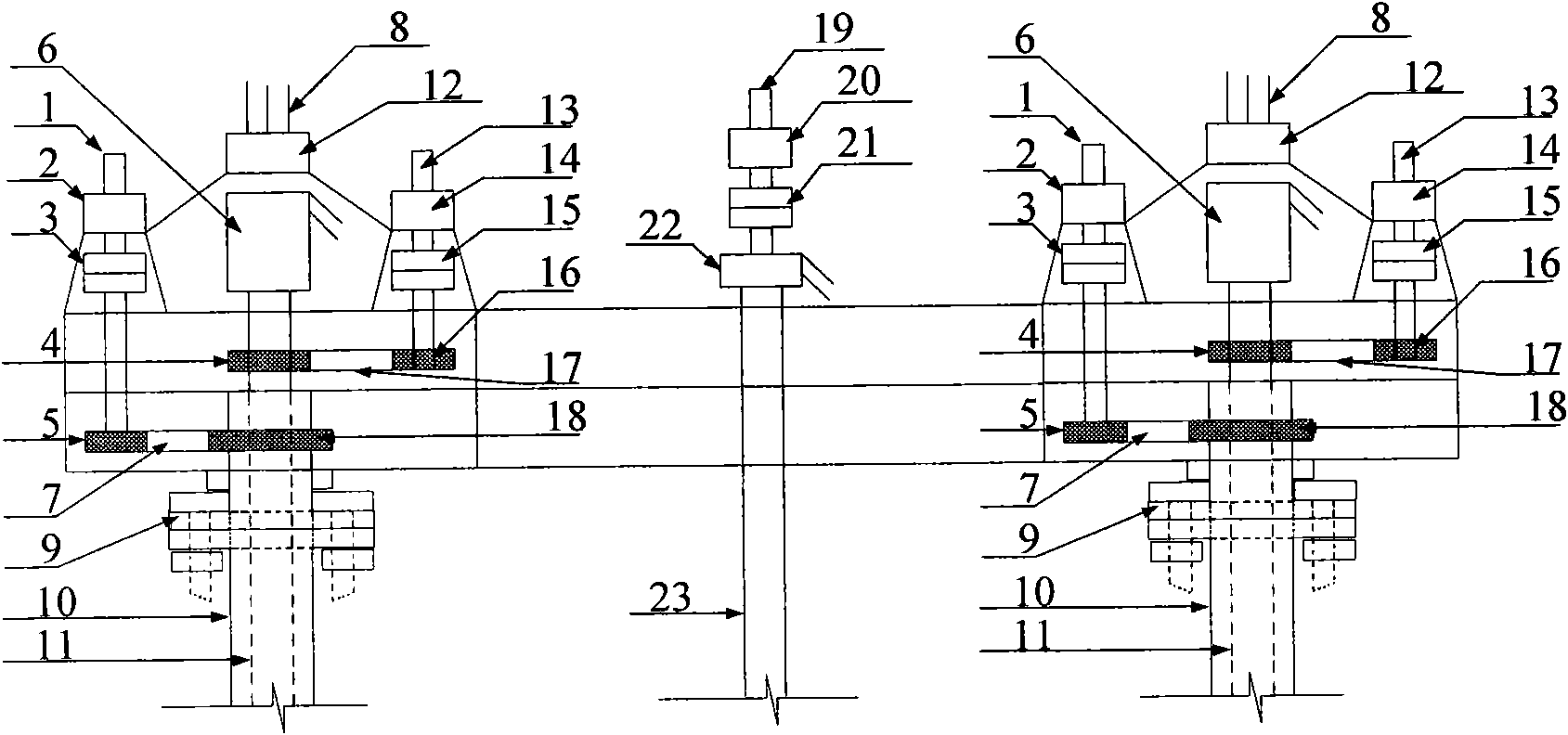

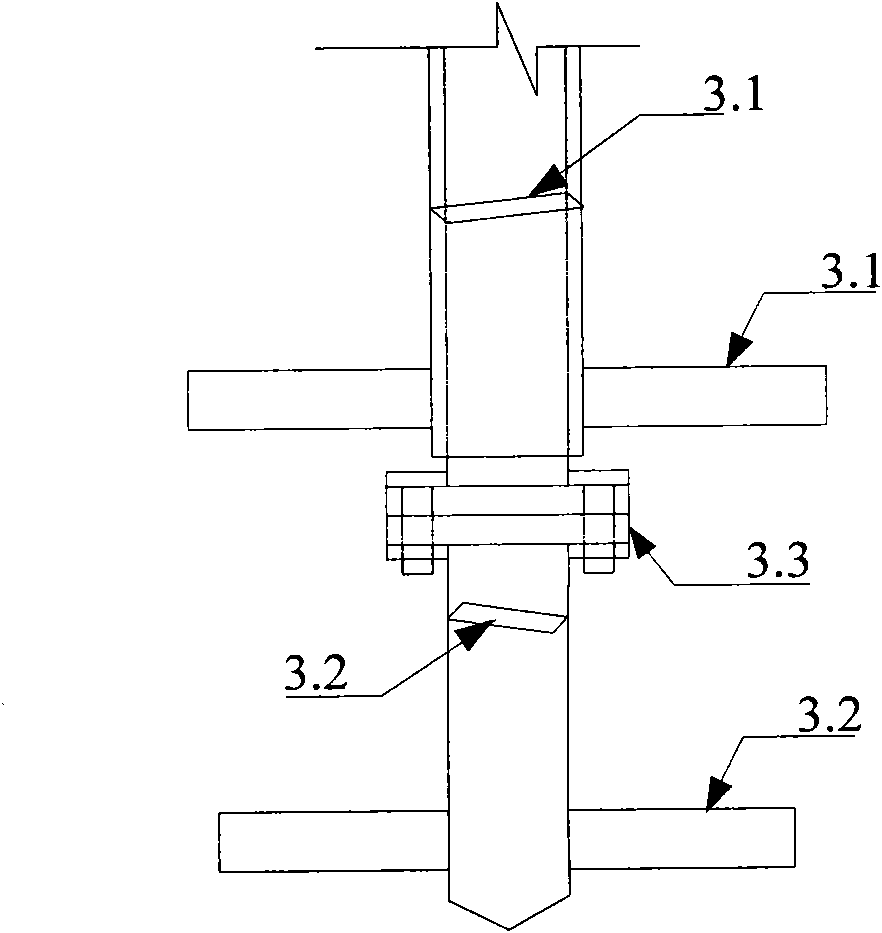

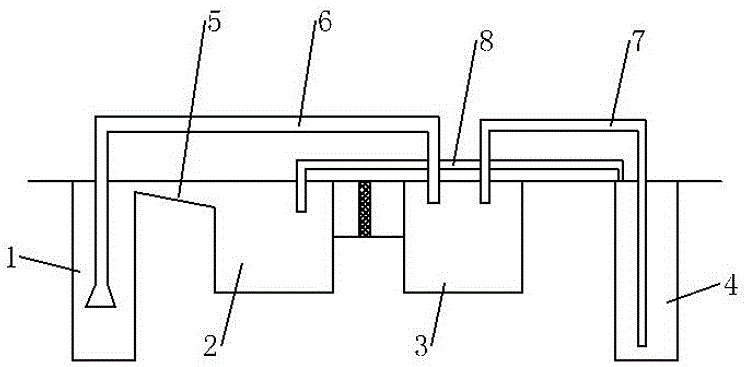

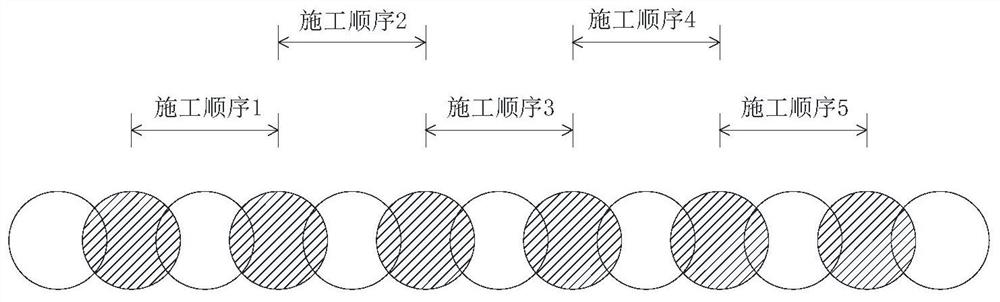

Two-way stirring based SMW construction method and tri-axial stirring equipment

InactiveCN101864765AReduce outbound volumeNo noiseBulkheads/pilesDrilling machinesPetroleum engineering

The invention relates to a two-way stirring based SMW construction method, comprising the following steps: 1) measurement and staking-out; 2) making a guide slot; 3) drilling machine stationing and drilling; 4) completion. The invention further relates to tri-axial stirring equipment for realizing the construction method; the equipment comprises a chassis, a rack, a power box body and three drilling rods; the rack is arranged on the chassis, the power box body is connected at the upper ends of the three drilling rods and drives the three drilling rods respectively; the bottom end of each drilling rod is provided with a drilling bit, the axle centers of the three drilling rods are arranged at the same straight line, and stirring drilling rods at two side shafts are two-way stirring drilling rods, the stirring drilling rod of a middle shaft is a one-way stirring drilling rod, and the middle shaft is provided with a compressed air pipe; the stirring drilling rods at two side shafts comprise an inner drilling rod and an outer drilling rod, and at least two groups of stirring blades are respectively arranged on the inner drilling rod and the outer drilling rod, and the stirring blades are sequentially arranged axially along the drilling rod; and the rotating directions of the inner and outer drilling rods are opposite. Compared with the prior art, the total construction time of the technical proposal can be shortened half, the construction cost of the SMW construction method is low, and environmental-protection requirements are met.

Owner:SOUTHEAST UNIV +1

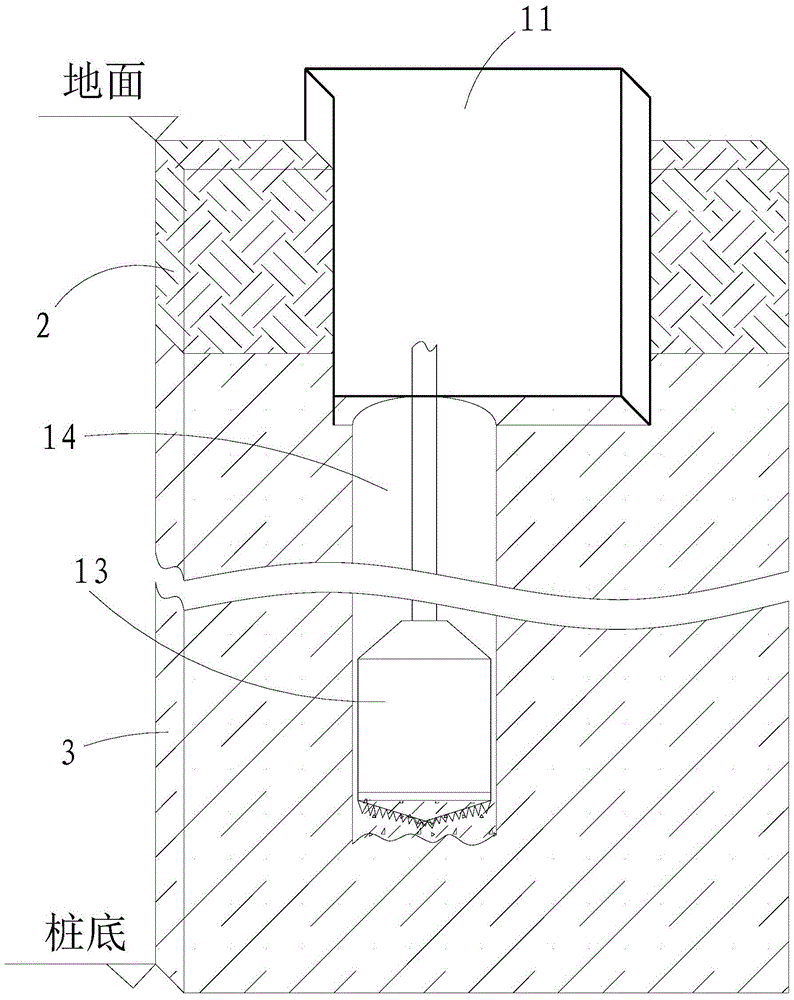

Forming method for square pile hole

InactiveCN105649011AFast molding speedQuality assuranceBulkheads/pilesDrilling machines and methodsResidual soilsDrill bit

The invention relates to the technical field of square pile holes, and discloses a forming method for a square pile hole. The forming method comprises the following construction methods that 1, trepanning is carried out, a square pile casing is put downwards, the lower end of the square pile casing penetrates a fill stratum and extends into a residual soil layer, and the upper end of the square pile casing extends out of the ground; 2, a round drill bit is utilized for carrying out hole guiding many times, a plurality of round holes are formed, the diameter of the round drill bit is consistent with the width of the square pile hole, the multiple round holes are sequentially connected in rows in the length direction of the square pile hole, and the extending length is consistent with the length of the square pile hole; and 3, a square drill bit is utilized for carrying out drilling from top to bottom, and the square pile hole is formed. The forming method for the square pile hole has the following beneficial effects that the forming speed of the square pile hole is high; the quality of the square pile hole is guaranteed; the construction cost is low, the construction speed is high, the single-machine comprehensive efficiency is high, and the mechanical construction cost is relatively low; and the construction site is clean, and field management is simplified.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

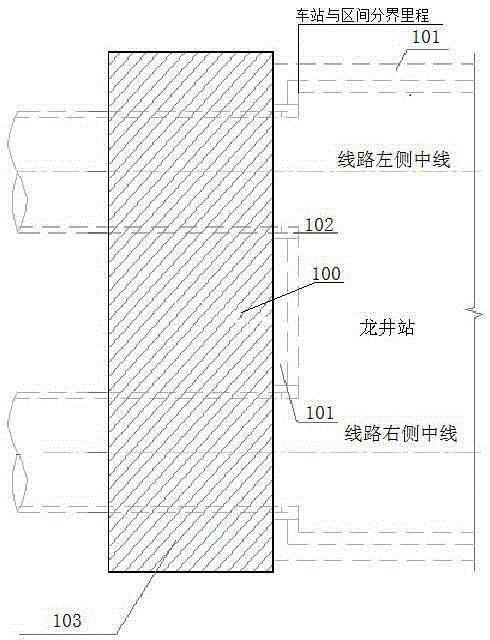

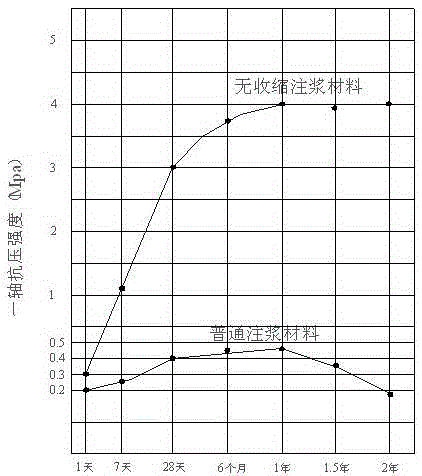

Application of WSS construction method in shield end reinforcement of water-rich sand layer

InactiveCN105971637AWide formation adaptabilitySpecial soil consolidation effectUnderground chambersDrainageSlurryEngineering

The invention provides an application of a WSS construction method in shield tool changing reinforcement of a water-rich sand layer. A WSS construction method grouting technology is characterized in that an underground drill rig is used for deep- hole grouting and reinforcement and solution-type grout composed of a solution A and a solution B is used firstly for back grouting and soil body drainage, so that soil body impermeability can be enhanced; and after completion of the back grouting construction of a whole reinforcement body with application of the solution-type grout composed of the solution A and the solution B, turbid-type grout composed of the solution A and a solution C is used for forward grouting and soil body solidification, so that physical natures of the original soil body can be changed and compressive strength of the soil body is increased. Finally, a soft soil layer (which is mainly composed of sandy soil, gravelly clayey soil and sand layers) becomes a soil body with the high impermeability, the high compressive strength and high stability. Hence, concrete grouting inspection and tool replacement become more convenient.

Owner:RANKEN RAILWAY CONSTR GROUP

Application of WSS construction method in shield tool changing reinforcement of water-rich sand layer

InactiveCN105971638AEasy to adjustHigh strengthUnderground chambersTunnel liningSlurryCompressive strength

Provides an application of WSS construction method in the reinforcement of shield tunneling in water-rich sand layer. The grouting process of WSS construction method adopts tunnel drilling rig to carry out deep hole grouting reinforcement. The slurry is used to drain the soil to improve the impermeability of the soil; when the whole solidification is completed by the solution-type slurry backward grouting composed of liquid A and liquid B, the suspension composed of liquid A and liquid C is used again. The forward grouting of the type slurry is used to consolidate the soil, change the physical properties of the original soil and improve the compressive strength of the soil, and finally make the weak soil layer (mainly sandy, gravel-cohesive soil and sand layer) impermeable. Soil with high resistance, high compressive strength and high stability is convenient for opening inspection and tool replacement.

