Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce cleavage reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aromatization catalyst and clean gasoline producing process

InactiveCN1488723AHigh yieldFacilitated DiffusionRefining to change hydrocarbon structural skeletonMolecular sieveAromatization

The present invention relates to an aromatization catalyst and production process of clean gasoline. Said invention adopts hydrofining and aromizing two-stage catalyst combined process to make the FCC gasoline with high sulfur content and high olefin content into clean gasoline. Said invented aromatization catalyst adopts small-grain molecular sieve catalyst, and makes the aromatization catalyst undergo the process of hydrothermal treatment and can make the strong acid quantity of said catalyst be reduced. Said invention can raise yield of gasoline, and can obtain high-quality clean gasoline product.

Owner:CHINA PETROLEUM & CHEM CORP +1

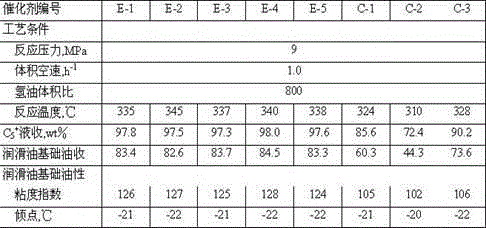

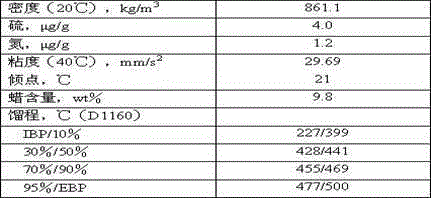

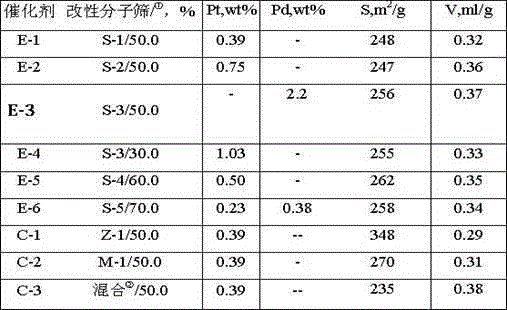

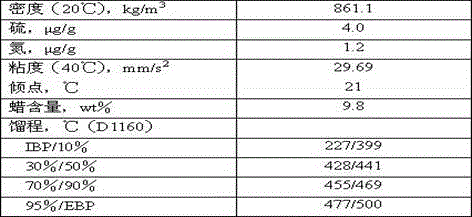

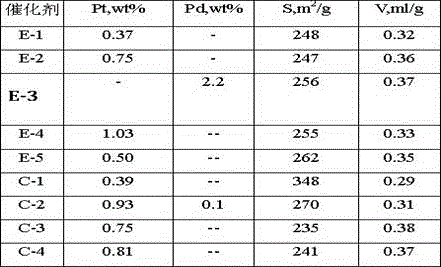

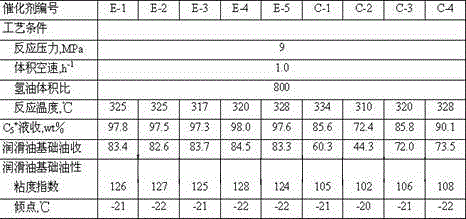

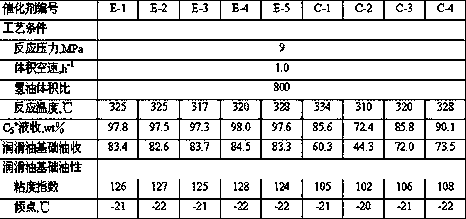

Paraffin hydrocarbon shape selective isomerization catalyst, preparation method and application thereof

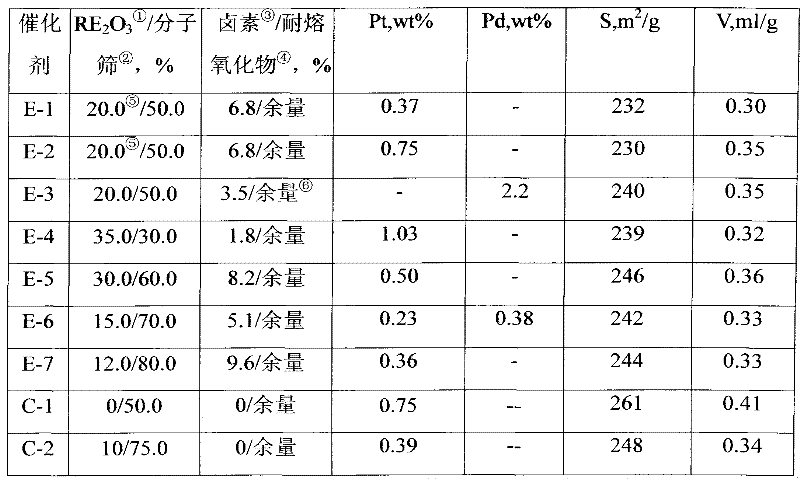

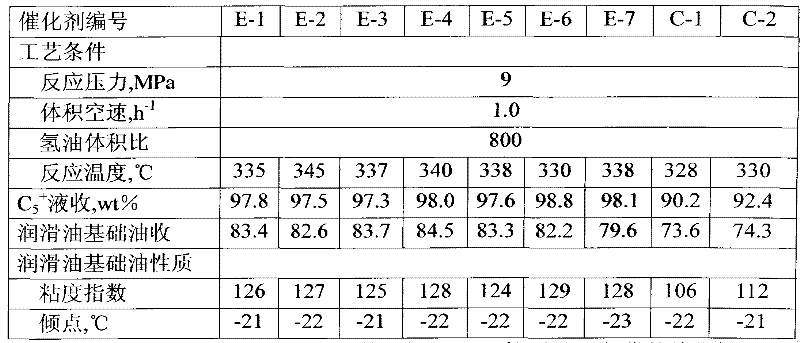

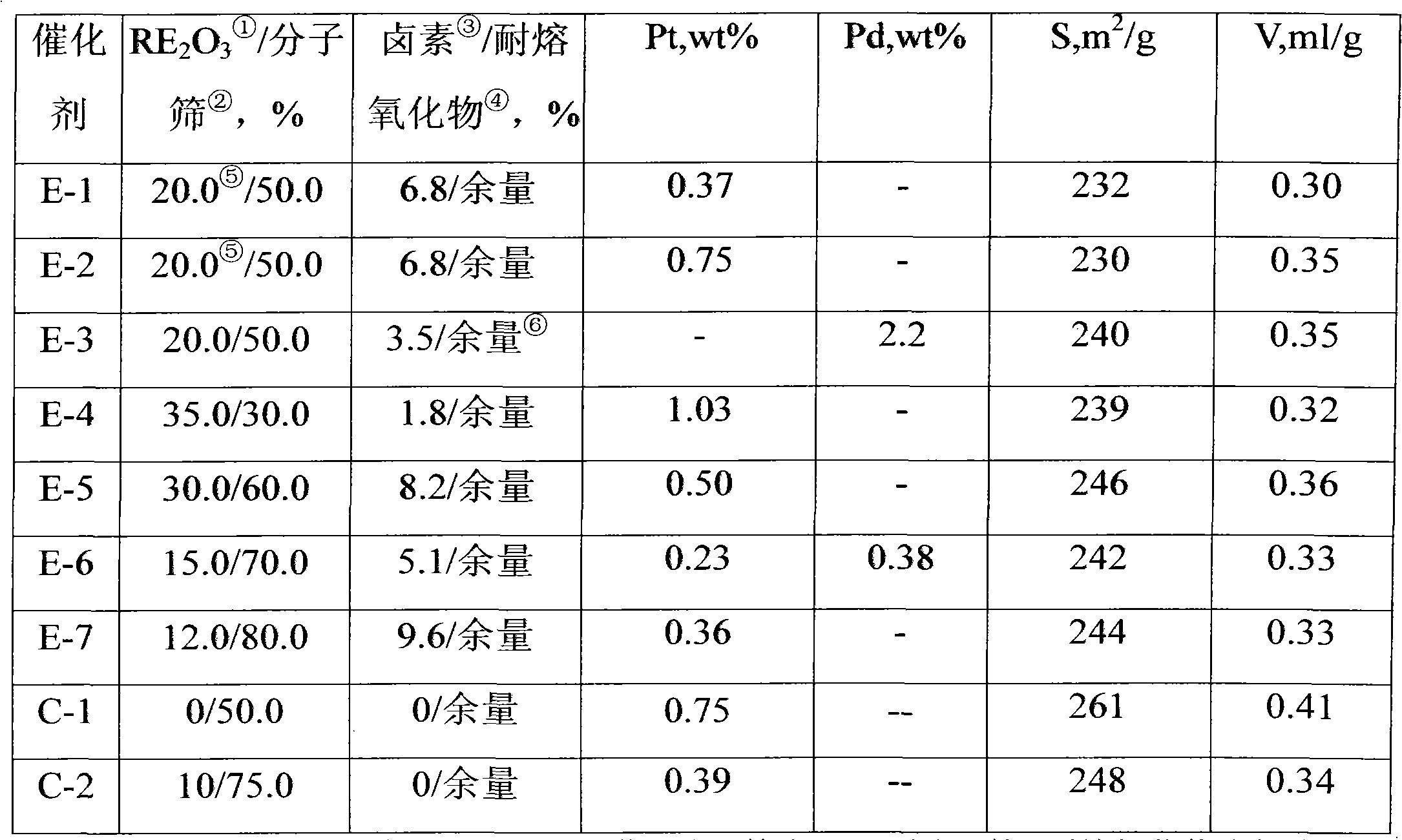

ActiveCN102441417AHigh yieldHigh viscosity indexMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a paraffin hydrocarbon shape selective isomerization catalyst, a preparation method and application thereof. The catalyst comprises a rare earth-modified molecular sieve and a halogen-modified inorganic melting-resisting oxide and at least one VIII-family precious metal, wherein the molecular sieve is a TON type molecular sieve, the weight ratio of the rare earth-modified molecular sieve to the halogen-modified inorganic melting-resisting oxide is 10:90-90:10, in the catalyst, the content of the VIII-family precious metal is 0.1-10 percent by weight, in the rare earth-modified molecular sieve, the mass content of the rare earth oxide is 0.5-60.0 percent, and in the halogen-modified inorganic melting-resisting oxide, the mass content of the halogen is 0.1-20.0 percent. Compared with the prior art, the catalyst is especially suitable for a hydroprocessing process of lubricating oil distillate, and has the characteristics of high yield of a target product, low flow point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

