Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce ammonia injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

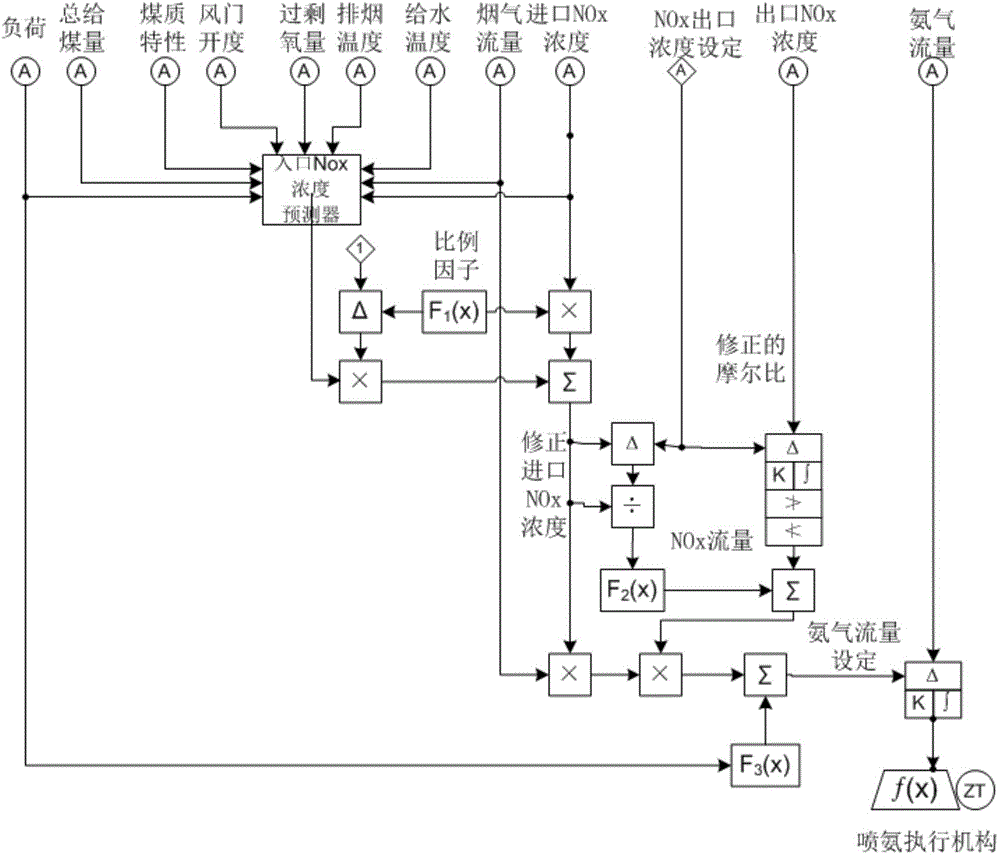

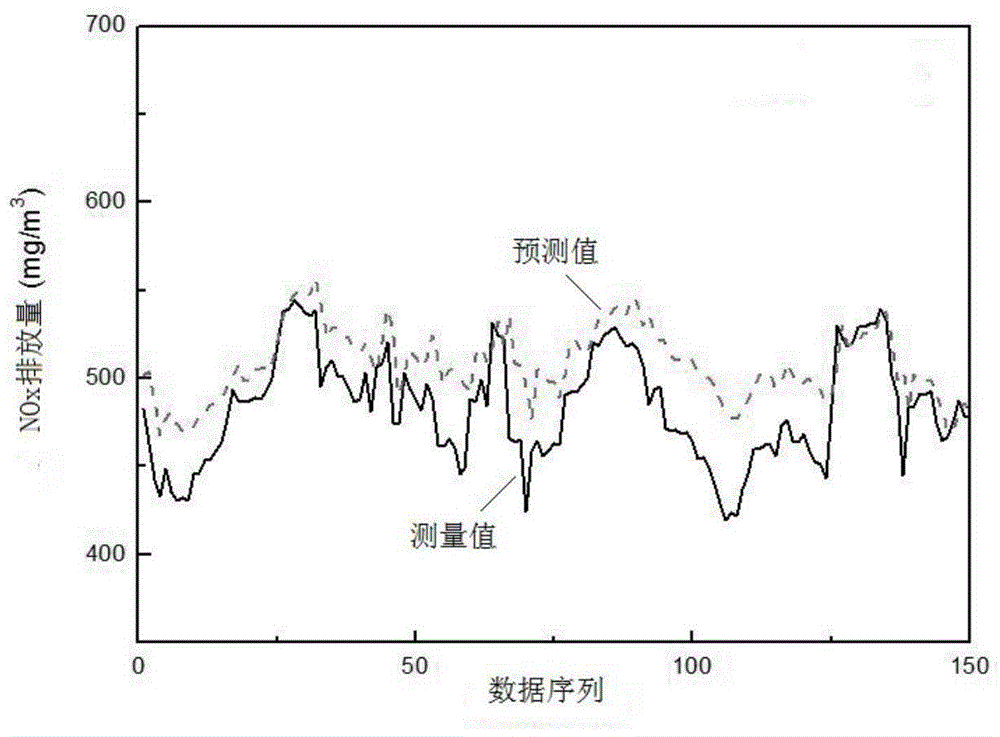

Control method for selective catalytic reduction flue gas denitrification system

ActiveCN104826493AThe escape rate does not exceed the standardSolve the problem of fluctuating denitrification control systemDispersed particle separationMeasurement deviceAutomatic control

The invention discloses a control method for a selective catalytic reduction flue gas denitrification system. The system includes: an entrance NOx concentration predictor, an ammonia injection flow controller, an entrance NOx concentration measurer and an NH3 concentration measurement device. The method utilizes a neural network unit to carry out weighted calculation on an entrance NOx concentration prediction value obtained by the entrance NOx concentration predictor and an NOx concentration measurement value measured by the entrance NOx concentration measurer to obtain a corrected NOx concentration, and according to the corrected NOx concentration and a set ammonia nitrogen mole ratio, the ammonia injection quantity demand of the ammonia injection flow controller can be positioned, thus realizing automatic control of the denitrification and ammonia injection quantity. The method provided by the invention matches the denitrification and ammonia injection quantity with the actual NOx concentration in flue gas, effectively reduces the error caused by the time delay problem of NOx concentration monitoring by instrument, and improves the reliability and economical efficiency of the denitrification system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

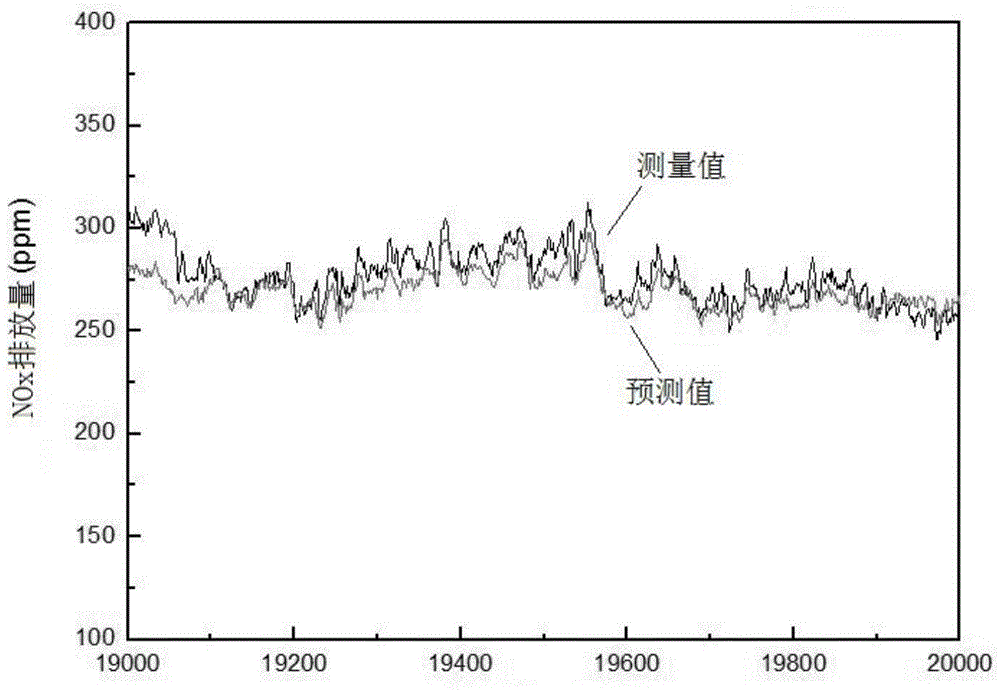

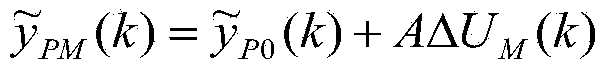

Selective catalytic reduction (SCR) denitration system and method based on constraint predictive control

ActiveCN104607042AQuick responseReduce escape rateDispersed particle separationEscape rateEngineering

The invention discloses a selective catalytic reduction (SCR) denitration system and method based on constraint predictive control. The flow of injected ammonia of the SCR denitration system is controlled by utilizing a predicting-proportioning cascade control policy; the flow of the injected ammonia is regulated by predicting the future change tendency of the concentration of NOx at an outlet of an SCR reactor and regulating the opening degree of an ammonia injection valve in advance; therefore, the defects of large inertia and delay of the SCR denitration system can be greatly overcome, the response speed of ammonia injection amount control to unit load change is increased, and the dynamic regulation quality of the SCR denitration system is improved; under the constraint predictive control, practical constrains, such as upper and lower constrains of valve opening degree, valve operation speed constrain and outlet NOx concentration constrain, are simultaneously considered and are used in parallel, so that the fact that the system performance is influenced due to saturation of execution mechanisms is avoided; based on ensuring the fact that the concentration of the NOx at the outlet reaches a target value, the ammonia injection amount is reduced as much as possible, and the operation cost and the ammonia escape rate are effectively reduced.

Owner:SOUTHEAST UNIV

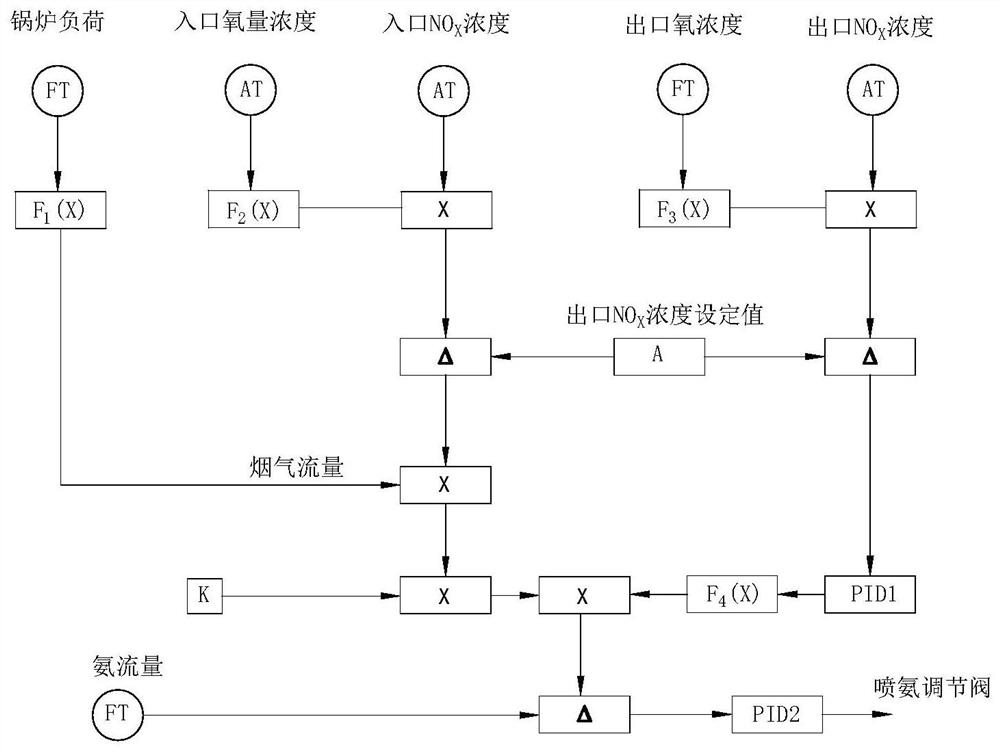

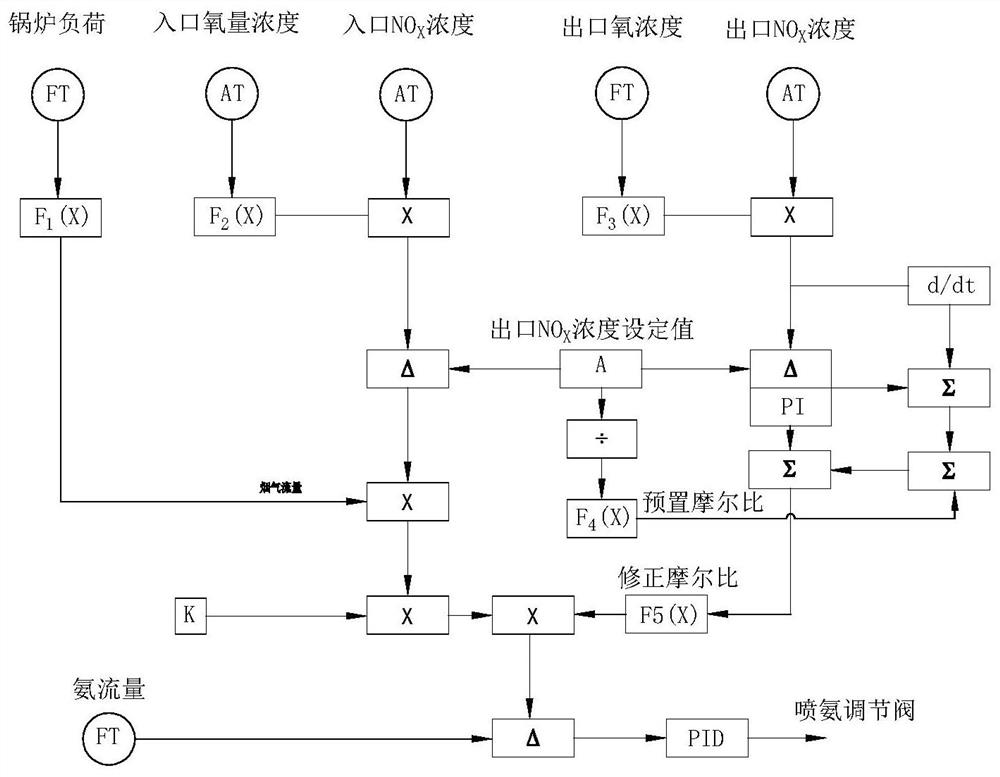

Denitration ammonia spraying control method based on multi-variable correction

ActiveCN109062053AReduce volatilityReduce excess spaceDispersed particle separationAdaptive controlAmmoniaComputer science

The invention relates to a denitration ammonia spraying control method based on multi-variable correction, belongs to the technical field of ammonia spraying control of a denitration system of a thermal power generating set, and solves the problem that NOx fluctuation in an outlet of an SCR system in the prior art is severe. The method comprises the steps of acquiring measurement data and workingcondition information of a denitration system instrument in real time; constructing a NOx content prediction model at the inlet of the SCR denitration system, and predicting the NOx content at the inlet of the SCR system at the current moment; and carrying out ammonia spraying amount feedforward control and prediction correction on the basis of the predicted NOx content at the inlet of the SCR system and the measured data, generating an ammonia spraying amount control instruction at the current moment, controlling an ammonia spraying adjusting valve and adjusting the ammonia spraying amount. According to the method, the NOx content precision prediction model of the SCR inlet denitration system and the intelligent feedforward control method are adopted, so that NOx fluctuation at the outletof the SCR denitration system and space deviation are greatly reduced under the premise that smoke NOx emission satisfies the environmental protection index, the average value of the outlet NOx is increased, the ammonia spraying amount is reduced, the ammonia escape level is reduced, and the denitration cost is lowered.