Owner:RANKEN RAILWAY CONSTR GROUP

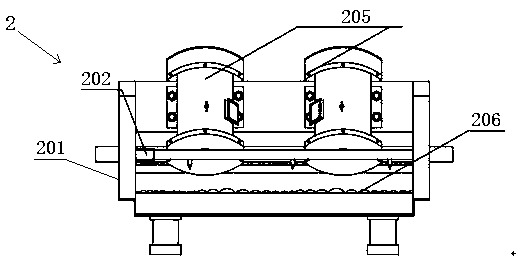

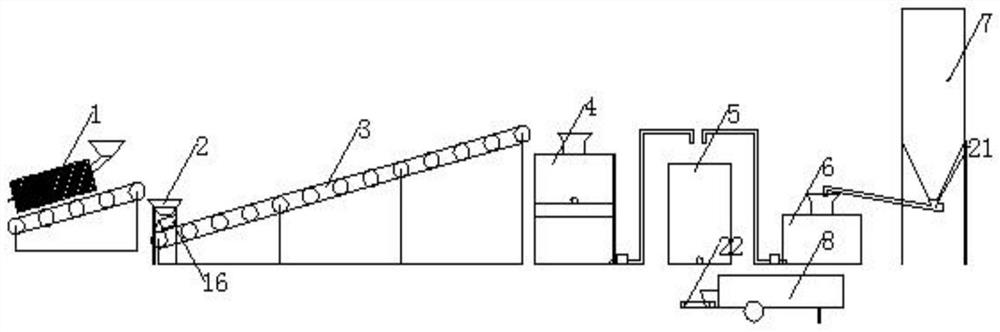

Shield muck treatment method and equipment

PendingCN109761396ASave water for cleaningAvoid pollutionMultistage water/sewage treatmentFlocculationBelt filter

The invention discloses a shield muck treatment method and equipment. The method comprises the steps that stones, sand and mud in the muck transported out in the shield construction process are subjected to vibrate separation under impact of water, the separated big sand is accumulated concentratedly through conveying equipment, meanwhile the separated thin sand and mud mixture is subjected to twisting separation, the thin sand is discharged, the separated mud is subjected to one flocculation treatment through a flow guiding tank or pipe, the mud subjected to flocculation treatment settles ina mud pool so as to separate mud and clear water, the clear water is drained into a clear water pool to serve as construction recycling water, the mud is pumped into a con ave-convex mud conveying pipe to be subjected to second flocculation treatment, and the mud subjected to second flocculation treatment is sent into a belt filter press to obtain dry mud cakes. The solid-liquid separation effectof the equipment is good, the automation degree is high, shield construction water is recycled, cleaning water for externally transported mud is greatly reduced, water is saved by50% or above in the whole construction process, and city pollution brought by external transportation of shield muck is thoroughly solved.

Owner:邓为成

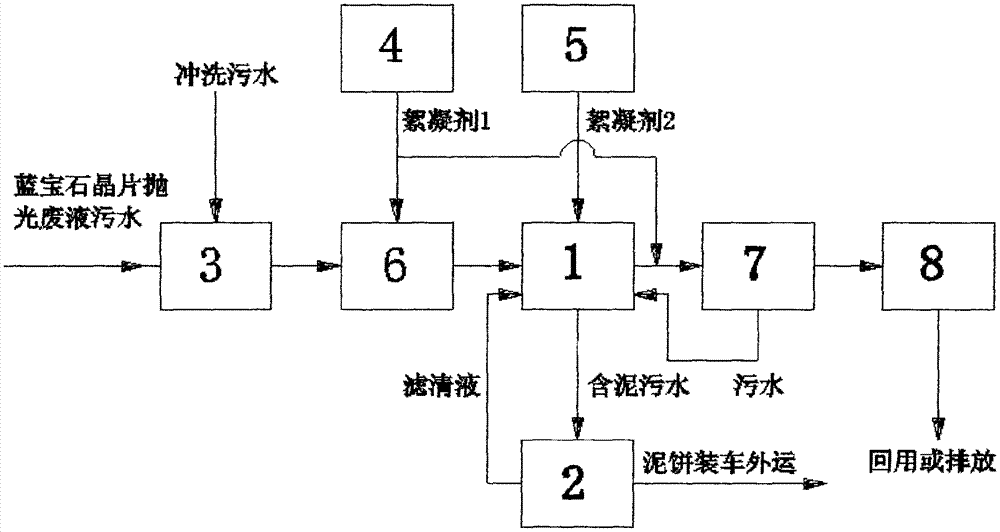

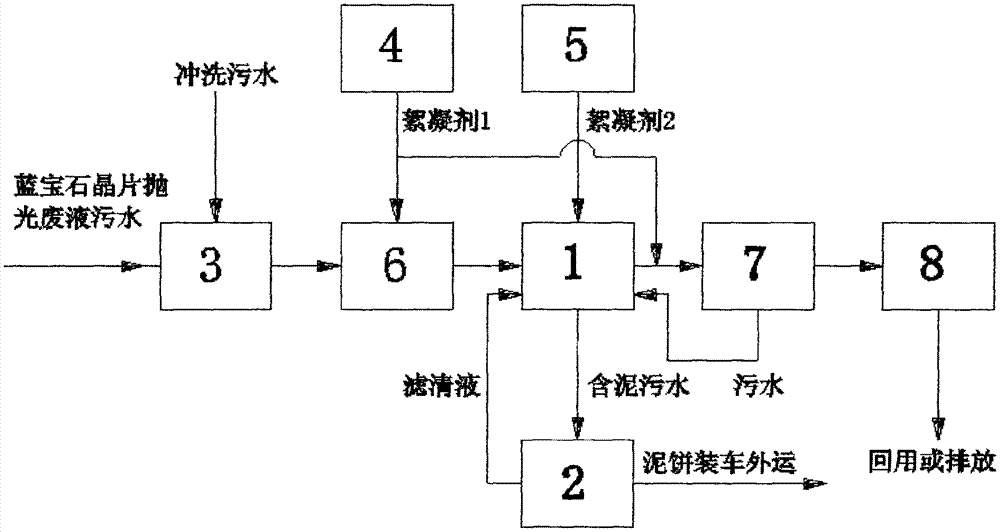

Sewage treatment method for sapphire crystal polishing liquid waste

ActiveCN103880216AImprove the settlement effectOrganic components are reducedSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSand filterSewage

The invention discloses a sewage treatment method for a sapphire crystal polishing liquid waste. The method comprises the following steps: adjusting the pH value of the sapphire crystal polishing liquid waste by using a rinse wastewater for rinsing a machine tool and ground, and forming an electric flocculation body by using a flocculant and suspended solids in the sapphire crystal polishing liquid waste; accelerating clarification by using a machine, and finely filtering the wastewater as rinse water to reuse through a continuous sand filter; separating sludge and liquid in mud sewage by using a folded screw sludge dewater, returning filtration liquid to the machine to accelerate clarification; outwardly transporting a dry mud cake to process, so as to efficiently, economically and safely process the sapphire crystal polishing liquid waste.

Owner:YANGZHOU MAOYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

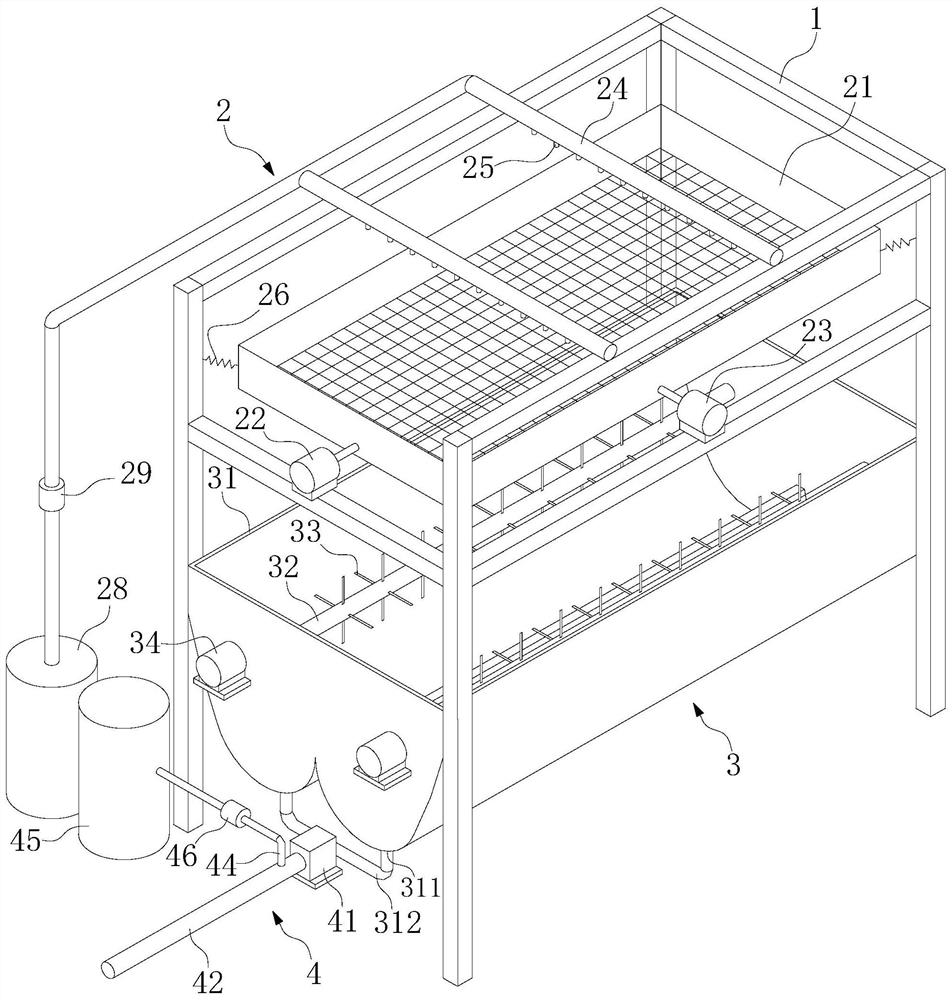

Integrated screening, curing and stirring system for shield tunneling muck and slurry

PendingCN112807816AEasy to eliminateReduce contentTransportation and packagingRotary stirring mixersElectric machineryProcess engineering

The invention discloses an integrated screening, curing and stirring system for shield tunneling muck and slurry. The system comprises a supporting frame, a screening and separating module, a collecting and stirring module and a curing agent adding and homogenizing module, wherein the screening and separating module comprises a square hole screen, a transverse vibration motor, a longitudinal vibration motor and one or more than one spraying pipe; the collecting and stirring module comprises a collecting box and a horizontal stirring device installed in the collecting box, and the collecting box is located below the square hole screen; and the curing agent adding and homogenizing module comprises a slurry pump, a conveying pipe and an automatic curing agent metering and adding device. The integrated screening, curing and stirring system of the invention realizes continuous line production of separation, homogenization, curing and stirring of coarse particles of the shield tunneling muck and the slurry; a curing agent and the slurry are uniformly mixed in the conveying pipe by virtue of the turbulent flow effect formed by the division bars in the conveying pipe, a slurry homogenization pool and a curing and stirring pool do not need to be arranged, and the system is small in occupied space and high in automation degree and provides equipment support for efficient and environment-friendly treatment of the shield tunneling muck.