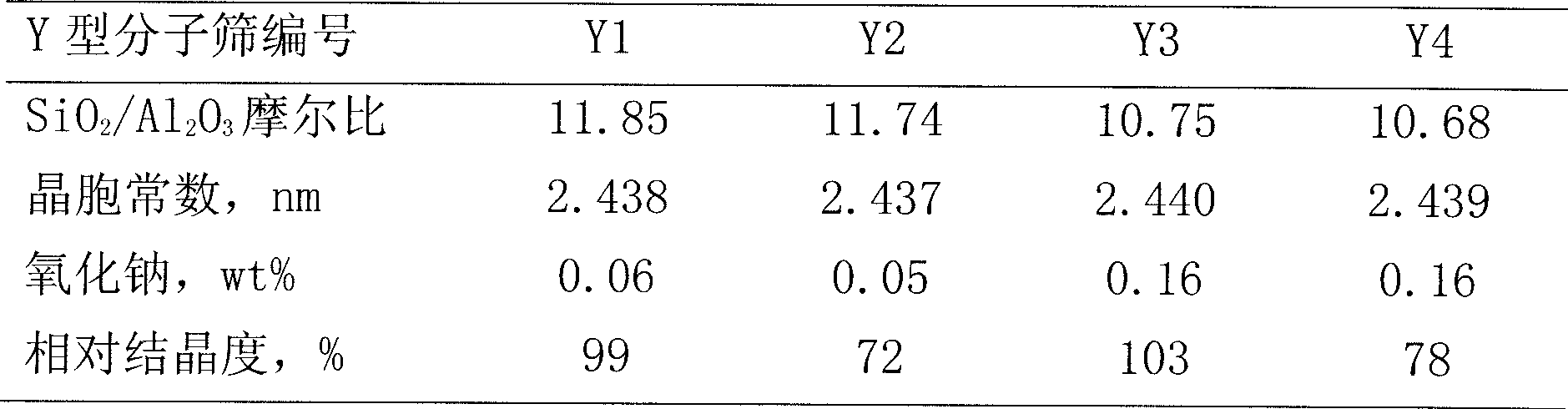

Aromatization modifying catalyst for catalytic gasoline and preocess

InactiveCN1290977CHigh yieldReduce carbon depositionRefining to change hydrocarbon structural skeletonLanthanideRare earth

Owner:CHINA PETROLEUM & CHEM CORP +1

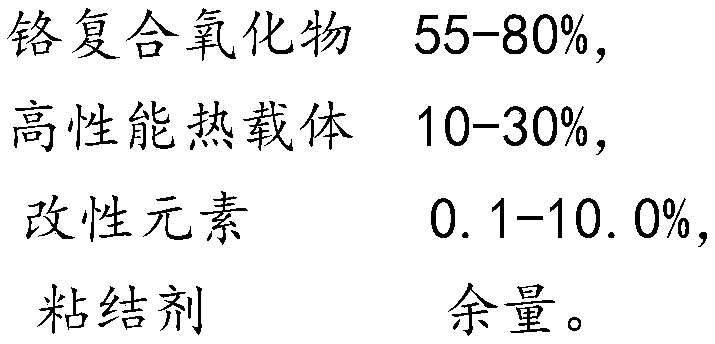

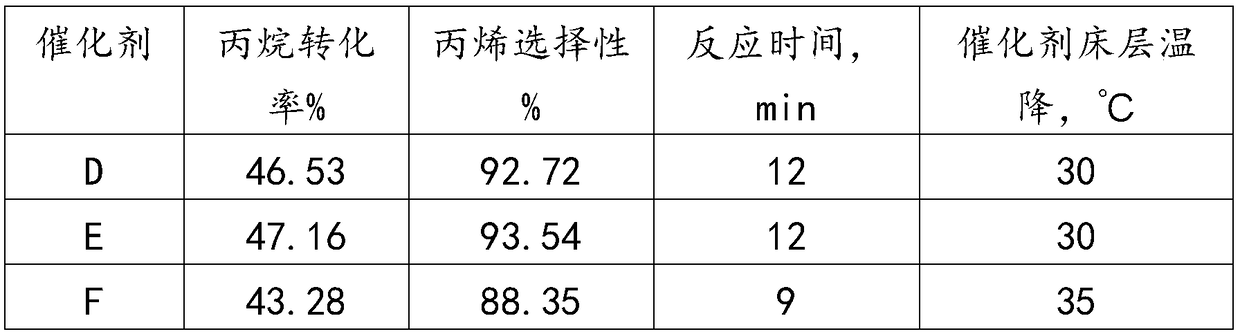

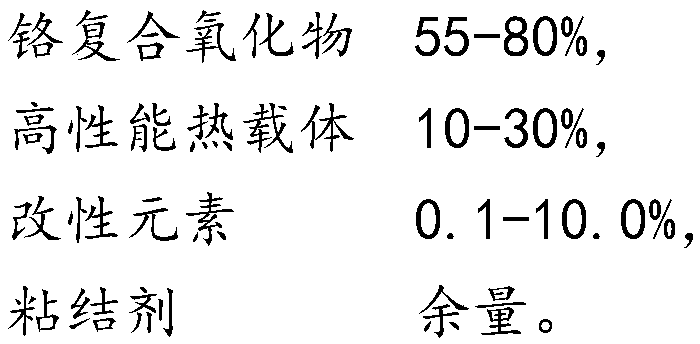

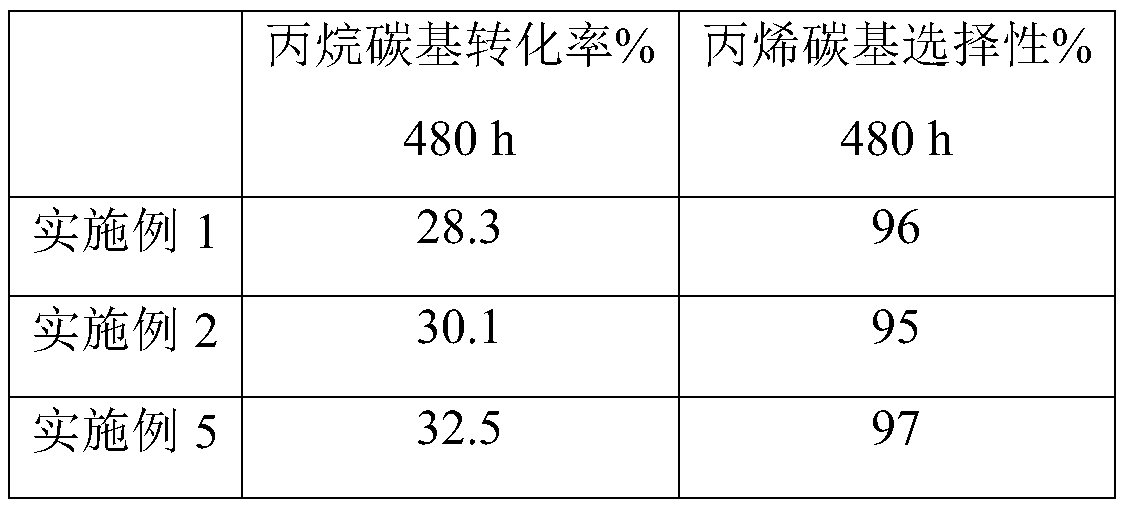

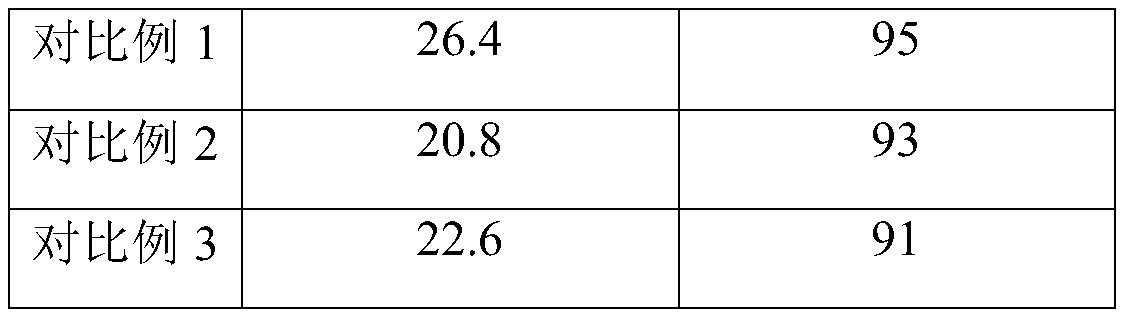

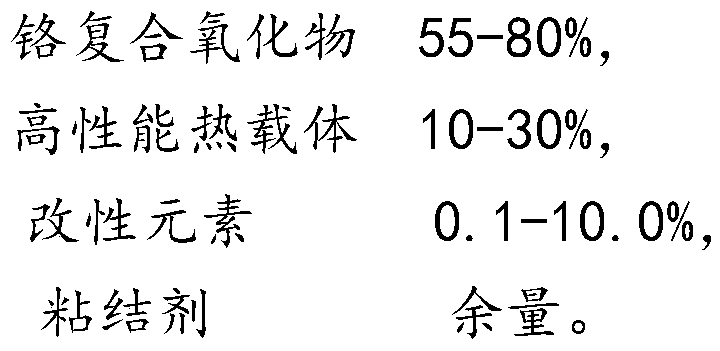

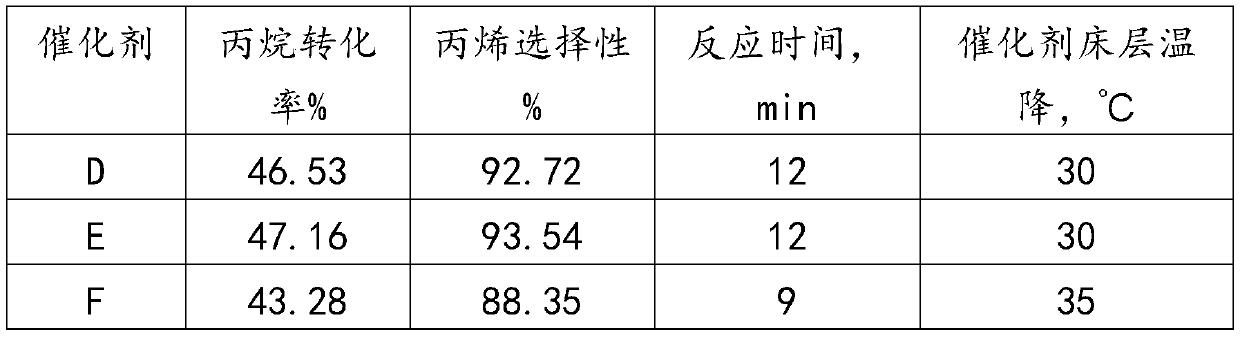

Propane dehydrogenation catalyst and preparation method thereof

ActiveCN108654596AGood dispersionImprove effective utilizationCatalystsHydrocarbon preparation catalystsDispersityChromium Compounds

The invention discloses a propane dehydrogenation catalyst and a preparation method thereof. Chromium compound oxide is used as an active component, is mixed with a high-performance thermal carrier, is added with an adhesive and a modifying element, and then is mixed and kneaded, subjected to band extrusion, dried and roasted to prepare the catalyst. The propane dehydrogenation catalyst comprisesthe following components in percentages by mass: 55-80% of the chromium compound oxide, 10-30% of the high-performance thermal carrier, 0.1-10.0% of a modifying element and the balance of the adhesive. The dispersity of chromium on the carrier is improved by synthesizing the chromium compound oxide, and the effective utilization rate of the active component and the conversion rate of the raw material propane are increased effectively; by metal modification treatment, the activity and selectivity of the catalyst are improved, and then, the yield of propylene is increased; by high-temperature water vapor treatment, the acid content and the acid strength of the surface of the carrier are greatly reduced, and the coking and olefin cracking reaction of the catalyst is relived effectively; and by addition of the high-performance thermal carrier, the catalyst utilization efficiency is improved effectively, and the production load of the device is increased.

