A kind of heavy oil hydrogenation reactor and hydrogenation method

A heavy oil hydrogenation and reactor technology, which is applied in chemical instruments and methods, hydrogenation process, hydrocarbon oil treatment, etc., can solve the problems of high viscosity of heavy oil, long residence time, coking of catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

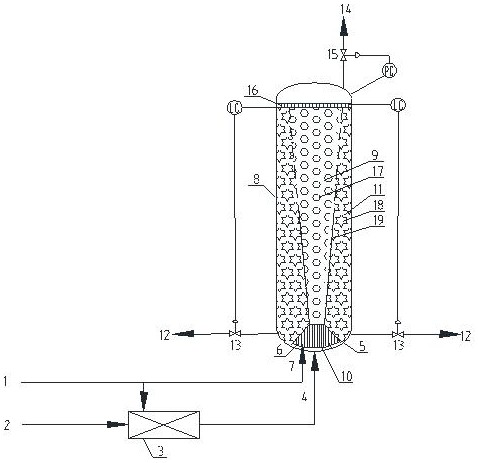

[0042] Attached figure 1 In the method described, the catalyst I used in the inner cylinder I of the heavy oil hydrogenation reactor adopts the FZC protective agent / 3996 catalyst developed by the Fushun Petrochemical Research Institute, and the catalyst II in the annular space adopts the FZC protective agent developed by the Fushun Petrochemical Research Institute / / For the 3936 catalyst, the FZC protective agent in the inner cylinder I is 14% of the total catalyst volume of the inner cylinder, and the FZC protective agent in the annular space is 14% of the total catalyst volume in the annular space. The hydrogen contained in the feed to the heavy oil hydrogenation reactor is 5.30% of the mass of the feedstock oil (the sum of fresh feedstock oil and circulating oil); The sum of oil) is 6.28% of the mass; the circulation ratio is 2.5.

[0043] The reaction conditions of the inner cylinder I of the hydrogenation reactor are as follows: the reaction temperature is 380-393°C, the...

Embodiment 2

[0047] Attached figure 1In the described method, the catalyst I used in the hydrogenation reactor inner cylinder I adopts the FZC protective agent / FF-26 catalyst developed by Fushun Petrochemical Research Institute, and the catalyst II in the annular space adopts the FZC protective agent / FF-26 developed by Fushun Petrochemical Research Institute. 3996 catalyst, wherein the FZC protective agent in the inner cylinder I is 15% of the total catalyst volume of the inner cylinder, and the FZC protective agent in the annular space is 15% of the total catalyst volume in the annular space. The hydrogen contained in the hydrogenation reactor feed is 6.62% of the mass of the raw material oil (the sum of fresh raw material oil and circulating oil); sum) 5.20% of the mass.

[0048] The reaction conditions of the inner cylinder I of the hydrogenation reactor are as follows: the reaction temperature is 380-393°C, the reaction pressure is 15.0MPaG, and the liquid hourly volume space velocity...

Embodiment 3

[0052] Attached figure 1 In the method described, the catalyst I used in the hydrogenation reactor inner cylinder I adopts the FZC protective agent / FF-46 catalyst developed by the Fushun Petrochemical Research Institute, and the catalyst II in the annular space adopts the FZC protective agent / FF-46 developed by the Fushun Petrochemical Research Institute. FF-26 catalyst, wherein the FZC protective agent is 15% of the total catalyst volume. The hydrogen contained in the hydrogenation reactor feed is 4.20% of the mass of the raw material oil (the sum of fresh raw material oil and circulating oil); sum) 8.15% of the mass.

[0053] The reaction conditions of the inner cylinder I of the hydrogenation reactor are as follows: the reaction temperature is 378-390°C, the reaction pressure is 15.0MPaG, and the liquid hourly volume space velocity is 1.0h -1 ;The reaction conditions in the annular space are as follows: the reaction temperature is 391-410°C, the reaction pressure is 14.5M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com