Owner:中铁十局集团有限公司 +1

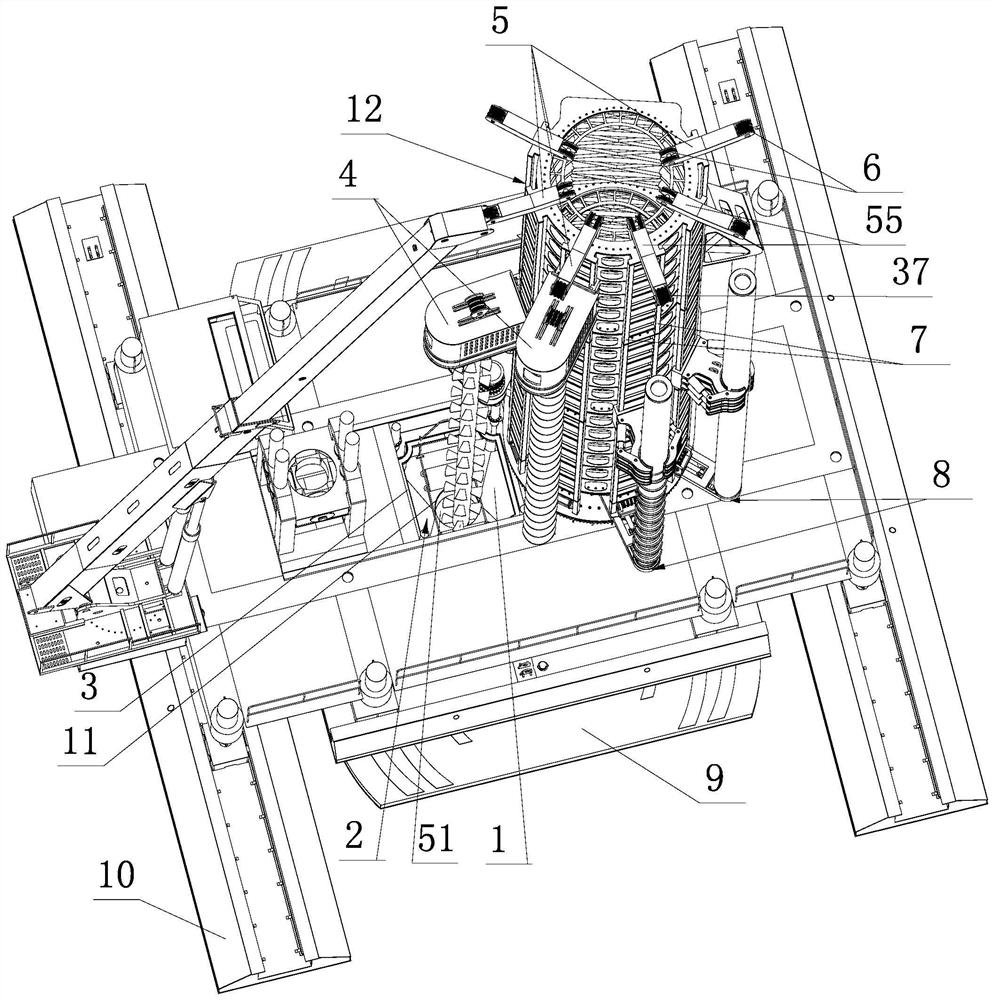

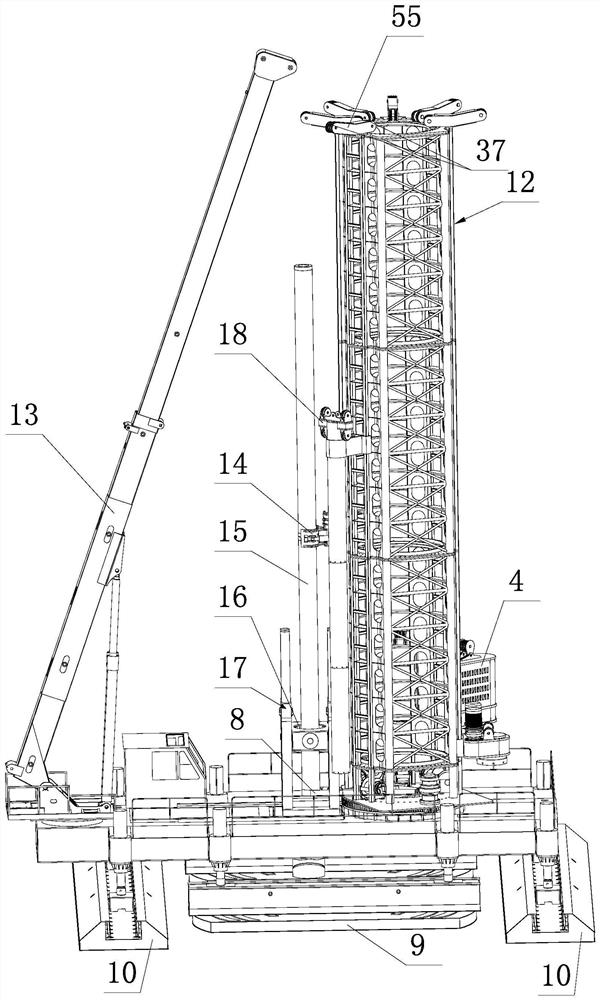

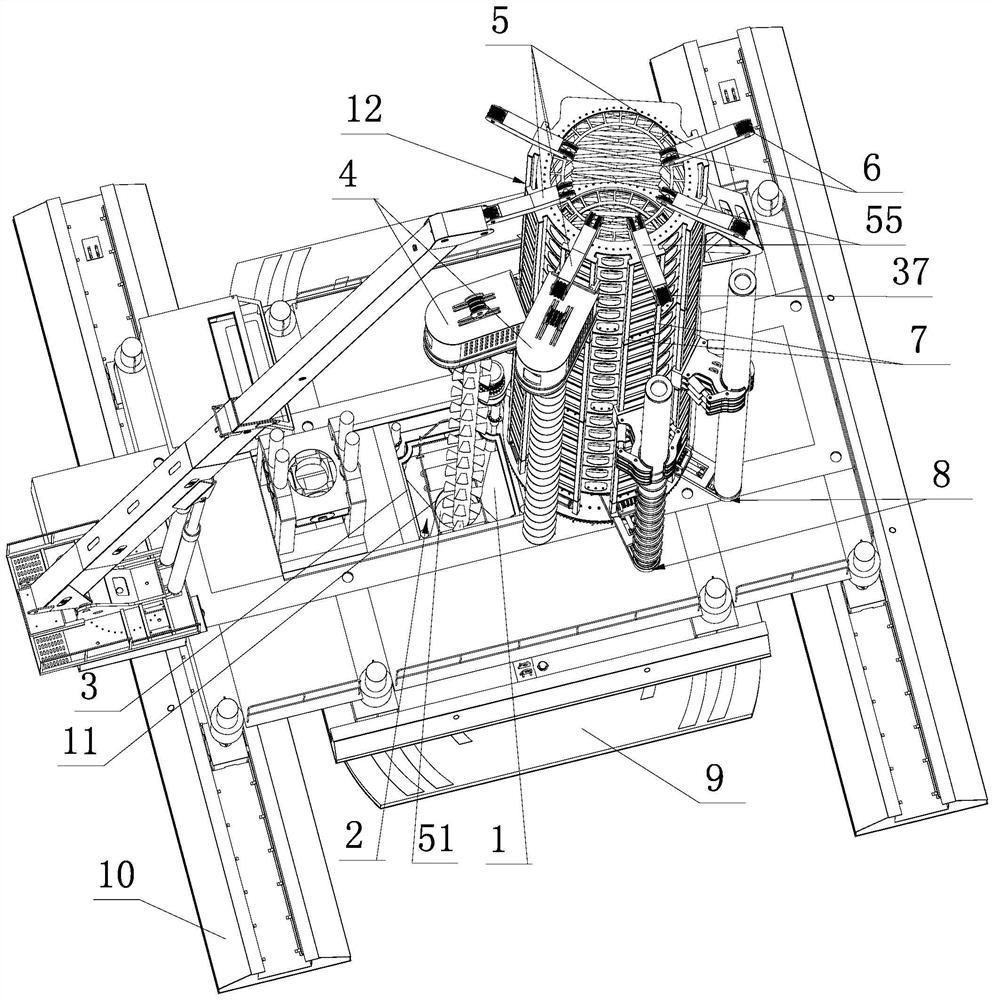

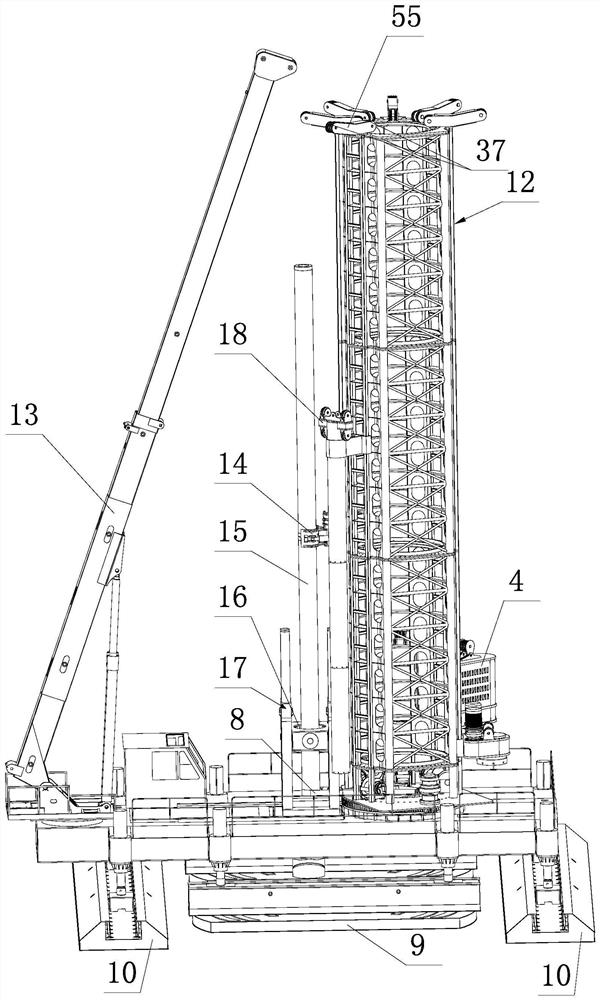

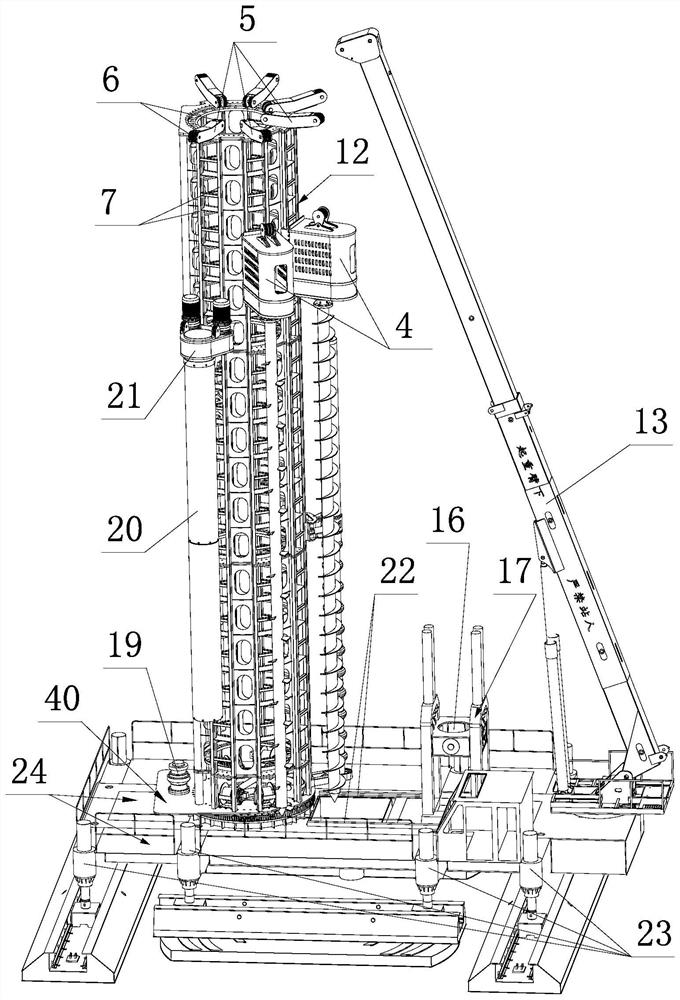

Drilling, pile splicing and pile planting all-in-one machine and construction method thereof

ActiveCN112096281AHigh concentricityReduce the probability of misalignmentConstructionsDerricks/mastsMachineTower

The invention discloses a drilling, pile splicing and pile planting all-in-one machine and a construction method thereof. The drilling, pile splicing and pile planting all-in-one machine comprises a walking mechanism, a base plate, a plurality of hoisting devices and a rotary disc capable of rotating relative to the base plate. Operation pile position holes for drilling and pile planting are formed in the base plate; a tower which has a circular truss structure and is coaxial with the rotary disc is fixed on the rotary disc; a pipe pressing power head, a plurality of drilling power heads, a plurality of rotary welding devices for lengthening and welding upper and lower pipe piles and a pile feeding pipe driving head are sequentially arranged along the outer circumference of the tower; eachpipe pressing power head, each drilling power head, each rotary welding device and each pile feeding pipe driving head can be located over the corresponding operation pile position holes in sequenceafter rotating along with the rotary disc of a rotary disc device; and pile pressing equipment driven by an oil cylinder for pile planting is mounted on the base plate through a guide rail. Accordingto the drilling, pile splicing and pile planting all-in-one machine, drilling, pile splicing and pile planting construction can be completed on one device, the height of the device is relatively low,the concentricity of devices with multiple functions on the rotary disc is good, and the stability of the device is high.