Owner:JIANGSU GUOXIN JINGJIANG POWER GENERATION CO LTD +1

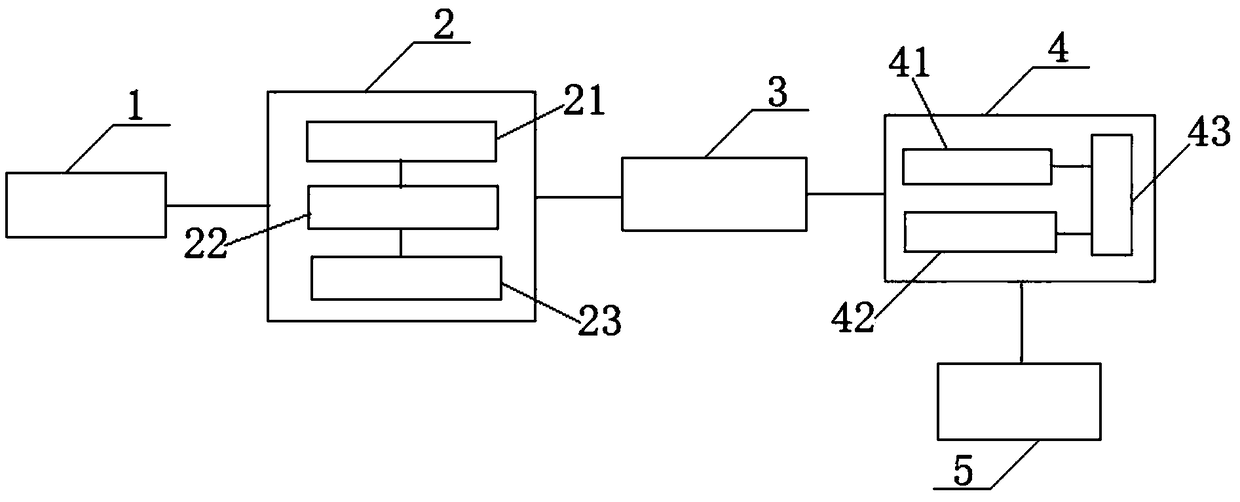

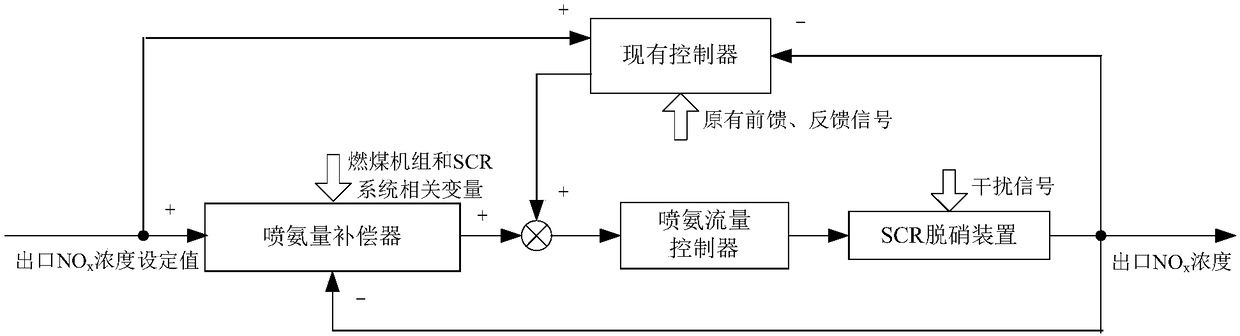

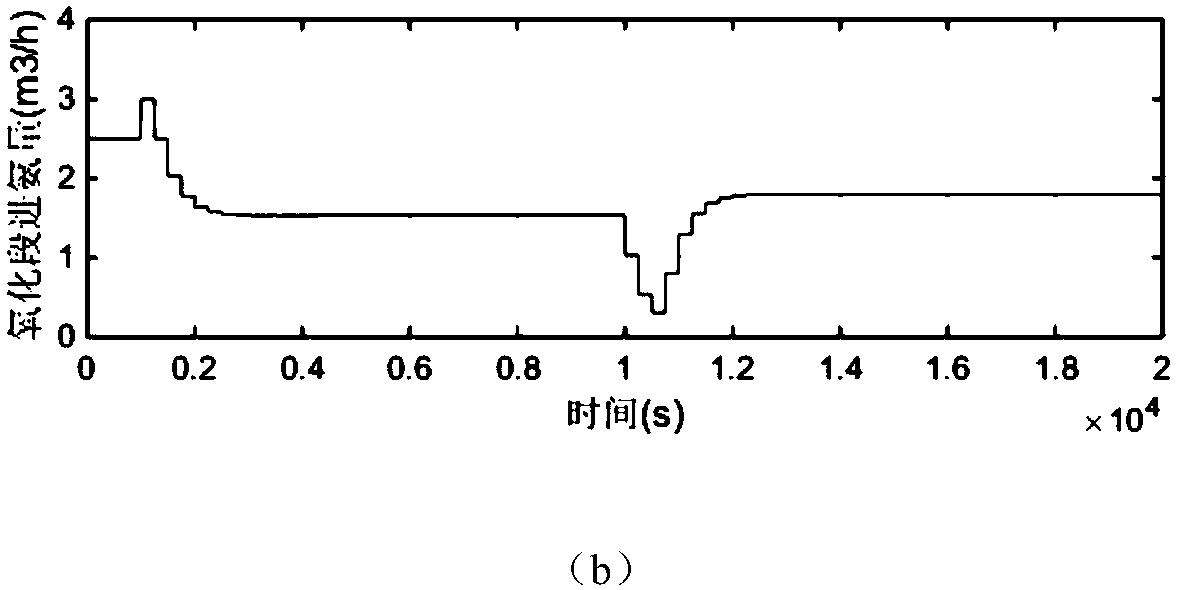

SCR flue gas denitration optimization control system and method based on ammonia spraying amount compensator

ActiveCN109343349AReduce escape rateReduce adverse effectsTotal factory controlAdaptive controlControl systemFlue gas

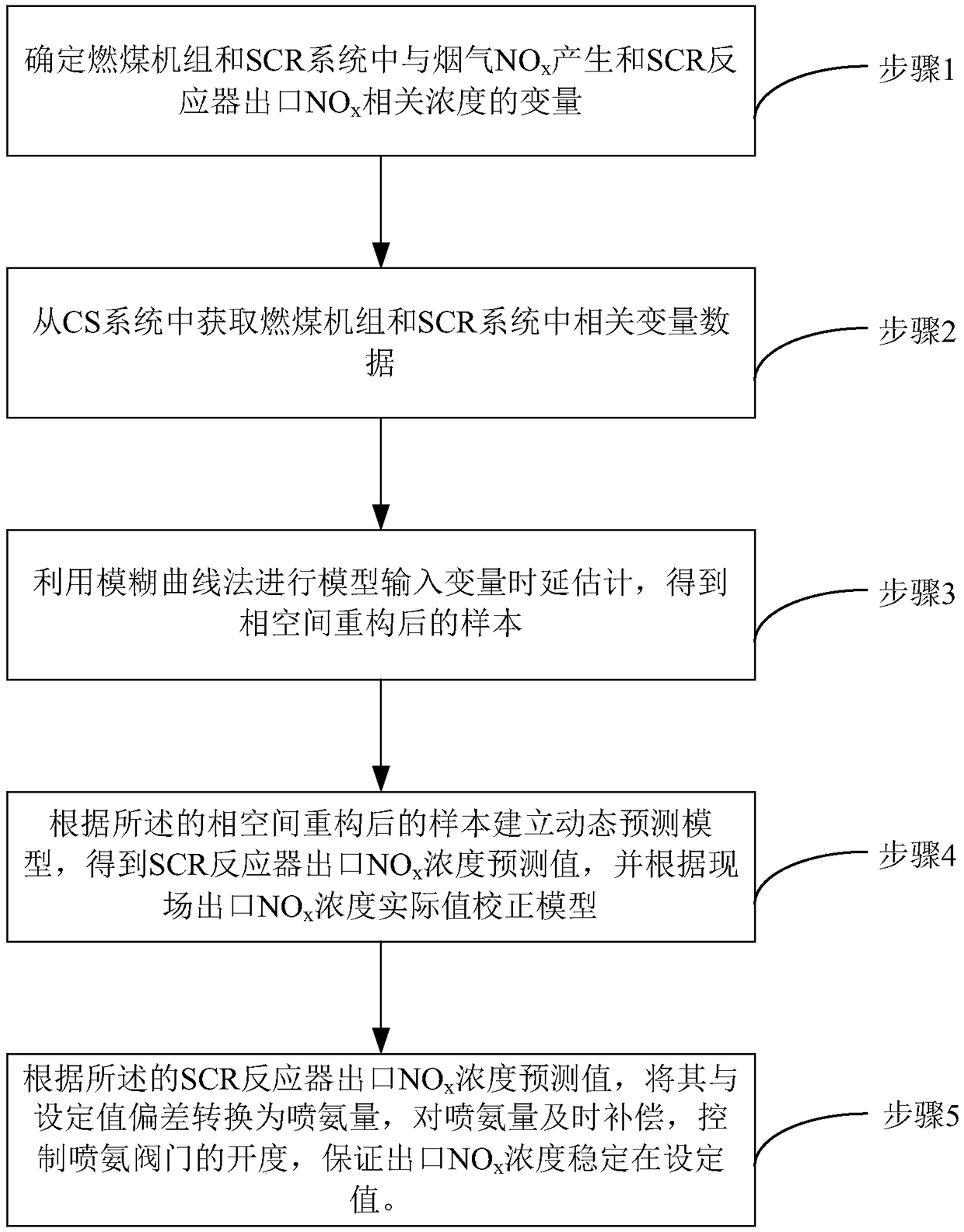

The invention discloses an SCR flue gas denitration optimization control method based on an ammonia spraying amount compensator. The method comprises the following steps of 1, determining variables related to the flue gas NOx generation and the outlet NOx concentration of an SCR reactor in a coal-fired unit and an SCR system; 2, acquiring related variable data in the step 1 from a DCS system; 3, performing input variable time delay estimation of a model by utilizing a fuzzy curve method, so that a sample after phase space reconstitution is obtained; 4, building an outlet NOx concentration dynamic prediction model according to the sample after the phase space reconstitution in the step 3, obtaining an outlet NOx concentration prediction value of the SCR reactor, and correcting the outlet NOx concentration dynamic prediction model according to an actual value of the field outlet NOx concentration; and 5, according to the outlet NOx concentration prediction value of the SCR reactor, obtained in the step 4, converting a deviation between the outlet NOx concentration prediction value of the SCR reactor and a set value into an ammonia spraying amount, timely compensating the ammonia spraying amount, and controlling the opening degree of an ammonia spraying valve to ensure that the outlet NOx concentration is stabilized to be the set value.

Owner:DATANG ENVIRONMENT IND GRP

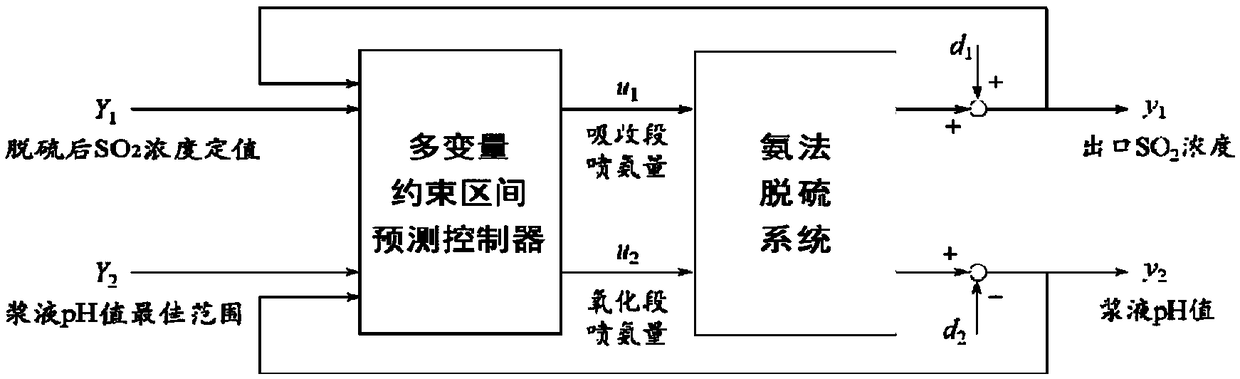

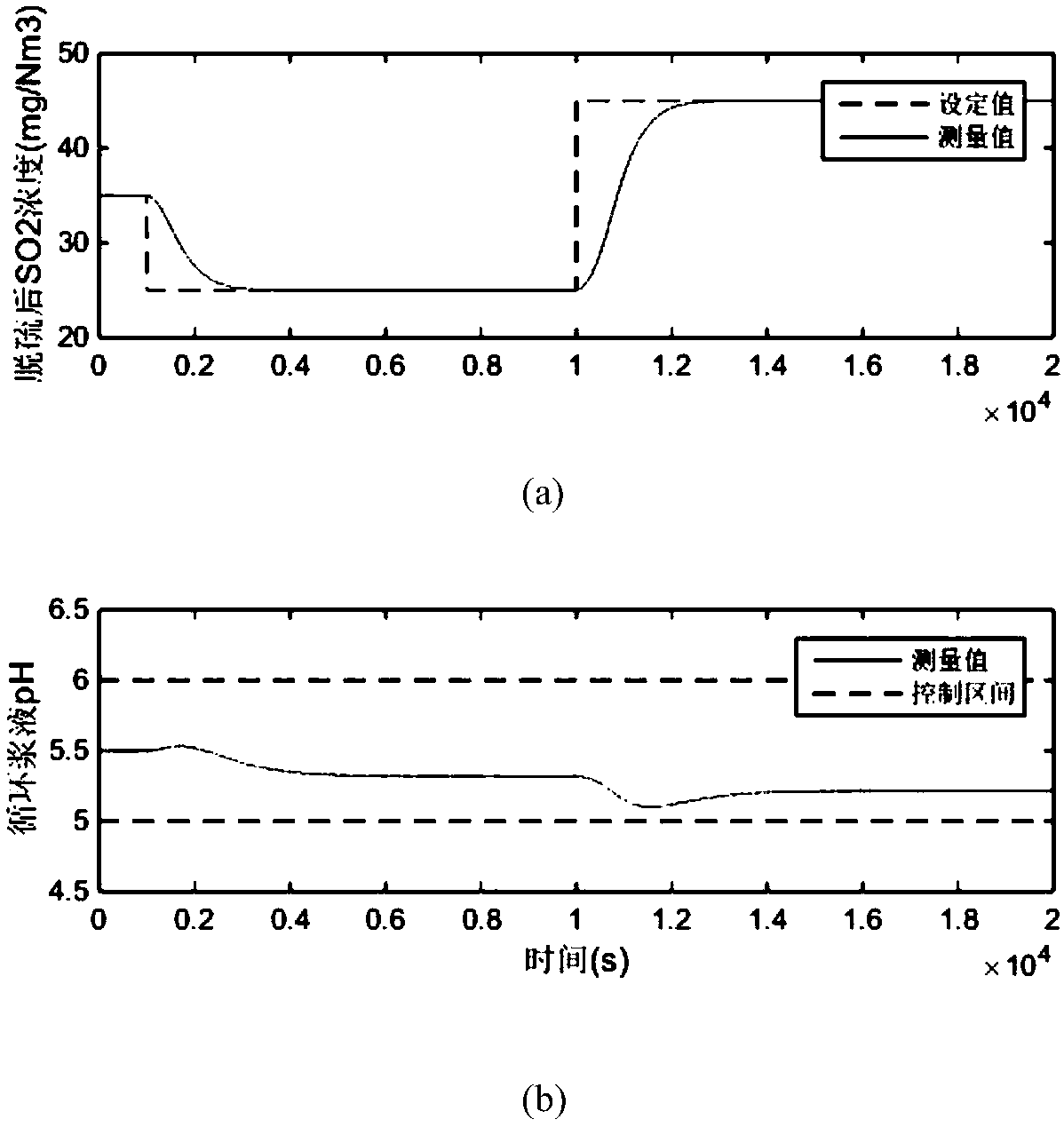

Ammonia-process desulfurization optimum control method based on multi-variable constraint zone predicting control

InactiveCN109224815AImplement schedulingRealize distributionDispersed particle separationProcess engineeringControl quality

The invention discloses an ammonia-process desulfurization optimum control method based on multi-variable constraint zone predicting control. The ammonia-process desulfurization optimum control methodhas the advantages that by adopting the multi-variable constraint zone predicting control method, the intake flow rate of ammonia water between the absorption section and oxidization section of a desulfurization tower can be well coordinated; at the premises of ensuring the desulfurization efficiency, the control quality of the system is improved, the running cost of the system is reduced, and the economic and environment-friendly running of the system is accelerated.

