Nickel surface treatment wastewater treatment system and method

A wastewater treatment system and surface treatment technology, used in metallurgical wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of residual sludge, insufficient sedimentation reaction, etc., and achieve easy scraping and cleaning. , Improve the cleaning effect, improve the effect of the settlement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

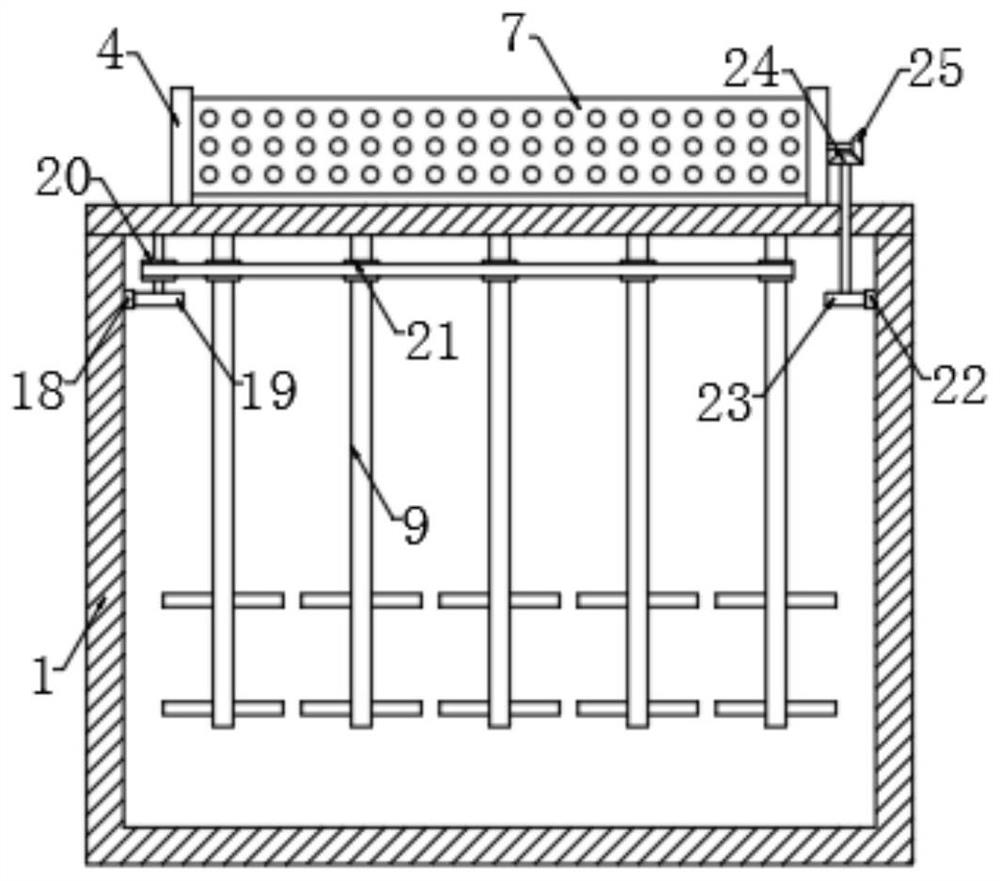

[0031] according to figure 1 , image 3 and Figure 4As shown, including the sedimentation tank 1, both sides of the top of the sedimentation tank 1 are provided with a first chute, and the first slider 2 is slidably connected in the two first chute, and the two first sliders 2 are slidably set respectively. On both sides of the bottom of the first slide plate 3, both sides of the top of the first slide plate 3 are fixedly provided with supporting blocks 4, one side of one of the supporting blocks 4 is fixedly provided with a first support bar 5, and the two sides of the first support bar 5 A plurality of stirring rods 6 are fixed on each side, and the stirring rods 6 mix and stir the decomplexing agent. The outer wall of the first support rod 5 is rotatably connected with a drum 7, and one side of the drum 7 is provided with a liquid inlet. The outer wall of 7 is provided with a plurality of liquid outlets. When the first slide plate 3 moves, the use of the second rack 22, ...