Owner:尚俏佳

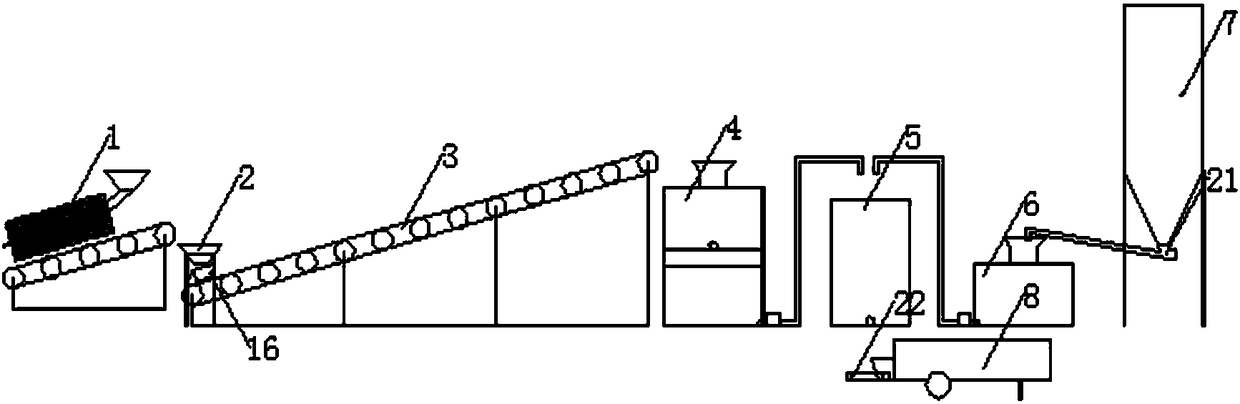

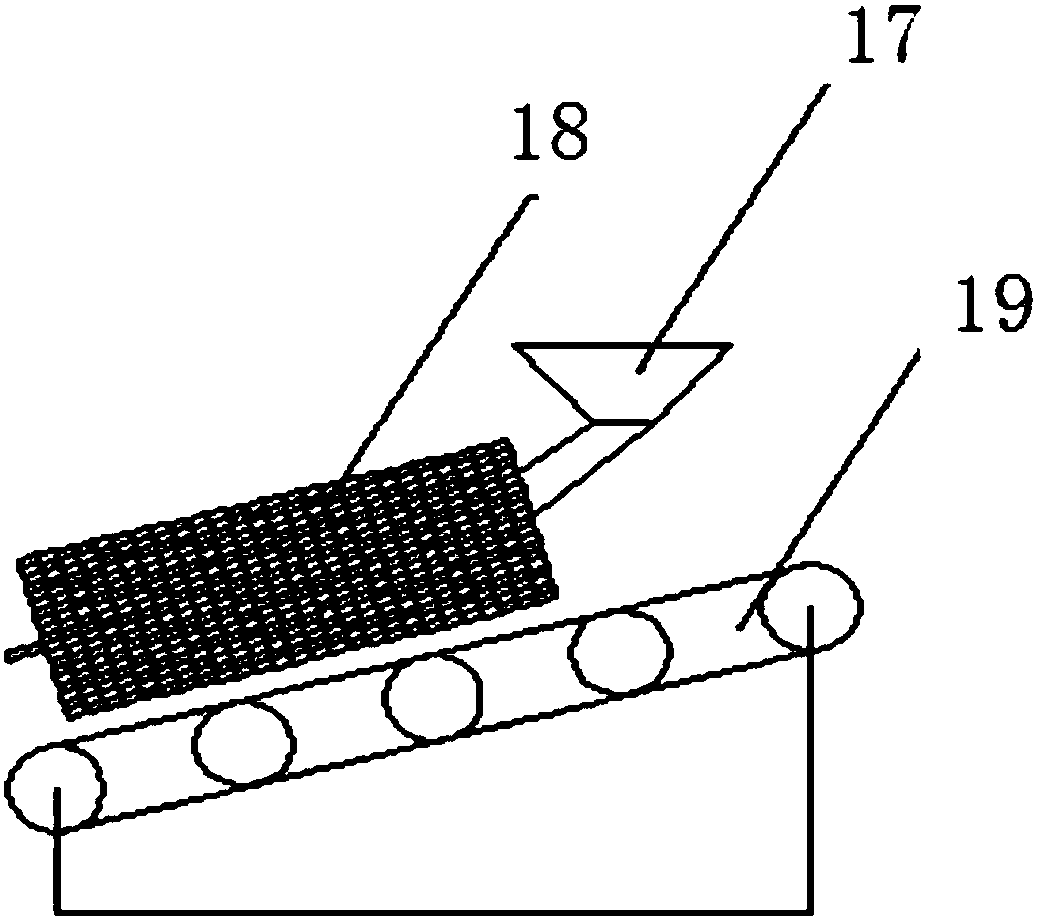

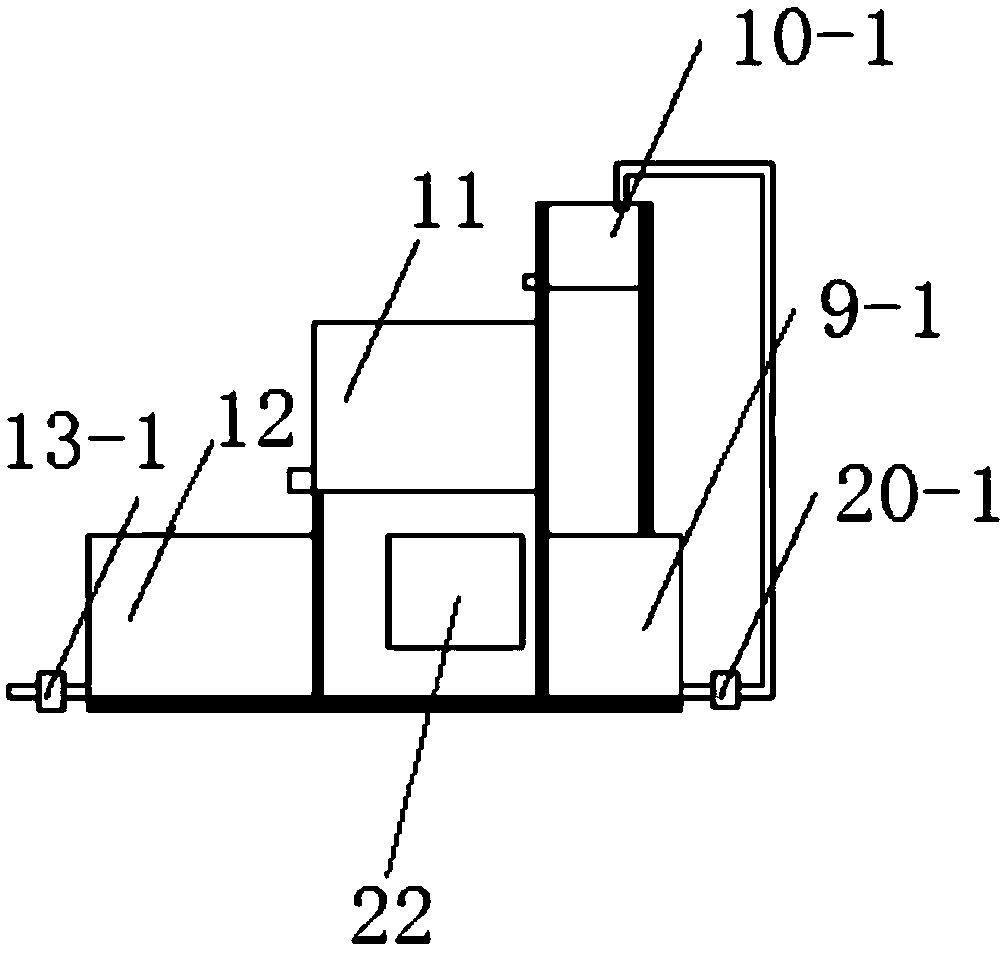

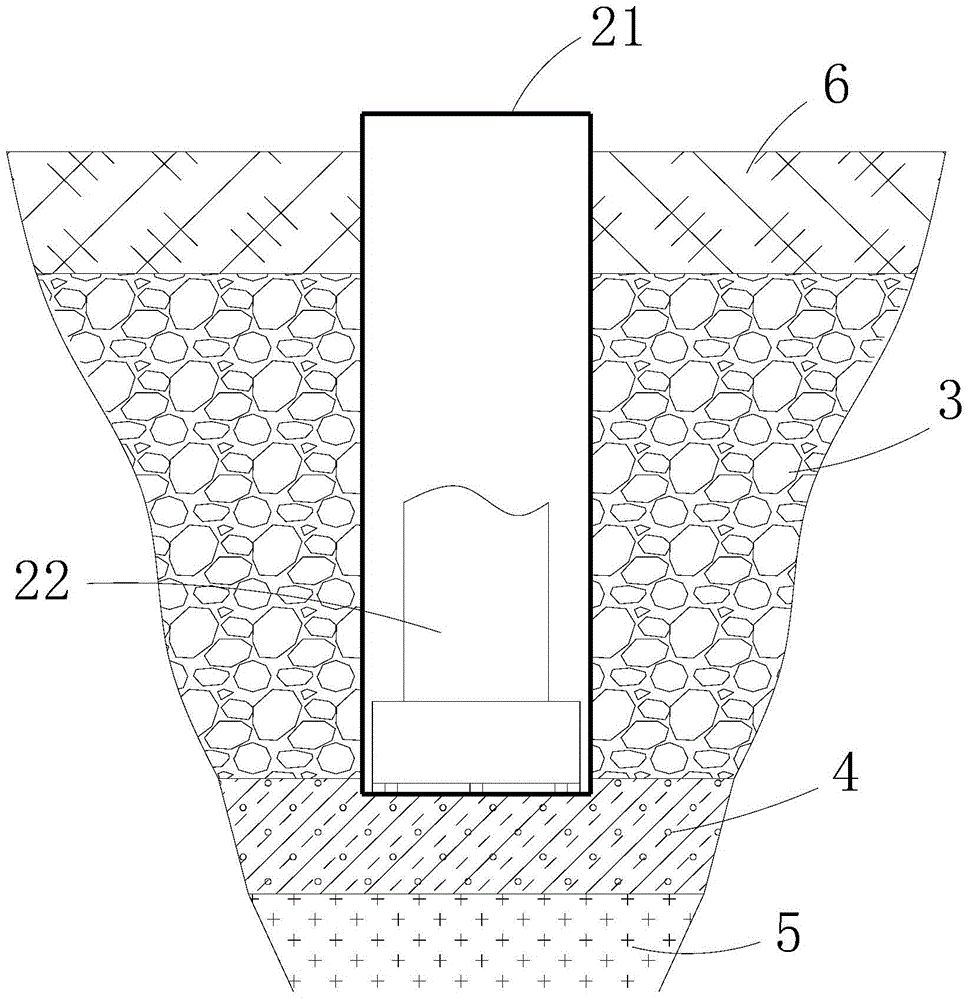

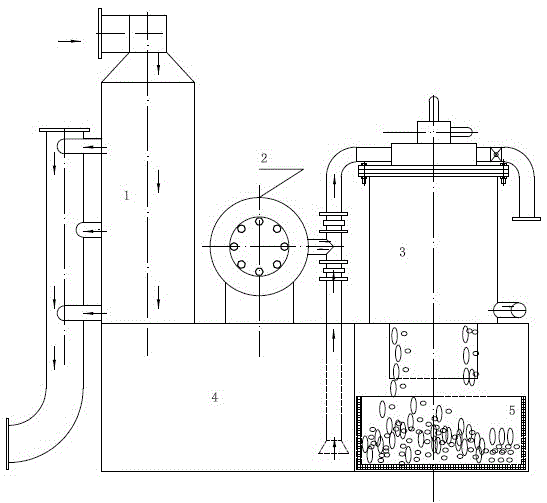

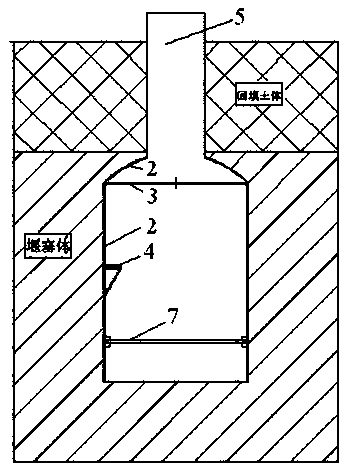

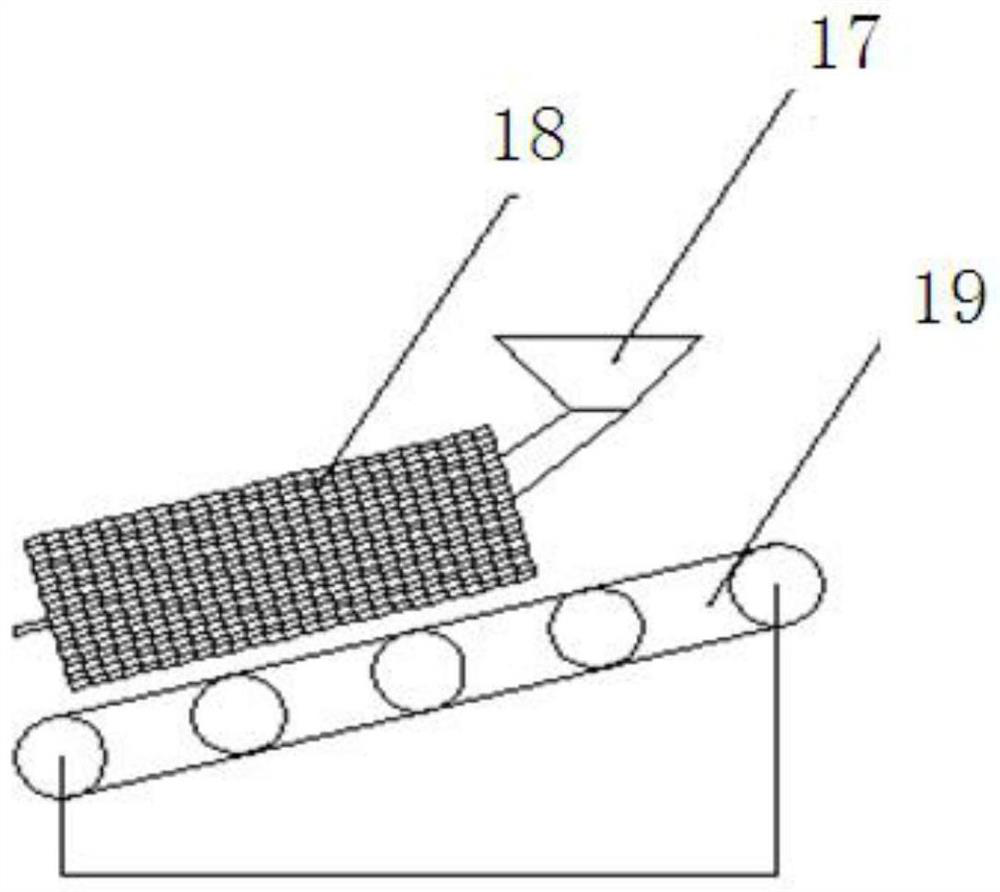

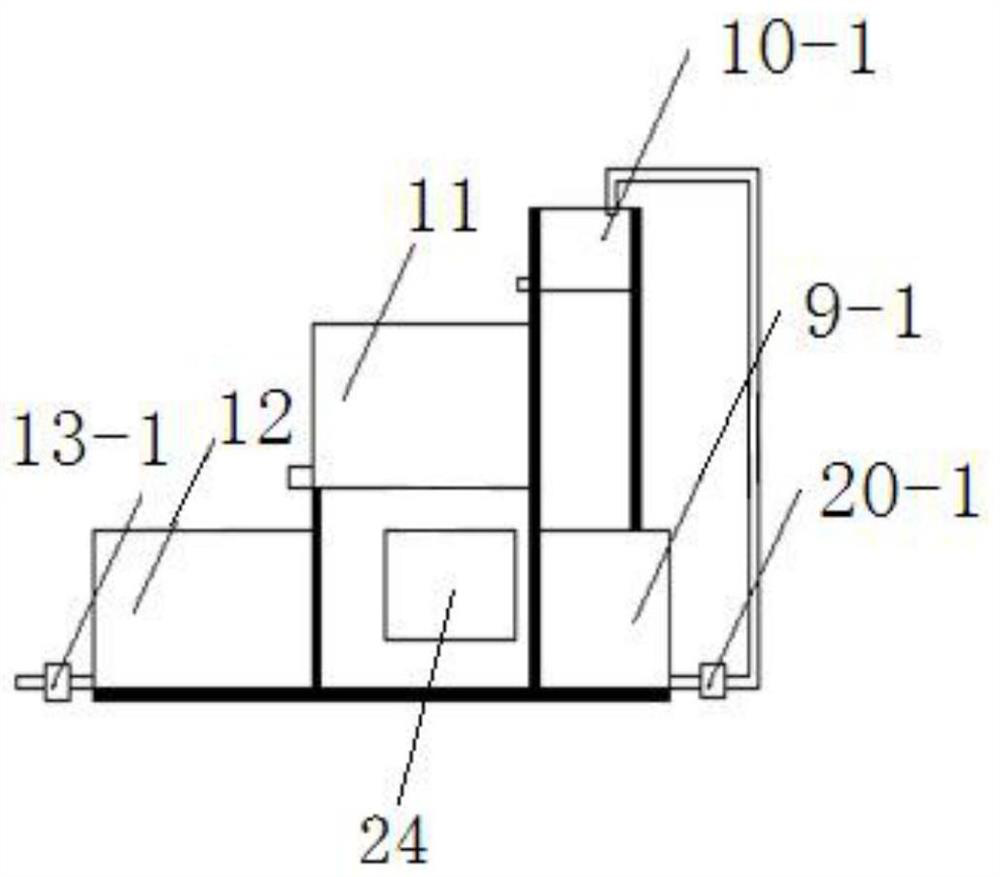

Cement soil preparation system suitable for different fluidities and soil bodies

ActiveCN108058269AImprove work efficiencyReduce outbound volumeMixing operation control apparatusClay mixing apparatusCement slurryAir compressor

A cement soil preparation system suitable for different fluidities and soil bodies includes a soil material sieve separator, a soil material measuring bin, a slurry stirring station, a cement bin, a cement measuring bin, a cement slurry stirring station and a slurry storage tank; the soil material sieve separator is used for sieving a soil material, and the sieved soil material is transported to the soil material measuring bin through a conveying belt 19; the soil material measuring bin is used for weighing a certain amount of soil material according to the set weight, and the weighed soil material is transported to the slurry stirring station through a conveying belt conveyor 3; the slurry stirring station is used for stirring the soil material and water according to the set fluidity, theslurry after stirring is transported into the slurry storage tank; the cement bin is used for storing cement, and a discharge port of the cement bin is connected to an inlet of the cement measuring bin by an air compressor; the cement measuring bin is used for weighing a certain amount of cement according to the set weight, the weighed cement is transported to the cement slurry stirring station through a delivery pipe 22; the cement slurry stirring station is used for stirring the cement and other material flows according to the set fluidity, and the slurry after stirring is transported intothe slurry storage tank; a discharge port of the slurry storage tank is connected with a grouting pipe.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Capsule-type solid-liquid separation device and method

ActiveCN103990315ANo pollution in the processEasy to keep airtightWater/sewage treatmentFiltration circuitsSewageSlurry

A capsule-type solid-liquid separation device comprises a rough filtration device, a slurry storage tank, a transfer pump, a filter press and associated pipelines and valves, which are intensively arranged on a box using as a storage tank for slurry and filter cake. A preliminary filtrate passage of the rough filtration device is connected with a sewage pipe network, and a slurry discharge passage is connected with the slurry storage tank; a slurry feed pipeline of the transfer pump is connected with the slurry storage tank, and a slurry discharge pipeline is connected with the filter press; the filter press is a capsule-type one, a filter cylinder is provided inside with the pressing capsules, and a blanking passage is provided inside with filling capsules; the pressing capsules expand under the effect of the introduced high pressure fluid, and extrude the filter material in the filter cylinder for operation; the filling capsules expand under the effect of the introduced pressure fluid and fill the blanking passage, to cut off a lower opening of the filter cylinder with the blanking passage; and the blanking passage is communicated with the filter cake storage tank. The device has the advantages of compact structure, little land occupation, no noise and easiness for movement, and is especially suitable for solid-liquid separation of kitchen garbage crushing fluid in high buildings and in the field.

Owner:重庆鑫珏环保科技有限公司

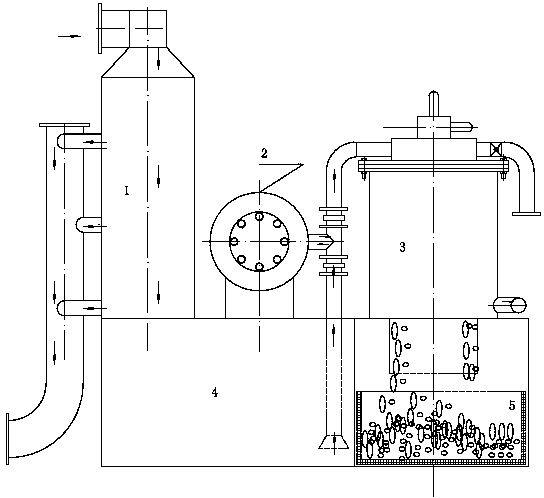

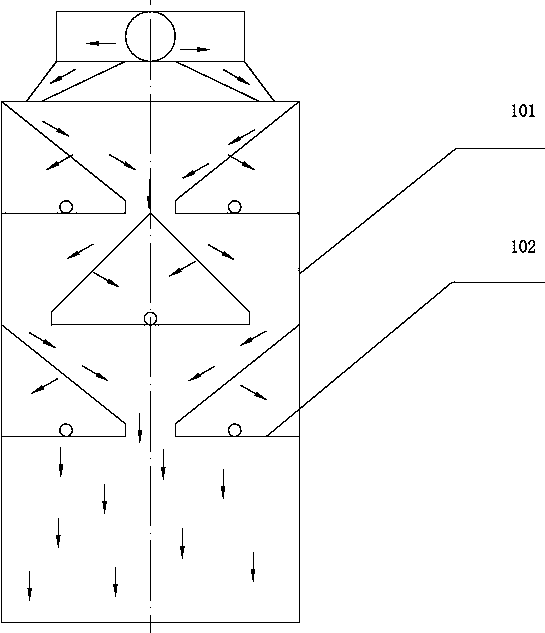

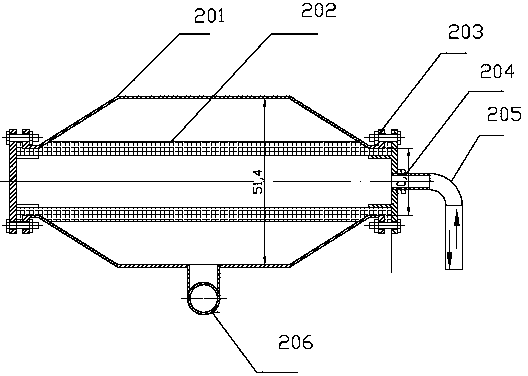

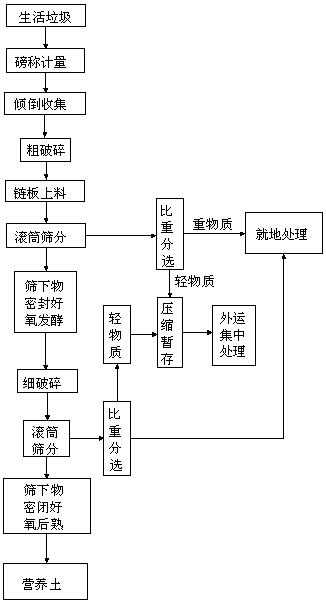

Harmless treatment process of domestic garbage in villages and towns

InactiveCN105798049BAvoid pollutionReduce pollutionSolid waste disposalClimate change adaptationDecompositionPrimary screening

