Supporting system with unloading and weight increasing effects and construction method thereof

A construction method and system technology, applied in the field of underground foundation pit engineering and slope support, can solve the problems of low construction efficiency and high construction cost of foundation pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

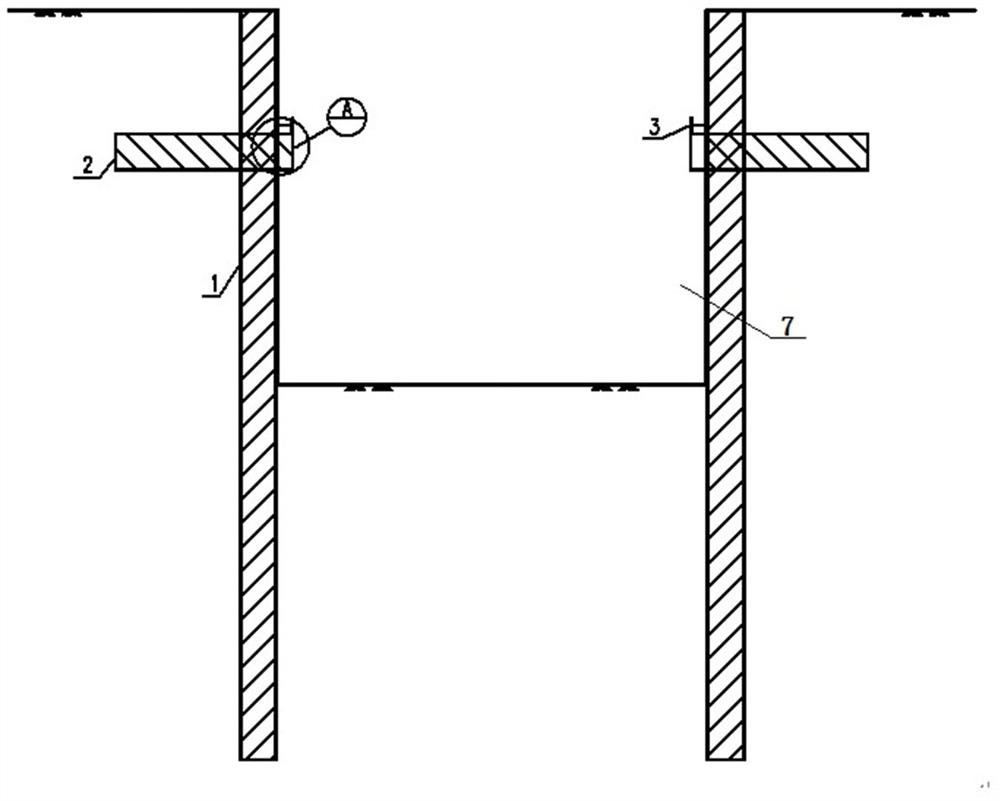

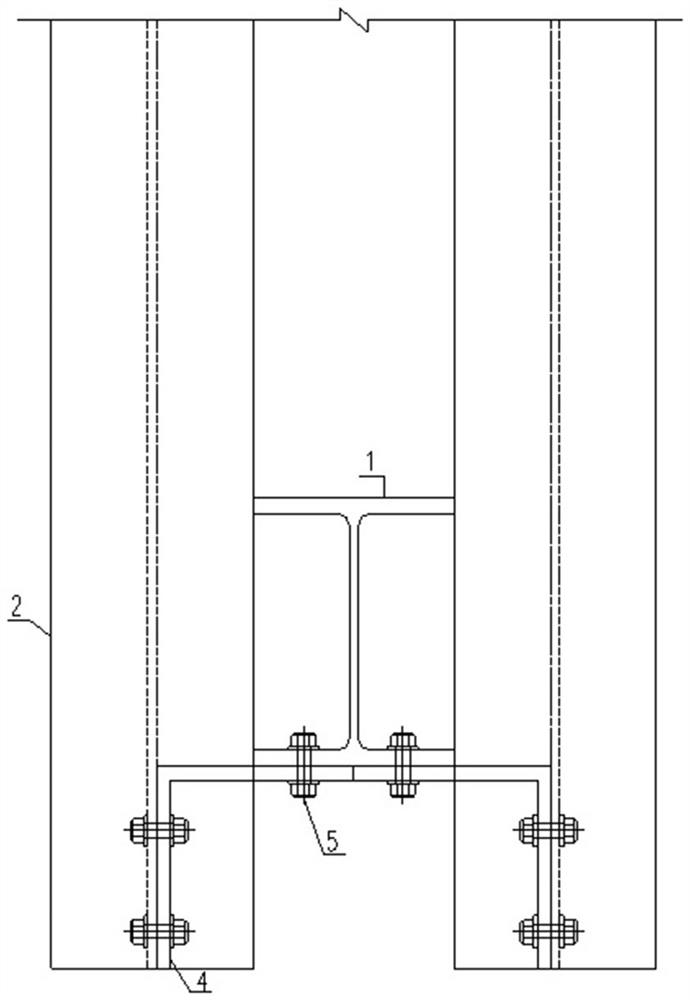

[0032] Example 1: Combining figure 1 and figure 2 As shown, the support system with unloading and weight-increasing functions in this embodiment includes a vertical support structure 1 , a lateral unloading and weight-increasing structure 2 , and a waist beam 3 . The vertical support structure 1 in this embodiment adopts H-shaped steel enclosure piles, and the horizontal unloading and weight-increasing structure adopts H-shaped steel.

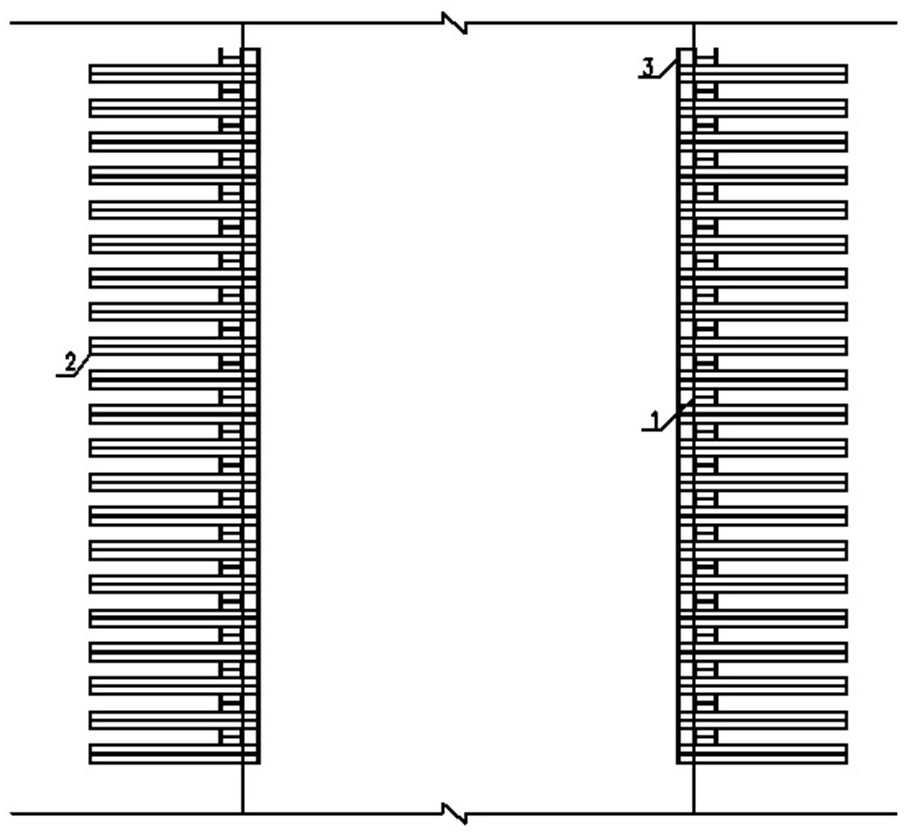

[0033] Among them, the vertical support structure 1 is arranged on the side of the pit wall of the foundation pit or slope 7 as the support object to support the foundation pit or slope 7, and the vertical support structure 1 is Resist the inward force of the external soil on both sides of the foundation pit or slope 7, and avoid overturning. Such as image 3 As shown, the vertical support structures 1 are evenly spaced along the extension direction of the side of the foundation pit or slope 7 .

[0034] The horizontal unloading weight-inc...

Embodiment 2

[0049] Embodiment 2: Compared with Embodiment 1, this embodiment differs in that: Figure 6 As shown, in this embodiment, the vertical support structure 1 adopts prefabricated piles, the horizontal unloading weight-increasing structure 2 adopts prefabricated piles, and the waist beam 3 is a cast-in-place structure. Pouring crown beam 6. Wherein, the waist beam 3 is a horizontal member connected to the protruding part of the lateral unloading weight-increasing structure 2 . In this embodiment, the waist beam 3 and the crown beam 6 of the cast-in-place structure are used as the connection structure, and the vertical support structure 1 and the lateral unloading weight-increasing structure 2 are connected to form an overall support system, which can ensure sufficient structural strength.

[0050] When implementing the above-mentioned embodiments: the structures of the vertical support structure 1, the lateral unloading structure 2 and the waist beam 3 can be selected according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com