Hydroisomerization catalyst, preparation method thereof, and method for producing lubricating base oil from hydrocarbon oil or Fischer-Tropsch synthetic oil

A technology of lubricating base oil and hydroisomerization, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to reduce the amount of strong acid, improve selectivity, Evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

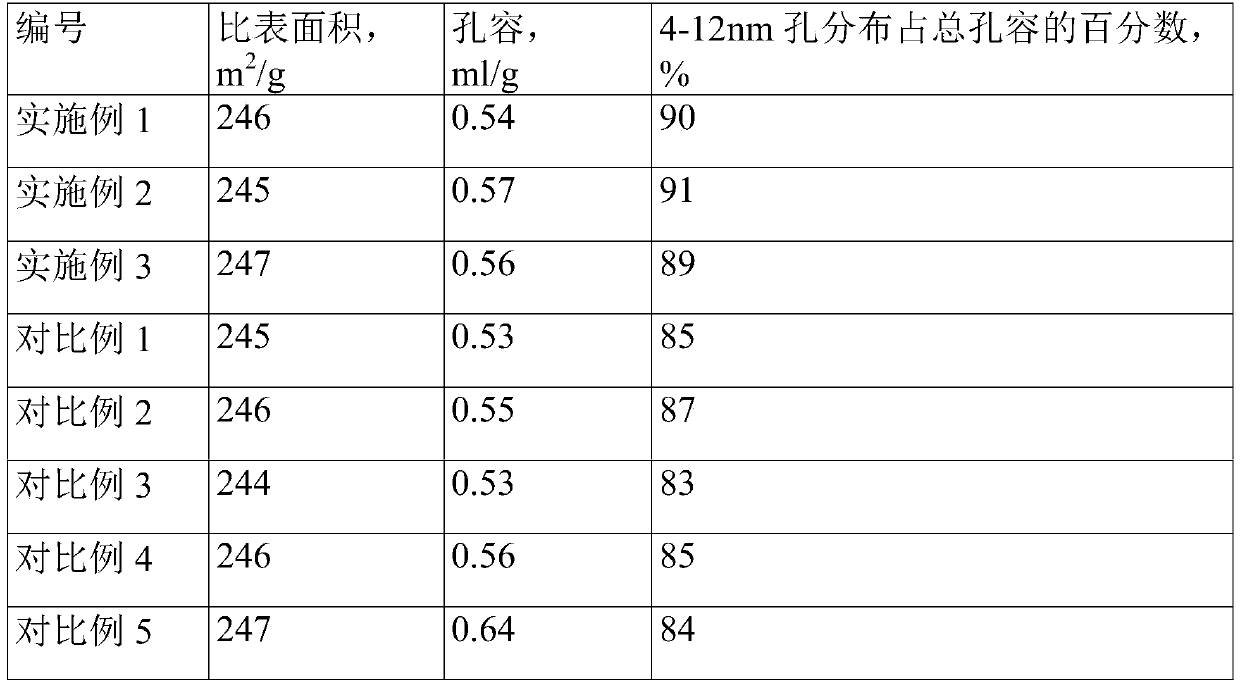

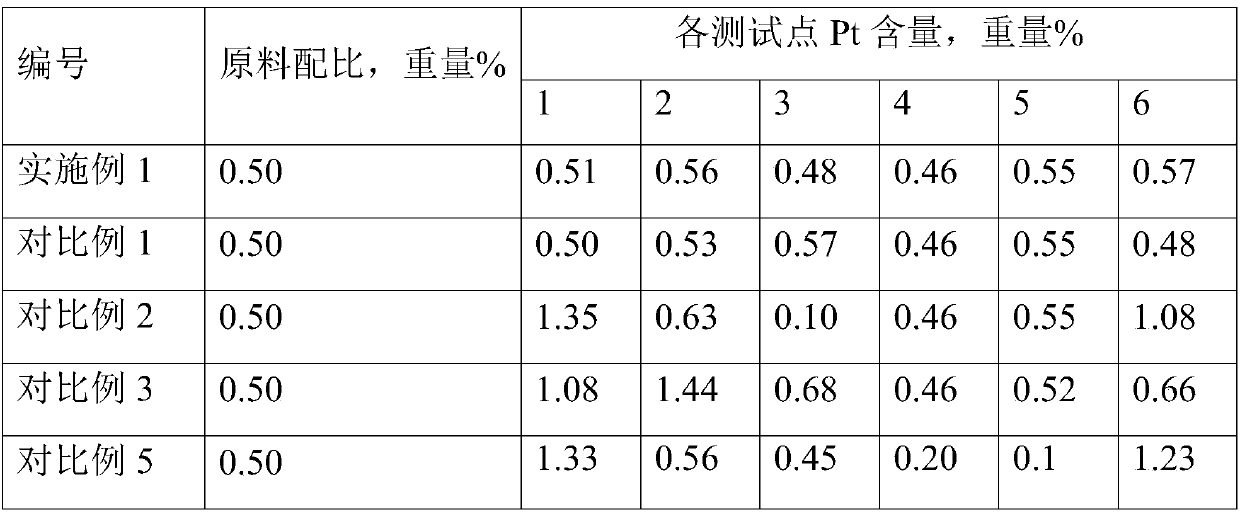

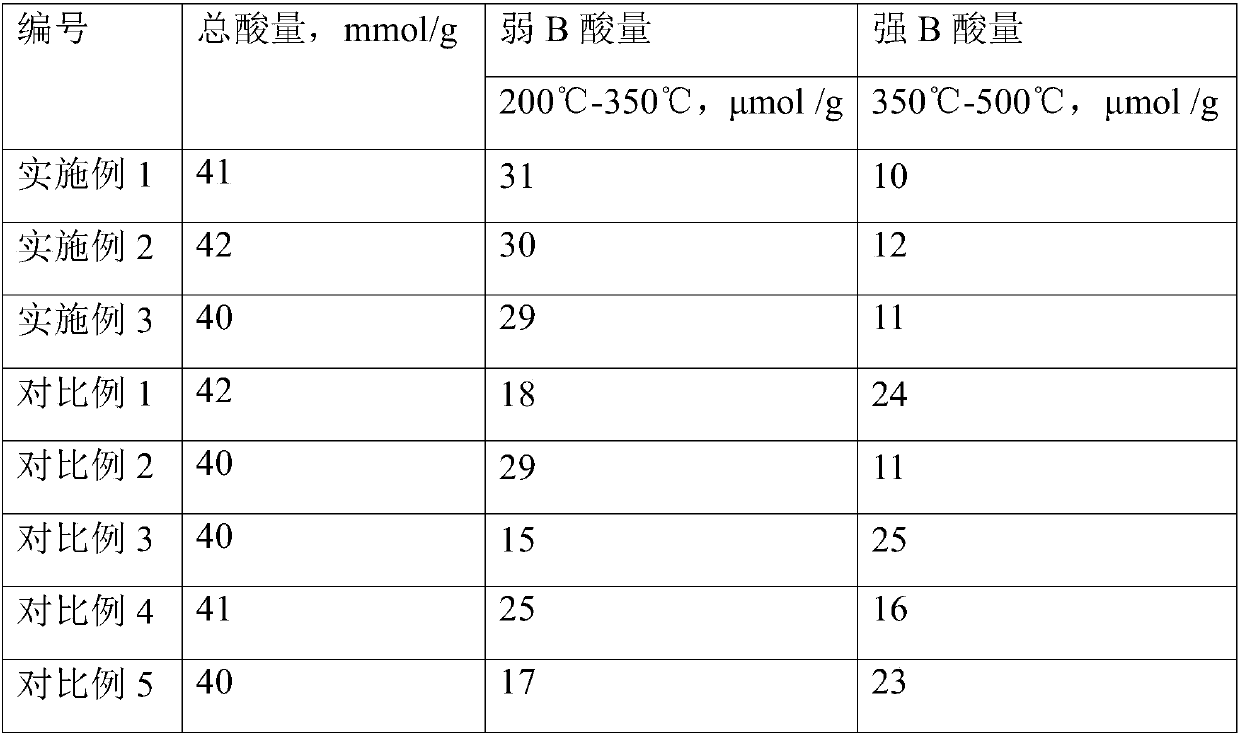

Examples

Embodiment 1

[0054] This example is used to illustrate the method for preparing a hydroisomerization catalyst provided by the present invention.

[0055] (1) the amorphous silicon aluminum of 86g (SIRAL company, ASA, specific surface area 500m 2 / g, pore volume 1.6ml / g, SiO 2 Content 40% by weight) and 74g of pseudo-boehmite (SB, uncalcined, specific surface area 233m 2 / g, pore volume 0.52ml / g) mix homogeneously, in the state of stirring, add by the nitric acid (concentration is 65% by weight, Beijing Reagent Company, chemically pure) of 2.0g, the sodium nitrate of 4.825g (Beijing Reagent Company, chemical pure) and 224g of water, and then kneaded in a mixer to form a ball, then put it into an extruder to extrude a cylindrical shape (maximum diameter is 2mm), and dried at 120°C for 4h, and roasted at 500°C for 4h, obtaining vector precursors;

[0056] (2) Put the carrier precursor into the hydrothermal device and feed air and water at 500 ° C. The feed rate of water vapor is 20% by volum...

Embodiment 2

[0062] This example is used to illustrate the method for preparing a hydroisomerization catalyst provided by the present invention.