Owner:张共敏 +2

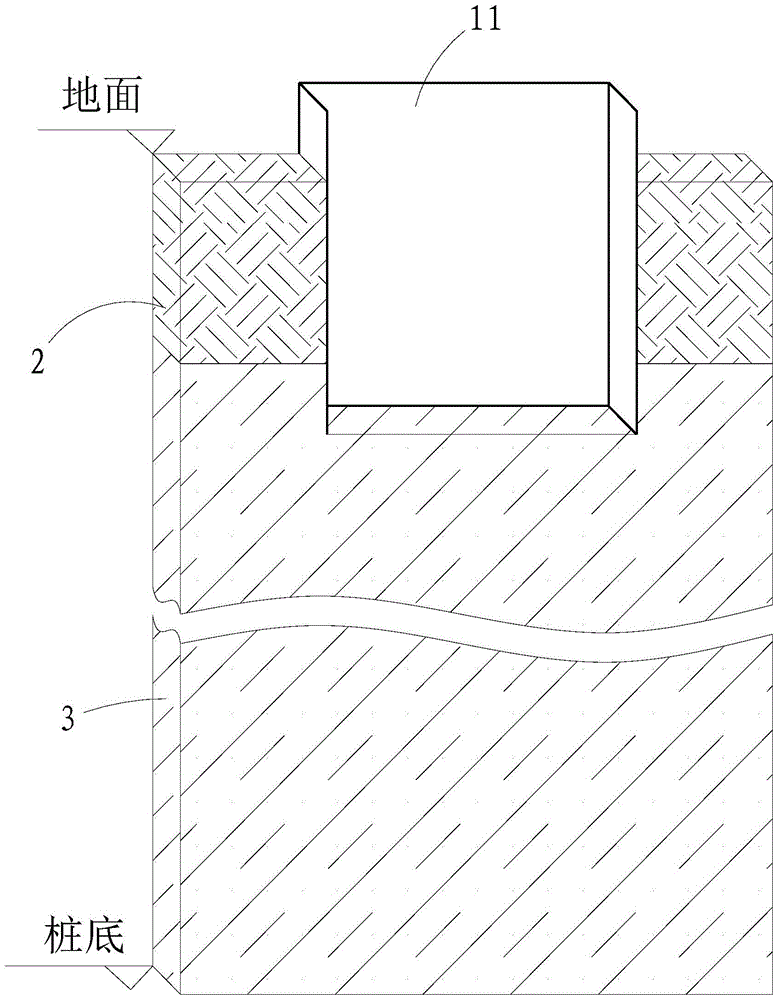

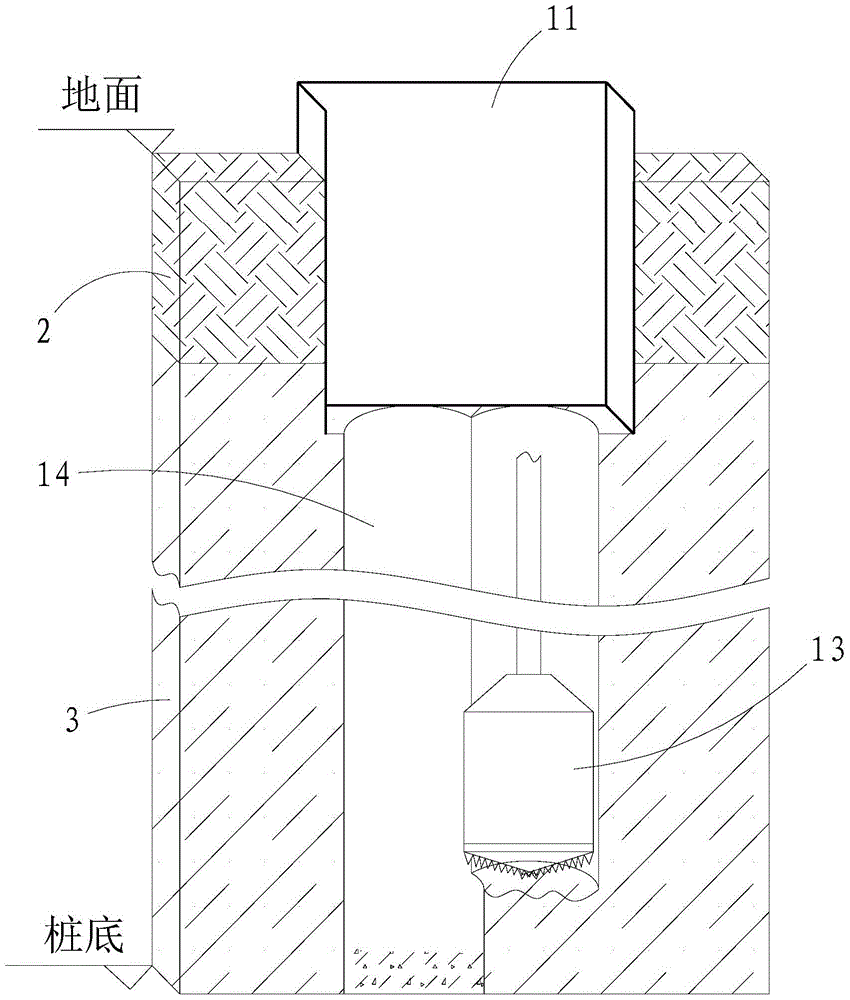

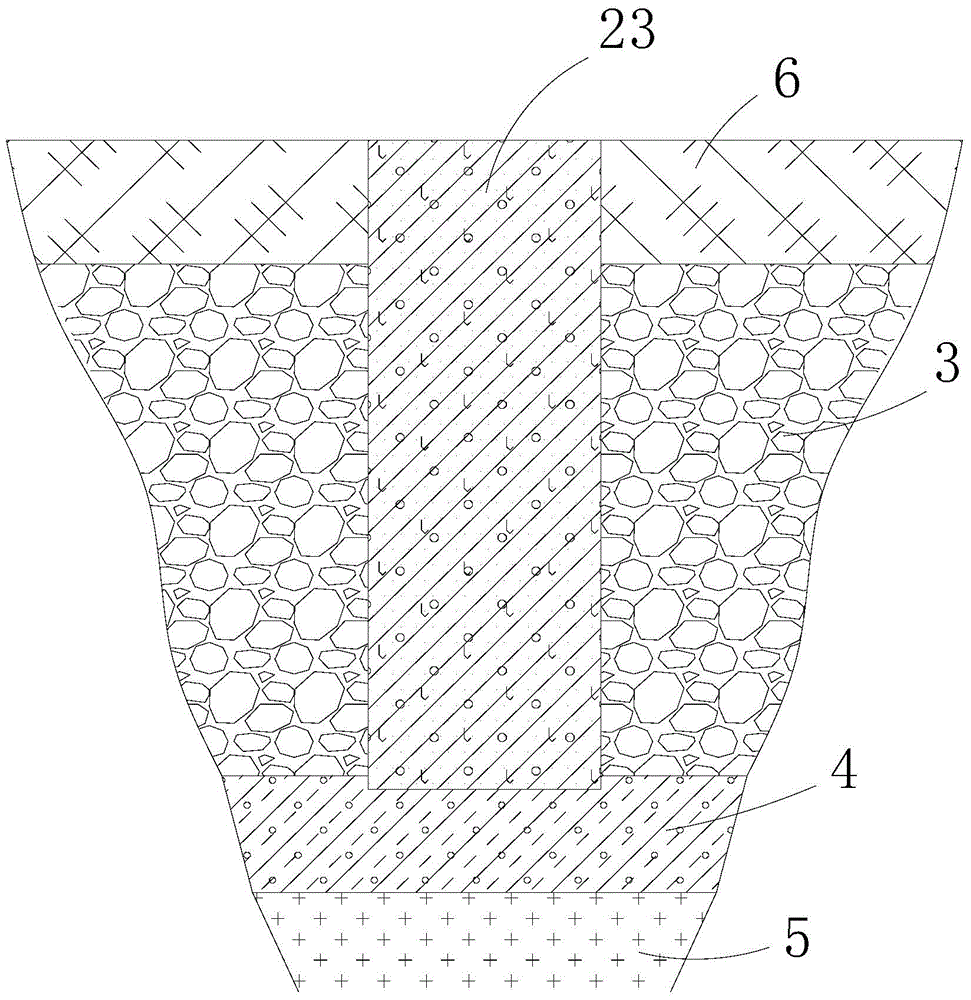

Compound type pile foundation construction site structure and compound type pile foundation construction process

The invention discloses a compound type pile foundation construction site structure. The compound type pile foundation construction site structure comprises a first pile hole, a slurry settling pond, a slurry standby pond and a second pile hole, wherein the first pile hole is conducted with the slurry settling pond via an oblique groove; the slurry settling pond is communicated with the slurry standby pond via a first external pipeline; the first external pipeline is provided with a pump and a filter screen; the slurry standby pond is connected with a second external pipeline; the second external pipeline is provided with a pump and an outlet facing to the second pile hole; a third external pipeline is arranged between the second pile hole and the slurry settling pond and is provided with a pump. The invention also provides a construction process implemented by application of the compound type pile foundation construction site structure. Through the scheme, the external transportation amount of waste residues formed by drilling can be reduced; the pile hole cleaning speed is accelerated; the holes are cleaned by normal circulation of impact drilling of the slurry; the wall protection effect is excellent; the sediment residues at the bottoms of the holes can be effectively controlled; and the cost can be greatly reduced.

Owner:泰昌建设有限公司

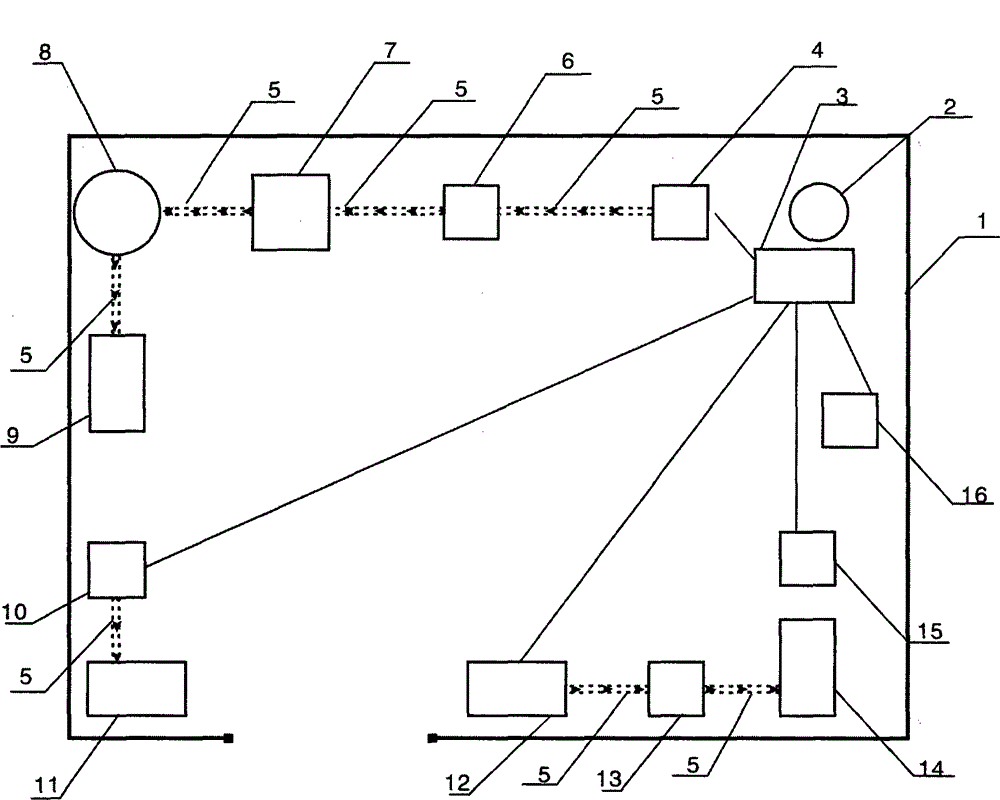

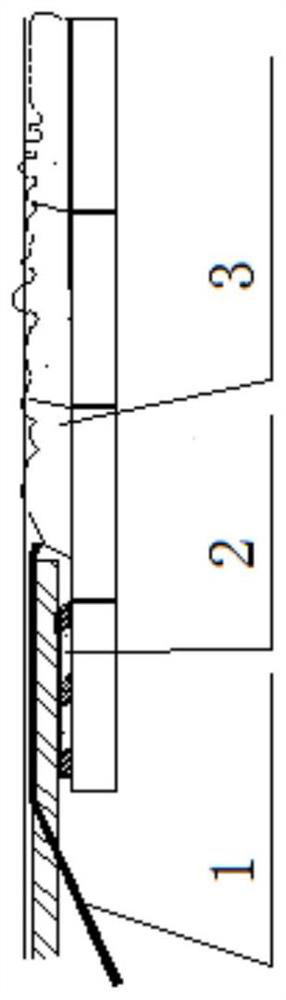

Integrated disposing and eliminating method for construction site rubbish

InactiveCN106140778AReduce outbound volumeReduce pollutionConstruction waste recoverySolid waste disposalBrickArchitectural engineering

The invention provides an integrated disposing and eliminating method for construction site rubbish. According to the method, a closed construction rubbish disposing workshop (1) is arranged on a construction site, and a vertical rubbish conveying pipeline (2), an anti-impact safety net (3), a jaw crusher (4), conveying belts (5), a stone crushing machine (6), a material bin (7), a stirring machine (8), a brick making machine (9), a plastic crushing machine (10), a plastic granulating machine (11), a formwork square-cutting saw (12), a timber crushing machine (13), a timber bar making machine (14), a water medium dust collector (15) and a liquid-solid separating hydraulic machine (16) are arranged inside the rubbish disposing workshop. The transportation amount can be reduced by more than 90% after the construction site rubbish is disposed through the method, raised dust generated in the vehicle transportation process is removed, environmental pollution is reduced, the construction rubbish is directly converted into wealth, and precious resources are saved.

Owner:BEIJING SHENZHOU BLUE SKY ENVIRONMENTAL PROTECTION TECH CO LTD

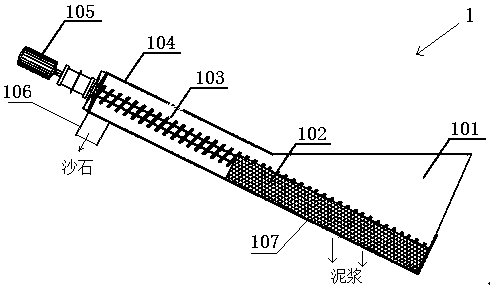

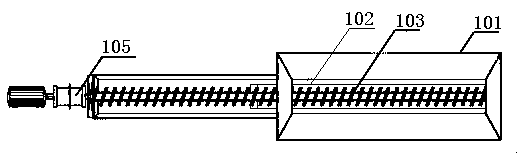

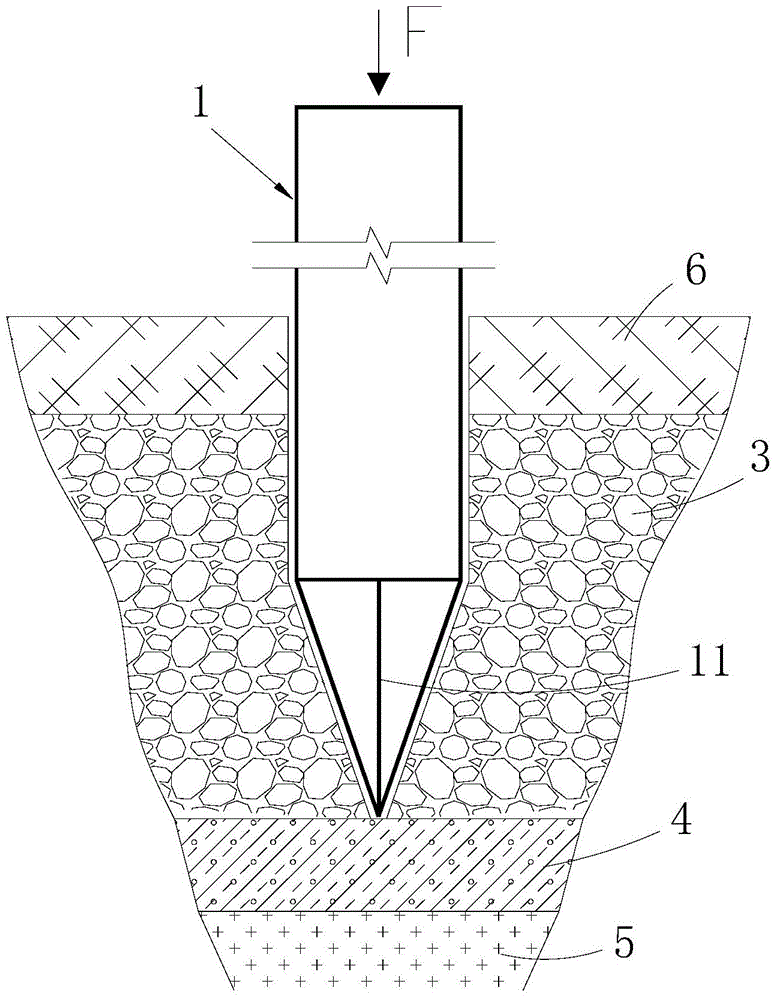

Prestressed pipe pile and its construction method

ActiveCN104164873BFast hole formingStrong penetrating powerBulkheads/pilesPre stressPrestressed concrete

The invention relates to the technical field of drilling equipment, and discloses a construction method for a prestressed pipe pile, wherein the method is used for pile forming in a reclamation area. The method comprises the following steps that firstly, a main drill hole is formed through a down hole hammer, and a total pile casing is utilized for following drilling of the down hole hammer until the down hole hammer and the total pile casing pass through a rock filling layer; secondly, the down hole hammer is lifted and pulled, the total pile casing is filled with sandy soil until the filled sandy soil reaches the upper surface of the reclamation area, the total pile casing is lifted and pulled, and a sand filling hole is formed through the main drilling hole; thirdly, external force is exerted on the upper end of the prestressed pipe pile, the prestressed pipe pile passes through the sand filling hole, and the lower end of the prestressed pipe pile is embedded in a bed rock below the rock filling layer. According to the construction method for the prestressed pipe pile, the position where a pile needs to be formed in the reclamation area is drilled through the cooperation of the down hole hammer and the total pipe casing pipe following, the main drilling hole passes through the rock filling layer, the rock filling layer is converted into the sandy soil, a hammer pile machine and the like are utilized for continuing to drive the pipe pile, the pipe pile easily passes through the rock filling layer, and the construction method has the advantages that the hole forming speed and construction efficiency are high, construction cost is low, the construction period is short, and the construction field is clean.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +2

Shield grouting method based on shield muck improvement under water-rich sand layer condition

ActiveCN113374485AGuaranteed settlement control requirementsReduce disturbanceUnderground chambersTunnel liningBalancing machineShield machine

The invention discloses a shield grouting method based on shield muck improvement under the water-rich sand layer condition, and belongs to the technical field of constructional engineering. Shield grouting ingredients in a soil bin are stirred through a concrete stirring machine, stirred slurry is transferred to a trolley slurry tank through a slurry vehicle, the slurry in a tank car is stirred evenly, and a transmission pump is started to start pumping the slurry into a slurry tank on a shield tunneling machine from the tank car; the shield tunneling machine needs to conduct synchronous grouting in the normal propelling process of each link so as to guarantee compactness of building gaps; and shield grouting can be carried out in a synchronous grouting manner and a secondary supplementary grouting manner, synchronous grouting is carried out along with tunneling through a synchronous grouting system at the same time, and secondary supplementary grouting is carried out through a segment grouting hole behind a shield tail by utilizing a supplementary grouting system. According to the shield grouting method, waste muck can be improved, a good soil pressure balance mechanism is established, and environmental pollution and resource waste are reduced.

Owner:中铁(上海)投资集团有限公司 +1

Sand pile construction method adopting multi-section composite casing punching

InactiveCN108487226AGuaranteed compactnessGuarantee the construction qualitySoil preservationPunchingEngineering

The invention discloses a sand pile construction method adopting multi-section composite casing punching. The construction method comprises the following steps that (1), a composite casing is vertically positioned; (2), the composite casing is hammered; (3), an inner pipe is raised and sand is poured into an outer pipe; (4), the inner pipe and the outer pipe are made to be flush; (5), the composite casing is hammered to compact the filling sand; and 6), the steps mentioned above are repeated till a pile pipe is pulled out of the ground. The method is standard in operation, the sand content andsilt content of the filler are strictly controlled, and the influence caused by hole collapse and the insufficient filler on quality is effectively avoided. Pile driving equipment adopts a vibrationpile driver to set up the composite steel casing and has a relatively mature safety system, and the safe construction can be effectively guaranteed. During pile sinking, the composite casing is used to form the outer pipe retaining wall, and the surrounding soil does not enter a pile body during the vibration extrusion process; and meanwhile the sand pile filler can be repeatedly extruded by usinga multi-section type punching construction method to ensure the compactness of the whole pile body, and the construction quality of a sand pile is ensured.

Owner:ZHONGQI JIAOJIAN GRP

Drilling pile connecting and planting integrated machine and its construction method

ActiveCN112096281BHigh concentricityReduce the probability of misalignmentConstructionsDerricks/mastsAgricultural engineeringMachine

The invention discloses an integrated machine for drilling, connecting piles and planting piles and a construction method thereof, which comprises a traveling mechanism, a chassis, a plurality of hoisting equipment, and a turntable capable of rotating relative to the chassis; on the chassis are working piles for drilling and planting piles. Position holes; a tower with a circular truss structure coaxial with the turntable is fixed on the turntable; along the outer circumference of the tower, a pressure tube power head, multiple drilling power heads, multiple extensions and welding up and down are arranged in sequence A rotary welding device for pipe piles, a driving head for sending pile pipes; after each pipe pressing power head, each drilling power head, each rotary welding device and each pile feeding pipe driving head rotate with the turntable of the turntable device, All can be located directly above the operation pile hole; a pile pressing device driven by an oil cylinder for pile planting is installed on the chassis through guide rails. The machine and the method can complete the drilling, pile connection and pile planting construction on one piece of equipment, and the equipment height is relatively low, the concentricity of the multifunctional device on the turntable is good, and the equipment stability is high.