Owner:SINOPEC YANGZI PETROCHEM +1

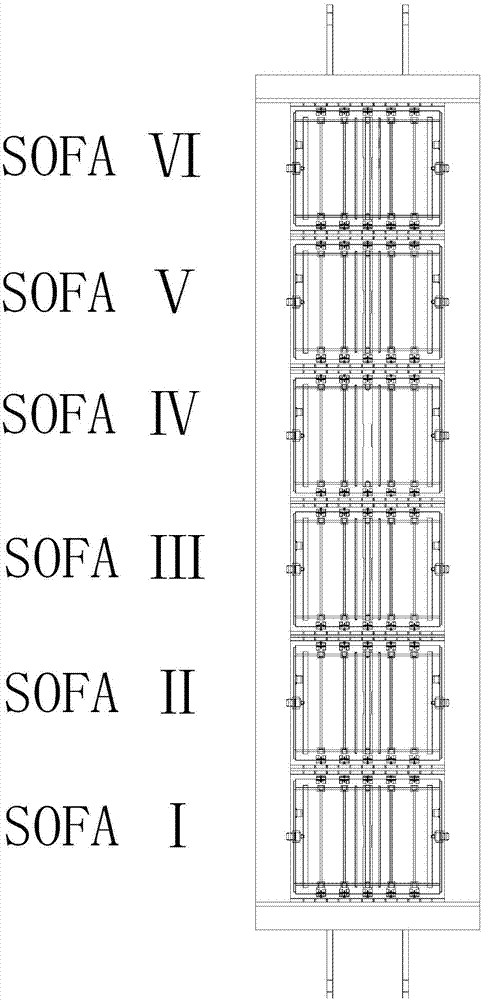

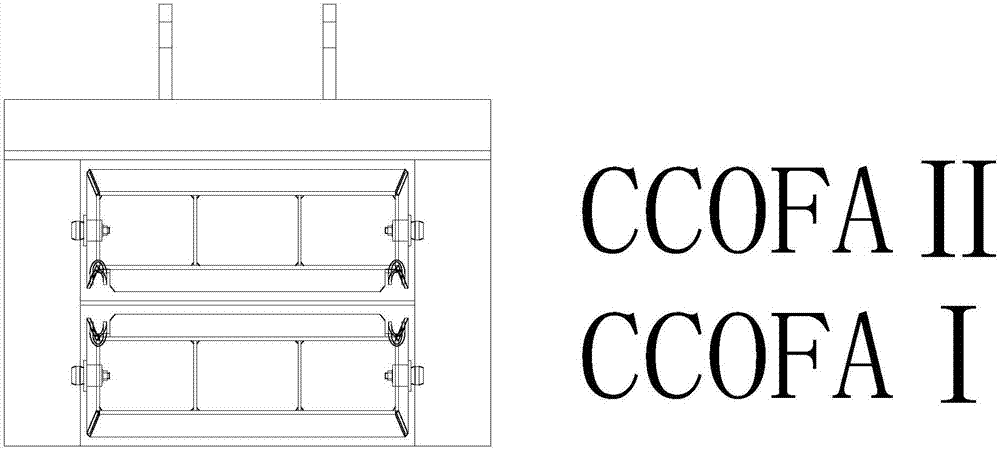

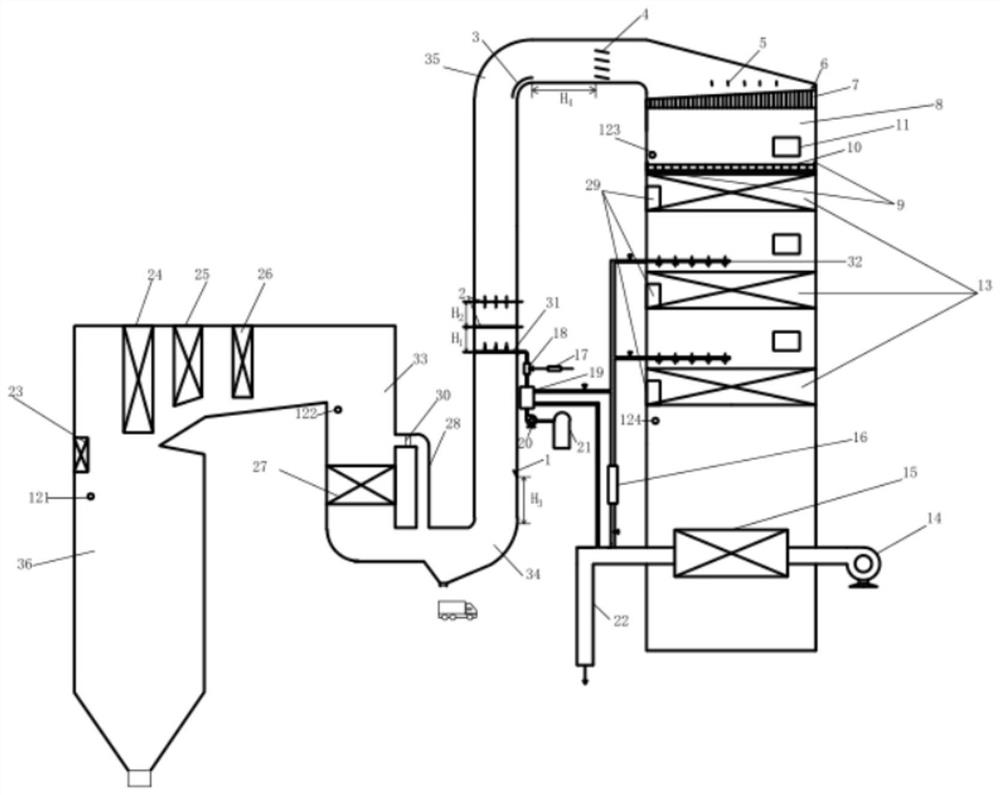

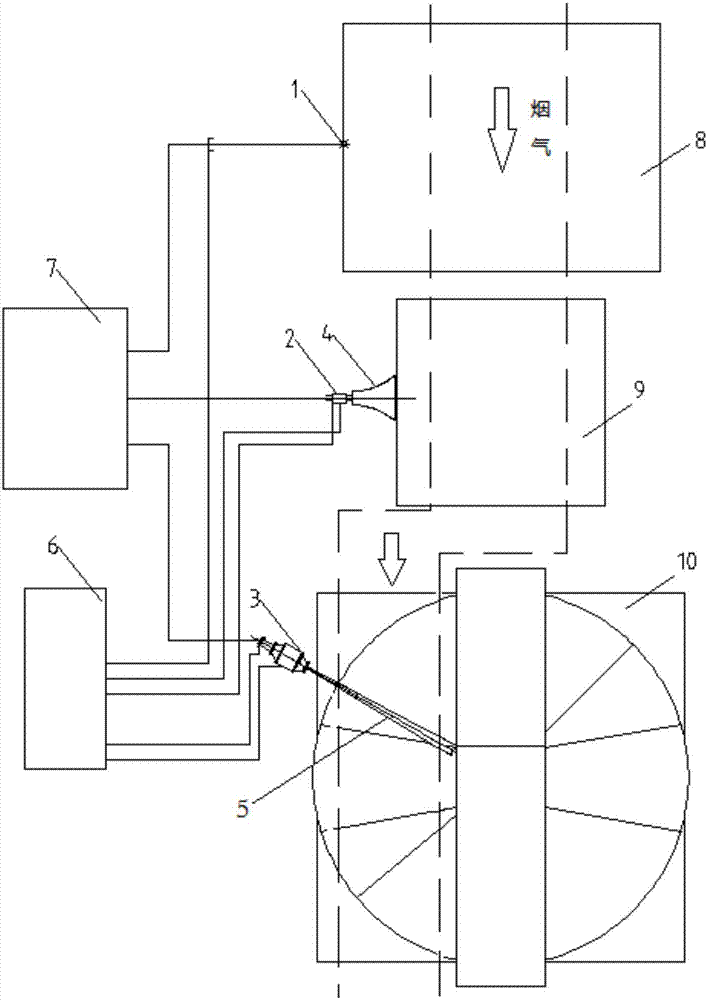

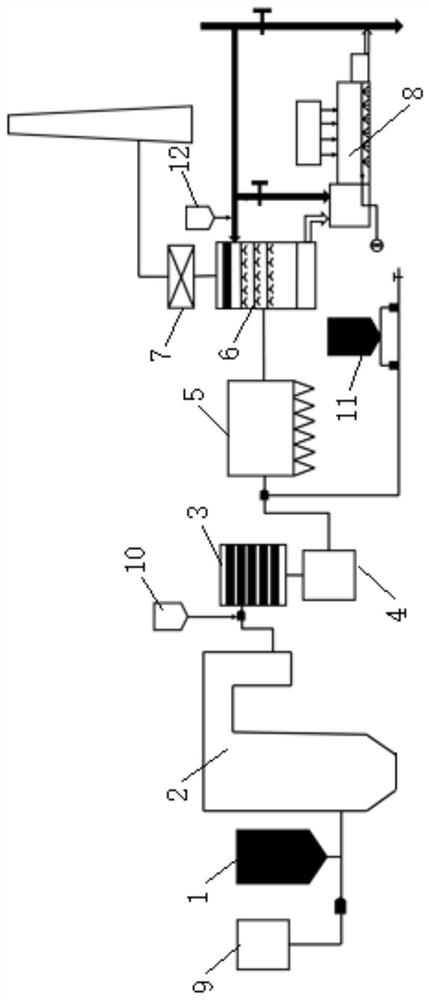

Multi-level refined intelligent denitration system and method based on big data and firefly algorithm

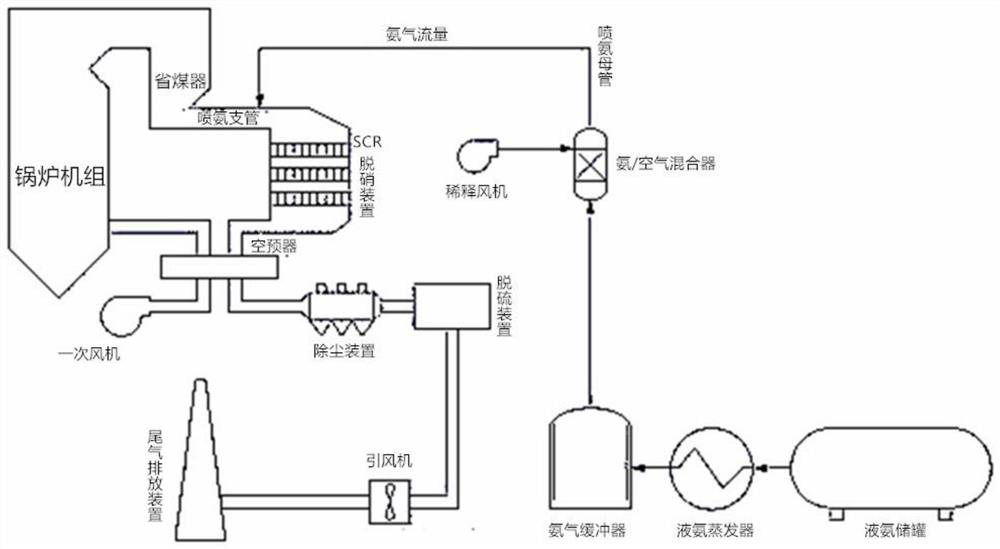

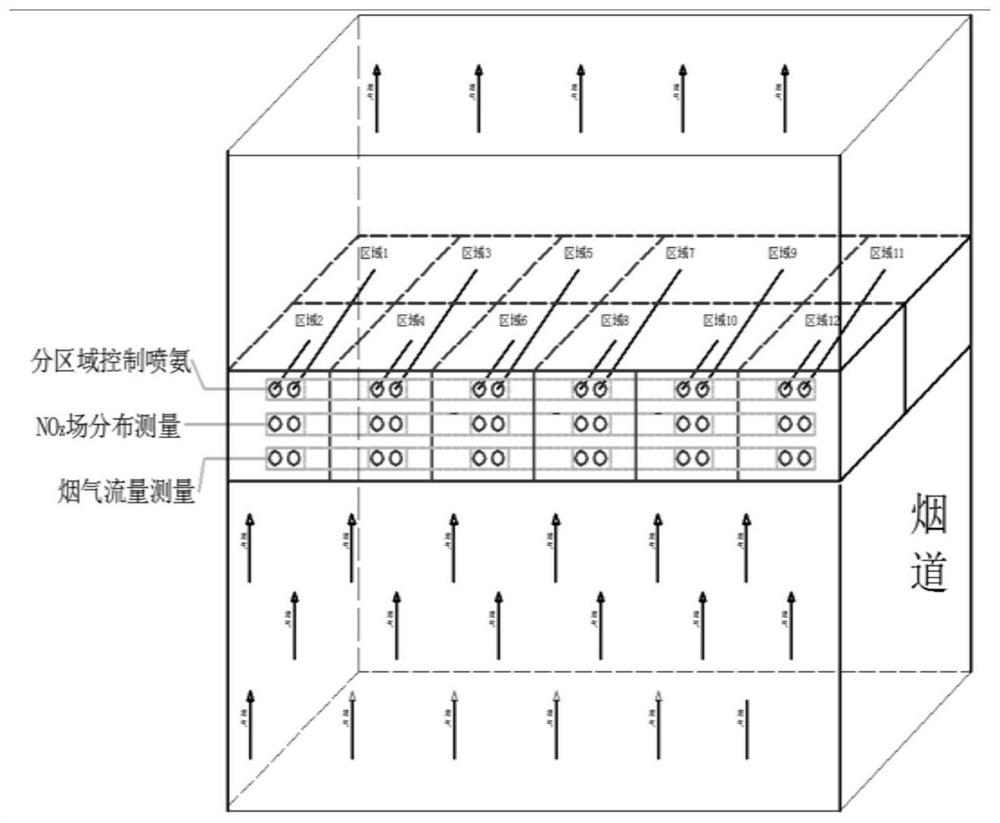

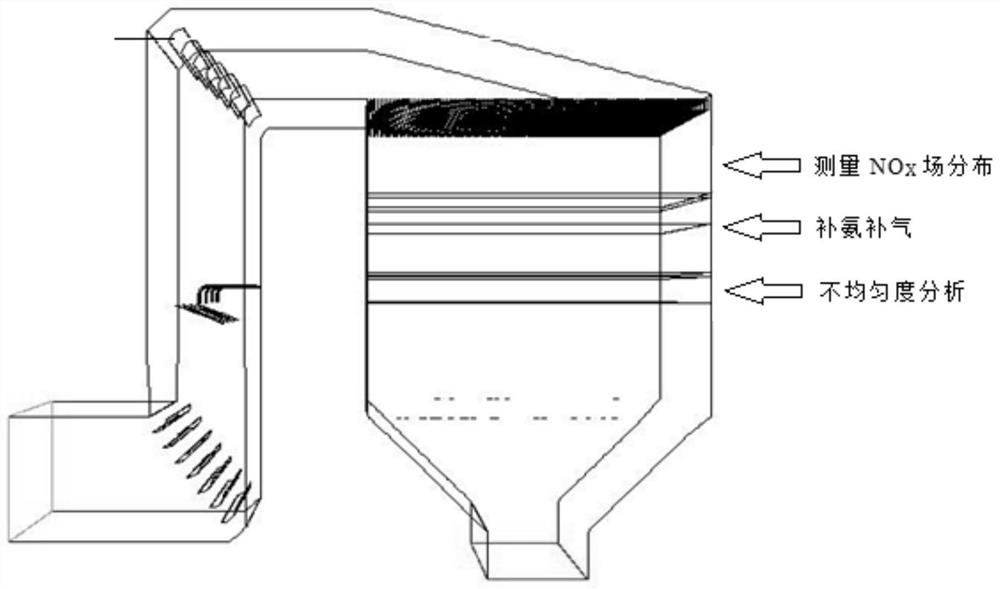

ActiveCN112156649AReduce emission concentrationReduce the chance of cloggingDispersed particle separationArtificial lifeAir preheaterPtru catalyst

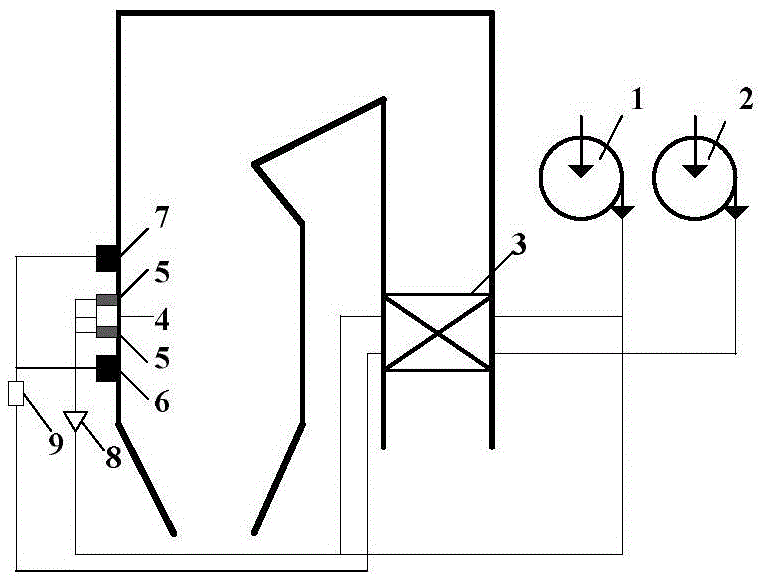

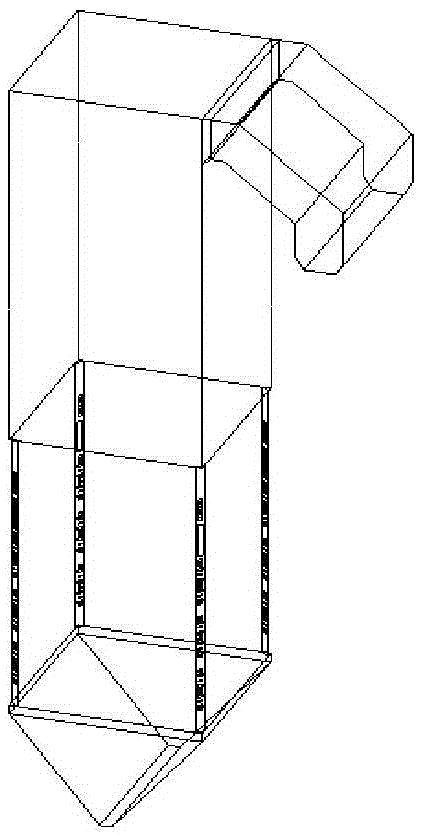

The invention discloses a multi-level refined intelligent denitration system based on big data and a firefly algorithm. The system comprises a coal economizer, an SCR denitration device, an air preheater, a dust removal device, a desulfurization device, a tail gas emission device, a boiler unit, an ammonia spraying main pipe assembly, a denitration inlet flow speed and NOx field distribution monitoring system, a denitration outlet NOx / NH3 field distribution monitoring system, a catalyst area NOx field distribution monitoring system and a catalyst area NOx / NH3 non-uniformity analysis system. According to the system disclosed in the invention, through big data and a particle swarm optimization algorithm, an ammonia spraying branch pipe real-time adjustment system is established, and dual control of partition control and ammonia spraying total amount optimization is realized; the flow field matching is accurate, the variable working condition adaptability is high, the quality of ammonia spraying control can be effectively improved, and the SCR performance can meet the NOx ultralow emission requirement; the comprehensive effects of saving the ammonia spraying amount, reducing the NOx emission concentration, reducing the air pre-heater blockage probability and reducing tail equipment dust accumulation are achieved.