Owner:洛阳市科创石化科技开发有限公司

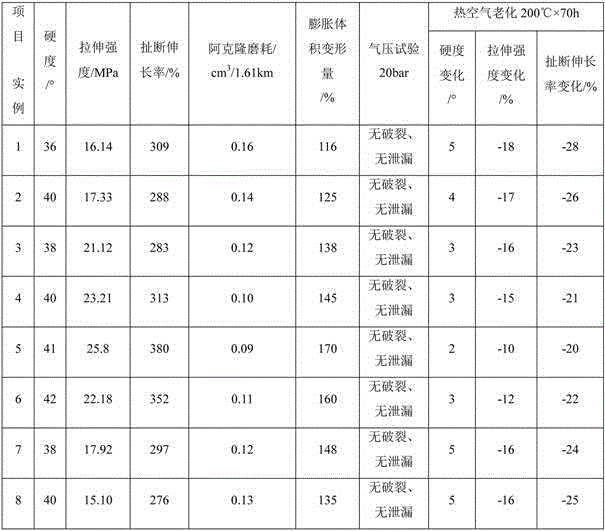

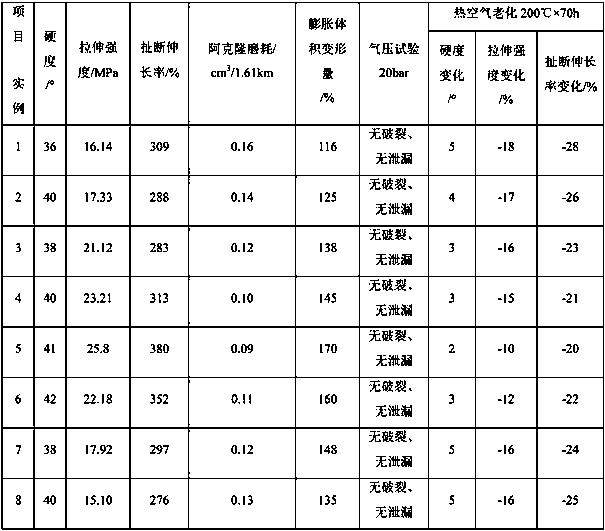

High-pressure-resistance abrasion-resistance dustproof capsule and preparation method thereof

The invention relates to a high-pressure-resistance abrasion-resistance dustproof capsule and a preparation process thereof. The dustproof capsule is prepared from the following raw materials in parts by weight: 85-90 parts of hydrogenated butadiene-acrylonitrile rubber, 15-20 parts of chlorinated butyl rubber, 5-10 parts of natural rubber, 5-10 parts of zinc oxide, 1-2 parts of magnesium oxide, 1-2 parts of stearic acid, 0.5-1 part of paraffin, 30-40 parts of N330 carbon black, 5-15 parts of N770 carbon black, 10-15 parts of white carbon black, 3-5 parts of solid coumarone resin, 1-2 parts of adhesive A, 2-3 parts of adhesive RS, 1-3 parts of accelerant NOBS, 1-3 parts of accelerant TMTD, 1-3 parts of accelerant CZ, 1-3 parts of sulfur, 1-3 parts of a vulcanizing agent, 1-2 parts of a co-curing agent HVA, 5-10 parts of TP759, 1-2 parts of an internal releasing agent and 3-5 parts of an antiaging agent. The dustproof capsule has the advantages of high pressure resistance and abrasion resistance.

Owner:南阳天一密封股份有限公司

MCM-22/ZSM-22 composite molecular sieve catalyst and its preparation method and application

InactiveCN106669811AReduce cleavage reactionsHigh isomerization selectivityMolecular sieve catalystsHydrocarbon oils refiningChemistryMolecular sieve

The invention discloses a MCM-22 / ZSM-22 composite molecular sieve catalyst and its preparation method and application. The catalyst comprises by weight, 10-90% of a modified MCM-22 / ZSM-22 composite molecular sieve, and a group VIII noble metal active component. The modified MCM-22 / ZSM-22 composite molecular sieve comprises, weight, 0.1-10% of silicon dioxide. MCM-22 molecular sieves in the MCM-22 / ZSM-22 composite molecular sieve coat ZSM-22 molecular sieves and the MCM-22 / ZSM-22 composite molecular sieve comprises, by weight, 1.0-50% of MCM-22. The catalyst can reduce the condensation point of the waxy raw material oil, improves a yield of the liquid product and has a high viscosity index of the lubricating base oil in lubricating oil fraction isodewaxing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization catalyst, and preparation method and application thereof

ActiveCN106669804ADiffusion fastAvoid contactMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveLiquid product

The invention discloses an isomerization catalyst, and a preparation method and an application thereof. The catalyst includes, by weight, 10-90% of an MCM-22 / ZSM-23 compound molecular sieve, 0.1-5.0% of gallium oxide and 0.1-1.5% a group VIII precious metal, wherein the MCM-22 / ZSM-23 compound molecular sieve is obtained through wrapping ZSM-23 molecular sieve with MCM-22 molecular sieve, and the weight content of the MCM-22 in the MCM-22 / ZSM-23 compound molecular sieve is 1.0-50%. The catalyst reduces the condensation point of wax-containing raw oil, improves the yield of liquid products, and has the high viscosity index characteristic of lubricating oil base oil when especially used in the isodewaxing process of a lubricating oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

