Two-way stirring based SMW construction method and tri-axial stirring equipment

A two-way mixing and construction method technology, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of ground slurry, uneven mixing of cement and soil, and affect the quality of walls, etc., and achieve the effect of small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

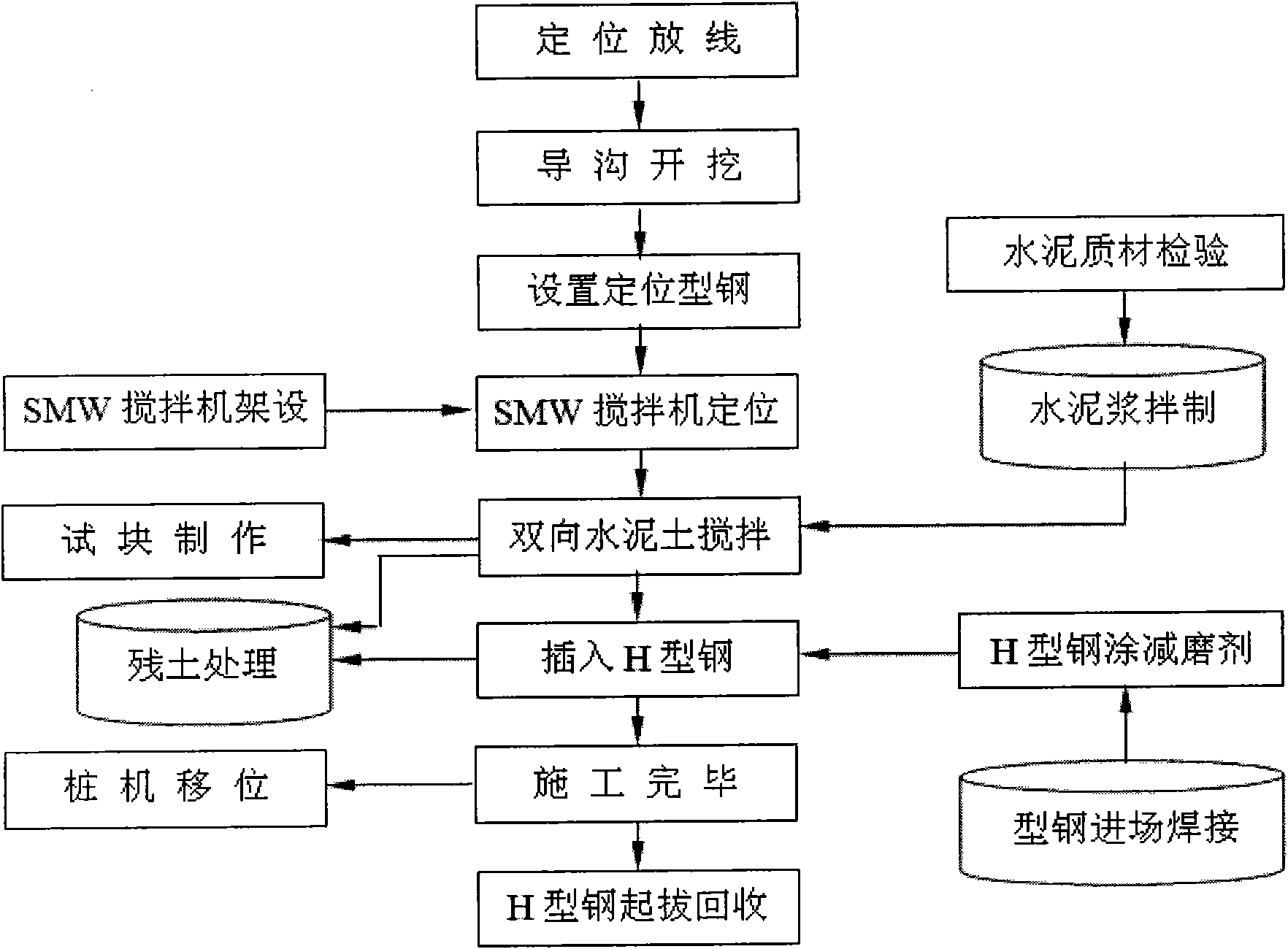

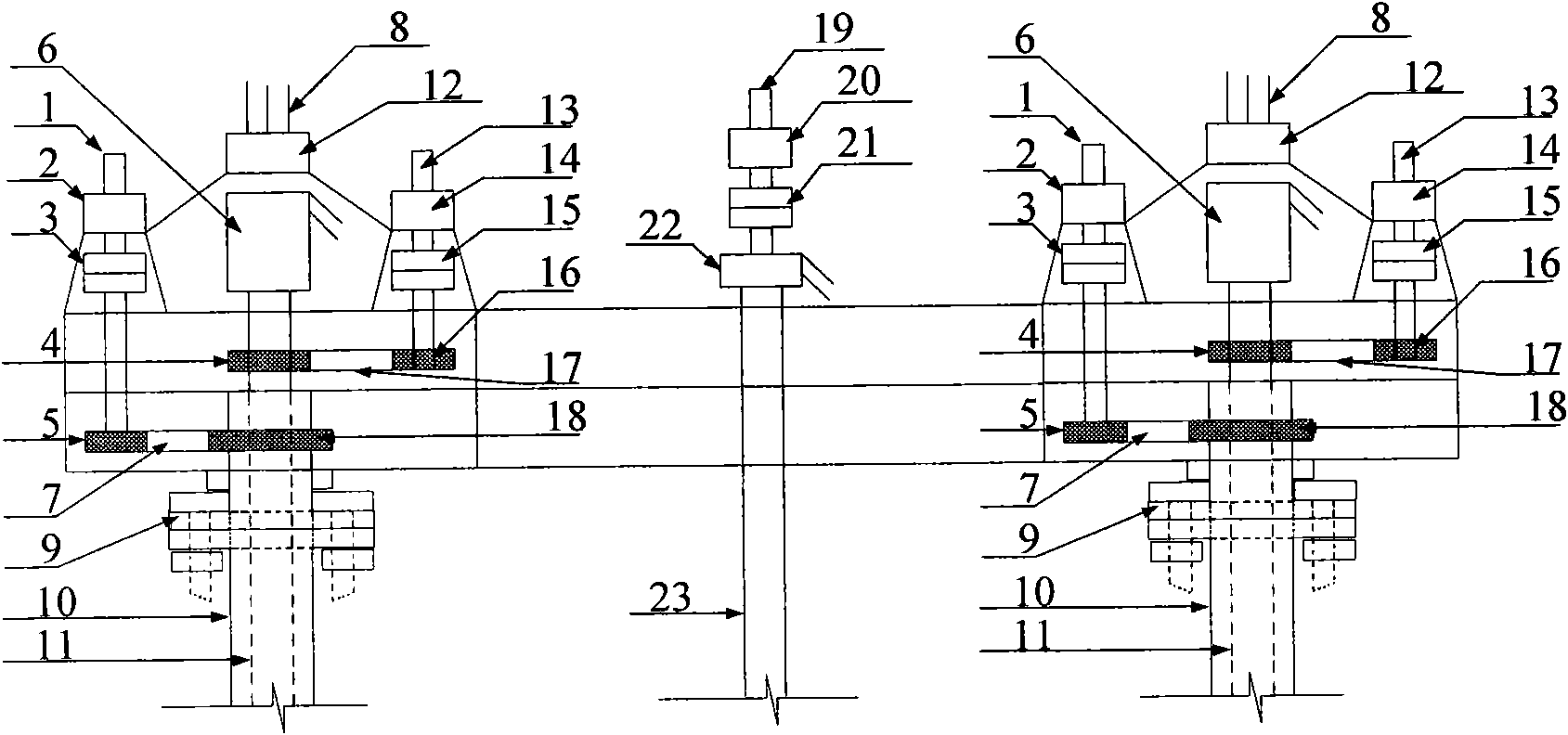

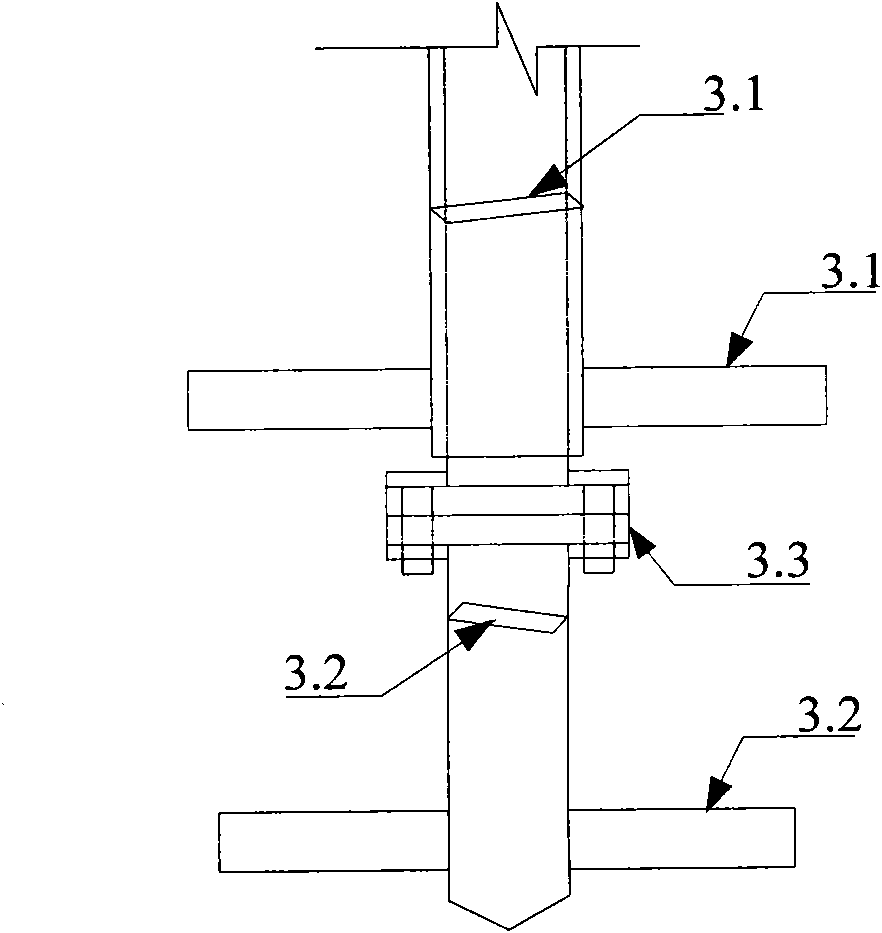

[0060] A SMW construction method based on two-way mixing. The process principle is to change the one-way mixing construction method in the traditional three-axis mixing construction into a two-way mixing construction method to form a new construction method. Specifically in this example, by using the concentric biaxial drill pipe, it plays the role of grouting and mixing cement and soil in the process of forward and reverse rotation, blocking the upward flow of cement slurry and ensuring the cement slurry in the pile. Evenly distributed in the body; at the same time, due to the addition of counter-rotating blades, the mixing of cement and soil is more complete, ensuring the construction quality. Such as Pic 4-1 and 4-2 As shown, the construction machine of this construction method includes a chassis 4.1, a frame 4.2, a power box 4.3, a drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com