Owner:尚俏佳

A capsule type solid-liquid separation device and method

ActiveCN103990315BNo pollution in the processEasy to keep airtightWater/sewage treatmentFiltration circuitsSewageSlurry

A capsule-type solid-liquid separation device comprises a rough filtration device, a slurry storage tank, a transfer pump, a filter press and associated pipelines and valves, which are intensively arranged on a box using as a storage tank for slurry and filter cake. A preliminary filtrate passage of the rough filtration device is connected with a sewage pipe network, and a slurry discharge passage is connected with the slurry storage tank; a slurry feed pipeline of the transfer pump is connected with the slurry storage tank, and a slurry discharge pipeline is connected with the filter press; the filter press is a capsule-type one, a filter cylinder is provided inside with the pressing capsules, and a blanking passage is provided inside with filling capsules; the pressing capsules expand under the effect of the introduced high pressure fluid, and extrude the filter material in the filter cylinder for operation; the filling capsules expand under the effect of the introduced pressure fluid and fill the blanking passage, to cut off a lower opening of the filter cylinder with the blanking passage; and the blanking passage is communicated with the filter cake storage tank. The device has the advantages of compact structure, little land occupation, no noise and easiness for movement, and is especially suitable for solid-liquid separation of kitchen garbage crushing fluid in high buildings and in the field.

Owner:重庆鑫珏环保科技有限公司

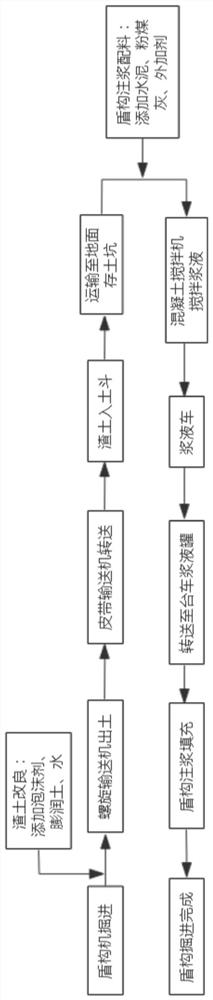

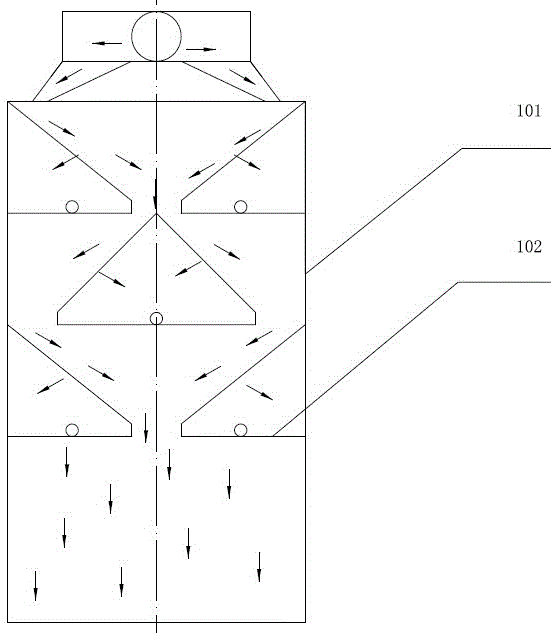

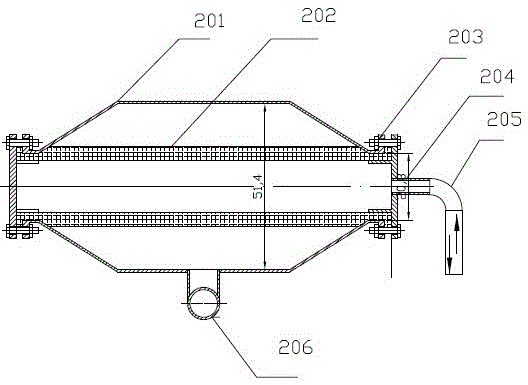

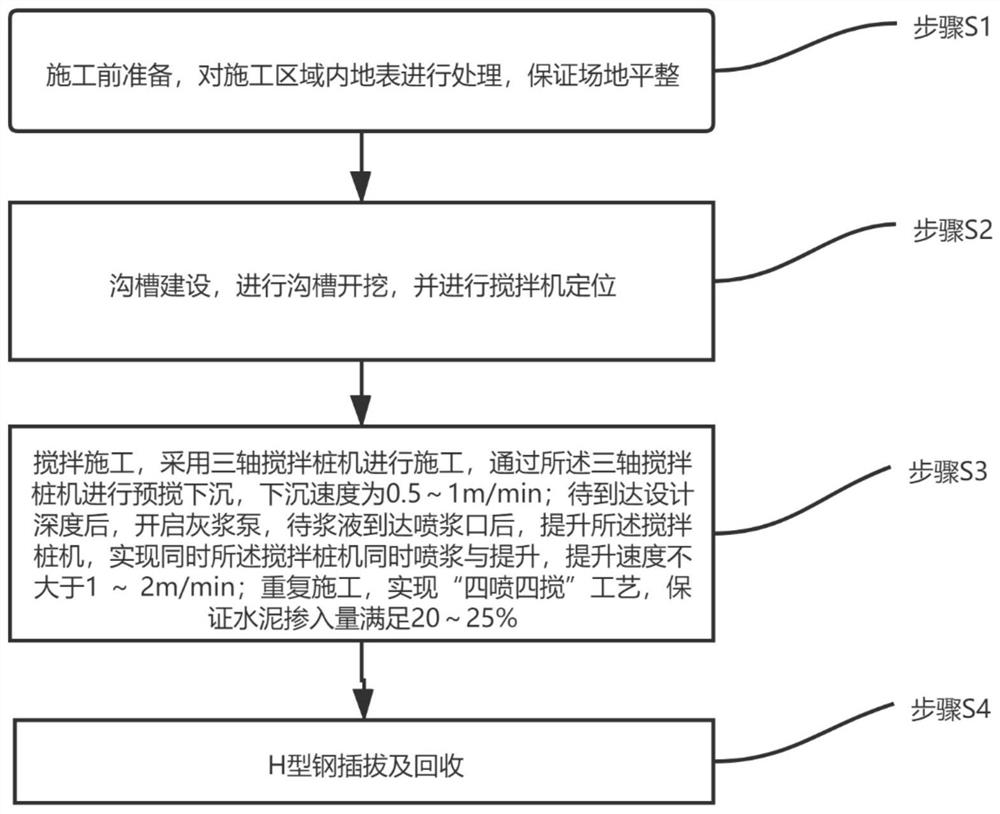

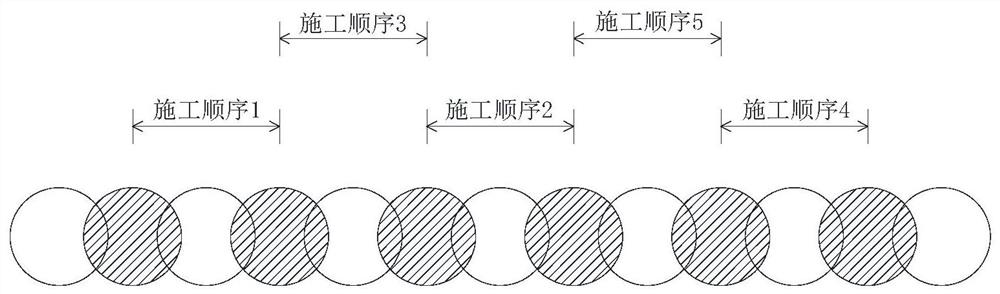

Construction method of mixing pile wall

PendingCN113756296AGuaranteed stabilityImprove construction efficiencyBulkheads/pilesBLENDER/MIXERStructural engineering

The invention discloses a construction method of a mixing pile wall. The construction method comprises the following steps that preparation is conducted before construction, specifically, the earth surface in a construction area is treated, and the flatness of a site is ensured; groove construction is conducted, specifically, a groove is excavated, and a mixer is positioned; mixing construction is conducted, specifically, a three-axis mixing pile machine is adopted for construction, pre-mixing sinking is conducted through the three-axis mixing pile machine, and the sinking speed is 0.5-1m / min; after the designed depth is reached, a mortar pump is started, after slurry reaches a slurry spraying opening, the mixing pile machine is lifted, slurry spraying and lifting of the mixing pile machine are achieved simultaneously, and the lifting speed is not larger than 1-2m / min; construction is repeated, the four-spraying and four-mixing process is achieved, and the cement mixing amount reaches 20-25%; and H-shaped steel is inserted, pulled and recycled. Construction of the mixing pile wall is conducted through the method, the stability of adjacent soil can be effectively ensured, and the construction efficiency is improved while the occurrence probability of hazards such as adjacent ground settlement, house inclination, road cracking and underground facility displacement is decreased.

Owner:RANKEN RAILWAY CONSTR GROUP

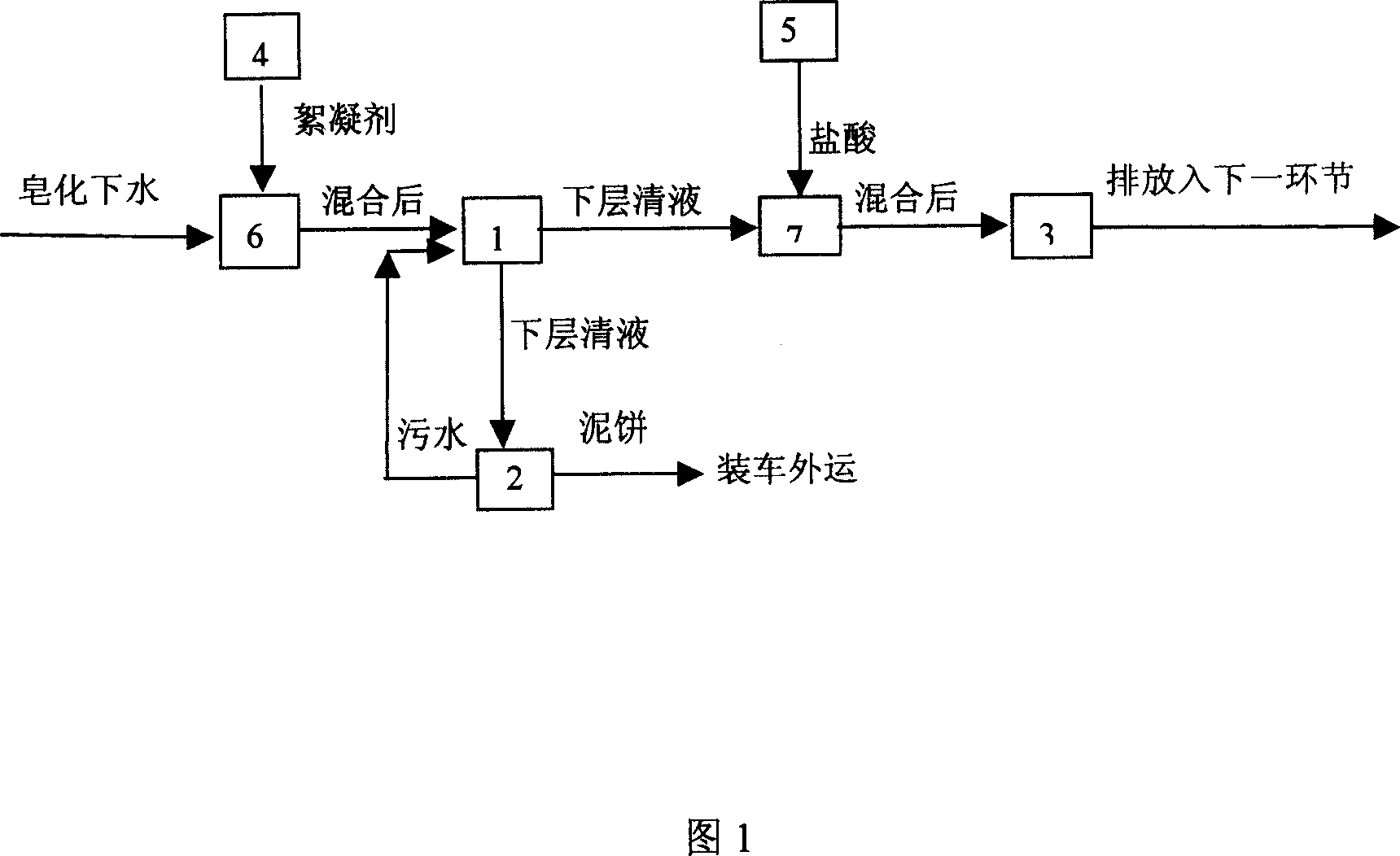

Method for processing saponified sewage

ActiveCN1331769CAccelerated settlementImprove settlement performanceCentrifugal force sediment separationWater/sewage treatment by neutralisationSewageEngineering

The present invention ptovides saponified sewage treating method, and the method is one mechanical speeded clarification plus horizontal screw centrifugal machine separation plus neutralization method. The method has the functions of smooth running, high economic property, high controllability and high separation effect.

Owner:BALING PETRO CHEM CO LTD SINOPEC

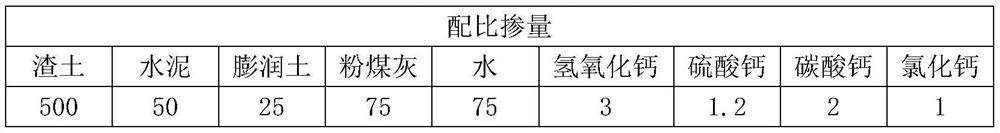

Scap type earth pressure balance shield opening mud and its preparation method

ActiveCN110436836BReduce outbound volumeAlleviate the problem of outbound transportationTunnelsSlagSlurry

The invention discloses a SCAP-type soil pressure balance shield mud for opening a cabin, which comprises the following components according to the mass parts: 50-80 parts of silt, 400-600 parts of clear water, 100-150 parts of calcium-based bentonite, and a modifier 2~6 parts and 0~2 parts of tackifier. It also discloses the preparation method of mud for SCAP-type earth pressure balance shield opening: the waste silt produced when the shield tunnels into the silt or silty clay layer is dried, passed through a mesh screen, and stored near the muck pit. When the shield machine needs to be opened under pressure, add stored silt, clear water, calcium-based bentonite, modifier and viscosifier to the mud truck, and stir continuously to prepare a product that meets the mud density and viscosity requirements. Utilizing the discarded dregs during the excavation process can save bentonite resources and opening costs, and reduce the environmental pollution caused by the amount of muck transported abroad, and prepare mud for opening that meets the requirements of density, viscosity, physical and chemical stability, etc. .

Owner:HOHAI UNIV

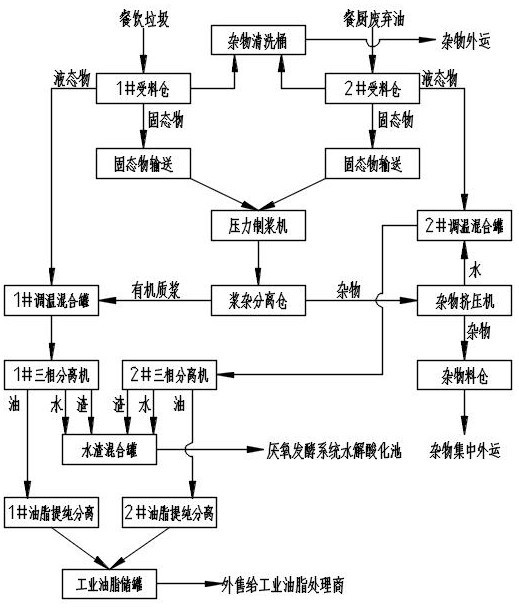

Comprehensive pretreatment process for food waste and kitchen waste oil

PendingCN112694949AReduce outbound volumeHigh extraction rateFatty oils/acids recovery from wasteFatty substance recoveryOil and greaseProcess engineering

The invention discloses a comprehensive pretreatment process for food waste and kitchen waste oil, which at least comprises the following process sections in closed connection: a received material separation section, a pulping section, a pulp impurity separation section, a temperature regulating and mixing section, a three-phase separation section and an oil storage section. By means of sufficient pressure pulping on solid substances and separation of non-organic impurities, organic matters are prevented from going out along with impurities, so that the outward transportation amount of the impurities is reduced. In addition, grease is easier to separate, and the grease extraction rate is increased. Chopping is not conducted in the whole process, so that non-organic matters are prevented from entering an anaerobic fermentation system in a fine manner. By means of comprehensive treatment of mutual cooperation and coexistence of the food waste and the kitchen waste oil, a pressure pulping machine, a pulp-impurity separator, a water-slag mixing tank and an industrial oil storage tank are shared, investment can be effectively reduced, the process is simplified, energy is complementarily used, resourceful treatment is better achieved, and economic, social and environmental comprehensive benefits are obtained.

Owner:ZHENGZHOU YUNDA PAPER EQUIP

A kind of sapphire wafer polishing waste liquid sewage treatment method

ActiveCN103880216BAccelerated settlementImprove settlement performanceSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentLiquid wasteFlocculation

The invention discloses a sewage treatment method for a sapphire crystal polishing liquid waste. The method comprises the following steps: adjusting the pH value of the sapphire crystal polishing liquid waste by using a rinse wastewater for rinsing a machine tool and ground, and forming an electric flocculation body by using a flocculant and suspended solids in the sapphire crystal polishing liquid waste; accelerating clarification by using a machine, and finely filtering the wastewater as rinse water to reuse through a continuous sand filter; separating sludge and liquid in mud sewage by using a folded screw sludge dewater, returning filtration liquid to the machine to accelerate clarification; outwardly transporting a dry mud cake to process, so as to efficiently, economically and safely process the sapphire crystal polishing liquid waste.