[0063] (1) 60g of amorphous silicon aluminum (SIRAL company, ASA, specific surface area 500m 2 / g, pore volume 1.6ml / g, SiO 2 Content 40% by weight) and 40g of pseudo-boehmite (SB, unroasted, specific surface area 233m 2 / g, pore volume 0.52ml / g) mix homogeneously, add the sodium nitrate (Beijing Reagent Company, Chemically pure) and 180g of water, then kneaded into a ball in a mixer, then put it into an extruder to extrude a cylindrical shape (maximum diameter is 2mm), and dried at 100°C for 6h, and roasted at 550°C for 2h , to obtain the carrier precursor;

[0064] (2) Put the carrier precursor into the hydrothermal device and feed air and water at 600°C, the feed rate of water vapor is 10% by volume of the hydrothermal device, wherein the air flow rate is 3L / min and the water flow rate is 0.25ml / min, the carrier precursor was subjected to...

Embodiment 3

[0070] This example is used to illustrate the method for preparing a hydroisomerization catalyst provided by the present invention.

[0071] (1) 50g of amorphous silicon aluminum (SIRAL company, ASA, specific surface area 500m 2 / g, pore volume 1.6ml / g, SiO 2 Content 40% by weight) and 50g of pseudo-boehmite (SB, uncalcined, specific surface area 233m 2 / g, pore volume 0.52ml / g) mix homogeneously, add under the state of stirring by the nitric acid (concentration is 65% by weight), Beijing Reagent Company, chemically pure) of 1.54g, the sodium nitrate of 3.7g (Beijing Reagent Company, chemical pure) and 120g of water, and then kneaded into a ball in a mixer, then put it into an extruder to extrude a cylindrical shape (maximum diameter is 2mm), and dried at 110°C for 4h, and roasted at 450°C for 6h, obtaining vector precursors;

[0072] (2) Put the carrier precursor into the hydrothermal device and feed air and water at 400°C, the feed rate of water vapor is 15% by volume of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com