A high-pressure resistant anti-wear dust-proof capsule and its preparation process

A preparation process and high-pressure-resistant technology, applied in the field of high-pressure-resistant and anti-wear dust-proof capsules and the preparation process thereof, can solve the problems of poor heat-resistant air performance, poor volume expansion deformation, poor wear resistance, etc., and achieve cross-linking. The effect of low density, suitable hardness and low vulcanization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

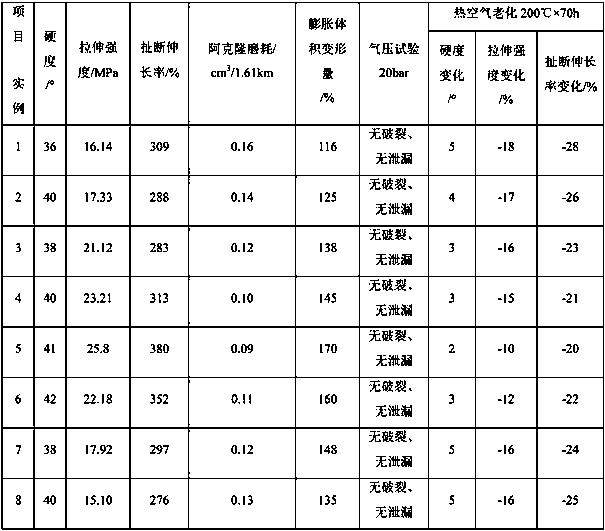

Examples

Embodiment 1

[0026] A high-pressure, wear-resistant and dust-proof capsule is made of the following raw materials in parts by weight: 85 parts of hydrogenated nitrile rubber, 15 parts of chlorinated butyl rubber, 5 parts of natural rubber, 5 parts of zinc oxide, 1 part of magnesium oxide, 1 part of stearic acid, 0.5 parts of paraffin, 30 parts of N330 carbon black, 10 parts of N770 carbon black, 10 parts of white carbon black, 3 parts of solid coumarone resin, 1 part of binder A, 2 parts of binder RS, 1 part of accelerator NOBS, 1 part of accelerator TMTD, 1 part of accelerator CZ, 1 part of sulfur, 1 part of vulcanizing agent DCP (dicumyl peroxide), 1 part of co-vulcanizing agent HVA2 (m-phenylene bismaleimide ) 1 part, plasticizer TP759 5 parts, internal release agent 18D 1 part and anti-aging agent 3 parts.

[0027] Described anti-aging agent is anti-aging agent 4010NA.

[0028] The preparation process of the above-mentioned high-pressure-resistant, wear-resistant and dust-proof capsul...

Embodiment 2

[0037] A high-pressure resistant, wear-resistant and dust-proof capsule is made of the following raw materials in parts by weight: 86 parts of hydrogenated nitrile rubber, 16 parts of chlorinated butyl rubber, 6 parts of natural rubber, 6 parts of zinc oxide, 2 parts of magnesium oxide, 1.5 parts of stearic acid, 0.6 parts of paraffin, 32 parts of N330 carbon black, 8 parts of N770 carbon black, 11 parts of white carbon black, 4 parts of solid coumarone resin, 1.5 parts of binder A, 3 parts of binder RS, Accelerator NOBS 2 parts, accelerator TMTD 2 parts, accelerator CZ 3 parts, sulfur 2 parts, vulcanizing agent DCP (dicumyl peroxide) 2 parts, co-vulcanizing agent HVA2 (m-phenylene bismaleimide ) 2 parts, 6 parts of TP759, 1 part of internal release agent 18D and 4 parts of anti-aging agent.

[0038] The anti-aging agent is anti-aging agent MB.

[0039] The preparation process of the above-mentioned high-pressure-resistant, wear-resistant and dust-proof capsule includes the f...

Embodiment 3

[0048] A high-pressure, wear-resistant and dust-proof capsule is made of the following raw materials in parts by weight: 87 parts of hydrogenated nitrile rubber, 17 parts of chlorinated butyl rubber, 7 parts of natural rubber, 7 parts of zinc oxide, 1 part of magnesium oxide, 2 parts of stearic acid, 0.7 parts of paraffin, 35 parts of N330 carbon black, 5 parts of N770 carbon black, 12 parts of white carbon black, 5 parts of solid coumarone resin, 2 parts of binder A, 2.5 parts of binder RS, 3 parts of accelerator NOBS, 2.5 parts of accelerator TMTD, 2 parts of accelerator CZ, 3 parts of sulfur, 3 parts of vulcanizing agent DCP, 2 parts of co-curing agent HVA2, 7 parts of TP759, 1.5 parts of internal release agent 18D and 4.5 parts of anti-aging agent share.

[0049] The anti-aging agent is a mixture of anti-aging agent 4010NA, anti-aging agent MB and anti-aging agent 445, and the weight ratio of the three is 1:1:1.

[0050] The preparation process of the above-mentioned high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com