Sludge foundation backfilling construction method

A construction method and silt quality technology, applied in basic structure engineering, excavation, construction, etc., can solve the problems of inability to accurately predict the treatment effect, great influence of treatment results, uneven foundation settlement, etc. Quantity, good reinforcement effect, and the effect of improving the efficiency of backfill construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

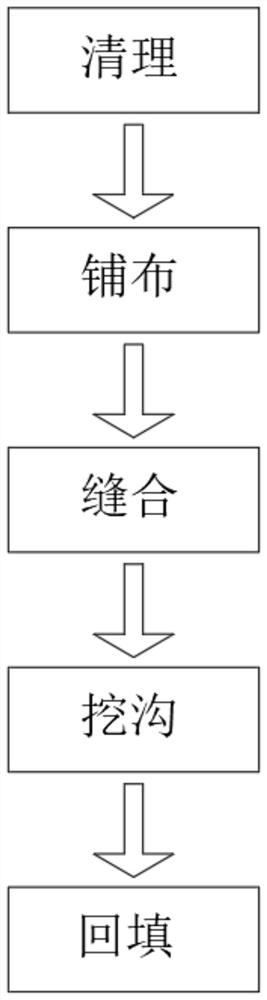

[0033] Such as Figure 1-3 Shown, a kind of silt foundation backfilling construction method comprises the following steps:

[0034] S1, cleaning, cleaning up the weeds, tree roots and other sundries on the surface of the mud layer;