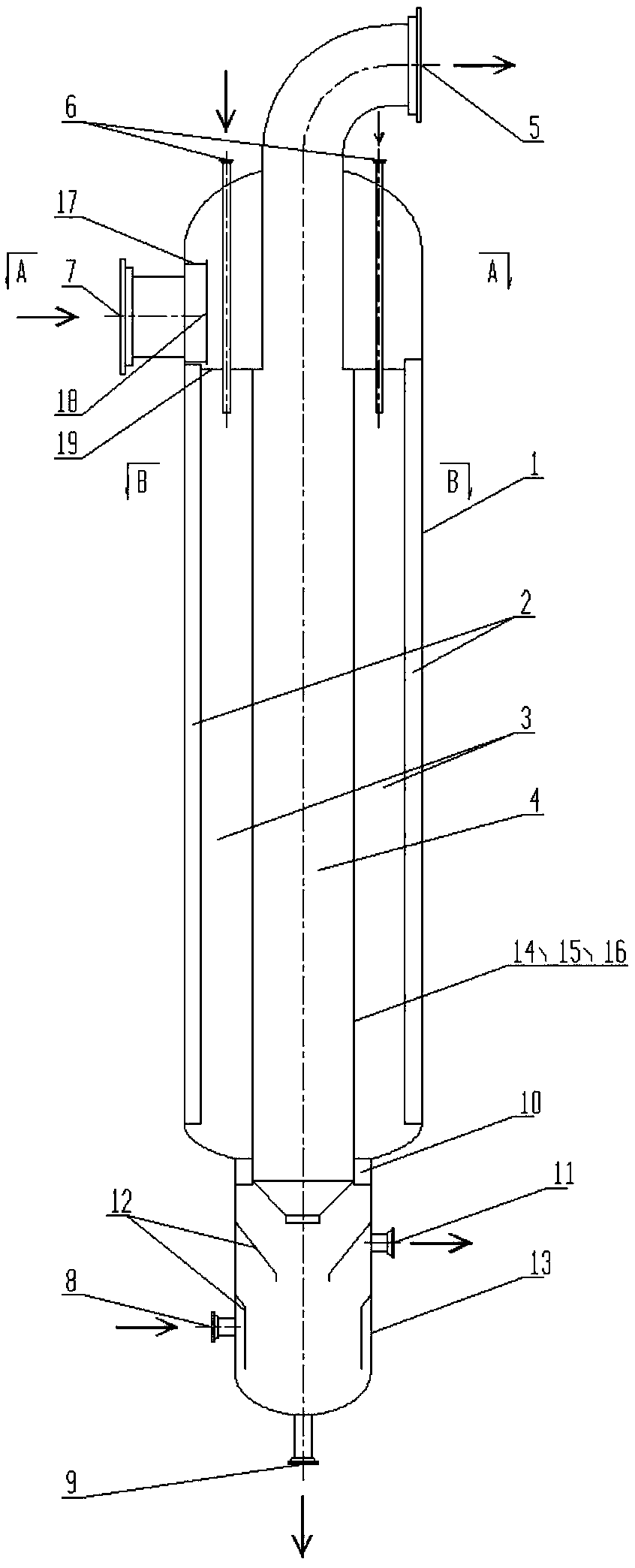

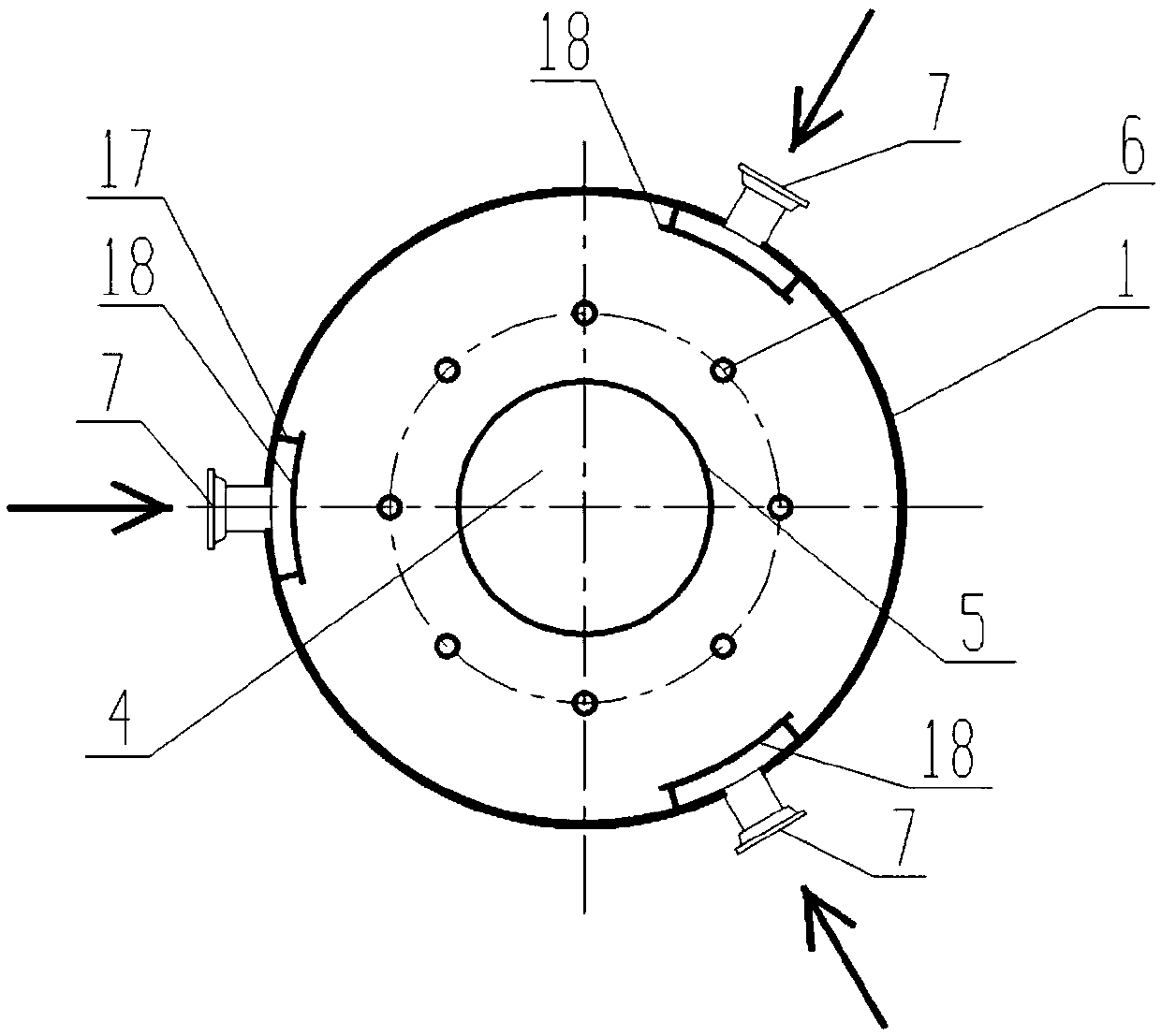

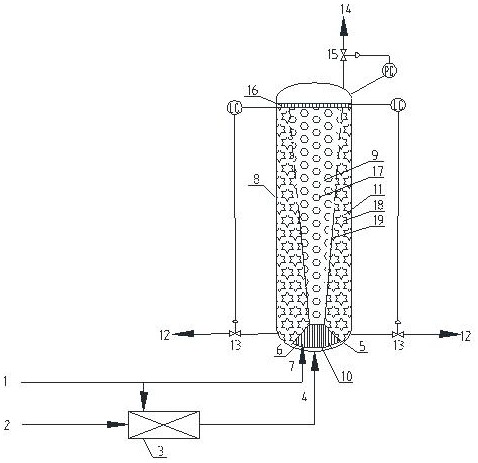

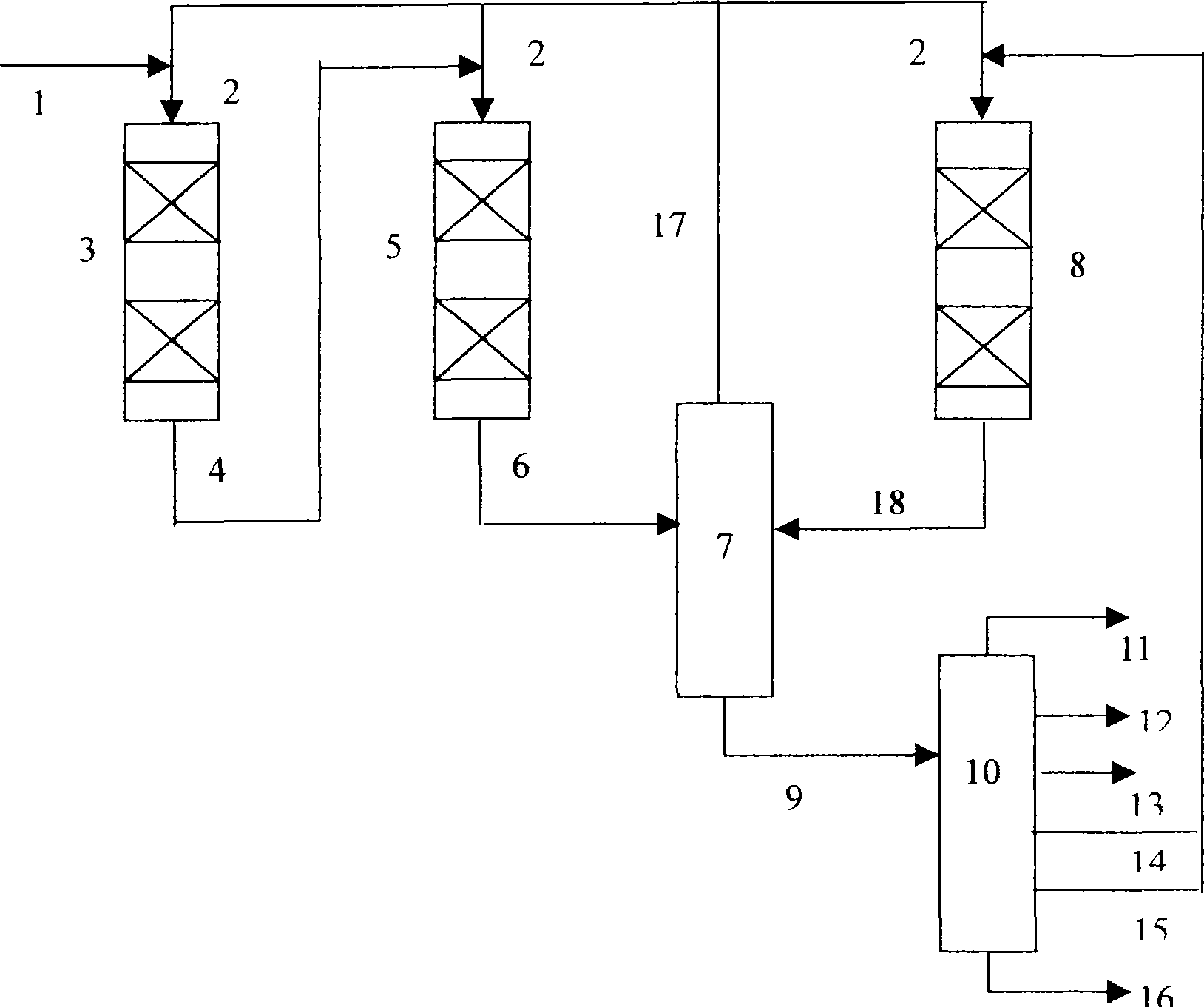

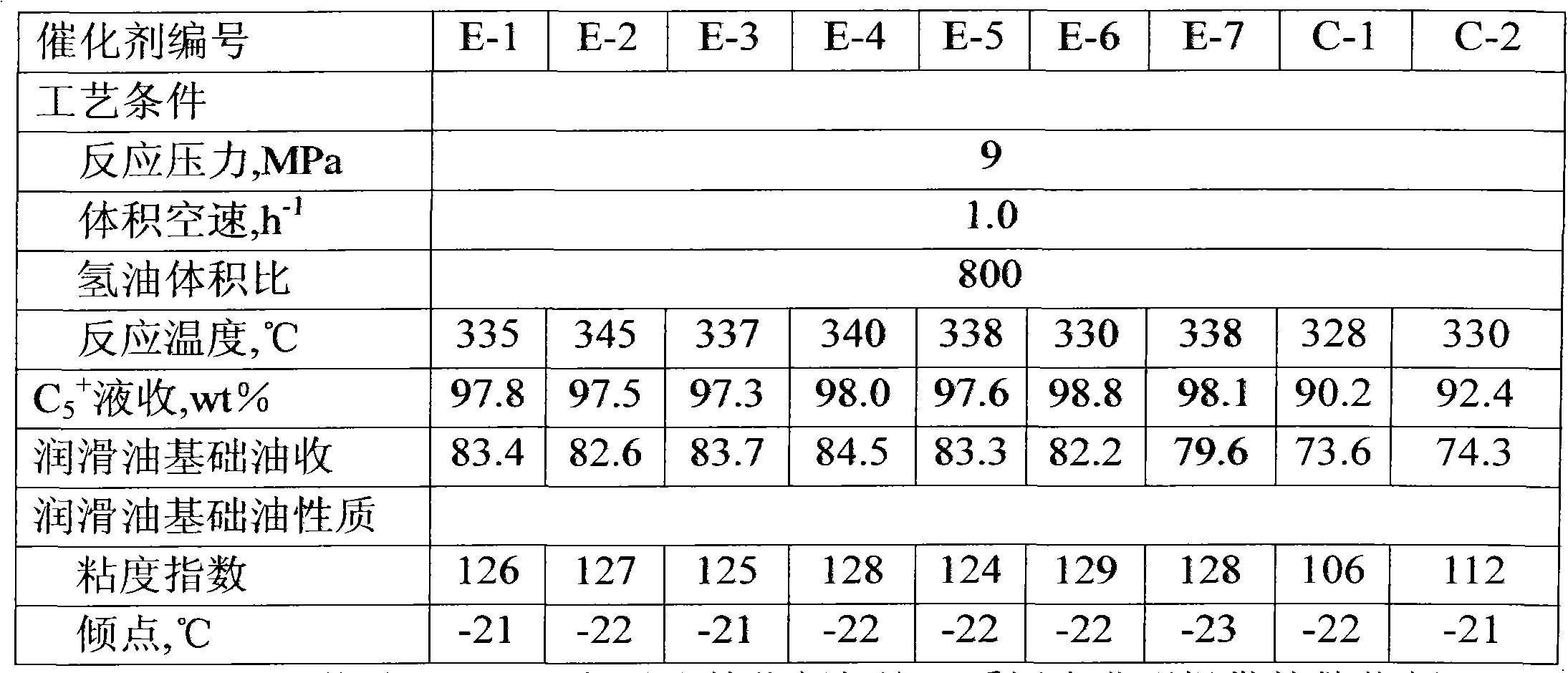

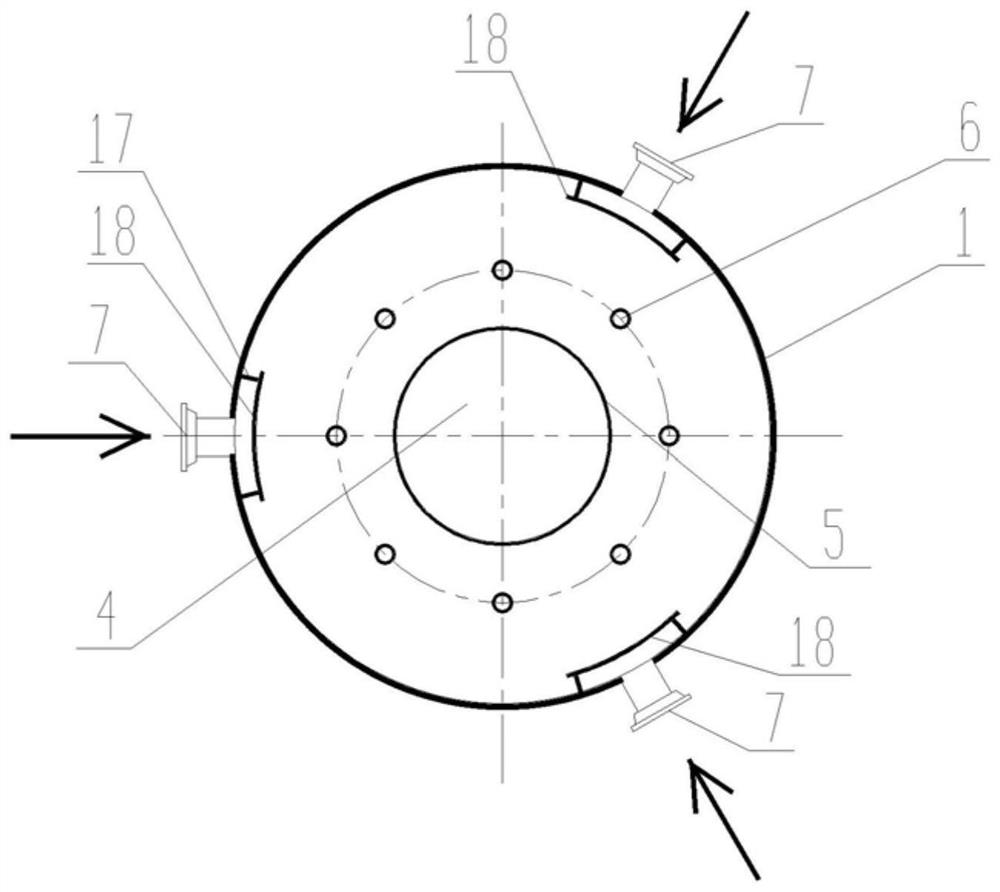

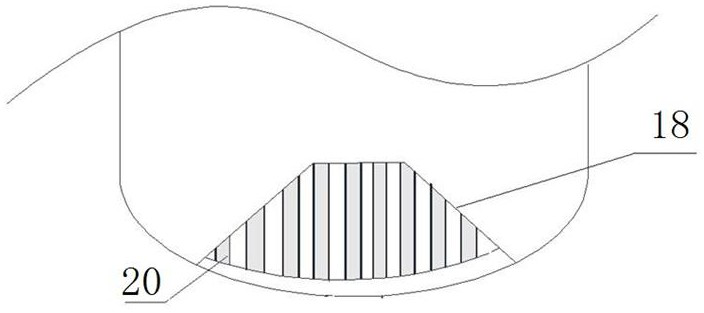

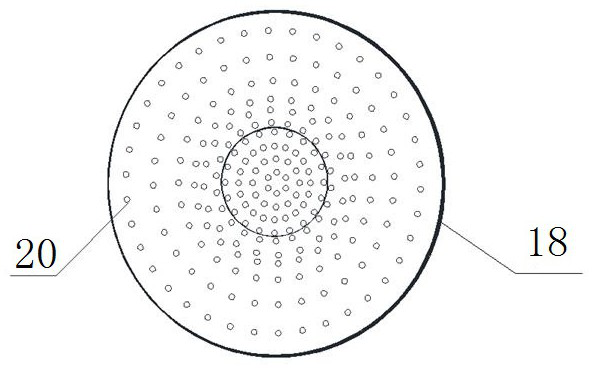

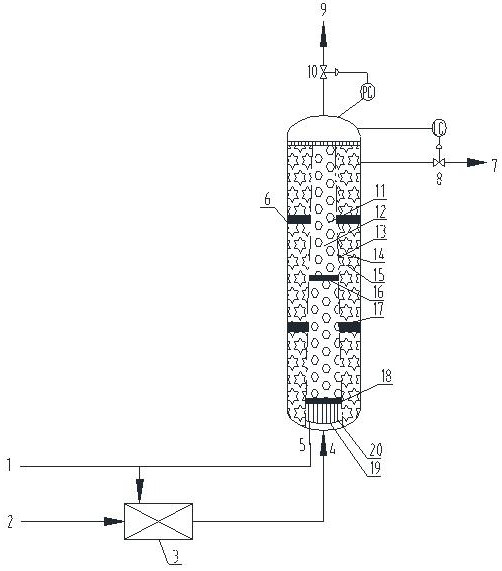

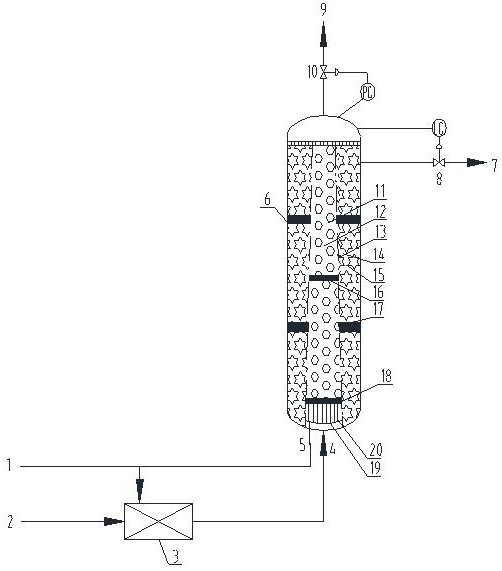

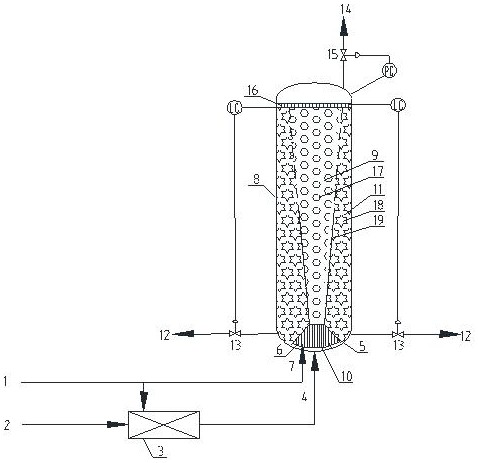

Reforming reactor and application thereof

ActiveCN109603690ASmall sizeFacilitate the dehydrocyclization reactionChemical/physical processesLine tubingHydrogen

The invention relates to a reforming reactor and application thereof. Mixed hydrogen is subjected to subsection, lifted hydrogen and stripped hydrogen are respectively introduced in different reactors, the molar ratio of H2 to HC in the reforming reactor is reasonably adjusted, and therefore compared with the prior art, the yield of aromatic hydrocarbon and hydrogen is greatly increased. Comparedwith the prior art, the reforming reactor adopts a radial reactor structure with an inlet formed in the side and an outlet formed in the top, the height of the reactor can be effectively reduced, theproblem that the larger top space of the reactor is wasted is solved, and a center cylinder and a fanshaped cylinder can be conveniently maintained; a catalyst collecting hopper is arranged at the bottom of the reforming reactor, hydrogen is adopted for steam stripping, through steam stripping, hydrocarbon