Owner:YANGZHOU MAOYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

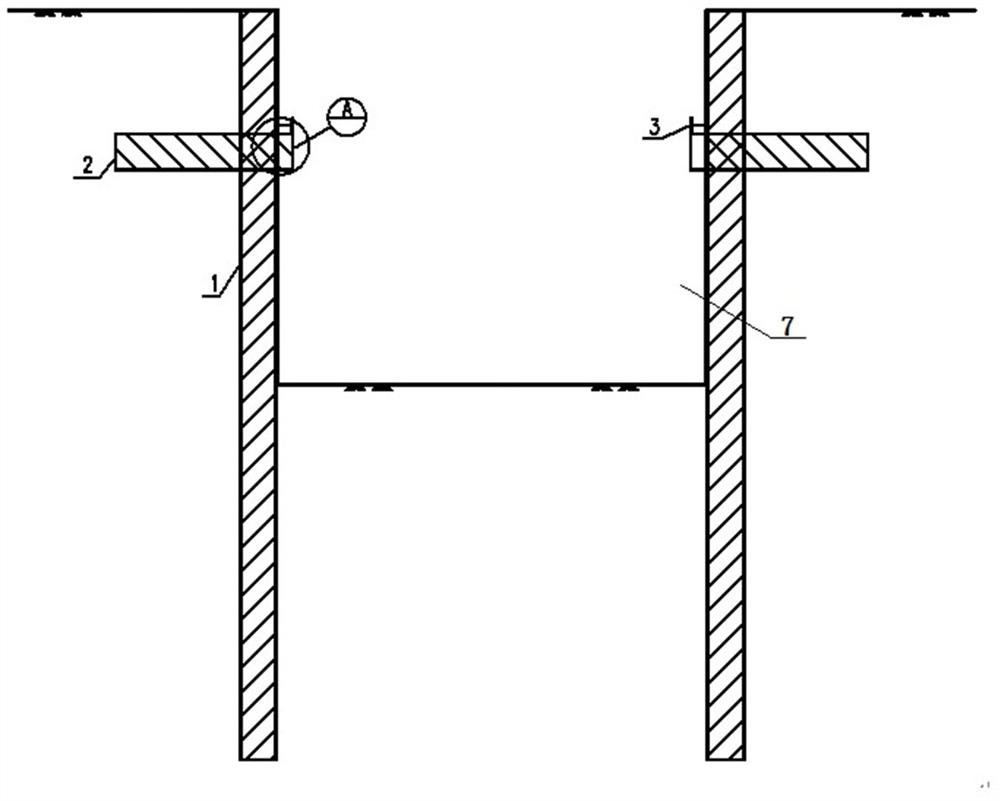

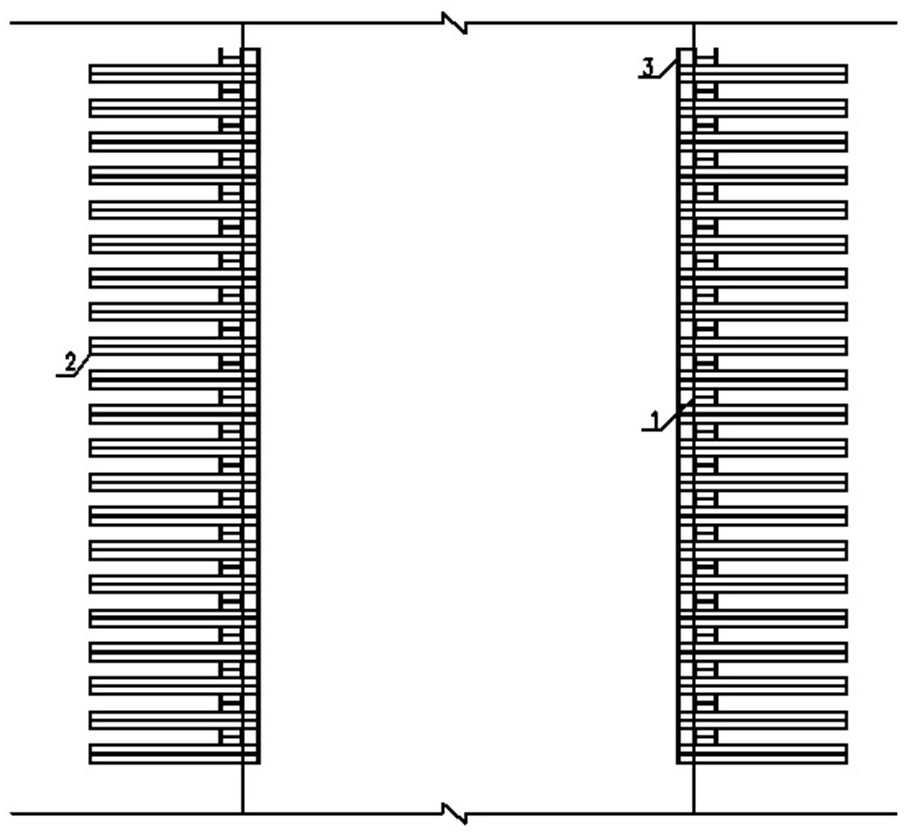

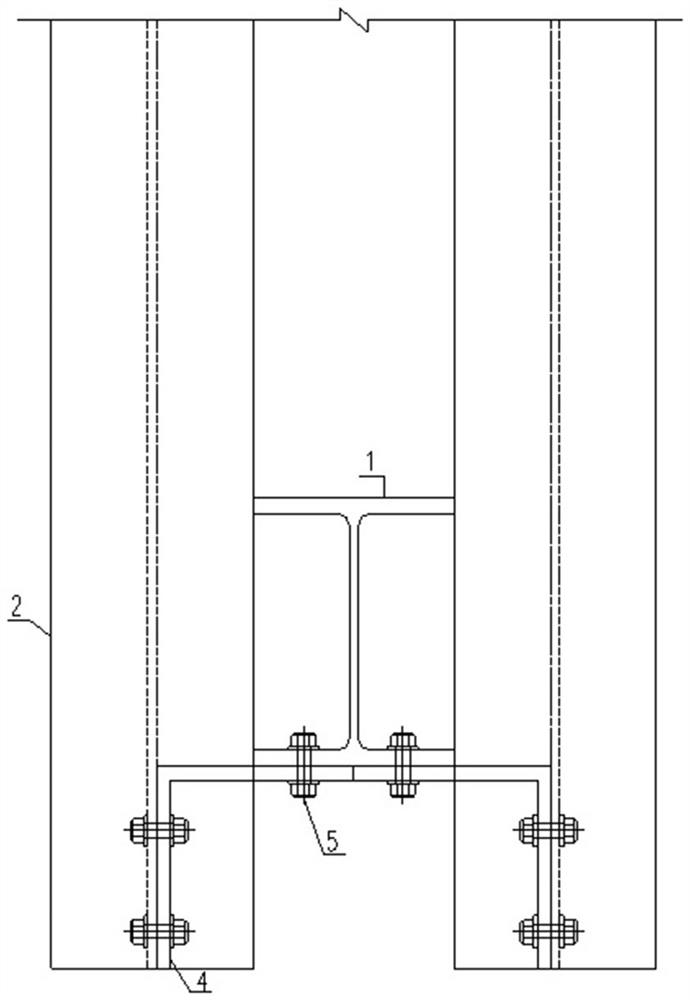

Supporting system with unloading and weight increasing effects and construction method thereof

PendingCN112900444ASmall sizeReduce horizontal earth pressureGeometric CADDesign optimisation/simulationSupporting systemArchitectural engineering

The invention relates to the technical field of underground foundation pit engineering and slope supporting, in particular to a supporting system with unloading and weight increasing effects and a construction method thereof, and is characterized in that the supporting system comprises a vertical supporting structure, a transverse unloading and weight increasing structure and a connecting structure. The vertical supporting structure is used for supporting the side edge, subjected to pressure of an outer side soil body, of a supported object, the transverse unloading and weight increasing structure is arranged in the height direction of the vertical supporting structure and located below the elevation of the supported object, and one end of the transverse unloading and weight increasing structure is arranged in the outer side soil body of the side edge. The transverse unloading and weight increasing structure is connected with the vertical supporting structure through the connecting structure to form an integral supporting system. The supporting system has the advantages that the construction efficiency is high, the environmental influence is small, the economical efficiency is good, materials can be recycled, the loading bearing capacity is high, the structural system fully utilizes the self weight of the soil body, certain self-stability is achieved, and the anti-overturning stability of the supporting structure is good.

Owner:CHINA RAILWAY SHANGHAI DESIGN INST GRP

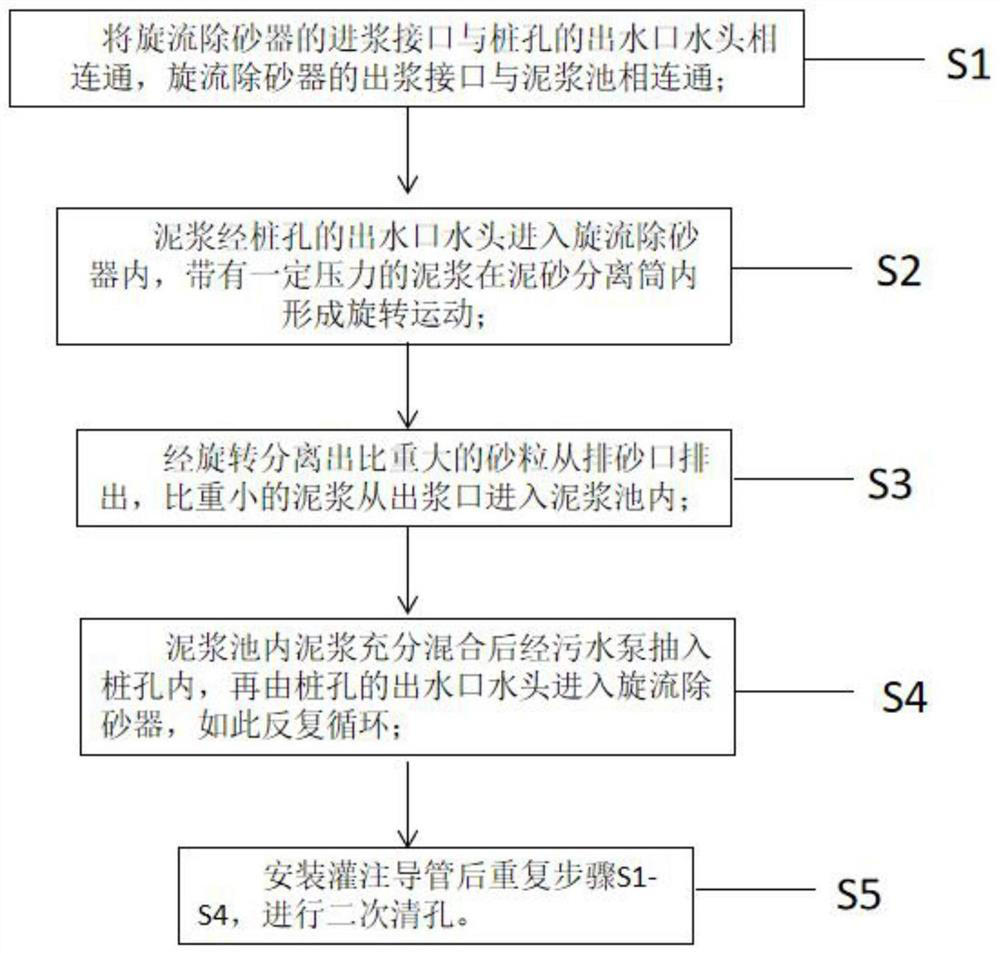

Method for cleaning drill hole

PendingCN113944165AShorten the construction periodMain indicators decreasedBulkheads/pilesDesanderOutfall

The invention discloses a method for cleaning a drill hole. The method comprises the following steps: S1, communicating a slurry inlet connector of a cyclone desander with a water outlet water head of a pile hole, and communicating a slurry outlet connector of the cyclone desander with a slurry pool; S2, feeding the slurry into the cyclone desander through the water outlet water head of the pile hole, wherein the slurry with certain pressure rotates in a mud-sand separation barrel; S3, separating out sand grains with large specific gravity through rotation and discharging the sand grains from a sand discharging opening, and feeding slurry with small specific gravity into the slurry pool from a slurry outlet; S4, pumping the slurry in the slurry pool after being fully mixed into the pile hole through a sewage pump and then feeding the slurry into the cyclone desander through the water outlet water head of the pile hole, and repeating the process; and S5, after the perfusion catheter is installed, repeating the steps S1 to S4 for secondary hole cleaning. The invention provides a method capable of efficiently and simply cleaning the drill hole.

Owner:SHANGHAI BAOYE GRP CORP

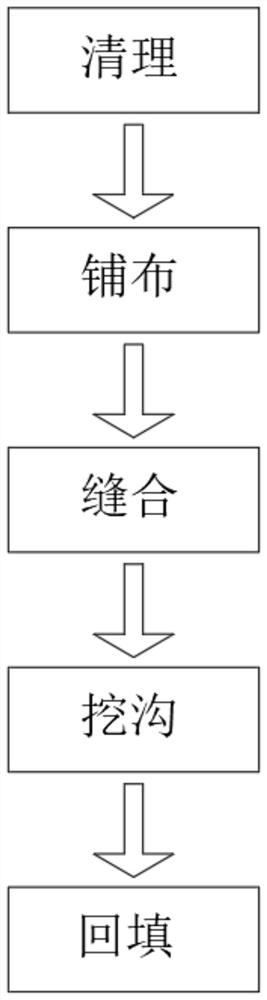

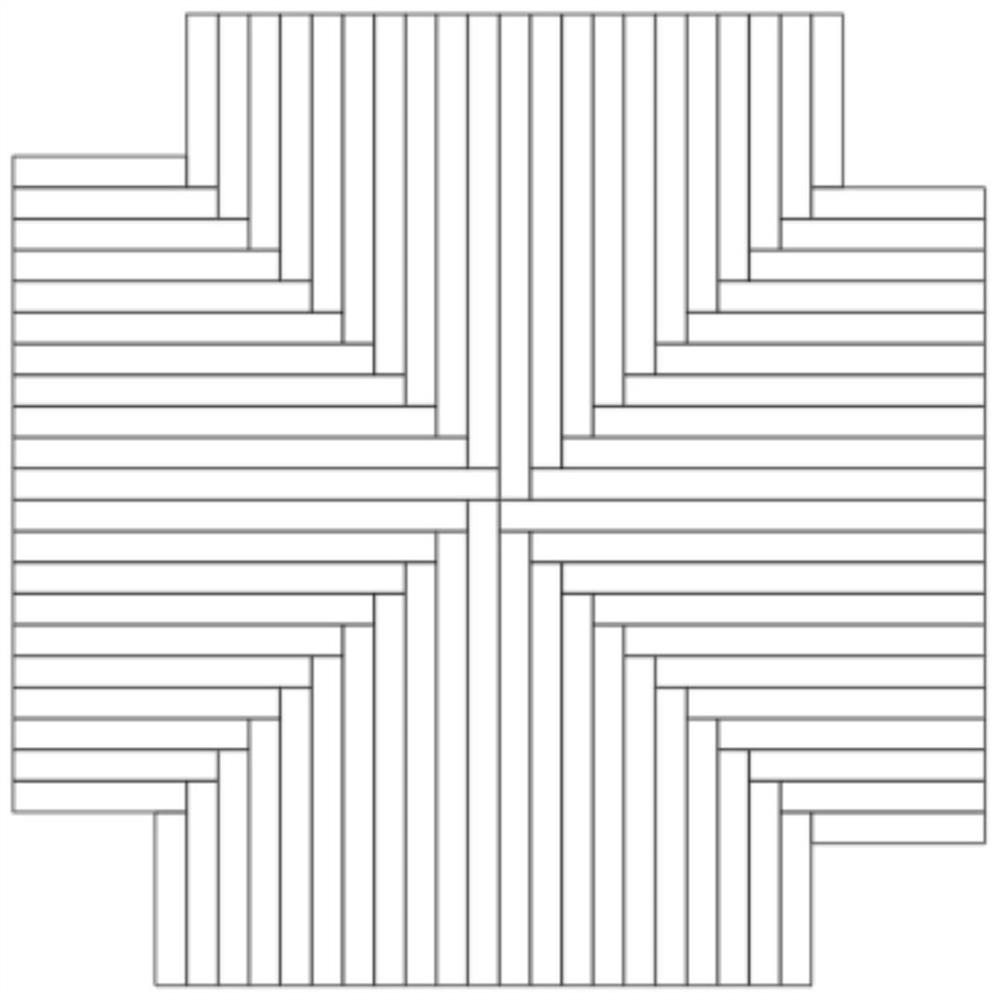

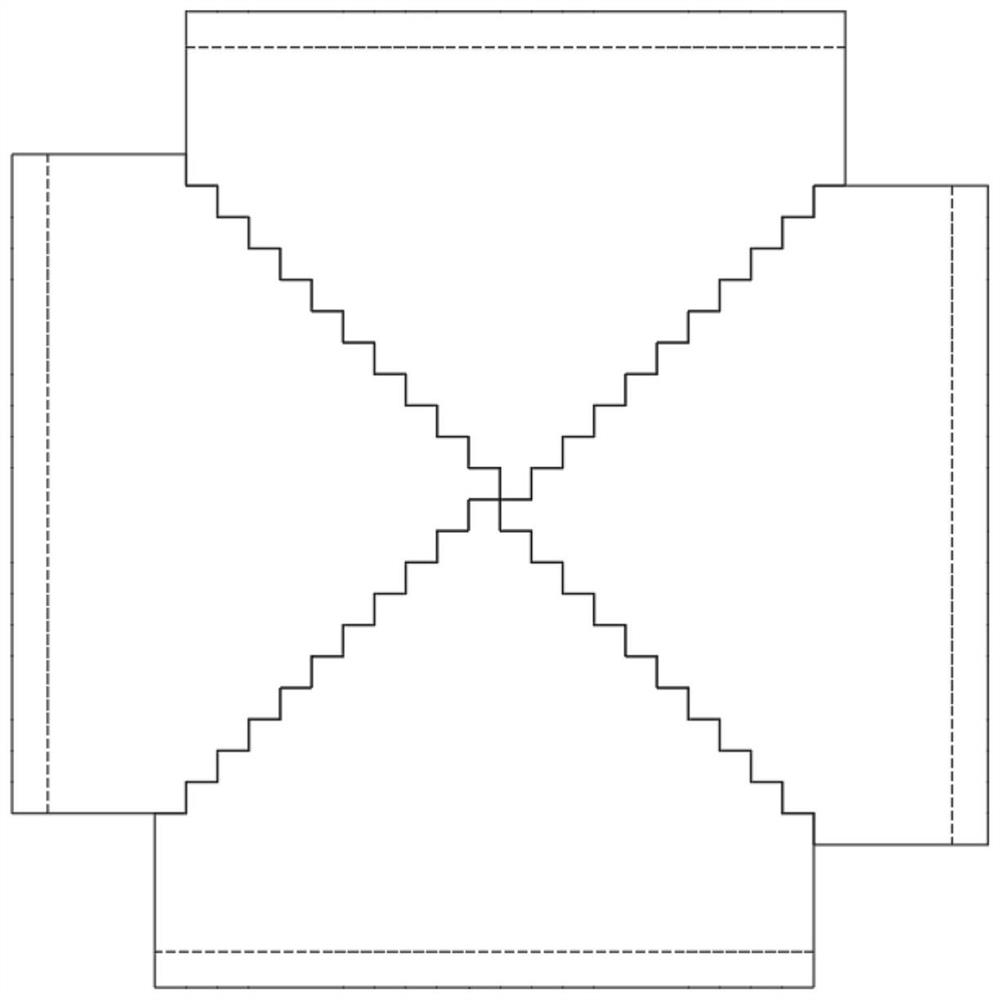

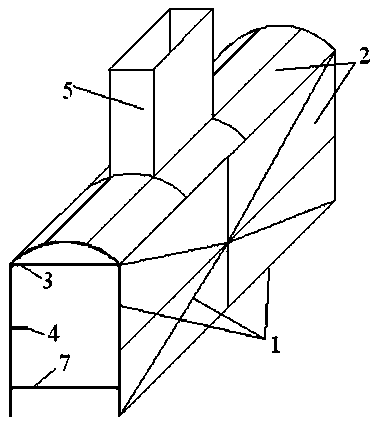

Sludge foundation backfilling construction method

ActiveCN111691392AConvenient laying and constructionHigh tensile strengthExcavationsSoil preservationSoil scienceSludge