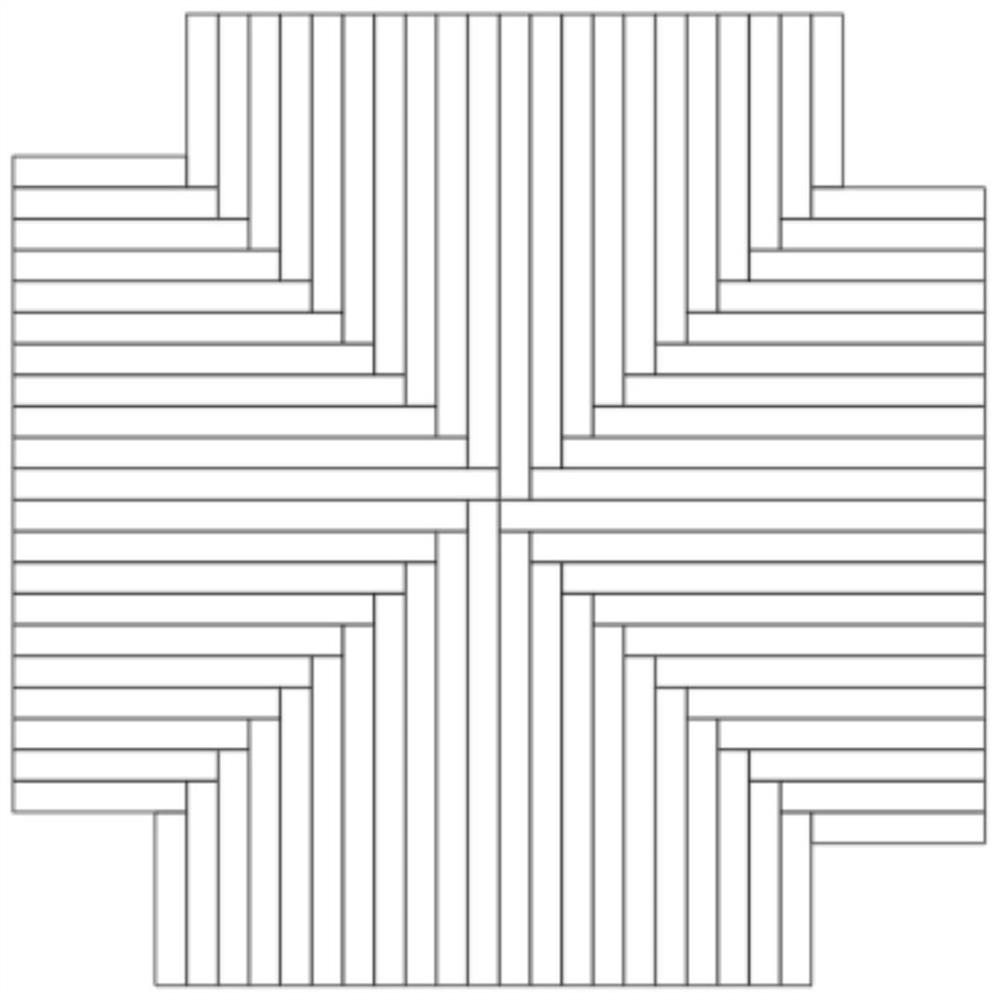

[0035] S2, laying the cloth, laying the geotextile on the surface of the silt layer, specifically, when the geotextile is laid, the silt layer is divided into at least four areas according to the orientation and laid separately, and the geotextiles in the same area are arranged in parallel , The overlapping joints of each adjacent area are distributed in a zigzag shape;

[0036] S3, stitching, stitching the lap joints of the geotextiles, specifically, using a hand-held portable sewing machine, and using nylon threads to sew the geotextiles. Less than 50mm, the distance between two sutures is 10-25mm;

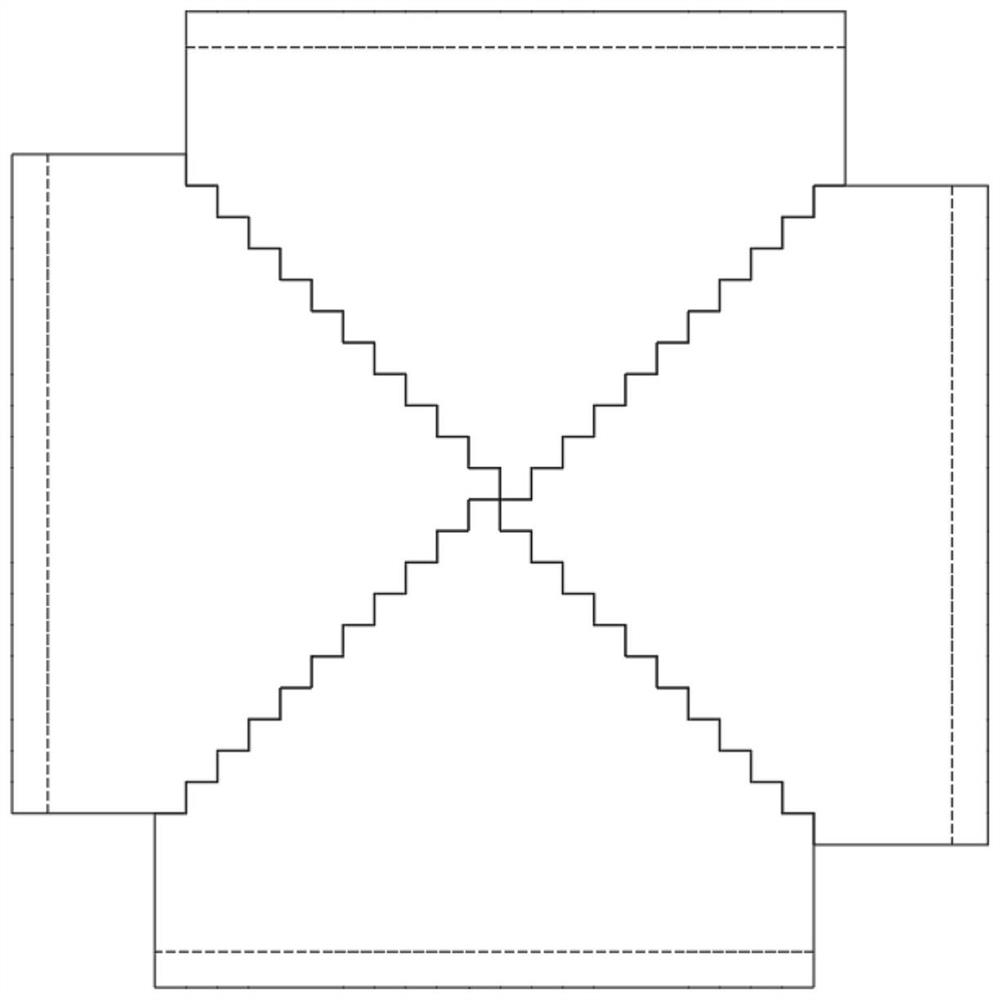

[0037] S4, digging a trench, digging a ring-shaped anchoring ditch around the geotextile, the shape of the anchor ditch corresponds to the layin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com