Construction method of mixing pile wall

A construction method and a technology of mixing pile walls, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as structural hazards of formed mixing pile walls, displacement of underground facilities, road cracks, etc. The effect of less transportation volume, lower construction cost and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

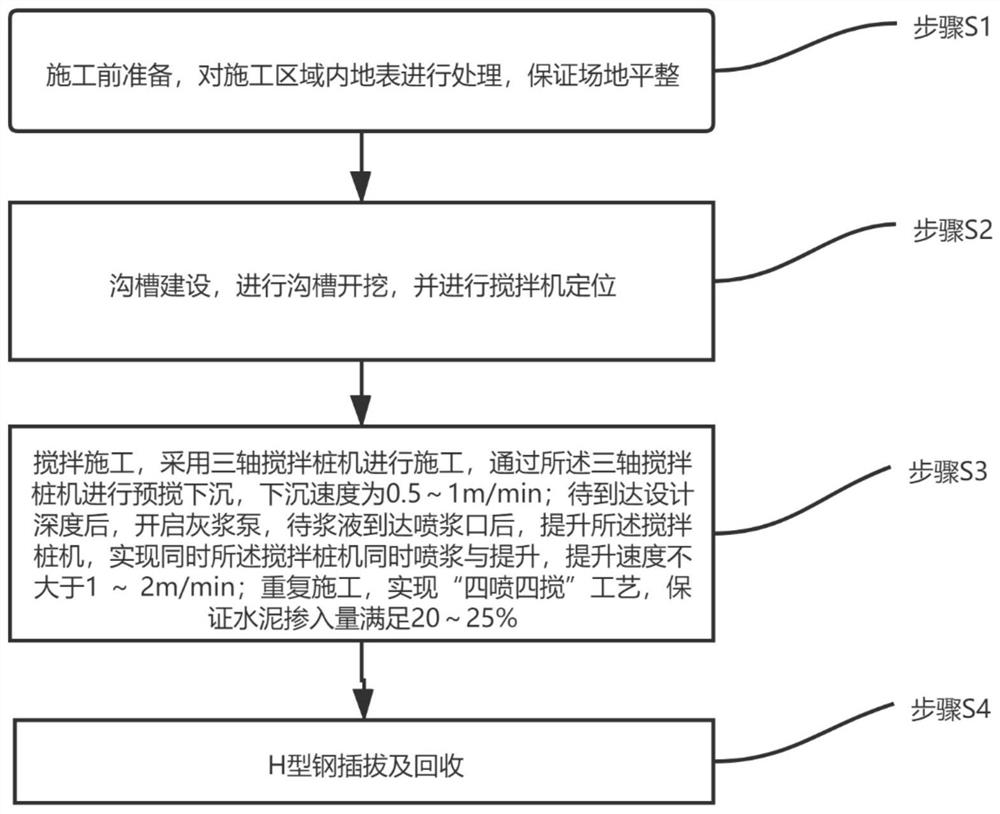

[0053] like figure 1 As shown, the embodiment of the present invention provides a kind of mixing pile wall construction method, comprises the steps:

[0054] Step S1: Preparation before construction, processing the ground surface in the construction area to ensure the level of the site;

[0055] Step S2: Trench construction, trench excavation, and mixer positioning;

[0056] Step S3: Stirring construction, using a three-axis stirring pile machine for construction, and pre-stirring and sinking through the three-axis stirring pile machine, the sinking speed is 0.5-1m / min; after reaching the design depth, turn on the mortar pump, wait After the slurry reaches the grouting port, lift the agitating pile machine to achieve simultaneous grouting and lifting of the agitating pile machine at the same time. The amount of cement added meets 20-25%;

[0057] Step S4: H-shaped steel plugging and recycling.

[0058] Among them, the ground surface in the construction area is treated, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com