Owner:NANJING GUODIAN ENVIRONMENTAL PROTECTION TECH

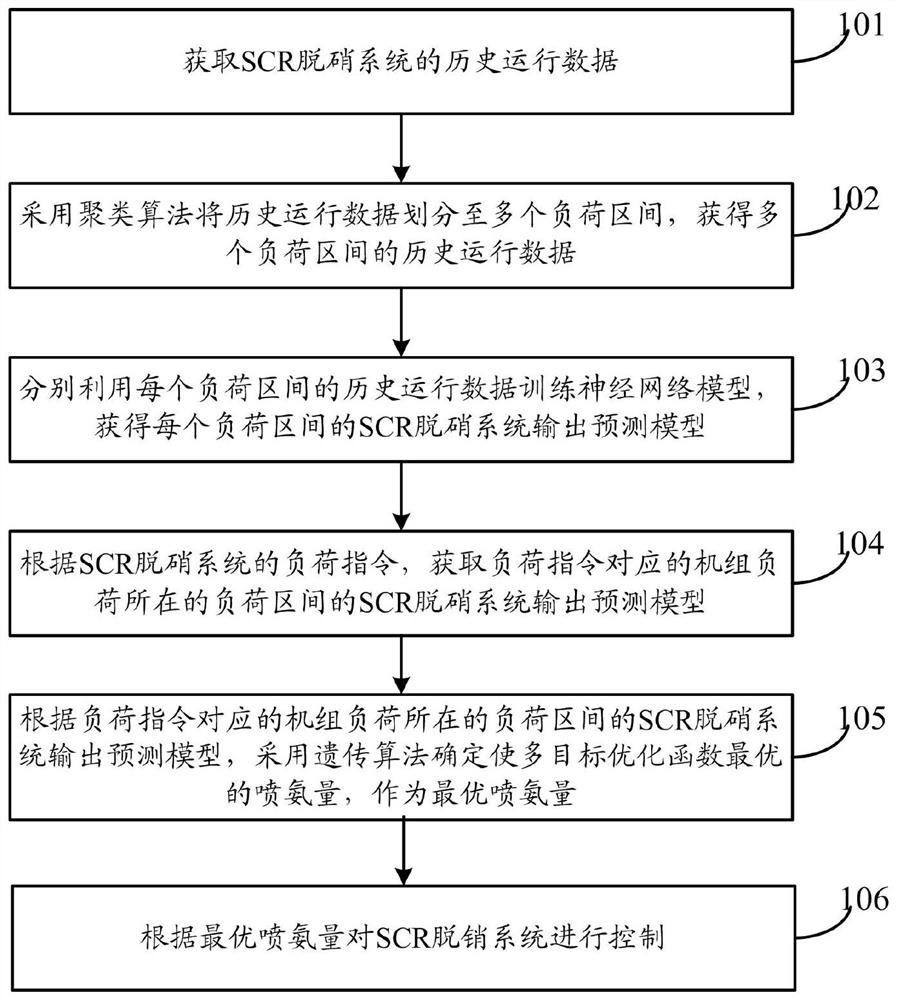

Control method and system for SCR denitration system of all-working-condition power station

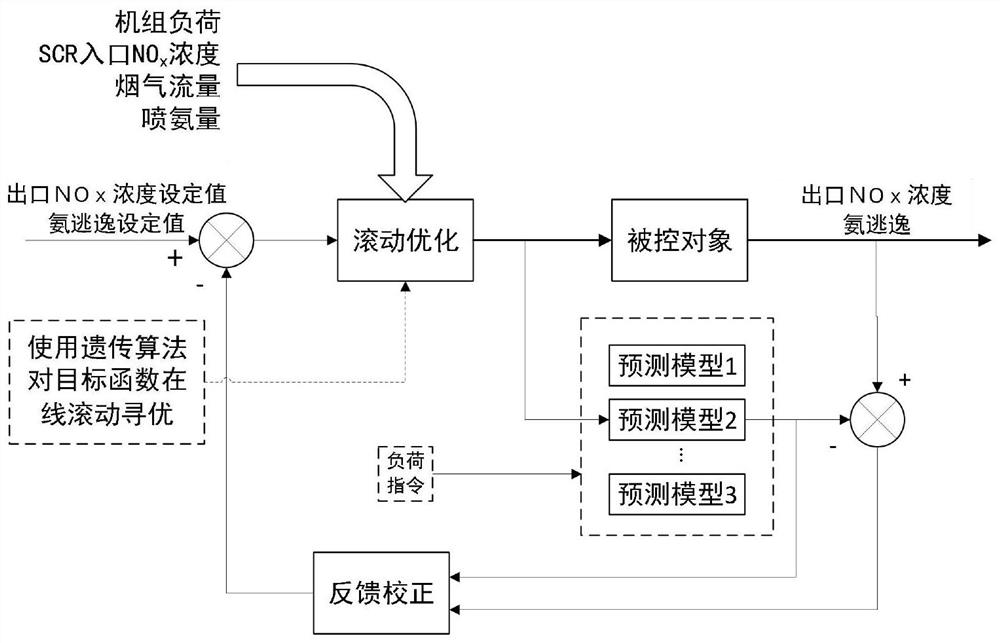

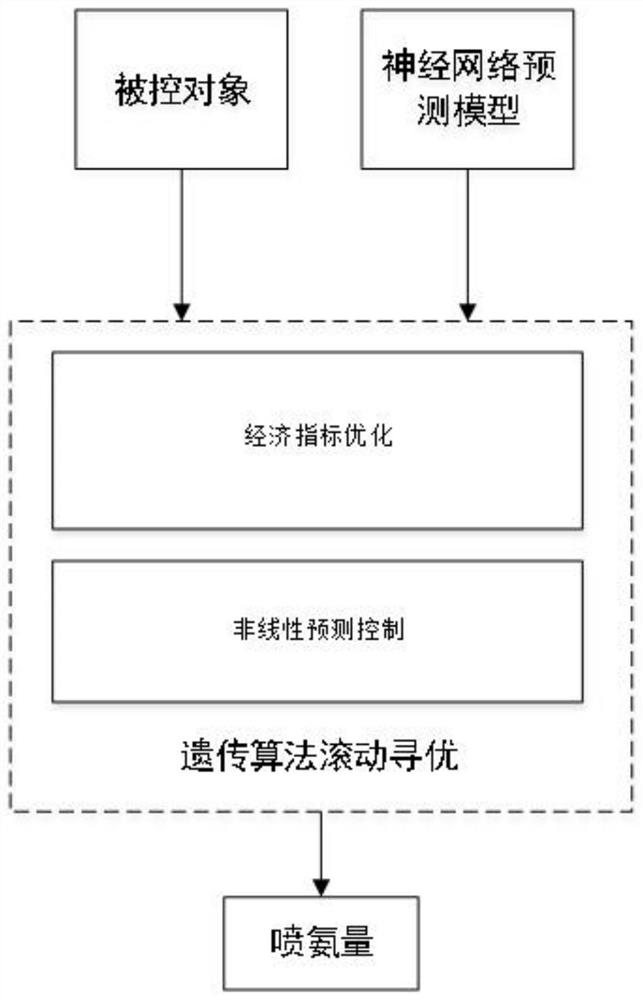

PendingCN112418284AImprove dynamic adjustment qualityQuick responseDispersed particle separationCharacter and pattern recognitionGenetics algorithmsProcess engineering

The invention discloses a control method and system for an SCR denitration system of an all-working-condition power station, and the control method comprises the steps of adding denitration cost intoan optimization objective function, employing a prediction control structure, carrying out the model building and control quantity optimization through combining a neural network and a genetic algorithm, and achieving the optimization control of ammonia spraying quantity. According to the invention, the future change trend of the NOx concentration at the outlet of the SCR reactor is predicted by constructing the neural network model, the ammonia injection flow of the SCR denitration system is determined by adopting genetic algorithm optimization, and the valve opening degree of the ammonia injection valve is adjusted, so that the method can better overcome the defects of large inertia and large delay of the SCR denitration system, the response speed of ammonia spraying amount control to unit load changes is increased, and the dynamic adjustment quality of the SCR denitration system is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Method and system for denitration control of thermal power plant

InactiveCN107551774AReduce cloggingReduce resistanceControlling ratio of multiple fluid flowsDispersed particle separationEngineeringAmmonia

The invention discloses a method and a system for denitration control of a thermal power plant. The method comprises the following steps: calculating an O'clock every hour average value of NOX emission amount according to an NOX emission concentration value detected at a chimney by a CEMS (Continuous Emission Monitoring System); then judging whether the O'clock every hour average value is within apreset NOX emission threshold value range or not, increasing the ammonia spraying amount if the O'clock every hour average value is higher than a preset NOX emission threshold value, and reducing theammonia spraying amount if the O'clock every hour average value is smaller than the preset NOX emission threshold value. Compared with a traditional method for controlling the ammonia spraying amountaccording to an emitted NOX real-time concentration value, environment protection assessment standard can be met by just ensuring that the O'clock every hour average value accords with the preset NOXemission threshold value no matter how big an emitted NOX real-time concentration value is, the ammonia spraying amount can be accurately controlled on the premise that the NOX emission amount according with the environment protection requirements is ensured, and the situation that too much or too less ammonia is sprayed can be prevented from happening, so that the probability of blocking an airpre-heater is reduced, the resistance of a draught fan is reduced, and the overhauling cost is reduced.

Owner:CHINA RESOURCES POWER HUBEI

SNCR denitration control method and device for circulating fluidized bed unit and storage medium

ActiveCN111841276ASmall fluctuations in concentrationReduce volatilityDispersed particle separationAir volumeControl system

The invention discloses an SNCR denitration control method and device for a circulating fluidized bed unit and a storage medium. The method comprises the following steps: S1, oxygen amount control: designing an oxygen amount control model prediction controller by taking the total air amount of secondary air as a control variable, the total coal amount as an interference variable and the oxygen content in flue gas as a controlled variable, and controlling the opening degree of a baffle door of a secondary air fan according to an output result of the oxygen amount control model prediction controller; and S2, denitration control: designing a denitration control model prediction controller by taking the total ammonia spraying amount as a control variable, taking the NOx concentration of the clean flue gas as a controlled variable and taking the oxygen content in the flue gas as an interference variable, and controlling the opening degree of an ammonia spraying valve according to an outputresult of the denitration control model prediction controller. The fluctuation range of the NOx generation amount under the variable load working condition can be reduced through oxygen amount controloptimization, oxygen amount measuring points serve as feedforward control through denitration control optimization, the delay time of a control system can be shortened, and the ammonia spraying amount can be saved through combination of the oxygen amount control optimization and the denitration control optimization.

Owner:YANTAI LONGYUAN POWER TECH

Surrounding air method for reducing NOx emission concentration of power station pulverized coal powder plant boiler

InactiveCN105605606AThe total air volume remains unchangedReduce Excess Air CoefficientFuel supply regulationAir supply regulationMomentumAir volume

The invention provides a surrounding air method for reducing the NOx emission concentration of a power station pulverized coal powder plant boiler. The method includes the specific step of replacing existing secondary air with primary air high in wind pressure under the condition that it is ensured that the total air volume of a hearth is not changed, wherein the primary air is used as surrounding air of a cooling pulverized coal spray nozzle. Because the wind pressure of primary air is higher than the wind pressure of secondary air, after the existing surrounding air is replaced with primary air, the flowing speed of surrounding air is increased. It is ensured that the momentum of surrounding air is constant before and after replacement, and therefore the mass flow rate of surrounding air is correspondingly decreased after replacement. Because the momentum of surrounding air is not changed, the cooling effect the same as that of a combustor can be achieved, and rigidity of the pulverized coal jet flow is also ensured. Meanwhile, the mass flow rate of surrounding air is decreased, and therefore the excess air coefficient of the initial combustion period of pulverized coal is decreased, NO generation in the initial period of combustion is restrained, and therefore the NO emission concentration during running of the boiler is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Flue gas treatment process and treatment system

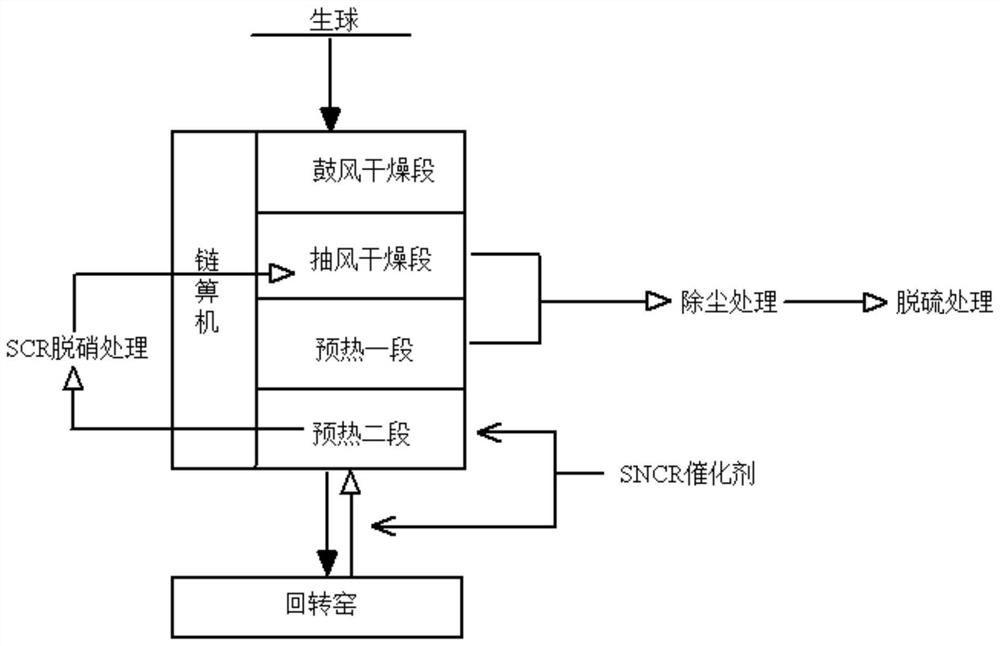

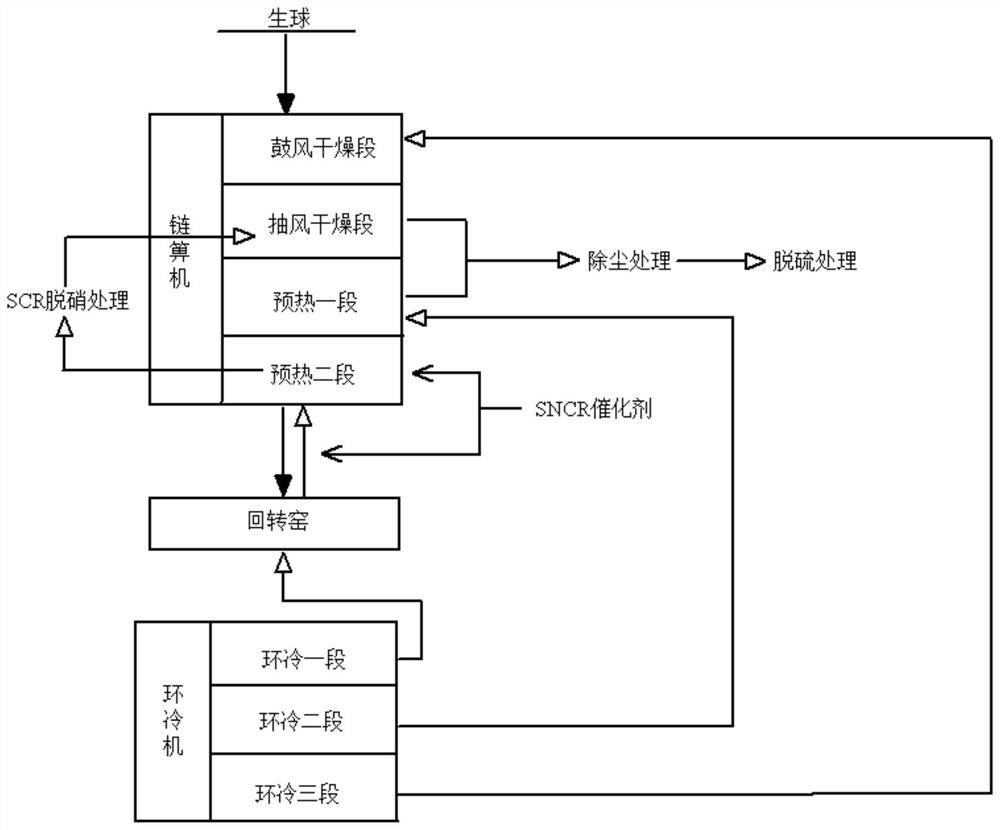

ActiveCN113908677ALow investment costLow running costGas treatmentRotary drum furnacesPtru catalystThermodynamics

The invention discloses a chain grate-rotary kiln flue gas treatment process and treatment system. A control method of an SNCR-SCR coupling denitration system is adopted, a composite additive is added into an SNCR denitration catalyst or a novel SNCR composite ammonia agent is provided; and meanwhile, a movable airflow balance plate is additionally arranged between a PH section and a TPH section of a chain grate, the air pressure of the TPH section is controlled to be larger than or equal to the air pressure of the PH section by utilizing the position change of the airflow balance plate, so that the problem that the content of NOx in flue gas of the TPH section is increased due to the fact that high-NOx-content waste gas of the PH section flees towards the TPH section is prevented. The optimal coupling ultralow NOx emission technology can be formed, the denitration efficiency can be effectively guaranteed on the premise that SNCR ammonia consumption is reduced, meanwhile, the service lifetime of an SCR denitration catalyst can be prolonged, and the denitration operation cost and investment cost of the system are obviously reduced. The utilization efficiency of a flue gas denitration reducing agent is further improved, and the escape amount of NH3 is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

