Comprehensive pretreatment process for food waste and kitchen waste oil

A technology for catering waste and waste oil, which is applied in the recovery of fat oil/fatty acid from waste, recycling technology, and fat production, which can solve problems such as non-compliance with environmental protection concepts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

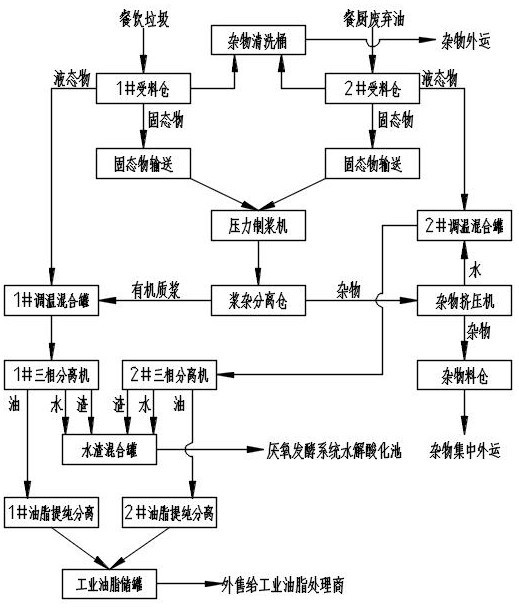

[0052] Such as figure 1 As shown, a comprehensive pretreatment process for catering waste and kitchen waste oil, at least including the following process sections in airtight connection: material receiving and separation section, pulping section, pulp and impurity separation section, temperature adjustment and mixing section, three-phase separation section and Oil storage section.

[0053] Receiving and separating section:

[0054] A. Eliminate non-organic impurities and clean them before shipping;

[0055] Large pieces of non-organic debris are removed from the food waste and kitchen waste oil respectively, and the removed large pieces of non-organic debris are transported to the debris cleaning device, and the large pieces of non-organic debris are transported out after cleaning by the debris cleaning device.

[0056] Catering garbage is loaded from the feed port I of the 1# receiving bin, and the 1# receiving bin removes large non-organic debris first, and the removed lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com