components carried by a catalyst can be obtained, the rising temperature of the catalyst isalso reduced, and the reforming reactor is beneficial for safe operation, subsequent equipment and material selection for pipelines.

Owner:SHANGHAI HOTO PETROCHEM ENG

Oil sludge treatment method

ActiveCN111377579AHigh yieldReduce secondary cracking reactionsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCombustionCoke

The invention discloses an oil sludge treatment method which comprises the following steps: the oil sludge enters a drying unit to be dried and dehydrated, and dehydrated oil sludge and a gas-phase material are obtained after dehydration treatment; the dehydrated oil sludge enters a pyrolytic reaction unit to be subjected to a pyrolytic reaction, and pyrolysis gas, oil and coke are obtained afterthe reaction; heat exchange on the gas-phase material is performed to obtain non-condensable gas and condensed water; pyrolysis gas and non-condensable gas enter the combustion unit to be in contact with oxygen-containing atmosphere for a combustion reaction, and hot smoke generated by the reaction serves as a heat source to provide heating heat for the drying unit and the pyrolytic reaction unit.According to the oil sludge reduction, harmlessness and resourceful treatment method, reduction and resourceful utilization of the oil sludge are achieved to the maximum extent, meanwhile, high-valueoil products are recycled, and secondary pollution is avoided in the whole treatment process.