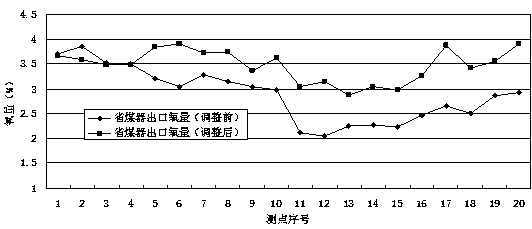

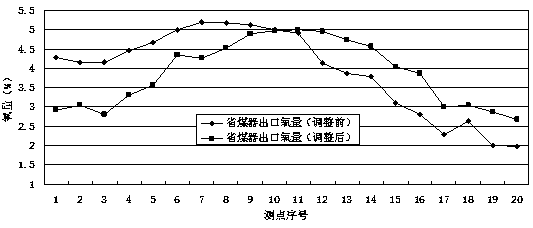

A method for controlling the oxygen amount at the outlet of a w-type flame boiler economizer

ActiveCN106196162BImprove outlet oxygen deviationPromote combustionFuel supply regulationHearthProcess engineering

The invention discloses a method for controlling the oxygen content of an outlet of an economizer for a W-shaped flame boiler. The method comprises the following steps: 1, under the conditions that the operation oxygen content of the boiler, the combustion coal category, the grinding operation mode, the air distribution mode and the like are not changed, actually measuring the oxygen content of the outlet of the economizer, and analyzing a deviation of the oxygen content; 2, analyzing the cause of the deviation of the oxygen content; 3, performing heating state adjustment on primary air; 4, adjusting the air distribution mode; and 5, adjusting the deviation of the powder content. According to the control method, the deviation of the oxygen content of the outlet of the economizer can be adjusted, so that the deviation of the oxygen content of the outlet of the economizer can be small as far as possible during operation of the boiler, the combustion in a furnace hearth is more uniform, and the boiler efficiency is improved.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

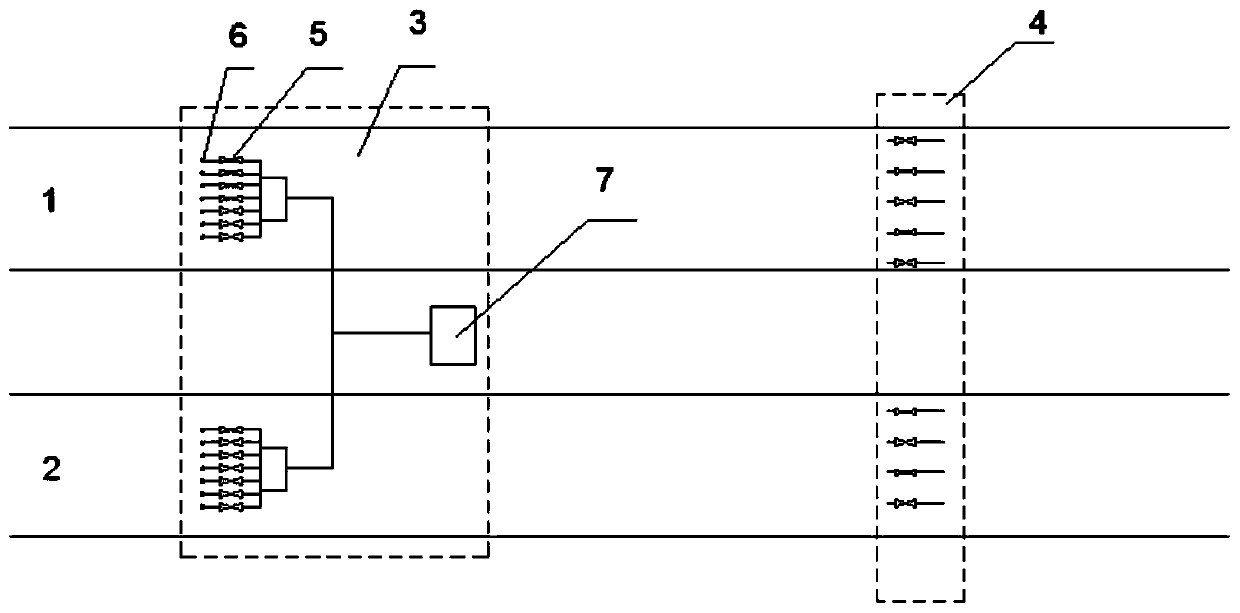

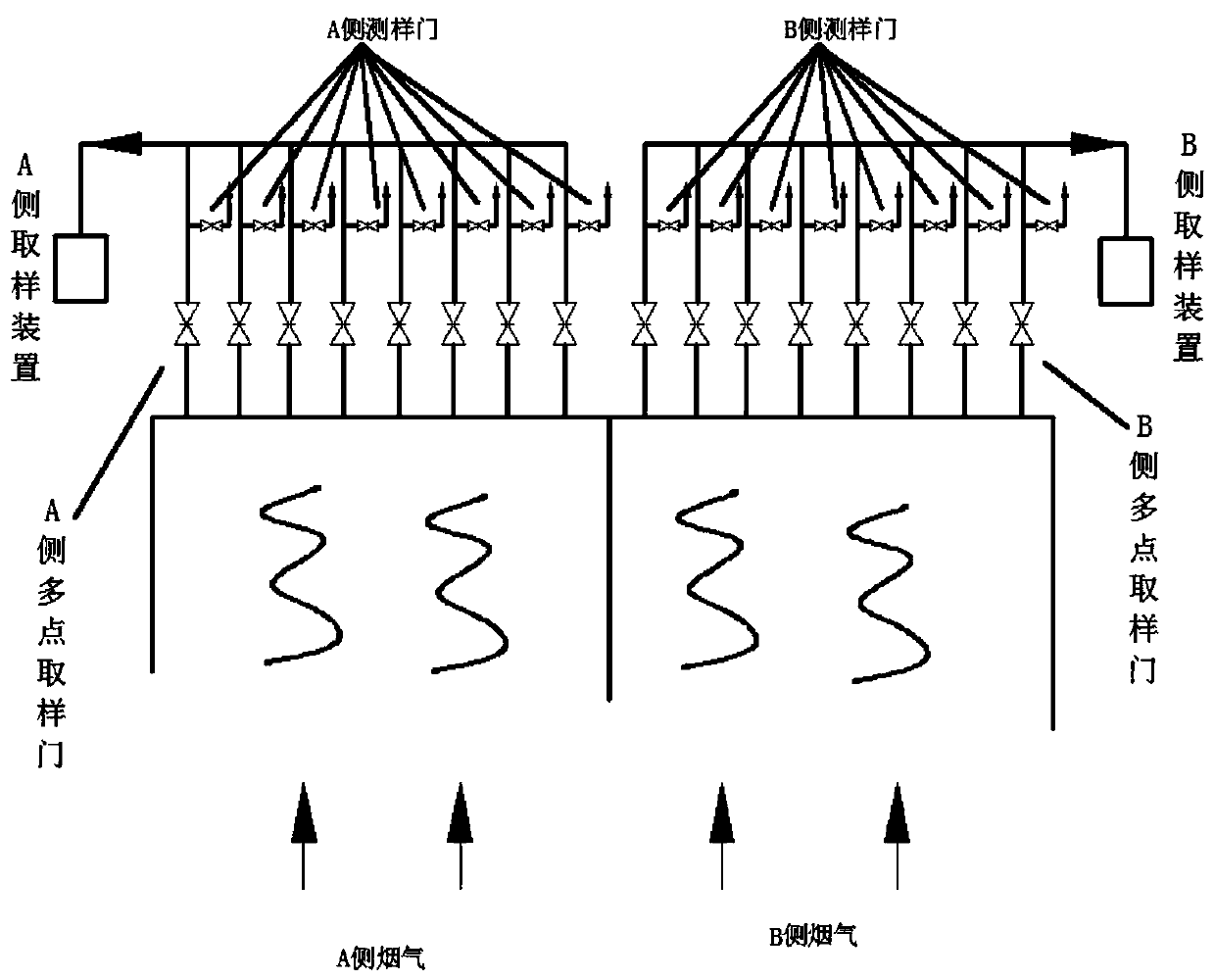

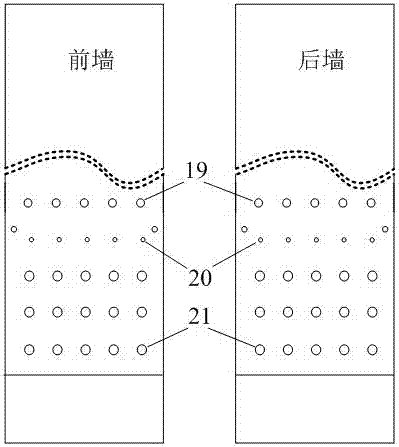

Optimizing system and method for denitration-system ammonia injection grating

InactiveCN109821417AEvenly distributedImprove mixing uniformityDispersed particle separationPtru catalystEnvironmental engineering

The invention provides an optimizing system and method for a denitration-system ammonia injection grating. The optimizing system comprises an A-side smoke outlet, a B-side smoke outlet, a sampling device and an ammonia injection control valve group; the ammonia injection control valve group is arranged in the A-side smoke outlet and the B-side smoke outlet, the sampling device is installed in theA-side smoke outlet and the B-side smoke outlet and located on the outer side of the ammonia injection control valve group, and comprises multiple sampling doors, and the sampling doors are evenly arranged in the A-side smoke outlet and the B-side smoke outlet. According to the optimizing system and method for the denitration-system ammonia injection grating, the multiple sampling doors are evenlyarranged at multiple sampling door outlets from the A side and the B side of a denitration outlet; through the adjusted denitration-reactor ammonia injection grating (AIG), the mixing uniformity of ammonia and smoke is improved, the using rate of a catalyst is increased, and the unit ammonia injection amount is decreased. By optimizing and adjusting the ammonia injection grating (AIG), outlets NOx are more evenly distributed, and denitration efficiency is better guaranteed; meanwhile, the ammonia consumption amount is decreased, the running cost is reduced, and the forming risk of ammonium bisulfate (ABS) is also reduced.

Owner:DATANG GUIZHOU FAER POWER GENERATION

Slag sensible heat recycling system for air-cooling dry slag machine

ActiveCN107741021AAvoid influenceImprove efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

Full-load selective catalytic reduction (SCR) denitration system of coal-fired boiler

PendingCN110141961ARaise the temperature levelGuaranteed uptimeGas treatmentLighting and heating apparatusAir preheaterEngineering

The invention relates to a full-load selective catalytic reduction (SCR) denitration system of a coal-fired boiler. The system comprises a denitration reactor and an air preheater; the air preheater comprises a flue gas channel and an air channel; a flue outlet of the denitration reactor is connected with an electrostatic dust removal device through the flue gas channel of the air preheater; the input end of the air channel of the air preheater is connected with an air blower; the output end of the air channel is connected with a secondary air box; the system further comprises an air heater; the input end of the air heater is connected with an air suction port of a pressure cylinder close to a steam turbine of a generator set and is connected with the output end of the air channel of the air preheater; and the output end of the air heater is connected with a flue inlet of the denitration reactor. Compared with the prior art, the system has the advantages that full-load full-period stable operation of the coal-fired boiler can be ensured at lowest technology output, NOx emission in flue gas meets the emission requirements set by the country, and full-load denitration operation in the true sense after the grid connection can be realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Sound wave temperature measurement cooperative control cement kiln SNCR denitration system and working principle thereof

PendingCN112403250AAccurate controlReduce control difficultyGas treatmentDispersed particle separationCement kilnTemperature measurement

The invention relates to a sound wave temperature measurement cooperative control cement kiln SNCR denitration system and a working principle thereof. The sound wave temperature measurement cooperative control cement kiln SNCR denitration system comprises a first air pipe, a second air pipe and a computer, wherein the first air pipe and the second air pipe are both provided with a plurality of denitration devices, and each denitration device comprises an ammonia water pipeline, a compressed air pipeline and a temperature measurement combination; and the temperature measurement combination comprises a plurality of sound wave temperature measurement devices which are distributed at equal angles in the circumferential direction, air inlets of the sound wave temperature measurement devices areconnected to one end of the compressed air pipeline in parallel, and a denitration combination is further arranged above the temperature measurement combination. According to the invention, the plurality of denitration devices are arranged in the flue gas flowing direction, and the temperature measurement combinations in the plurality of denitration devices can accurately measure the temperaturedata of any position in the flue gas flowing process, so that the temperature data of flue gas can be measured in real time. In addition, the distance between the temperature measurement combination and the denitration combination in each denitration device is small, and the ammonia spraying amount can be accurately and quickly determined by a plurality of ammonia water spray guns in the denitration combination according to the temperature of the flue gas at the nearby position, so that the denitration control difficulty is reduced, and the control flexibility is greatly improved.

Owner:NANJING KISEN INT ENG

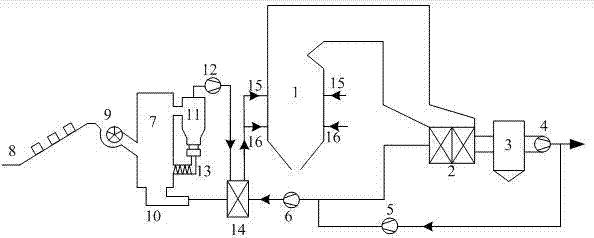

1000MW ultra-supercritical tower-type furnace advanced denitration running method

InactiveCN106895435AReduce conversionReduce concentrationFuel supply regulationDamper arrangementAir volumeCombustor

The invention relates to a 1000MW ultra-supercritical tower-type furnace advanced denitration running method. The method comprises the following steps that S1, 80%-95% of air amount needed by combustion is fed in from a spraying opening of a lower layer main combustion zone, and the air amount in the lower layer main combustor zone is controlled to be small than the air amount needed by complete combustion; and S2, 25%-35% of air amount needed by combustion is fed in from a spraying opening in the upper portion of a combustor, the air amount of a hearth upper layer after-combustion zone is controlled to be larger than the air amount needed by complete combustion. During blending combustion of coal types with different heating amounts, the method can guarantee reasonable lower layer main combustion zone anoxycausis and upper layer after-combustion zone oxygen-enriched combustion manners by automatically controlling secondary air baffles, conversion of volatile matter nitrogen to NOx is reduced, the concentration of the NOx at an SCR inlet is reduced to 160 mg / Nm<3> to 190 mg / Nm<3> from 230 mg / Nm<3> to 280 mg / Nm<3>, and the nitrogen spraying amount is reduced to 80 mg / Nm<3> to 100 mg / Nm<3> from 130 mg / Nm<3> to 180 mg / Nm<3>.

Owner:JIANBI POWER PLANT OF CHINA GUODIAN

Coal-fired boiler combustion operation method and combustion operation system

PendingCN107120639APrevent dust and slaggingAvoid corrosionCombustion using gaseous and pulverulent fuelGaseous fuel feeder/distributionLower gradeProcess engineering

The invention discloses a coal-fired boiler combustion operation method and a combustion operation system. According to the combustion operation method, biomass gasified gas is injected into a hearth to assist fire coal burning. Not only can the problems of the dust deposition, scorification and corrosion be avoided, but the emission concentration of SO2 and NOx can be reduced remarkably, the carbon content of flue dust is reduced, and the high grade use of low grade biomass energy is realized.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