Embodiment 2

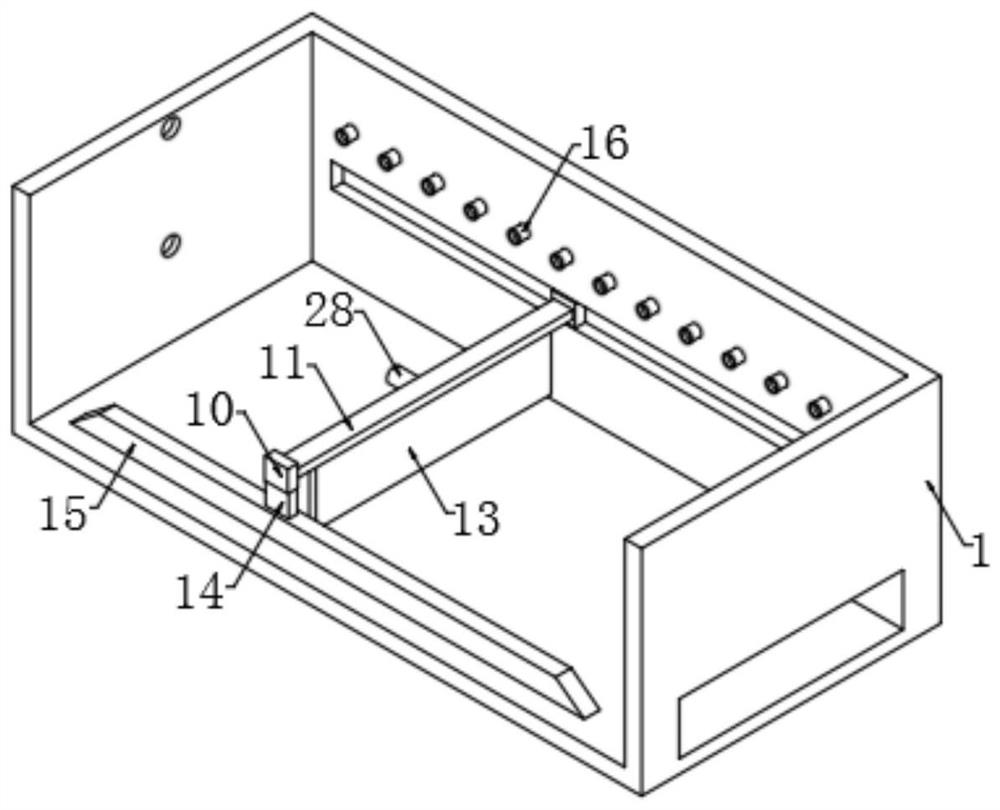

[0033] On the basis of embodiment one, according to figure 2 , Figure 5 and Image 6 As shown, the middle part of both sides of the inner wall of the sedimentation tank 1 is provided with a second chute, and a second slide block 10 is slidably connected in the two second chute, and the two second slide blocks 10 are fixedly arranged on the second slide plate respectively. On both sides of 11, the bottom end of the second slide plate 11 is provided with a through groove, and the first air bag 12 is fixed in the through groove, and the bottom end of the first air bag 12 is fixed with a scraper 13, and the scraper 13 is interspersed with the through groove. , the bottom ends of the two second sliders 10 are fixedly provided with a pressure plate 14, and the bottom ends of the two pressure plates 14 are fitted with a second air bag 15. During the movement of the second slider 10, the second slider 10 and the friction bar 17, the gas in the second airbag 15 is heated, and at th...

Embodiment 3

[0035] On the basis of embodiment one and embodiment two, according to Figure 1-6 As shown, the rotating drum 7 and the stirring shaft 9 rotate synchronously to realize mixing and stirring of the decomplexing agent and waste water while spraying the decomplexing agent evenly to make them evenly mixed, and then place it in the sedimentation tank 1 for further The sediment is left standing, and during the movement of the second slider 10, through the frictional contact with the friction bar 17, and then through the action of the pressure plate 14, the second air bag 15, the exhaust pipe and the nozzle 16, the water is passed into the sedimentation tank 1. The hot steam dries the sludge settled in the sedimentation tank 1. At the same time, during the continuous friction between the second slider 10 and the friction bar 17, the first air bag 12 expands, driving the scraper 13 to move downward, and the sediment The sludge in the pool 1 is scraped and cleaned, and as the first air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com