Owner:CHINA PETROLEUM & CHEM CORP +1

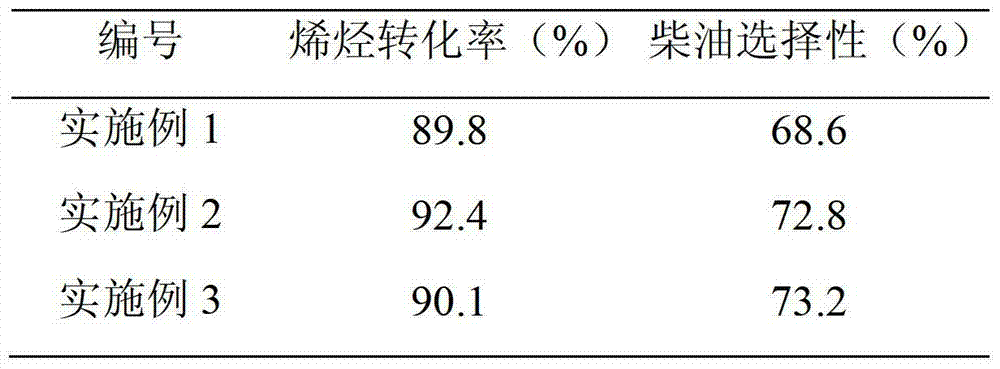

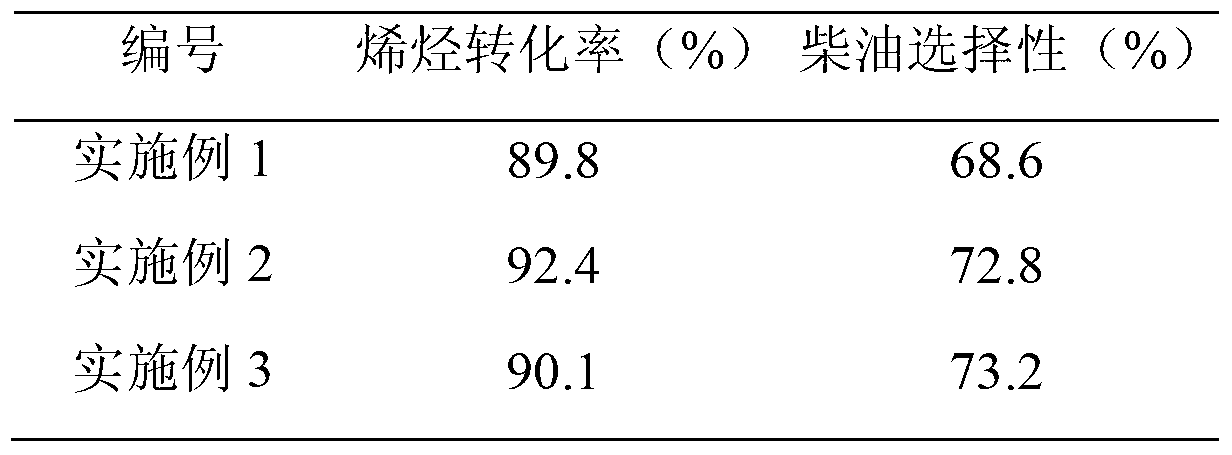

Mesoporous molecular sieve catalyst and preparation method thereof

ActiveCN103316708BHigh yieldGood choiceMolecular sieve catalystsLiquid hydrocarbon mixtures productionIon exchangeLanthanum

The invention discloses a mesoporous molecular sieve catalyst and a preparation method thereof. The mesoporous molecular sieve catalyst comprises a matrix, an active component and a binder; the matrix is an H-type MSU-SMFI mesoporous molecular sieve; the active component is Na; and the binder is alumina. The preparation method comprises the following steps: 1, carrying out ion exchange of an MSU-SMFI mesoporous molecular sieve with an NH4NO3 solution, and roasting to obtain the H-type MSU-SMFI mesoporous molecular sieve; 2, carrying out ion exchange of the H-type MSU-SMFI mesoporous molecular sieve and an NaNO3 solution, adding the alumina binder and a nitric acid solution after the ion exchange, grinding, carrying out extrusion molding, and roasting; and / or 3, dipping the mesoporous molecular sieve obtained in step 2 in an aqueous solution containing at least one of a lanthanum salt and a zirconium salt, and drying and stoving. High olefin oligomerization activity and high diesel yield can be obtained through adopting the mesoporous molecular sieve MSU-SMFI as the matrix of an olefin oligomerization catalyst.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Composite carrier catalyst for preparing propylene by adopting propane conversion and preparation method of composite carrier catalyst

ActiveCN109647494ACurb churnSuppress generationMolecular sieve catalystsCatalyst activation/preparationMolecular sieveActive component

The invention discloses a composite carrier catalyst for preparing propylene by adopting propane conversion and a preparation method for the composite carrier catalyst. The catalyst is prepared from 50%-90% of Al-doped SBA-15 molecular sieves, 10%-40% of iota-Al2O3, 0.1%-0.6% of an active component, 0.1%-4.0% of modifiers and the balance adhesive. The modifier comprises a first modifier containingany one of Cu and Sn modified elements, a second modifier containing any one of La, Ce, Ag and Zr modified elements, and a third modifier containing any one of Sr, Ba, Ca and K modified elements, thecontent of each modifier is greater than 0%, and the mass percentage sum of all the components is 100%. The catalyst is good in intensity, and has good dehydrogenation activity and stability in the process of propane dehydrogenation.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Mesoporous molecular sieve catalyst and preparation method thereof

ActiveCN103316708AHigh olefin oligomerization activity and diesel yieldReduce cleavage reactionsMolecular sieve catalystsLiquid hydrocarbon mixtures productionIon exchangeMolecular sieve

The invention discloses a mesoporous molecular sieve catalyst and a preparation method thereof. The mesoporous molecular sieve catalyst comprises a matrix, an active component and a binder; the matrix is an H-type MSU-SMFI mesoporous molecular sieve; the active component is Na; and the binder is alumina. The preparation method comprises the following steps: 1, carrying out ion exchange of an MSU-SMFI mesoporous molecular sieve with an NH4NO3 solution, and roasting to obtain the H-type MSU-SMFI mesoporous molecular sieve; 2, carrying out ion exchange of the H-type MSU-SMFI mesoporous molecular sieve and an NaNO3 solution, adding the alumina binder and a nitric acid solution after the ion exchange, grinding, carrying out extrusion molding, and roasting; and / or 3, dipping the mesoporous molecular sieve obtained in step 2 in an aqueous solution containing at least one of a lanthanum salt and a zirconium salt, and drying and stoving. High olefin oligomerization activity and high diesel yield can be obtained through adopting the mesoporous molecular sieve MSU-SMFI as the matrix of an olefin oligomerization catalyst.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116AReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesMaterials scienceCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

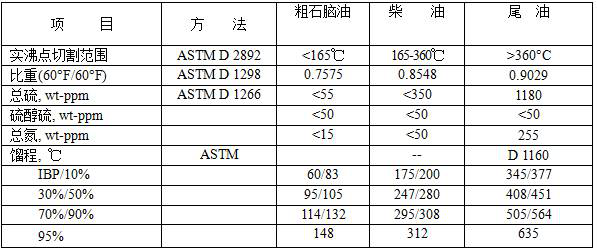

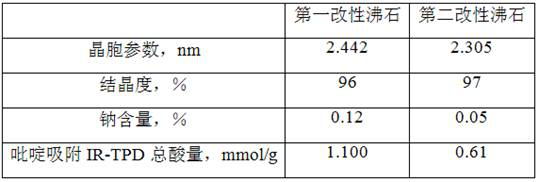

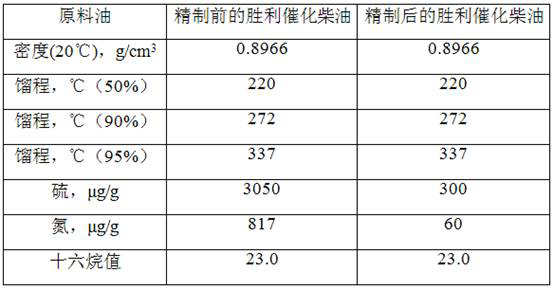

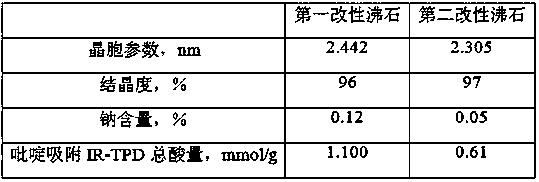

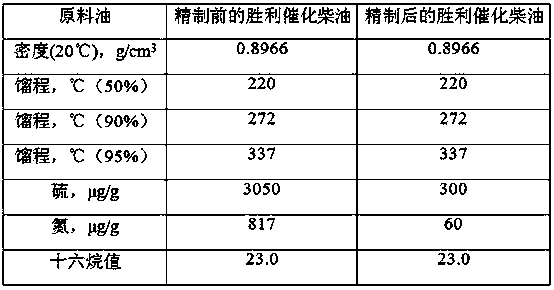

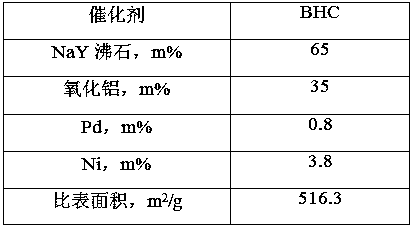

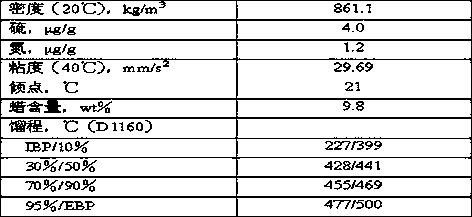

A reduced bimetallic diesel hydroconversion catalyst

ActiveCN109954513BSimple processLess investmentMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationPtru catalystQuinoline

A reduced bimetallic diesel hydroconversion catalyst, which uses the first modified zeolite, the second modified zeolite and alumina as a carrier to simultaneously support non-precious metal and noble metal hydrogenation components, after reduction with low hydrogen partial pressure, It is obtained after passing through at least one gaseous nitrogen compound selected from pyridine, quinoline, isoquinoline, azaanthene and azaphenanthrene. The acidic cracking component of the catalyst, the molecular sieve, is embedded in the highly active reducing state bimetallic diesel hydroconversion catalyst, so that the polycyclic aromatic hydrocarbons in the diesel oil are hydrogenated and saturated while opening the ring, which simplifies the process flow and can save equipment investment, Save on operating costs. And the gaseous nitrogen compound is used to passivate the acid center of the catalyst, so as to weaken the acid site of the molecular sieve, reduce the cracking reaction of the alkyl group, and improve the quality and yield of the target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

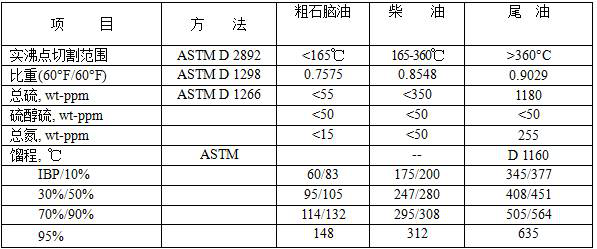

Hydrocracking method of midbarrel oil circulation

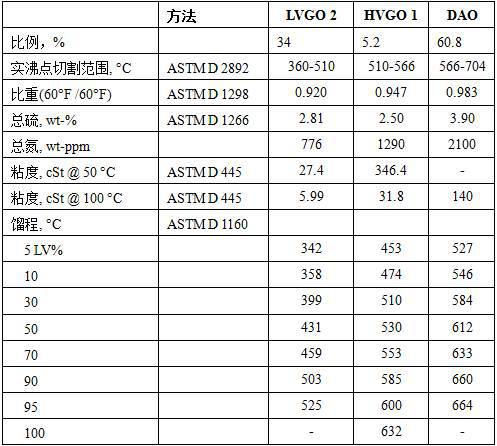

ActiveCN100513531CHigh hydrogen contentReduce hydrogen contentTreatment with hydrotreatment processesNaphthaSulfur

