Hydrocracking method of midbarrel oil circulation

A hydrocracking and hydrotreating technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of high production cost, large hydrogen consumption, no economic advantages, etc., and achieves low BMCI value, High yield and the effect of rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

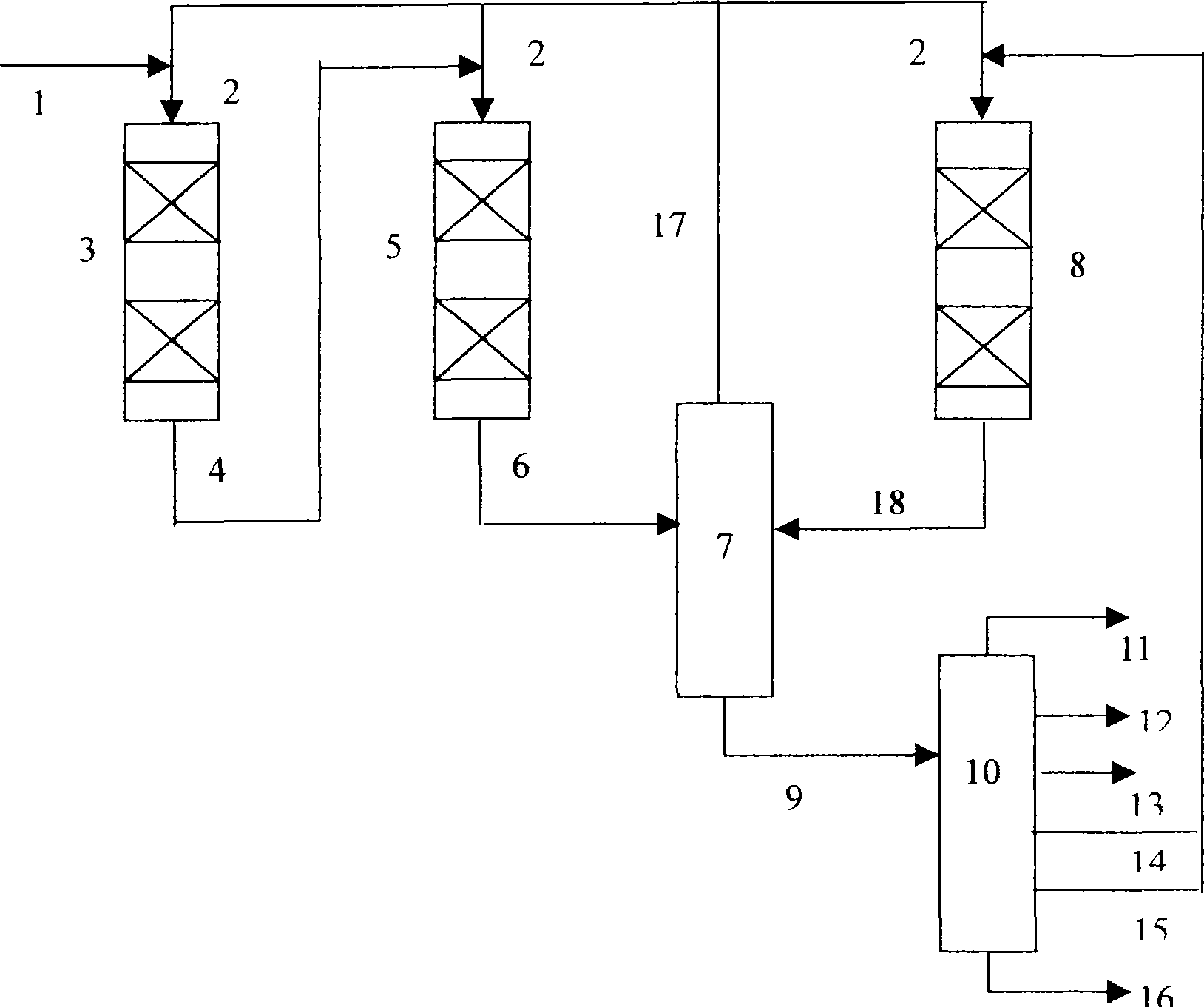

Method used

Image

Examples

preparation example Construction

[0037] The second preparation method of the hydrocracking catalyst recommended by the present invention is as follows: the Y-type molecular sieve precursor is mixed with the binder obtained by the peptization of small-pore alumina and dilute nitric acid solution, extruded, and formed, wherein the mixing process Selectively add macroporous alumina and / or amorphous silica-alumina; treat the above molded product at high temperature with water vapor or ammonia-water vapor, the treatment conditions are as follows: temperature 400-700°C, pressure 0-0.2MPa, ammonia gas The partial pressure is 0-0.05 MPa, and the treatment time is 0.5-3.0 hours to prepare the carrier; the catalyst carrier is impregnated with the solution containing active metal, dried and calcined to prepare the hydrocracking catalyst of the present invention. Wherein, after the mixture containing the Y-type molecular sieve precursor is treated with water vapor or ammonia gas-high temperature, the Y-type molecular siev...

