A capsule type solid-liquid separation device and method

A solid-liquid separation and capsule technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of limited area and space, difficulty in equipment selection, and many auxiliary facilities, so as to achieve long service life and reduce external transportation The effect of the simple principle of volume and pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, describe structure of the present invention and technological realization process:

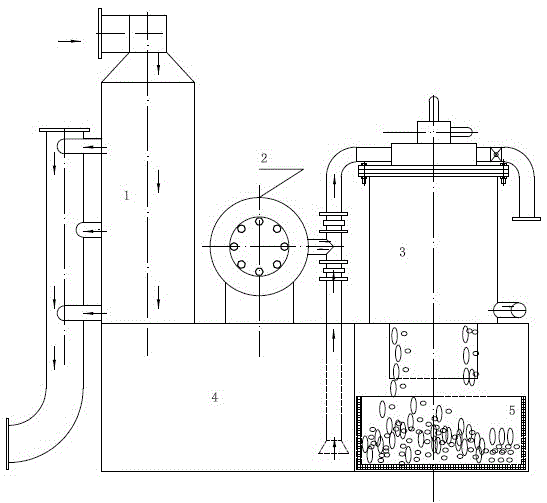

[0039] see figure 1 It is the equipment layout structure of the capsule filter press device:

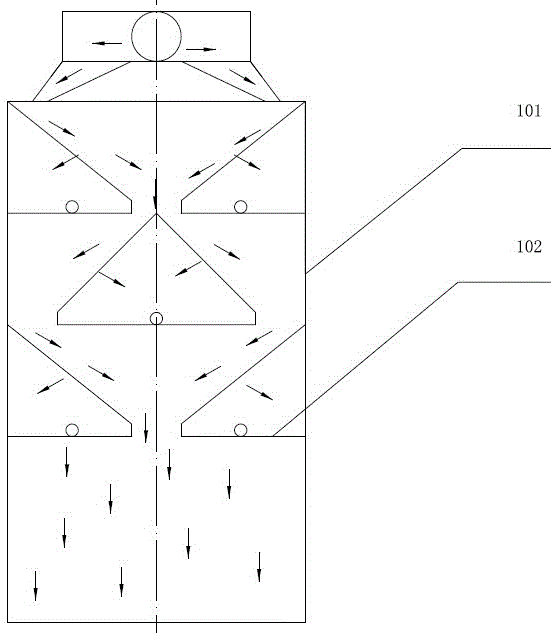

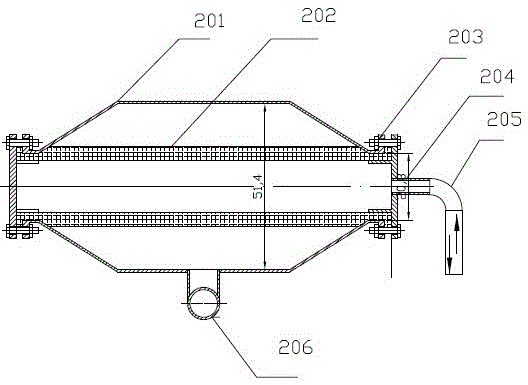

[0040] The device consists of three major components: a sieve-plate type coarse filter tank 1, a capsule-type positive displacement pump 2 and a capsule-type filter press 3, which are collectively arranged on a box used as a slurry storage tank 4 and a filter cake storage tank 5. This device is aimed at the characteristics of high-rise building sewer flow fluctuating, sometimes not, and sometimes a large amount of clear water. The sieve plate type coarse filter tank with simple structure is used for primary filtration to reduce the amount of slurry entering the filter press system. The capsule volume tank is used to transport the slurry, which can not only achieve silent operation, but also utilize the pressure energy of the urban tap water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com