Owner:CHINA PETROLEUM & CHEM CORP +2

A high-pressure resistant anti-wear dust-proof capsule and its preparation process

The invention relates to a high-pressure-resistance abrasion-resistance dustproof capsule and a preparation process thereof. The dustproof capsule is prepared from the following raw materials in parts by weight: 85-90 parts of hydrogenated butadiene-acrylonitrile rubber, 15-20 parts of chlorinated butyl rubber, 5-10 parts of natural rubber, 5-10 parts of zinc oxide, 1-2 parts of magnesium oxide, 1-2 parts of stearic acid, 0.5-1 part of paraffin, 30-40 parts of N330 carbon black, 5-15 parts of N770 carbon black, 10-15 parts of white carbon black, 3-5 parts of solid coumarone resin, 1-2 parts of adhesive A, 2-3 parts of adhesive RS, 1-3 parts of accelerant NOBS, 1-3 parts of accelerant TMTD, 1-3 parts of accelerant CZ, 1-3 parts of sulfur, 1-3 parts of a vulcanizing agent, 1-2 parts of a co-curing agent HVA, 5-10 parts of TP759, 1-2 parts of an internal releasing agent and 3-5 parts of an antiaging agent. The dustproof capsule has the advantages of high pressure resistance and abrasion resistance.

Owner:南阳天一密封股份有限公司

Reduced bimetallic diesel oil hydrogenation conversion catalyst

ActiveCN109954513ASimple processLess investmentMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationQuinolineHigh activity

A reduced bimetallic diesel oil hydrogenation conversion catalyst is obtained by simultaneously loading non-noble metal hydrogenation components and noble metal hydrogenation components on first modified zeolite, second modified zeolite and alumina as carriers, reducing with low hydrogen partial pressure, and treating with at least one gaseous nitrogen compound selected from pyridine, quinoline, isoquinoline, azaanthracene and azaphenanthrene. As that acid crack component-molecular sieve of the catalyst is implanted into the high-activity reduced bimetallic diesel oil hydrogenation conversioncatalyst, the condensed ring aromatic hydrocarbon in the diesel oil is subjected to hydrogenation and ring opening, the process flow is simplified, the equipment investment can be saved, and the operation cost can be saved. The acid sites of the catalysts are passivated by gaseous nitrogen compounds, which weakens the acid sites of the zeolites, reduces the alkyl cleavage reaction and improves thequality and yield of the target products.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of composite carrier catalyst for propane conversion to propylene and preparation method thereof

ActiveCN109647494BCurb churnSuppress generationMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a composite carrier catalyst for preparing propylene by adopting propane conversion and a preparation method for the composite carrier catalyst. The catalyst is prepared from 50%-90% of Al-doped SBA-15 molecular sieves, 10%-40% of iota-Al2O3, 0.1%-0.6% of an active component, 0.1%-4.0% of modifiers and the balance adhesive. The modifier comprises a first modifier containingany one of Cu and Sn modified elements, a second modifier containing any one of La, Ce, Ag and Zr modified elements, and a third modifier containing any one of Sr, Ba, Ca and K modified elements, thecontent of each modifier is greater than 0%, and the mass percentage sum of all the components is 100%. The catalyst is good in intensity, and has good dehydrogenation activity and stability in the process of propane dehydrogenation.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Paraffin hydrocarbon shape selective isomerization catalyst, preparation method and application thereof

ActiveCN102441417BHigh activityImprove stabilityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a paraffin hydrocarbon shape selective isomerization catalyst, a preparation method and application thereof. The catalyst comprises a rare earth-modified molecular sieve and a halogen-modified inorganic melting-resisting oxide and at least one VIII-family precious metal, wherein the molecular sieve is a TON type molecular sieve, the weight ratio of the rare earth-modified molecular sieve to the halogen-modified inorganic melting-resisting oxide is 10:90-90:10, in the catalyst, the content of the VIII-family precious metal is 0.1-10 percent by weight, in the rare earth-modified molecular sieve, the mass content of the rare earth oxide is 0.5-60.0 percent, and in the halogen-modified inorganic melting-resisting oxide, the mass content of the halogen is 0.1-20.0 percent. Compared with the prior art, the catalyst is especially suitable for a hydroprocessing process of lubricating oil distillate, and has the characteristics of high yield of a target product, low flow point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatization catalyst and clean gasoline producing process

InactiveCN1268720CHigh yieldFacilitated DiffusionRefining to change hydrocarbon structural skeletonMolecular sievePtru catalyst

The present invention relates to an aromatization catalyst and production process of clean gasoline. Said invention adopts hydrofining and aromizing two-stage catalyst combined process to make the FCC gasoline with high sulfur content and high olefin content into clean gasoline. Said invented aromatization catalyst adopts small-grain molecular sieve catalyst, and makes the aromatization catalyst undergo the process of hydrothermal treatment and can make the strong acid quantity of said catalyst be reduced. Said invention can raise yield of gasoline, and can obtain high-quality clean gasoline product.

Owner:CHINA PETROLEUM & CHEM CORP +1

A reforming reactor and its application

ActiveCN109603690BSmall sizeFacilitate the dehydrocyclization reactionChemical/physical processesThermodynamicsPtru catalyst

Owner:SHANGHAI HOTO PETROCHEM ENG

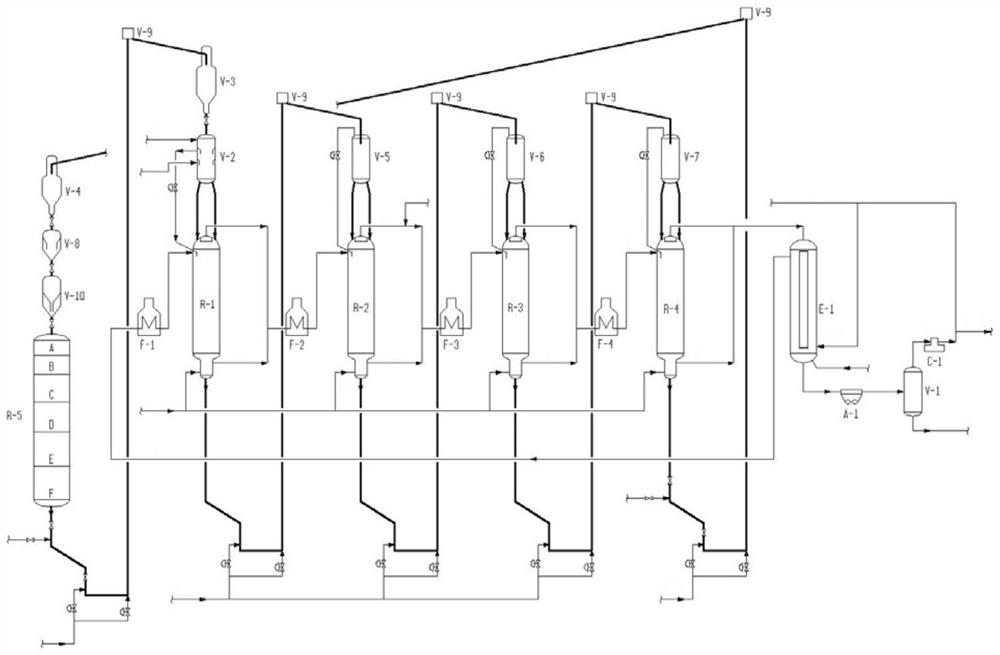

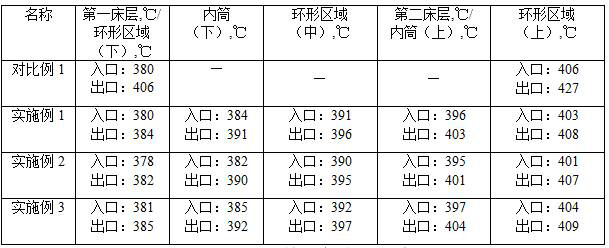

Heavy oil hydrogenation process

ActiveCN114437779AReduce viscosityImprove liquidityTreatment with hydrotreatment processesBulk chemical productionFluid phaseHydrogenation reaction

The invention discloses a heavy oil hydrogenation process which comprises the following steps: (1) mixing hydrogen and a heavy oil raw material to obtain a first mixed feed; (2) the first mixed feed enters the shell side of the shell-and-tube inorganic membrane tube assembly from the bottom of the fixed bed reactor, and hydrogen is supplemented to enter the tube side to form a second mixed feed; and (3) enabling the second mixed feed to flow upwards into the upper cylinder, alternately carrying out hydrogenation reaction on the inner cylinder and the annular region under the action of a plurality of partition plates axially arranged in the inner cylinder and the annular region, and finally enabling a hydrogenation product to flow out from the upper part. The method solves the problem of large temperature rise in the early reaction stage of the heavy oil liquid phase hydrogenation process, ensures high conversion rate in the middle reaction stage, reduces the later deep cracking reaction, and improves the liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fixed bed hydrogenation reactor and heavy oil liquid phase hydrogenation process

ActiveCN112705121AReduce viscosityGood dispersionChemical industryTreatment with hydrotreatment processesFluid phaseFixed bed

The invention discloses a fixed bed hydrogenation reactor and a heavy oil liquid phase hydrogenation process, the hydrogenation reactor comprises a reactor outer cylinder body and an inner cylinder, an annular area is arranged between the outer cylinder body and the inner cylinder, the cross sectional area of the inner cylinder is gradually increased from top to bottom, and the cylinder wall of the inner cylinder is uniformly provided with holes communicated with the annular area; the top opening of the inner cylinder is flush with the bottom of a upper seal head of the reactor; the bottom of the inner cylinder is hermetically connected with a lower seal head of the reactor; a shell-and-tube ceramic membrane tube assembly is arranged at the bottom of the inner cylinder, a hydrogen supplementing pipeline is communicated with the ceramic membrane tube, and a liquid phase feeding pipeline is communicated with an in-shell cavity outside the ceramic membrane tube; partition plates are alternately arranged in the inner cylinder and the annular area at different heights; the inner cylinder is filled with a hydrogenation catalyst I, the annular area is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than that of the hydrogenation catalyst II. According to the method, firstly, the heavy oil raw material is subjected to visbreaking treatment, and then the material is alternately subjected to hydrogenation reaction with different active catalysts in the inner barrel and the annular area along the flow channel arranged in the reactor, so that the problems of high activity and large temperature rise in the early stage of reaction can be controlled, and higher conversion rate in the middle stage of reaction is ensured; the deep cracking reaction in the later high-temperature stage of the reaction can be reduced, and the liquid yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of sludge treatment method

