Fixed bed hydrogenation reactor and heavy oil liquid phase hydrogenation process

A hydrogenation reactor and hydrogenation reaction technology are applied in the petrochemical field and can solve the problems of high activity and large temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

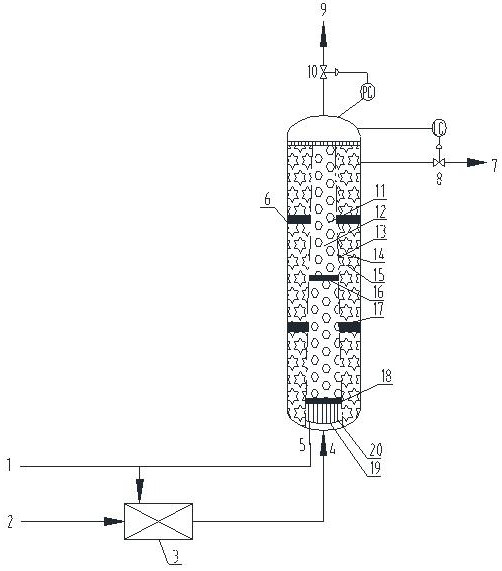

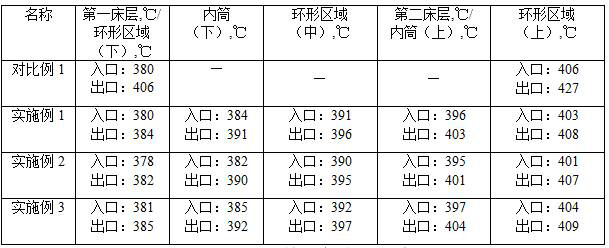

[0039] Attached figure 1 In the described method, the catalyst I packed in the inner cylinder of the heavy oil hydrogenation reactor adopts the FZC protective agent / FF-46 catalyst developed by the Fushun Petrochemical Research Institute, wherein the FZC protective agent is 15% of the total catalyst volume of the outer cylinder, and the annular area The packed catalyst II adopts the 3936 catalyst developed by Fushun Petrochemical Research Institute.

[0040] The hydrogen contained in the raw material oil in the feed of the heavy oil hydrogenation reactor is 3.66% of the mass of the raw material oil (the sum of fresh raw material oil and cycle oil); The sum of raw oil and circulating oil) is 9.28% of the mass; the circulation ratio is 2.5.

[0041] The reaction conditions of the inner cylinder of the hydrogenation reactor are as follows: the reaction temperature is 384-403°C, the reaction pressure is 15.0MPaG, and the liquid hourly volume space velocity is 2.8h -1 ;The reactio...

Embodiment 2

[0045] Attached figure 1 In the described method, the catalyst I filled in the inner cylinder of the heavy oil hydrogenation reactor adopts the FZC protective agent / 3996 catalyst developed by the Fushun Petrochemical Research Institute, wherein the FZC protective agent is 15% of the total catalyst volume of the outer cylinder, and the annular area is filled Catalyst II uses 3936 catalyst developed by Fushun Petrochemical Research Institute.

[0046] The hydrogen contained in the raw material oil in the feed of the heavy oil hydrogenation reactor is 5.40% of the mass of the raw material oil (the sum of fresh raw material oil and cycle oil); The sum of raw oil and circulating oil) is 7.74% of the mass; the circulation ratio is 2.0.

[0047] The reaction conditions of the inner cylinder of the hydrogenation reactor are as follows: the reaction temperature is 382-401°C, the reaction pressure is 15.0MPaG, and the liquid hourly volume space velocity is 2.2h -1 ;The reaction condit...

Embodiment 3

[0051] Attached figure 1 In the described method, the catalyst I packed in the inner cylinder of the heavy oil hydrogenation reactor adopts the FZC protective agent / FF-46 catalyst developed by the Fushun Petrochemical Research Institute, wherein the FZC protective agent is 15% of the total catalyst volume of the outer cylinder, and the annular area The packed catalyst II adopts FF-16 catalyst developed by Fushun Petrochemical Research Institute.

[0052] The hydrogen contained in the raw material oil in the feed of the heavy oil hydrogenation reactor is 7.66% of the mass of the raw material oil (the sum of fresh raw material oil and cycle oil); The sum of raw oil and circulating oil) is 5.28% of the mass; the circulation ratio is 2.0.

[0053] The reaction conditions of the inner cylinder of the hydrogenation reactor are as follows: the reaction temperature is 385-404°C, the reaction pressure is 15.0MPaG, and the liquid hourly volume space velocity is 2.0h -1 The reaction co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com