Propane dehydrogenation catalyst and preparation method thereof

A technology for propane dehydrogenation and catalyst, applied in catalyst activation/preparation, catalyst, carbon compound catalyst, etc. Utilization and other issues, to achieve the effect of improving the effective utilization rate, improving the processing capacity of the device, and improving the activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

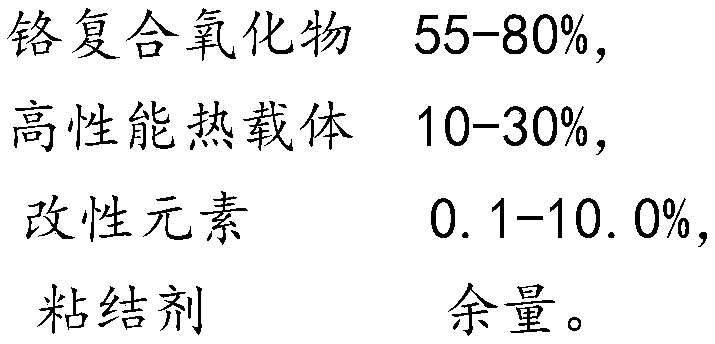

Method used

Image

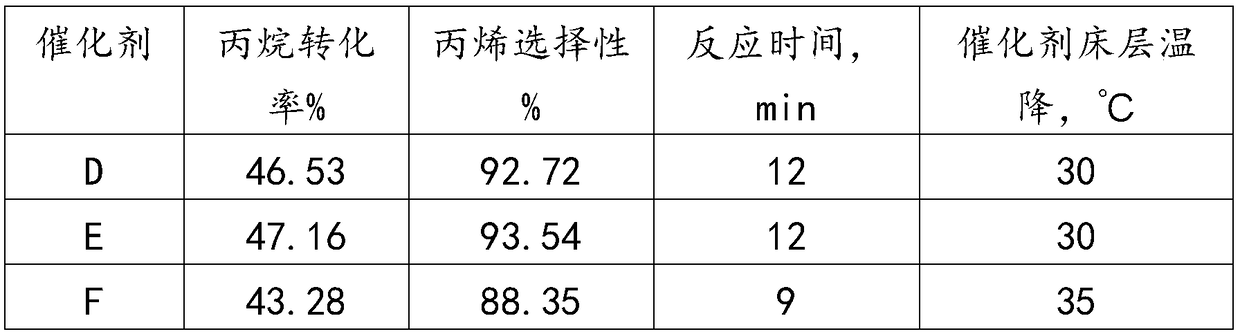

Examples

Embodiment 1

[0038] Weigh 1579 grams of Cr(NO 3 ) 3 9H 2 O was dissolved in deionized water, added 2000 grams of silica sol and stirred evenly, continued to stir and slowly added 250 grams of 10% sodium hydroxide solution, and 300 grams of 10% hexamethylenetetramine solution became viscous and continued to stir for 2 hours. The slurry was poured into a 5000ml autoclave lined with polytetrafluoroethylene, sealed and stirred, and reacted at 180°C for 50 hours, then taken out and dried at 120°C for 4 hours, and calcined at 600°C for 6 hours to obtain a small particle size chromium composite oxide A.

Embodiment 2

[0040] Weigh 1579 grams of Cr(NO 3 ) 3 9H 2 O, 5147 g Al(NO 3 )3·9H 2 O is dissolved in deionized water, continue to stir and slowly add 250 grams of 10% sodium hydroxide solution, 300 grams of 10% hexamethylenetetramine solution becomes viscous, continue stirring for 2 hours, and pour the slurry into 5000ml of polytetrafluoroethylene Sealed and stirred in an ethylene-lined autoclave, reacted at 180°C for 50 hours, took it out and dried it at 120°C for 4 hours, and roasted it at 600°C for 6 hours to obtain the small particle size chromium composite oxide B.

Embodiment 3

[0042] Weigh 700 grams of A, 100 grams of ultrafine α-alumina, mix evenly, add 300 grams of nitric acid acidified pseudo-boehmite, knead evenly, extrude into strips, dry at 120°C for 2 hours, and roast at 600°C for 6 hours to obtain Unmodified catalyst C 1 , weighed 57 g of ZrCl 4 , adding deionized water to prepare a solution, weighing 1000 grams of C 1 Uniformly impregnated in ZrCl 4 solution, after standing for 2 hours, dry at 120°C for 4 hours, and roast at 600°C for 6 hours to obtain modified catalyst C 2 , the modified catalyst C 2 Under the conditions of 750° C., normal pressure, and 100% steam, high-temperature steam aging treatment was carried out for 12 hours to obtain propane dehydrogenation catalyst D.

[0043] Wherein, the mass content of chromium oxide on the catalyst is 20%, and the mass content of zirconium oxide is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com