Sewage treatment method for sapphire crystal polishing liquid waste

A sewage treatment method, sapphire chip technology, applied in energy waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of slow natural water removal, secondary environmental pollution, and acid pollution problems such as prolonging the cycle of cleaning sludge, obvious direct economic benefits, and reducing organic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

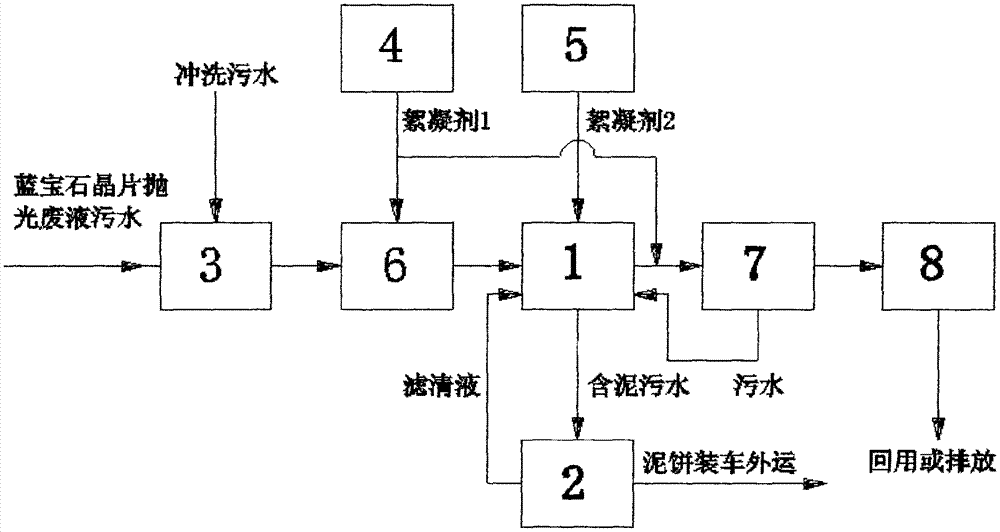

Method used

Image

Examples

Embodiment 1

[0028] Collect the flushing sewage from washing the machine tool and the ground and introduce it into the adjustment pool, adjust the ratio of sapphire wafer polishing waste water to flushing sewage in the adjustment pool at a ratio of 1:15, until the pH is 8-9, and the flocculant 1 is selectively polymerized Aluminum chloride is configured as a 0.5% aqueous solution and stored in a flocculant tank. The average treatment water volume of sapphire wafer polishing waste water is 5t / h, SS is 6800mg / L, and the addition amount of flocculant 1 aqueous solution is 5Kg / h, ( The amount of flocculant 1 added is about 10mg / Kg sewage), after mixing in the mixer, it enters the mechanical acceleration clarifier, and the flocculant 2 selects polyacrylamide, which is configured as a 0.5% aqueous solution and stored in the flocculant tank. The addition amount of the agent 2 aqueous solution is 10Kg / h, (the addition amount of the flocculant 2 is about 20mg / Kg sewage), and the flocculant reacts wi...

Embodiment 2

[0032]Collect the washing water from washing the machine tool and the ground and introduce it into the adjustment pool, and adjust it according to the ratio of sapphire wafer polishing waste water to washing water at a ratio of 1:20 in the adjustment pool until the pH is 8-9, and the flocculant 1 is selectively polymerized Aluminum chloride is configured as a 0.5% aqueous solution and stored in a flocculant tank. The average treatment water volume of sapphire wafer polishing waste water is 5t / h, SS is 6800mg / L, and the addition amount of flocculant 1 aqueous solution is 5Kg / h, ( The amount of flocculant 1 added is about 10mg / Kg sewage), after mixing in the mixer, it enters the mechanical acceleration clarifier, flocculant 2 selects polyacrylamide with a solid molecular weight of 14 million, configures it into a 0.2% aqueous solution, and stores In the flocculant tank, the addition amount of the flocculant 2 aqueous solution is 7.5Kg / h, (the addition amount of the flocculant 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com