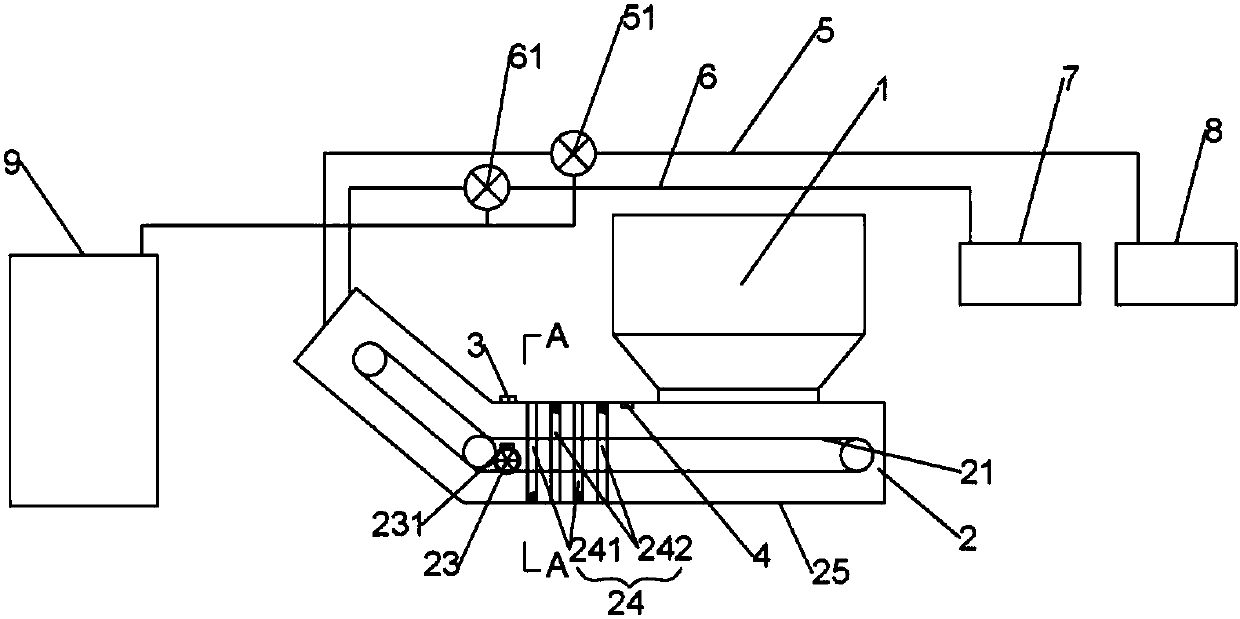

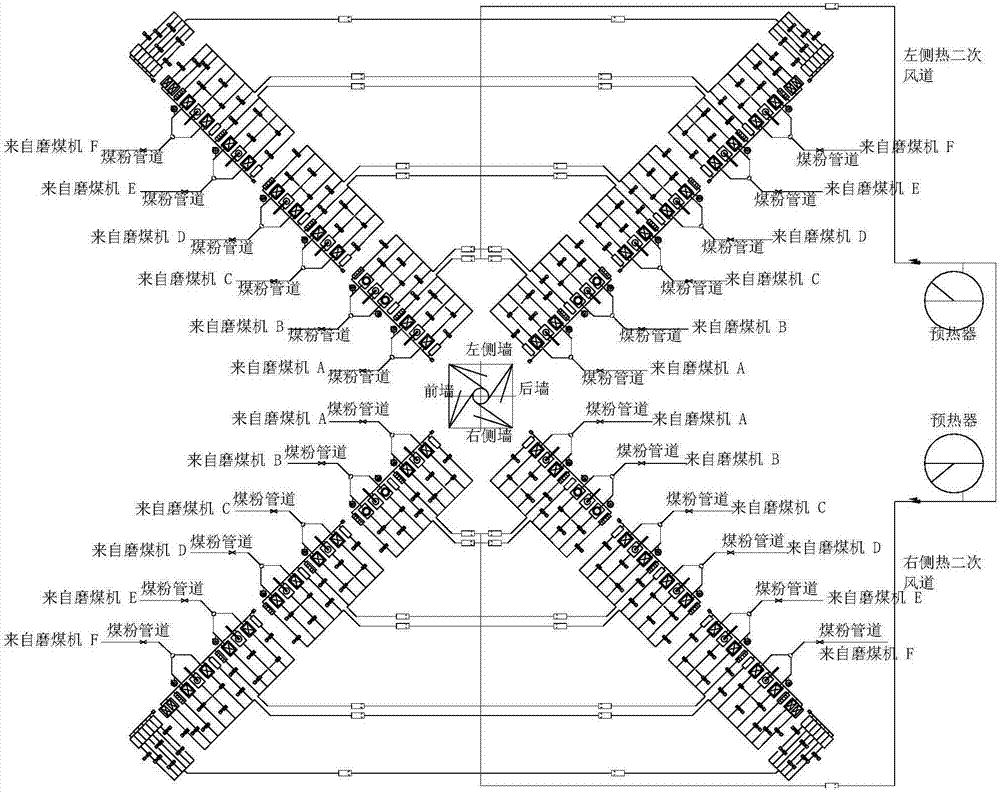

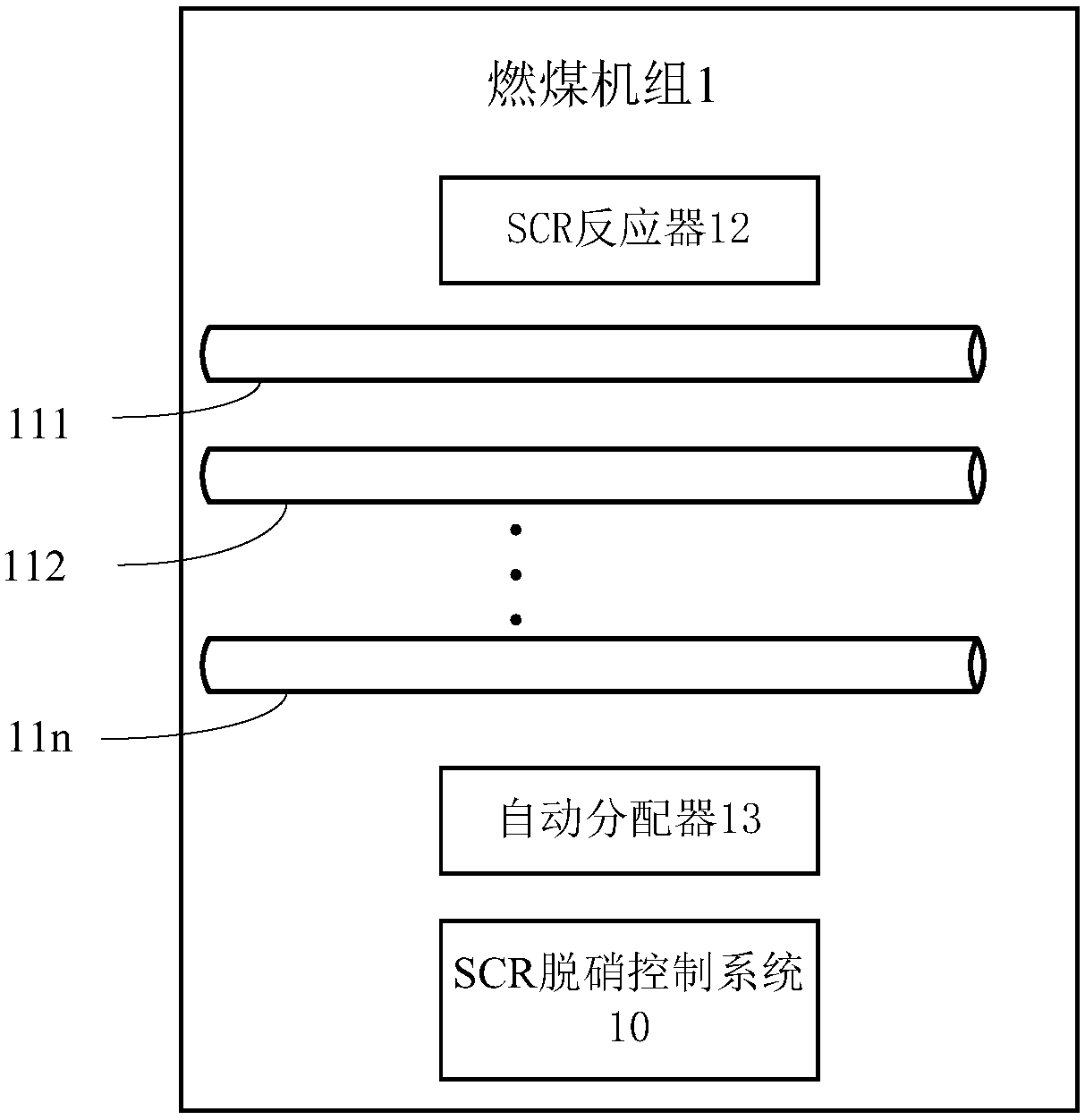

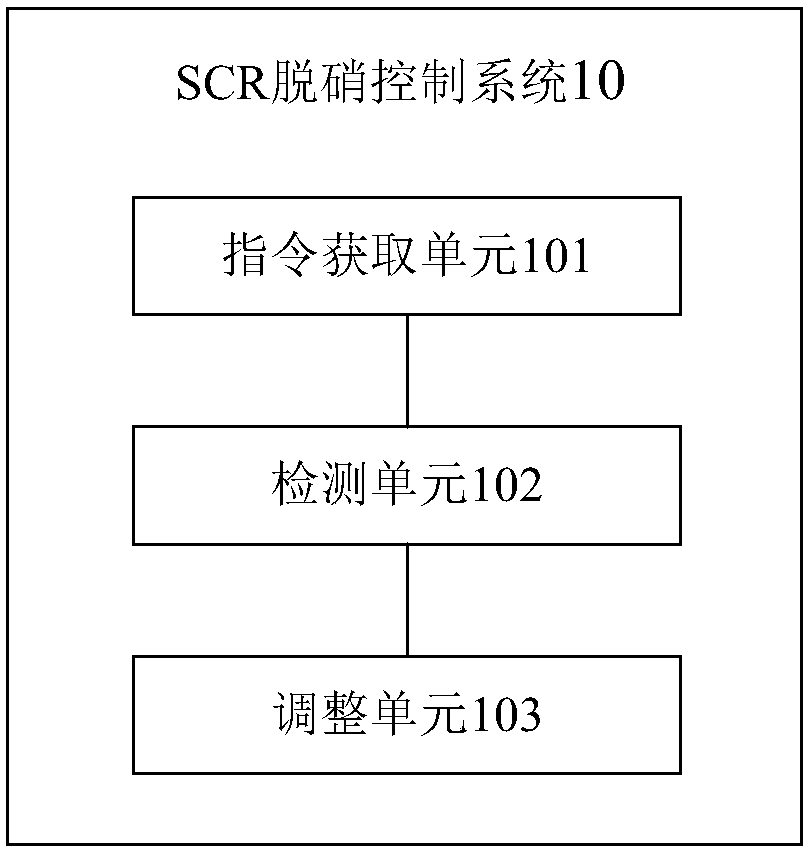

SCR denitration control system and method of coal-fired unit

ActiveCN108278630ASolve the technical problem of the surge of ammonia injectionReduce ammonia injectionSolid fuel pretreatmentCombustion regulationControl systemProcess engineering

The embodiment of the invention provides an SCR denitration control system of a coal-fired unit and belongs to the field of coal-fired unit denitration. The SCR denitration control system of the coal-fired unit comprises an instruction acquiring unit, a detecting unit and an adjusting unit. The instruction acquiring unit is used for acquiring a load reducing instruction, wherein the load reducinginstruction is used for indicating that the coal-fired unit is in the working condition of load reduction. The detecting unit is used for detecting the total coal amount related with the coal-fired unit according to the load reducing instruction. The adjusting unit is used for adjusting the work operation state of one or more of multiple coal mills according to the total coal amount, so that the coal amount of the coal mills provided with bi-register turbulent burners is larger than a preset threshold value. Therefore, the situation that a large amount of NOx is generated due to the fact thatthe coal feed of the bi-register turbulent burners is insufficient in the load reducing process is avoided, the ammonia spraying amount of an SCR reactor is reduced in the process of load reducing operation, and the denitration cost in the load reducing operation process of a boiler is reduced accordingly.

Owner:浙江浙能兰溪发电有限责任公司

Novel dry-method denitrification and denitration method of cement kiln

InactiveCN109569239AReduce ammonia injectionReduce NOx emissionsDispersed particle filtrationIncreasing energy efficiencyExhaust emissionMonitoring Plan

The invention discloses a novel dry-method denitrification and denitration method of a cement kiln. The method comprises the following steps of a, preparation before production: connecting water and electric pipelines through according to the production, arranging a workplace, arranging a production device of each link of the cement kiln for producing cement, staffing, preparing a raw material, according to a production technical requirement and a waste gas emission standard, seriously drawing up production organization design, and making a production monitoring plan; and b, additional mounting of double channels on a kiln tail burner: mounting the kiln tail burner with the double channels on a vertebral body of an existing novel dry-method preheater decomposing furnace for a cement plant,and arranging an ammonia water delivery pipeline on one channel of the kiln tail burner. The method has the beneficial effects that the invention, compared with the prior art, provides a dry-method production method of the cement kiln, through which an ammonia water spraying-into amount can be reduced by a wide margin and moreover the emission of NOx is reduced; and the method not only does not need the huge investment of SCR, but also has no the worry of pollutant interchange, and is also used for eliminating the existing problem of the transfer of an SNCR pollutant.

Owner:李世旭

Denitration system

PendingCN111992025ASolve prone to blockageSolve temperature problemsGas treatmentDispersed particle separationAir preheaterPtru catalyst

The invention discloses a denitration system. According to the denitration system, a first probe and an SNCR ammonia spraying device are arranged in a hearth, and a platen superheater, a high-temperature superheater, a low-temperature superheater and a second probe are sequentially arranged in a tail flue of a boiler in a flue gas flowing direction; a reactor and an air preheater are arranged in asecond vertical flue in the flue gas flowing direction, a third probe, a catalyst layer and a fourth probe are sequentially arranged in the reactor in the flue gas flowing direction, and the output end of an annunciator is connected with the input end of an ammonia spraying controller; the outlet of the ammonia spraying controller communicates with the inlet of an ammonia spraying grid; the inletof the ammonia spraying controller communicates with the heat absorption side outlet of a buffer tank; and the heat absorption side inlet of the buffer tank communicates with the outlet of a urea / liquid ammonia storage tank through a solution pump. The system can effectively solve the problems that denitration efficiency deviates from a design value, ammonia gas and flue gas are insufficiently mixed, the injection amount of the ammonia gas and the proportion of the flue gas cannot be controlled, a catalyst layer is prone to blockage, and the temperature of the flue gas, entering an SCR flue,of a reducing agent is low in the prior art.

Owner:XI AN JIAOTONG UNIV

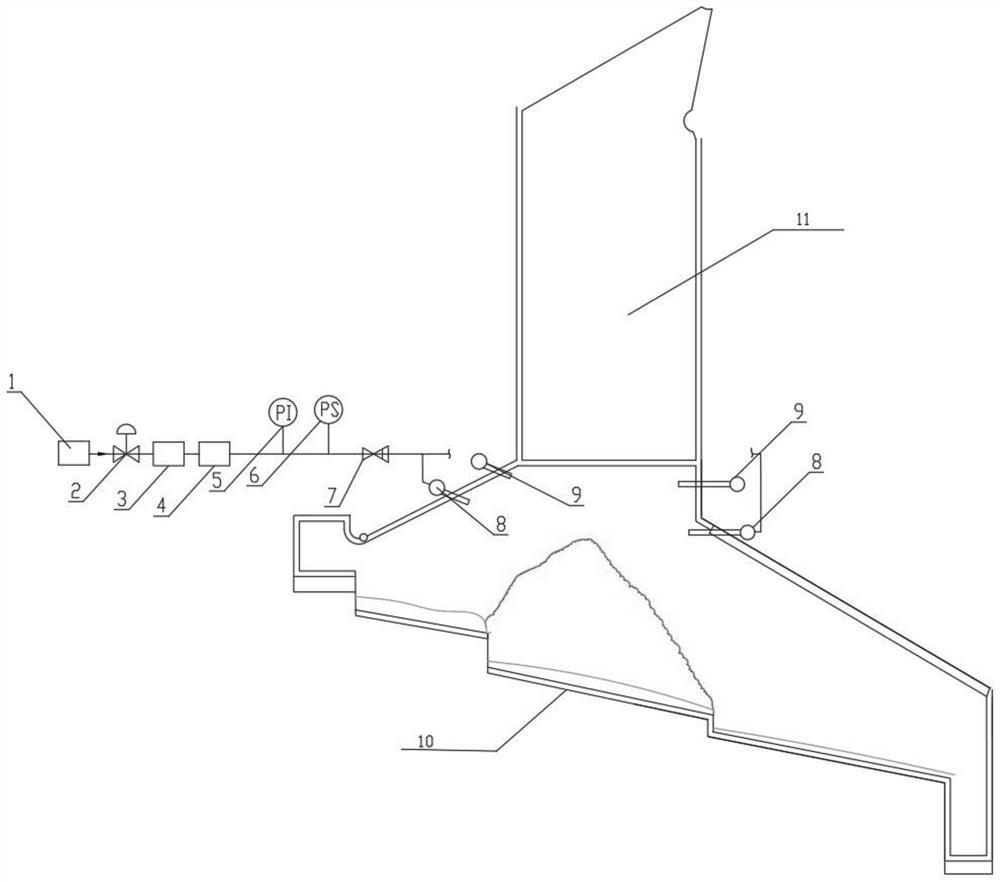

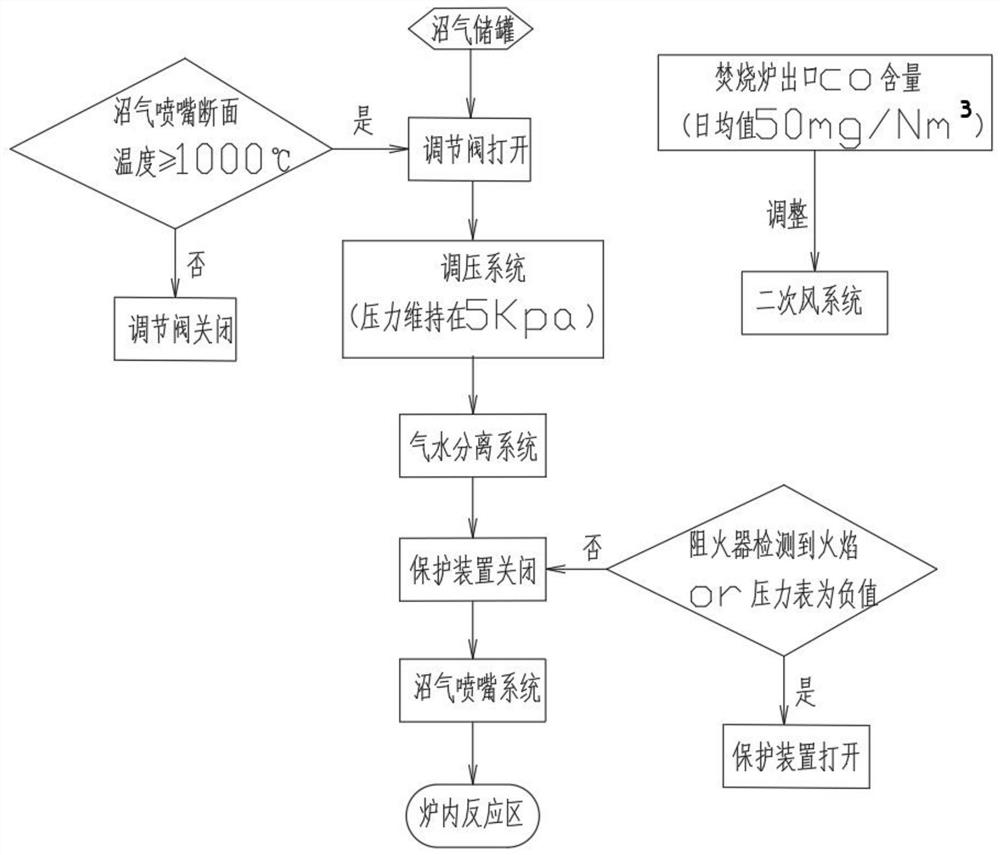

Reburning denitration biogas treatment system of garbage incineration grate furnace

PendingCN112944348AWell mixedImprove responseIncinerator apparatusNon-combustible gases/liquids supplyEngineeringTreatment system

The invention is suitable for the field of household garbage incineration, and relates to a reburning denitration biogas treatment system of a garbage incineration grate furnace. The reburning denitration biogas treatment system is composed of hearth biogas back-spraying nozzles, a secondary air nozzle, a biogas conveying device, a pneumatic control valve, a pressure switch, a flame retardant device, a grate and a flue; the biogas back-spraying nozzles are arranged in front and back arch areas, and the inclination angles of the nozzles are arranged according to a hearth structure, so that flue gas is fully mixed, and the flue gas retention time is prolonged; the secondary air nozzle is arranged at the upper part of the biogas back-spraying nozzles so as to supplement oxygen to enable the combustible gas to be completely combusted; and biogas is taken from a leachate anaerobic fermentation system and is conveyed into the furnace through the biogas conveying device. According to the reburning denitration biogas treatment system, the biogas can be treated by spraying the biogas into the high-temperature oxygen-deficient area of the hearth, and meanwhile, NOx is reduced into N2; the system has the functions of adjusting the amount of biogas entering the furnace and protecting the safety of the whole system through a biogas system protection device; and according to the reburning denitration biogas treatment system, combustible substances can be completely combusted by supplementing secondary air.