The invention belongs to the field of building construction, and particularly relates to a sludge foundation backfilling construction method. The sludge foundation backfilling construction method comprises the steps of cleaning, cloth laying, sewing, ditching and backfilling, specifically, firstly, weeds, tree roots and other sundries on the surface of a sludge layer are cleaned, then geotechnicalcloth is laid on the surface of the sludge layer, and lapped seams of the geotechnical cloth are sewn; digging an annular anchoring ditch around the geotechnical cloth, and finally filling the mixture into the anchoring ditch and the upper surface of the geotechnical cloth. According to the sludge foundation backfilling construction method, a reinforced isolation layer can be adopted, differential settlement of the foundation caused by the water content difference of the sludge layer can be ignored, backfill materials can be isolated from an original-state soft sludge layer, the integrity ofthe backfill layer is high, the backfill quality is effectively guaranteed, and the soft foundation reinforcing effect is good.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

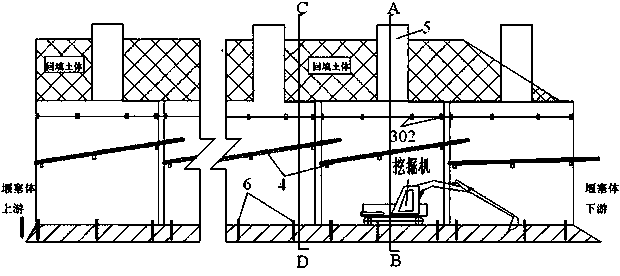

Open caisson for mechanical excavation of barrier lake sluice channel and excavation method

PendingCN110042856AReduce excavationReduce outbound volumeCaissonsLandslide damStructural engineering

The invention relates to an open caisson for mechanical excavation of a barrier lake sluice channel and an excavation method. The open caisson is characterized by being placed vertically, the open caisson is provided with an open bottom and openings on the two longitudinal sides, the open caisson is composed of a skeleton, an upper supporting beam, a lower supporting beam, enclosure plates, a transfer device and a safety patio, the enclosure plates are installed on the two transverse sides and at the top of the skeleton, the enclosure plates longitudinally enclose the skeleton into open caisson passages, the safety patio is installed at the top of the skeleton and communicates with the open caisson passages, a conveyor belt of the transfer device is longitudinally arranged in the open caisson passages, and the multiple open caisson passages are longitudinally spliced to form a sluice channel passage. The excavation method includes the following steps of open shallow slot excavation, open caisson structure installation, stake driving and excavation in the first stage and second stage, and lower supporting beam installation and stake pulling out and recycling. The earthwork excavatedvolume is greatly decreased, the grooving time is shortened, the section of open put slope excavation is an inverted trapezoid with narrow bottom and wide top, and the excavation section of the opencaisson type excavation method is rectangular, so that the cross section area is greatly decreased.

Owner:EAST CHINA UNIV OF TECH

Slurry for SCAP (slurry, cake, air, pressure) type earth pressure balance shield bulk breaking and preparation method of slurry

ActiveCN110436836AReduce outbound volumeAlleviate the problem of outbound transportationTunnelsEarth pressure balanceAir drying

The invention discloses slurry for SCAP (slurry, cake, air, pressure) type earth pressure balance shield bulk breaking. The slurry comprises the following components in parts by mass: 50-80 parts of clay, 400-600 parts of clean water, 100-150 parts of calcium bentonite, 2-6 parts of an improver and 0-2 parts of a tackifier. The invention further discloses a preparation method of the slurry for SCAP type earth pressure balance shield bulk breaking. The preparation method comprises the following steps: performing air drying on waste powdered soil generated when a shield excavates into a powderedsand or powdered clay layer, performing screening, and storing the soil near a muck pit; when a shield needs pressurized bulk breaking, adding the stored powdered soil, the clean water, the calcium bentonite, the improver and t he tackifier into a slurry vehicle, and performing continuous stirring, so as to prepare a product which meets requirements of slurry on densities and viscosities. As muckdiscarded in the tunneling process is utilized, bentonite resources can be saved, the bulk breaking cost can be reduced, environment pollution caused by muck transportation can be reduced, and slurryfor bulk breaking, which meets requirements such as densities, viscosities and physical and chemical stability, can be prepared.

Owner:HOHAI UNIV

Cement-soil preparation system suitable for different fluidity and soil

ActiveCN108058269BImprove work efficiencyClean up in timeMixing operation control apparatusClay mixing apparatusSoil scienceCement slurry

A cement soil preparation system suitable for different fluidities and soil bodies includes a soil material sieve separator, a soil material measuring bin, a slurry stirring station, a cement bin, a cement measuring bin, a cement slurry stirring station and a slurry storage tank; the soil material sieve separator is used for sieving a soil material, and the sieved soil material is transported to the soil material measuring bin through a conveying belt 19; the soil material measuring bin is used for weighing a certain amount of soil material according to the set weight, and the weighed soil material is transported to the slurry stirring station through a conveying belt conveyor 3; the slurry stirring station is used for stirring the soil material and water according to the set fluidity, theslurry after stirring is transported into the slurry storage tank; the cement bin is used for storing cement, and a discharge port of the cement bin is connected to an inlet of the cement measuring bin by an air compressor; the cement measuring bin is used for weighing a certain amount of cement according to the set weight, the weighed cement is transported to the cement slurry stirring station through a delivery pipe 22; the cement slurry stirring station is used for stirring the cement and other material flows according to the set fluidity, and the slurry after stirring is transported intothe slurry storage tank; a discharge port of the slurry storage tank is connected with a grouting pipe.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

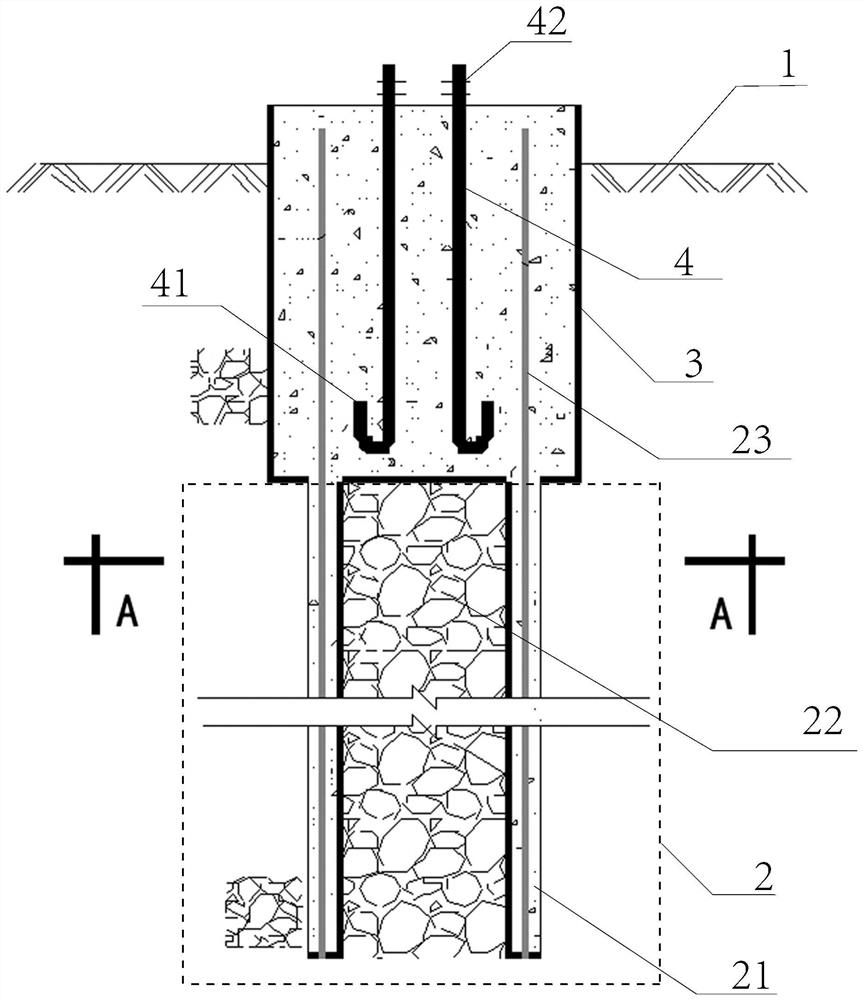

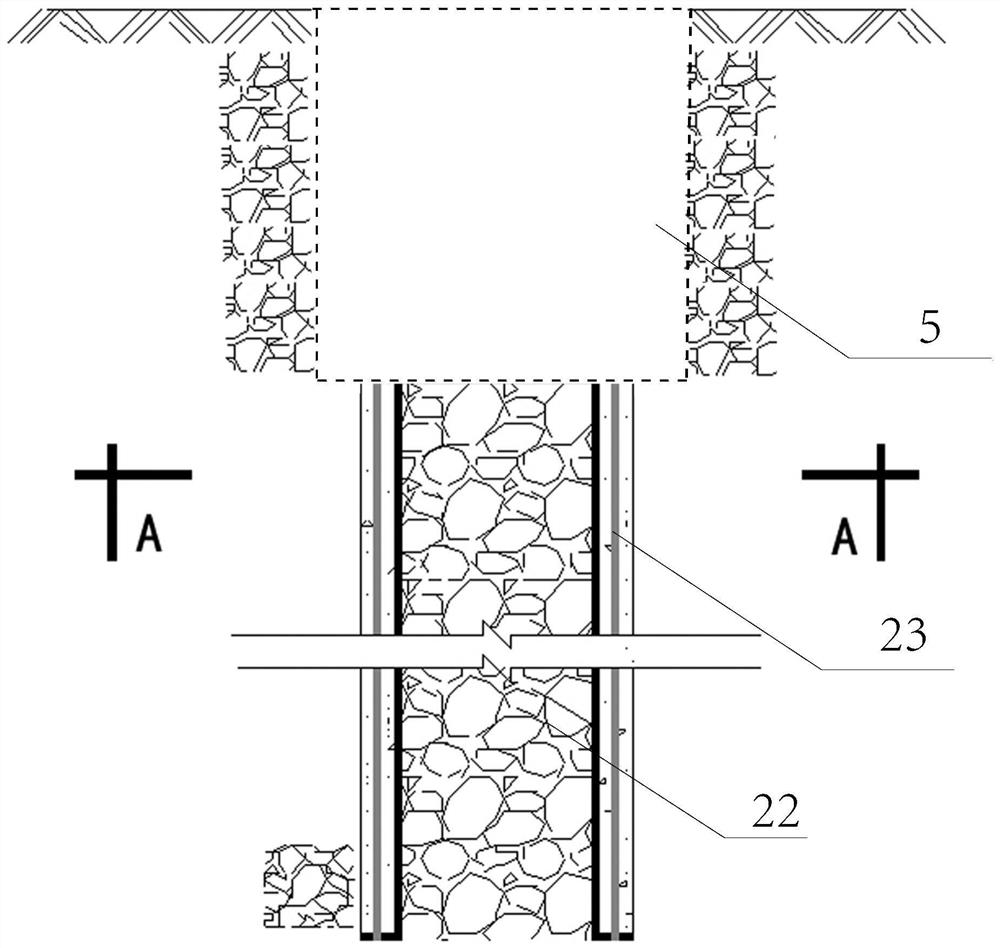

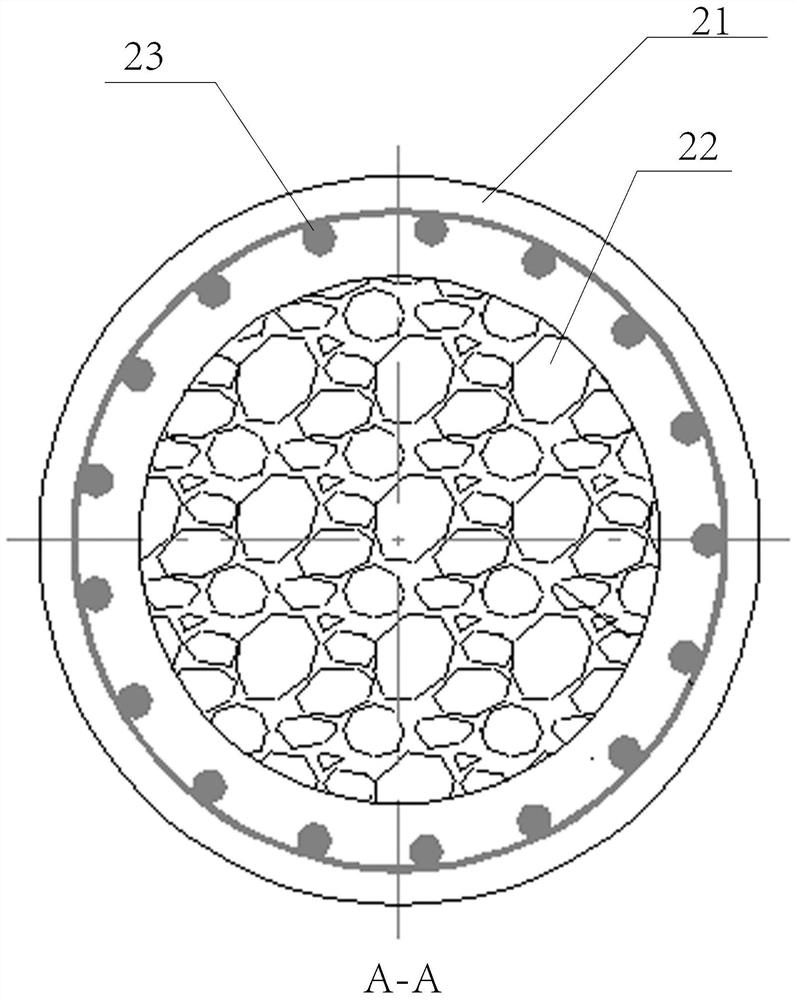

Annular-section rock foundation suitable for mountainous area and construction method of annular-section rock foundation

PendingCN113789806AImprove the bearing capacity of the foundationReduce dosageFoundation engineeringArchitectural engineeringEarth surface

The invention discloses an annular-section rock foundation suitable for a mountainous area and a construction method of the annular-section rock foundation. The annular-section rock foundation comprises a ground surface, a foundation annular column body, a concrete solid column body and foundation bolts; the foundation annular cylinder is located below the earth surface; the concrete solid column body is embedded into a solid column body foundation pit between the foundation annular column body and the ground surface and is positioned right above the foundation annular column body; the foundation annular cylinder is composed of an annular foundation trench and a rock mass surrounded by the annular foundation trench; a reinforcement cage is placed in the annular foundation trench, and concrete is poured in the annular foundation trench; the height of the reinforcement cage is larger than the sum of the depth in the annular foundation trench and the depth of the solid cylinder foundation pit, but the height of the reinforcement cage is smaller than the sum of the height of the foundation annular cylinder and the height of the concrete solid cylinder; the foundation bolt comprises a fixed end; and the fixed end is connected with equipment needing to be fixed. By means of the construction method, the problems that foundation pit excavation is difficult, the construction method is complex, the construction potential safety hazard is high, the mechanization degree is low, and economical efficiency is poor are solved.

Owner:NORTH CHINA POWER ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com