Embodiment 1

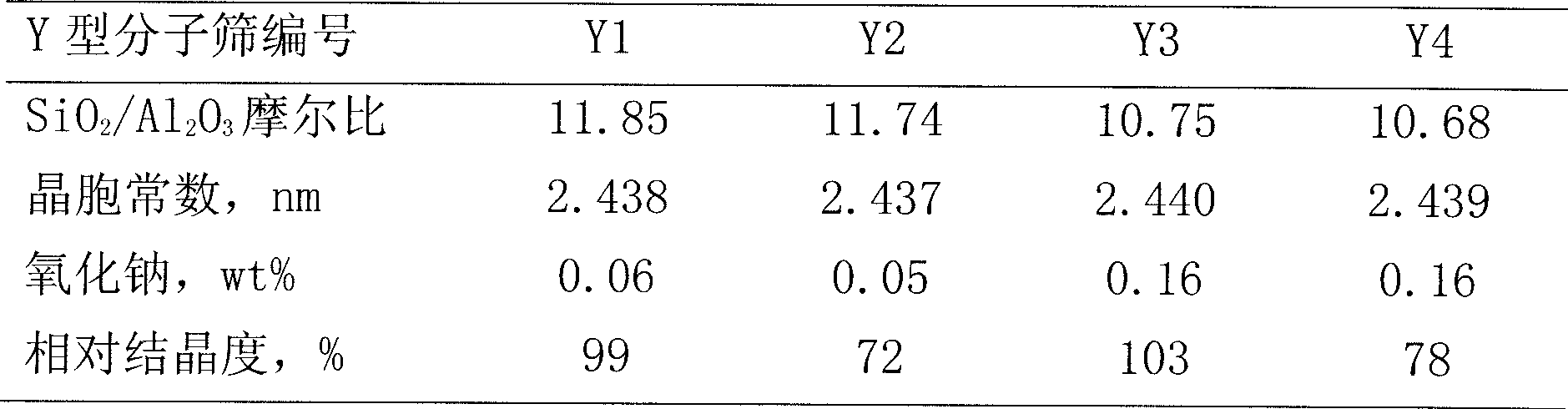

[0043] Example 1 prepared Y-type molecular sieve, and Examples 2-5 prepared the two-stage hydrocracking catalyst of the present invention. The properties of the obtained Y molecular sieve and hydrocracking catalyst are listed in Tables 1 and 2, respectively.

[0044] Example 1

[0045] Weigh raw material NH 4 NaY type molecular sieve (ammonium exchange degree is 80%, weight loss on ignition is 27.1%, SiO 2 / Al 2 o 3 Molar ratio is 5.3, sodium oxide content is 4.0wt%) 2057.6 grams, add 9 liters of distilled water to make slurry, and under stirring condition, heat slurry and be warmed up to 95 ℃; Add dropwise by 495.0 grams of ammonium hexafluorosilicate The solution prepared with 3500 milliliters of distilled water was dripped in 2 hours, then continued to stir at 95° C. for 2 hours, stopped stirring and stood for about 10 minutes, and separated the precipitated sodium ammonium fluoride (silicon) aluminate crystals by decantation. And after washing with water and drying, th...

Embodiment 2

[0048] The present embodiment prepares hydrocracking catalyst C1, and concrete steps are as follows:

[0049] (1) The Y-type molecular sieve precursor A1 is subjected to hydrothermal treatment, wherein the hydrothermal treatment conditions are as follows: the temperature is 600° C., the water pressure is 0.1 MPa, and the treatment time is 1 hour to obtain the Y-type molecular sieve Y1.

[0050] (2) Get the Y-type molecular sieve Y1 of 153.5 grams of step (1) gained, by 120 grams of small hole alumina (pore volume 0.47ml / g, specific surface area is 280m 2 / g), 0.2N dilute nitric acid solution 440ml peptized binder mixed, after extrusion, molding, then through 110 ℃ of drying 5 hours, 600 ℃ of roasting 6 hours obtain catalyst carrier,

[0051] (3) impregnating the catalyst carrier obtained in step (2) with an aqueous solution containing molybdenum and nickel, drying at 110°C for 5 hours, and calcining at 500°C for 5 hours to prepare the hydrocracking catalyst C1 of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com