Owner:SHANGHAI SUS ENVIRONMENT

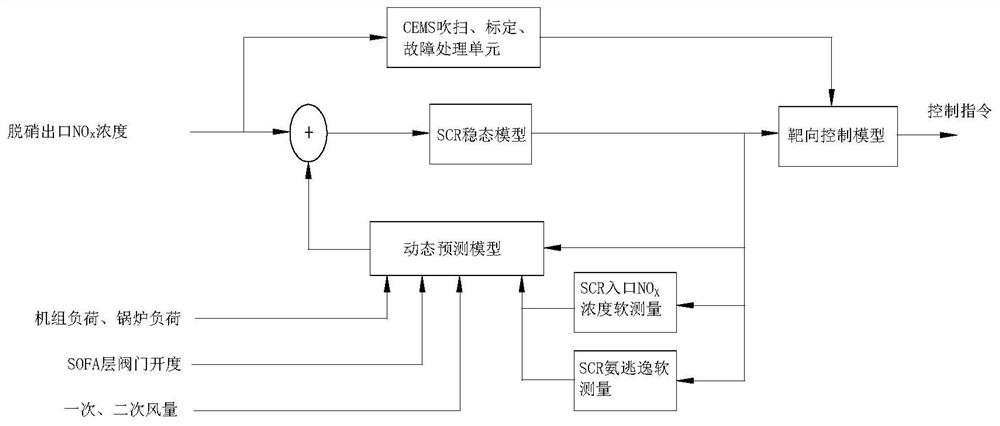

And driving SCR denitration ammonia spraying targeted control loop based on model

PendingCN111931358AImprove operating economyImprove the level of economic operationDesign optimisation/simulationSpecial data processing applicationsTarget controlEngineering

The invention relates to an SCR denitration ammonia spraying targeted control loop based on model driving. The system comprises an SCR steady-state model, a dynamic prediction model, a targeting control model, an SCR inlet NOx concentration soft measurement model and an SCR ammonia escape soft measurement model. Adding the NOx concentration at the outlet of the SCR denitration system to the outputvalue of the dynamic prediction model; wherein the signal is used as an input signal of the SCR steady-state model; the SCR steady-state model gives a reference instruction according to the directionand the size of an input signal and the deviation degree in a front period and a rear period so as to be adjusted by the targeting control model; and meanwhile, the reference instruction also servesas signal input values of the dynamic prediction model, the SCR inlet NOx concentration soft measurement model and the SCR ammonia escape soft measurement model, and signal outputs of the SCR inlet NOx concentration soft measurement model and the SCR ammonia escape soft measurement model are fed back to the dynamic prediction model. The ammonia spraying amount can be effectively reduced, and the operation economy of the unit is improved.

Owner:INNER MONGOLIA JINGNENG KANGBASHI THERMAL POWER CO LTD

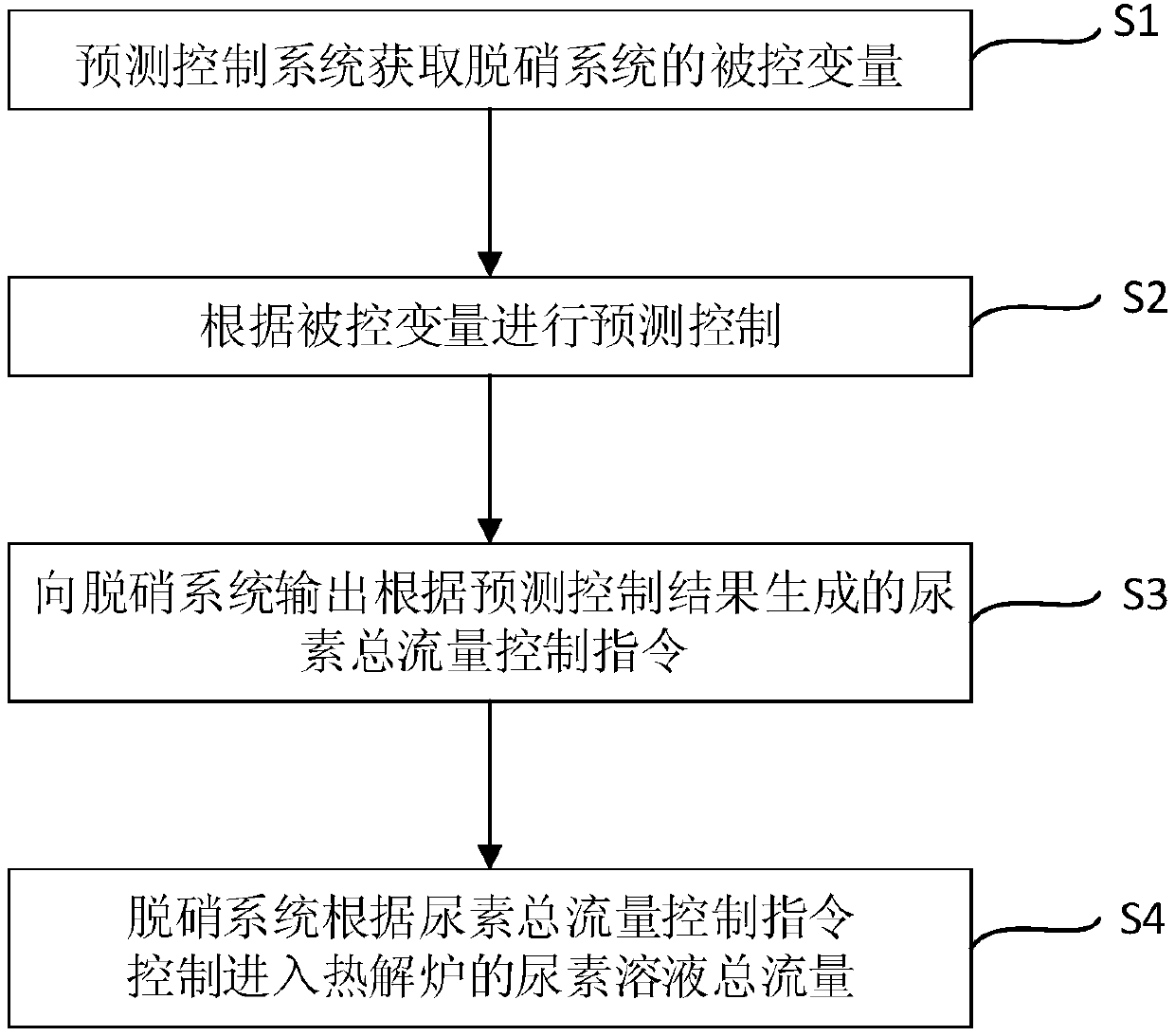

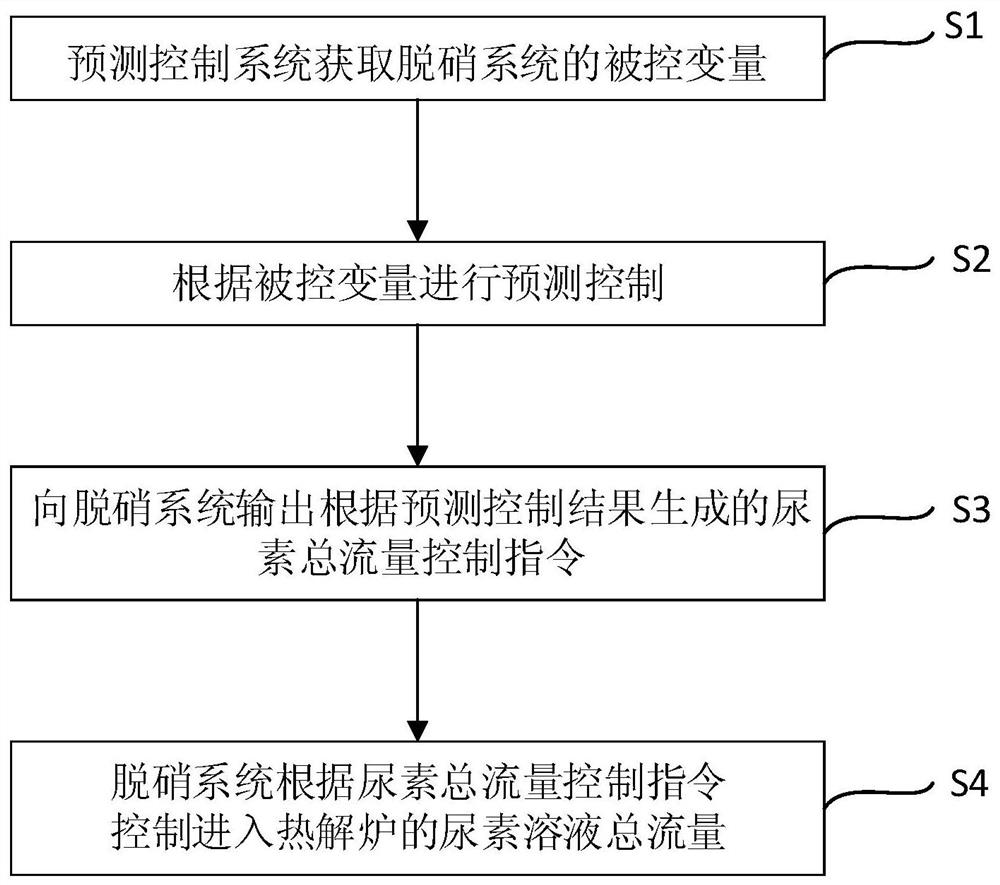

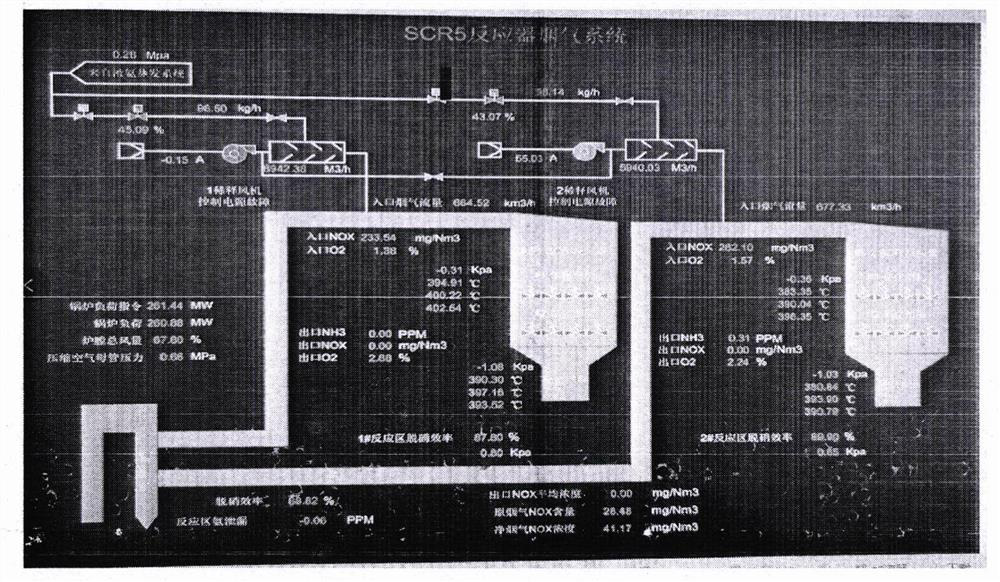

Urea pyrolysis denitrification control system

ActiveCN107812449ASetpoint increaseImprove stabilityGas treatmentDispersed particle separationControl systemAmmonia

The embodiment of the present invention discloses a urea pyrolysis denitrification control system. The urea pyrolysis denitration control system includes a denitration system and a predictive controlsystem; the predictive control system is used to obtain the controlled variable of the denitration system, performs predictive control according to the controlled variable, and outputs a urea total flow control command generated based on a predicted control result to the denitration system; the denitration system is used to control the total flow of a urea solution entering a pyrolysis furnace according to the urea total flow control command, so that absolute value of difference between the NOx concentration of the outlet of the denitration system and first preset NOx concentration is less than or equal to a first preset value. The total flow of the urea solution is taken as a control amount, and the total flow of the urea solution is given by the predictive control to realize the optimalcontrol of ammonia injection, the large lag of a control loop in the prior art can be overcome, the stability of the control system is improved, and the urea pyrolysis denitrification control system has the advantages of good stability, strong anti-interference ability and quick response, and the like.

Owner:YANTAI LONGYUAN POWER TECH +1

Supercritical tower-type boiler medium and low temperature area dusting and energy-saving device

PendingCN107152692AImprove heat transfer efficiencyAchieve removalSolid removalAir preheaterSound sources

The invention discloses a supercritical tower-type boiler medium and low temperature area dusting and energy-saving device which comprises a coal economizer, a denitration selective catalytic reduction (SCR) reactor and an air preheater in sequential connection, wherein a frequency-variable high-strength sound source is arranged on each of the coal economizer, the denitration selective catalytic reduction (SCR) reactor and the air preheater and is controlled to produce sound through a unified control unit. The supercritical tower-type boiler medium and low temperature area dusting and energy-saving device can ensure cleaning of a heated surface, ensures that the coal economizer, the air preheater and a heat exchanger reach the designed heat exchanging efficiency, ensures that the denitration catalyst activity of the denitration selective catalytic reduction (SCR) reactor, reduces added fuel consumption caused by reduction of heat exchanging efficiency of a boiler due to surface pollution of the heat exchanger, reduces the added ammonia spraying amount caused by activity reduction of the denitration catalyst, saves energy, and ensures emission of NOX to reach the standard.