ActiveCN111377579BHigh yieldReduce secondary cracking reactionsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFiberCombustion

The invention discloses an oil sludge treatment method. The treatment method comprises the following steps: oil sludge enters a drying unit for drying and dehydration, and after dehydration treatment, dewatered oil sludge and gas-phase materials are obtained; the dewatered oil sludge enters a pyrolysis reaction unit for pyrolysis reaction, and cracked gas is obtained after the reaction. , oil and coke; the gas-phase material obtains non-condensable gas and condensed water after heat exchange; the cracked gas and non-condensable gas enter the combustion unit, contact with the oxygen-containing atmosphere for combustion reaction, and use the hot flue gas generated by the reaction as the heat source as the drying unit And the pyrolysis reaction unit provides heating heat. The invention provides a sludge reduction, harmless and resourceful treatment method, which realizes the maximum reduction and resource utilization of sludge, and at the same time recovers high-value oil products without causing secondary pollution in the whole processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of isomerization catalyst and its preparation method and application

ActiveCN106669804BDiffusion fastAvoid contactMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveLiquid product

The invention discloses an isomerization catalyst and its preparation method and application. The catalyst contains MCM-22 / ZSM-23 composite molecular sieve, gallium oxide and Group VIII noble metal active components. Based on the weight content of the catalyst, MCM- The content of 22 / ZSM-23 composite molecular sieve is 10~90%, the content of calcium oxide is 0.1%~5.0%, and the content of Group VIII noble metal is 0.1%~1.5%. The MCM-22 / ZSM-23 composite molecular sieve is It means that MCM-22 molecular sieve is wrapped around ZSM-23 molecular sieve. The weight content of MCM-22 in MCM-22 / ZSM-23 composite molecular sieve is 1.0~50%. The catalyst can not only reduce the freezing point of waxy raw oil, but also improve the yield of liquid products. It is especially used in the isomerization dewaxing process of lubricating oil fractions and has the characteristics of high viscosity index of lubricating oil base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

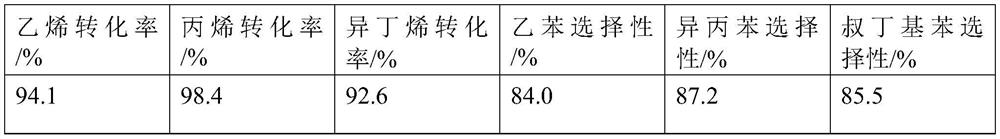

Composite ionic liquid catalyst, and preparation method and application thereof

PendingCN112958149AReduce sensitivityAddress sensitivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPtru catalystMetal halides

The invention relates to a preparation method of a composite ionic liquid catalyst, and the prepared catalyst and application of the catalyst. The method comprises the following steps: 1) under the protection of dry inert gas, slowly adding metal halide into alkyl halogenated amine in batches, stirring for 10-50 minutes at room temperature, when part of the solid is converted into liquid with relatively strong fluidity, heating to 50-100 DEG C, and continuously stirring and reacting until all the solid is completely converted into uniform liquid A; and 2) adding nitrate into the liquid A, and continuously stirring to react for 6-12 hours to obtain the composite ionic liquid catalyst. The catalyst system prepared by the invention can greatly reduce the sensitivity of an ionic liquid catalyst to CO in the prior art, alkylation reaction can be directly carried out without separating mixed olefin, the total amount of target products ethylbenzene and / or isopropyl benzene and / or tert-butylbenzene accounts for 95% or above of the total molar weight of the product, byproducts are low, the raw material utilization rate is high, and the overall economic benefit is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

A kind of fixed bed hydrogenation reactor and heavy oil liquid phase hydrogenation process

ActiveCN112705121BReduce viscosityGood dispersionChemical industryTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses a fixed-bed hydrogenation reactor and a heavy oil liquid-phase hydrogenation process. The hydrogenation reactor comprises an outer cylinder and an inner cylinder of the reactor, an annular area is formed between the outer cylinder and the inner cylinder, and the transverse direction of the inner cylinder is The cross-sectional area gradually increases from top to bottom, the inner cylinder wall is evenly opened and connected to the annular area, the top opening of the inner cylinder is flush with the bottom of the upper head of the reactor, and the bottom of the inner cylinder is tightly connected with the lower head of the reactor; A shell-and-tube ceramic membrane tube assembly is arranged at the bottom, the hydrogen supplementation pipeline is communicated with the ceramic membrane tube, and the liquid-phase feed pipeline is communicated with the inner cavity of the shell outside the ceramic membrane tube; the inner tube and the annular area are alternately arranged with baffles at different heights; The cylinder is filled with hydrogenation catalyst I, the annular region is filled with hydrogenation catalyst II, and the activity of hydrogenation catalyst I is higher than that of hydrogenation catalyst II. The method of the invention firstly performs viscosity reduction treatment on the heavy oil raw material, and then makes the material undergo hydrogenation reaction with different active catalysts alternately in the inner cylinder and the annular area along the flow channel arranged in the reactor, that is, the high activity and temperature rise in the early stage of the reaction can be controlled. It is a big problem, ensuring a high conversion rate in the middle of the reaction, reducing the deep cracking reaction in the high-temperature stage in the later stage of the reaction, and improving the liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of propane dehydrogenation catalyst and preparation method thereof

ActiveCN108654596BGood dispersionImprove effective utilizationCatalystsHydrocarbon preparation catalystsChromium CompoundsPtru catalyst

The invention discloses a propane dehydrogenation catalyst and a preparation method thereof. Chromium compound oxide is used as an active component, is mixed with a high-performance thermal carrier, is added with an adhesive and a modifying element, and then is mixed and kneaded, subjected to band extrusion, dried and roasted to prepare the catalyst. The propane dehydrogenation catalyst comprisesthe following components in percentages by mass: 55-80% of the chromium compound oxide, 10-30% of the high-performance thermal carrier, 0.1-10.0% of a modifying element and the balance of the adhesive. The dispersity of chromium on the carrier is improved by synthesizing the chromium compound oxide, and the effective utilization rate of the active component and the conversion rate of the raw material propane are increased effectively; by metal modification treatment, the activity and selectivity of the catalyst are improved, and then, the yield of propylene is increased; by high-temperature water vapor treatment, the acid content and the acid strength of the surface of the carrier are greatly reduced, and the coking and olefin cracking reaction of the catalyst is relived effectively; and by addition of the high-performance thermal carrier, the catalyst utilization efficiency is improved effectively, and the production load of the device is increased.

Owner:洛阳市科创石化科技开发有限公司

A kind of heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116BReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesPtru catalystHydrogenation reaction

The invention discloses a heavy oil hydrogenation reactor and a hydrogenation method. The reactor consists of an outer cylinder of the reactor, an inner cylinder I and an inner cylinder II arranged along the axial direction of the reactor. The cross-sectional area of the inner cylinder I gradually decreases from top to bottom, and the cross-sectional area of the inner cylinder II gradually decreases from top to bottom. increase; an annular space is formed between the inner cylinder I, the inner cylinder II and the outer cylinder of the reactor; the inner cylinder I is filled with a hydrogenation catalyst I, and the annular space is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than Activity of Hydrogenation Catalyst II. The present invention reduces the viscosity of the material through the viscosity-reducing component installed in the inner cylinder II, and then passes through the inner cylinder I and the annular space to undergo a hydrogenation reaction, improves the driving force and reaction rate of the mass transfer process of the heavy oil liquid phase hydrogenation reaction, and controls the reaction between the reaction material and the hydrogenation reaction. The contact time of different active catalysts can slow down the coking of the catalyst surface, reduce the deep cracking reaction of light oil, and improve the liquid yield and heavy impurity removal conversion rate of heavy oil liquid phase hydrogenation reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

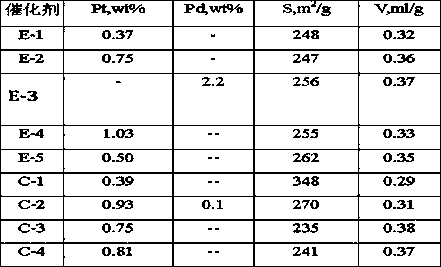

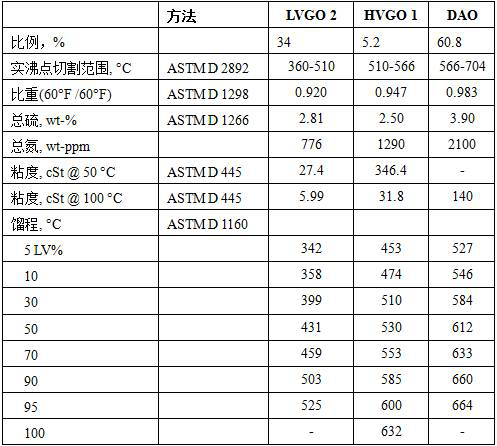

Hydroisomerization catalyst, preparation method thereof, and method for producing lubricating base oil from hydrocarbon oil or Fischer-Tropsch synthetic oil

ActiveCN105771970BEvenly dispersedStrong Acid ReductionBase-materialsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPtru catalyst

The invention discloses a hydroisomerization catalyst and a preparation method thereof, and a method for producing base oil of lubricating oil from hydrocarbon oil or Fischer-Tropsch synthesis oil. The preparation method for the hydroisomerization catalyst comprises the following steps: (1) mixing amorphous silicon-aluminum, an alumina adhesive, nitric acid, an auxiliary agent and water so as to obtain a mixture and subjecting the mixture to mixing and kneading, extrusion molding, primary drying and secondary roasting so as to obtain a carrier precursor; (2) subjecting the carrier precursor to carrier modification in the presence of water vapor so as to obtain a modified carrier; (3) introducing a material containing an active component precursor to the modified carrier and carrying out secondary drying and secondary roasting so as to obtain a catalyst precursor; and (4) reducing the catalyst precursor in a hydrogen-containing atmosphere so as to obtain the hydroisomerization catalyst. The auxiliary agent used in the invention is nitrate and / or carbonate of alkali metals and / or alkaline earth metals. According to the invention, high yield of the isomerization product is realized; and the pour point of the product base oil of lubricating oil is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com