Owner:国网能源哈密煤电有限公司 +1

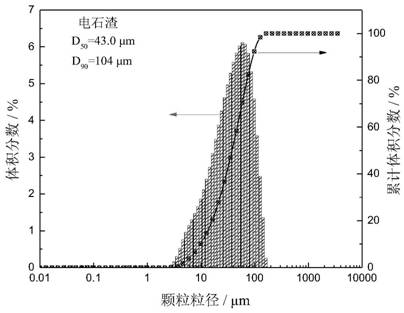

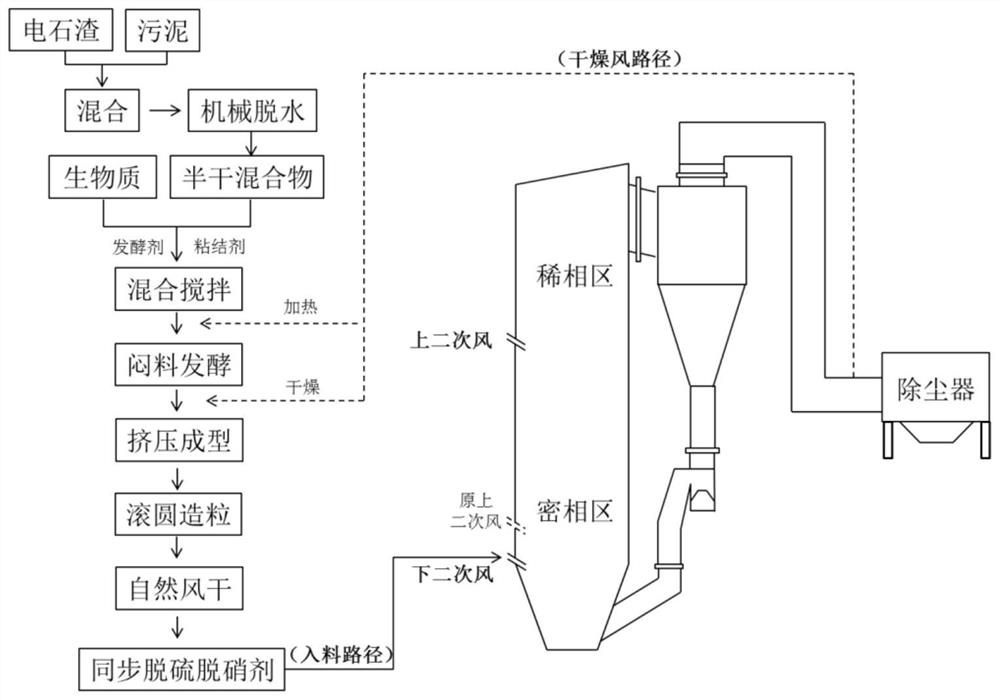

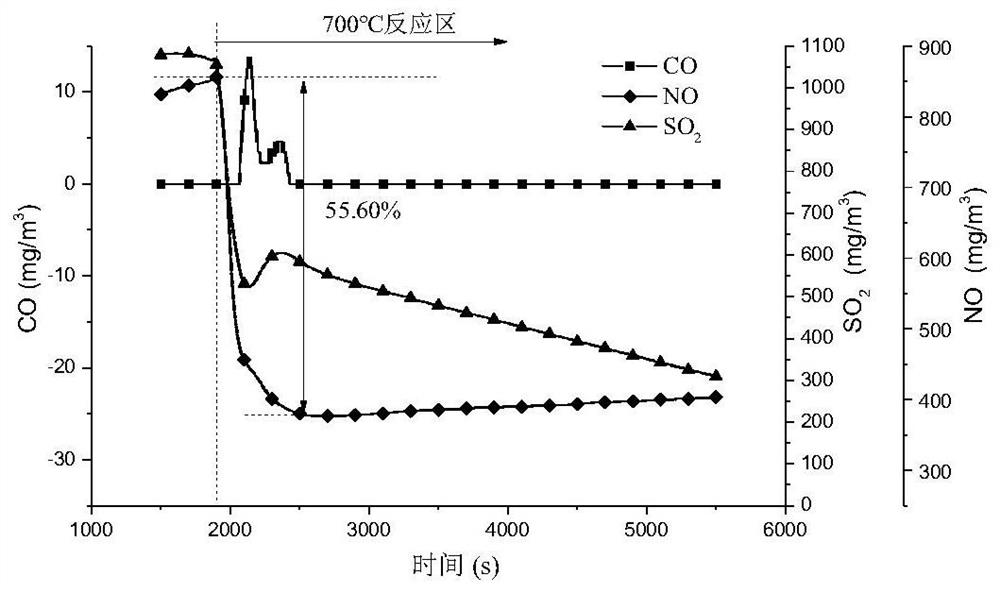

Solid waste-based in-furnace synchronous desulfurization and denitrification agent as well as preparation method and application thereof

ActiveCN113509833ASolve pollutionSolve the problem of moisture is still too highFluidized bed combustionGas treatmentSludgeSlag

The invention relates to the field of in-furnace synchronous desulfurization and denitrification during low-load operation of a circulating fluidized bed boiler, in particular to a solid waste-based in-furnace synchronous desulfurization and denitrification agent as well as a preparation method and application thereof. Biomass, sludge in a semi-dry state and carbide slag are mixed, then, under the action of a binder and a leavening agent, a formed mixture is extruded, cut, rounded and air-dried to obtain an in-furnace synchronous desulfurization and denitrification agent, mixed pellets with certain strength and suitable in-furnace particle size are formed, moisture difficult to remove in the carbide slag and the sludge is fully utilized for mixing and forming, and the problem that carbide slag is too small in particle size and easy to escape is solved. Rich pore structures are formed in the particles, two reaction paths of chemical and adsorption are provided, and a good NO removal effect is still achieved at the low temperature of 500-800 DEG C. According to the system and the method, the NO emission reduction pressure during normalized low-load operation peak regulation of the circulating fluidized bed boiler is relieved while various solid waste pollution and resource waste are solved.

Owner:SHANXI UNIV

A urea pyrolysis denitrification control system

ActiveCN107812449BSetpoint increaseImprove stabilityGas treatmentDispersed particle separationThermodynamicsControl system

The embodiment of the present invention discloses a urea pyrolysis and denitration control system. The urea pyrolysis and denitration control system includes: a denitration system and a predictive control system; predictive control, and output to the denitrification system the urea total flow control command generated according to the predictive control results; the denitrification system is used to control the total flow of urea solution entering the pyrolysis furnace according to the urea total flow control command, so that the denitrification system exports NOx The absolute value of the difference between the concentration and the first set NOx concentration is less than or equal to the first preset value. In the embodiment of the present invention, the total flow rate of the urea solution is used as the control amount, and the total flow rate of the urea solution is given by predictive control, so as to realize the optimal control of ammonia injection, overcome the problem of large hysteresis of the control loop in the prior art, and improve the stability of the control system. It has the advantages of good stability, strong anti-interference ability and fast response speed.

Owner:YANTAI LONGYUAN POWER TECH +1

Control method for solving thermal power plant coal-fired boiler Nox signal upside-down hanging

InactiveCN111871169AReduce uncertaintyImprove automation control levelDispersed particle separationAutomatic controlControl system

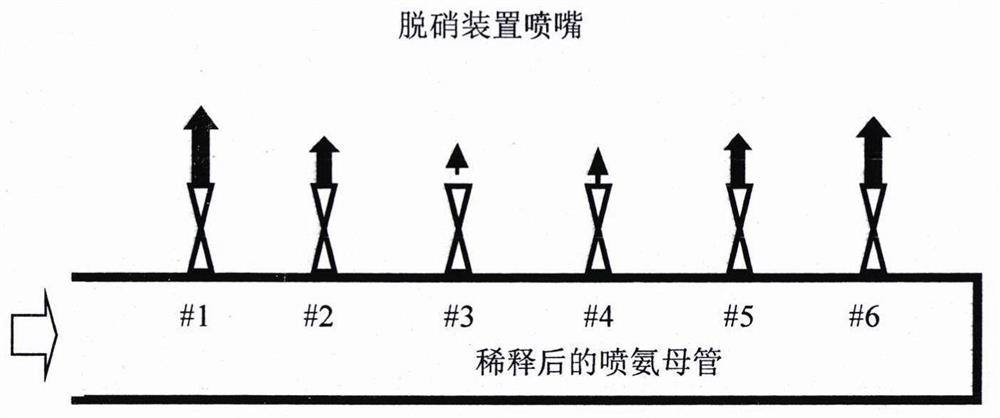

According to the problem that flue gas NOx signals of denitration control systems generally exist in boilers of some thermal power plants in China at present, a control method of the present inventionutilizes installation equipment and DCS control systems of existing boiler denitration control systems according to the flowing characteristic of flue gas serving as fluid and the working principle of measurement and installation of thermal instrument sensors; under the condition that equipment and investment are not increased, related data of a DCS control system are comprehensively analyzed andreasonably distributed to adjust the ammonia spraying amount of each nozzle, so that the problem that a clean flue gas Nox signal of a coal-fired boiler of a thermal power plant is larger than a desulfurization inlet flue gas Nox signal, and the desulfurization inlet flue gas Nox signal is larger than an outlet Nox signal of a denitration device is solved. According to the invention, the automatic control level of the denitration system is improved, and the ammonia spraying amount at the outlet of the denitration device matched with the load is controlled as much as possible in different stages of the load, so that the purposes of energy conservation and environmental protection are achieved, and more solution benefits are created for enterprises.

Owner:高利斌

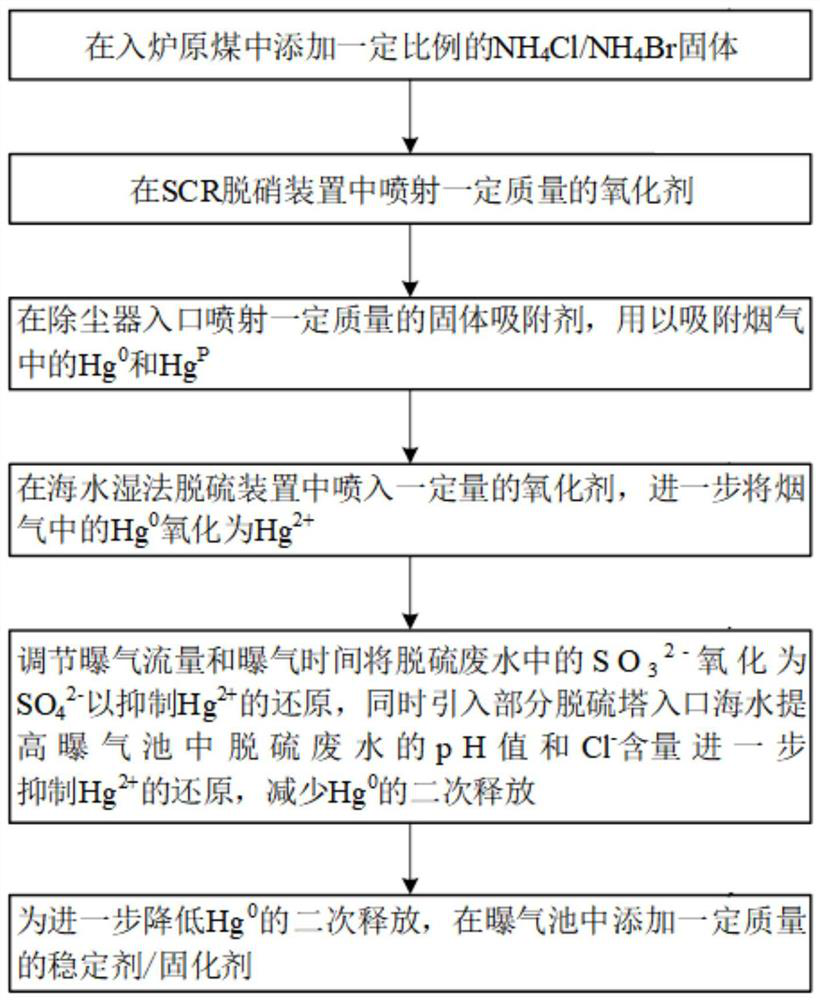

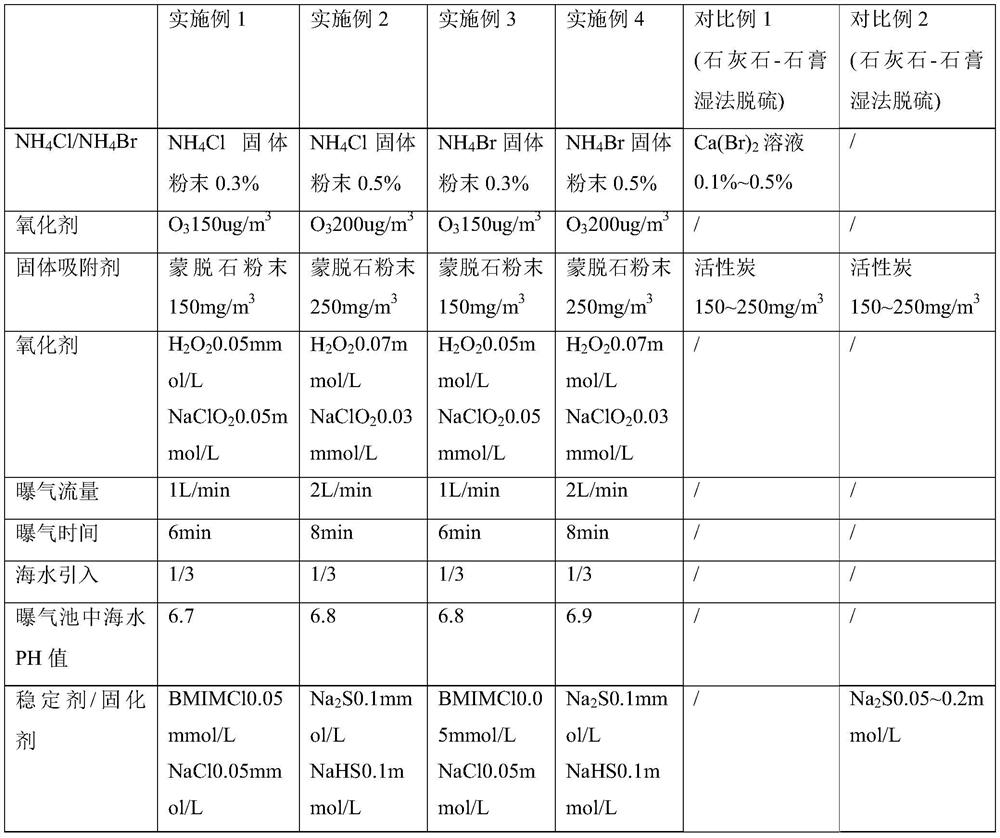

Method for inhibiting secondary release of mercury in seawater desulfurization process

InactiveCN113477055AImprove mercury removal efficiencyReduce secondary releaseGas treatmentWater contaminantsSeawaterEnvironmental chemistry

The invention relates to a method for inhibiting secondary release of mercury in a seawater desulfurization process. The method comprises multiple or all of the following steps: adding NH4Cl and / or NH4Br solids into raw coal fed into a furnace; spraying an oxidizing agent into the SCR denitration device; spraying a solid adsorbent into the dust removal device; and spraying the oxidizing agent into the seawater wet desulphurization device, and adding a stabilizer and / or a curing agent into an aeration tank; and adjusting the pH value of the desulfurization wastewater in the aeration tank to 6-7. Mercury in the flue gas is promoted to be oxidized by adding a proper oxidant, and secondary release of mercury in the desulfurization wastewater is inhibited by adding a proper stabilizer / curing agent, so that the mercury removal efficiency of the system is improved, and the secondary release amount of Hg<0> is effectively reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +2

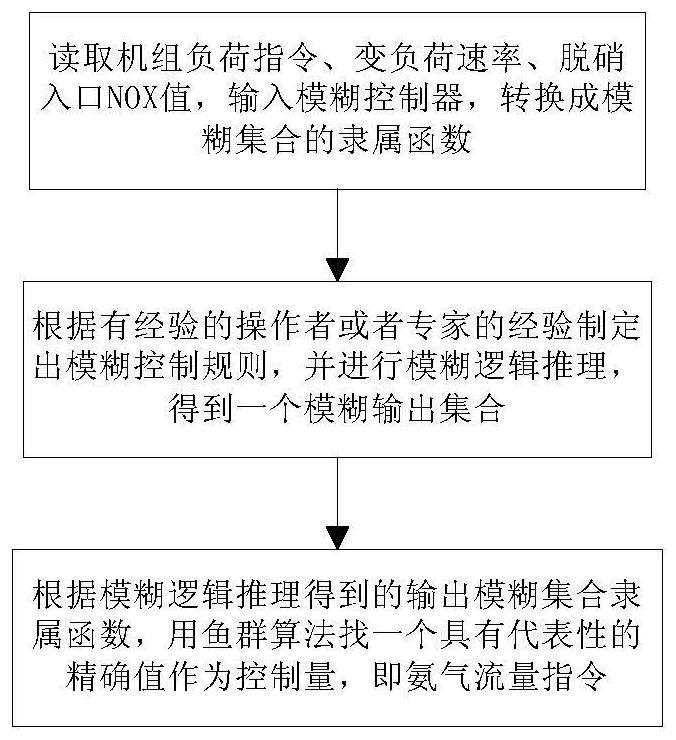

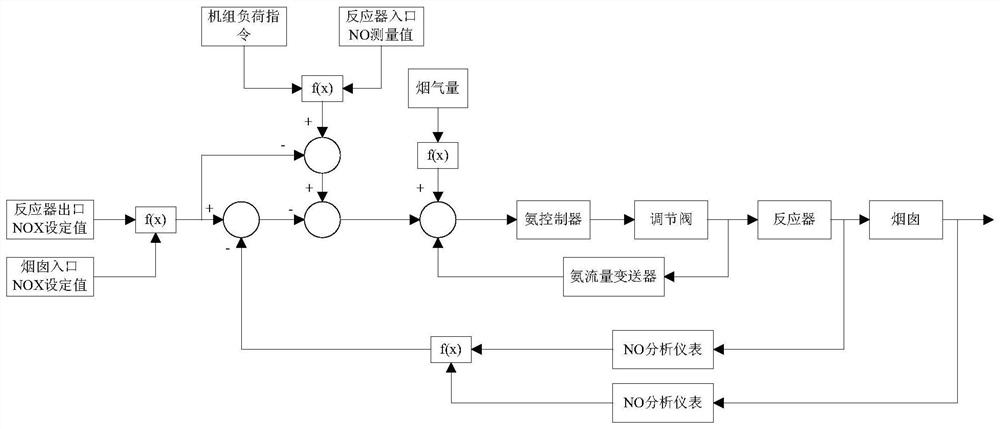

A precise control method for high-efficiency denitrification ammonia flow

ActiveCN109833773BGuaranteed uptimeHigh operating costsDispersed particle separationUnit loadConstant load

The invention discloses a precise control method for high-efficiency denitrification ammonia flow, which determines the operating state of the boiler according to the unit load command and variable load rate: when the unit is operating in a variable load state, the fuzzy control system is invoked; when the unit is operating in a constant load state, Call for an improved cascade control system. The invention introduces the chimney analysis instrument data into the control system to ensure that the assessment of environmental protection and denitration is up to standard, and introduces a fuzzy control method and a data preprocessing mechanism to solve the problem of large lag in the current control system and the problem of low system control accuracy when CEMS data has bad points. Thereby, the control quality of the denitration control system is improved, and it is suitable for high-efficiency denitration. The invention can effectively solve the problem of large lag in the SCR denitrification process, the problem of low system control accuracy when CEMS data has bad points, and the difficulty in debugging the advanced denitrification control system, low reliability, and the need for real-time calculation and update of parameters. Problems suitable for engineering applications.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com