Control method for solving thermal power plant coal-fired boiler Nox signal upside-down hanging

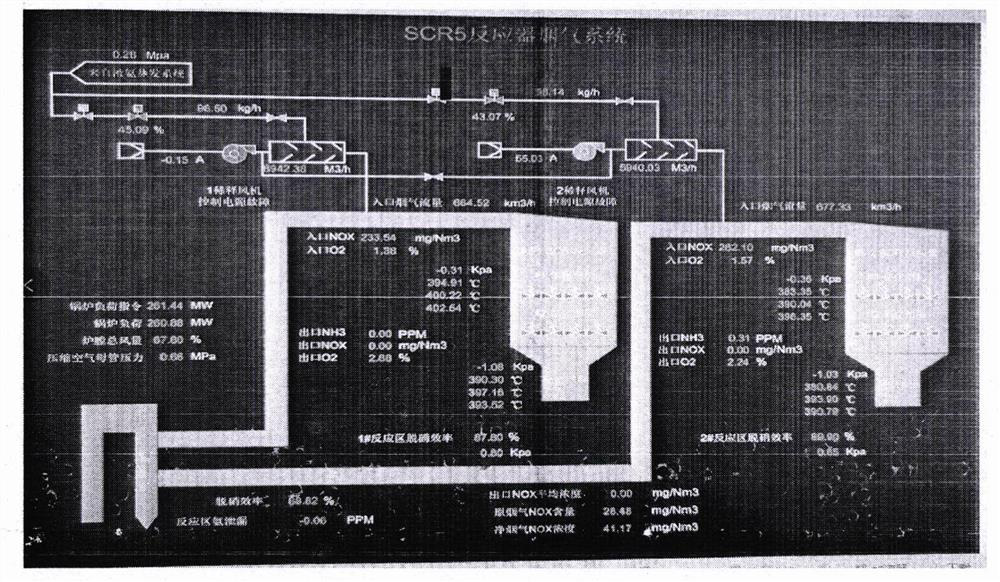

A technology for coal-fired boilers and control methods, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of NOx signal inversion, NOx emission exceeding the standard, and boiler denitrification system NOx measurement signal inversion, so as to reduce production. Operating cost, reducing the amount of ammonia injection, and improving the effect of automatic control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

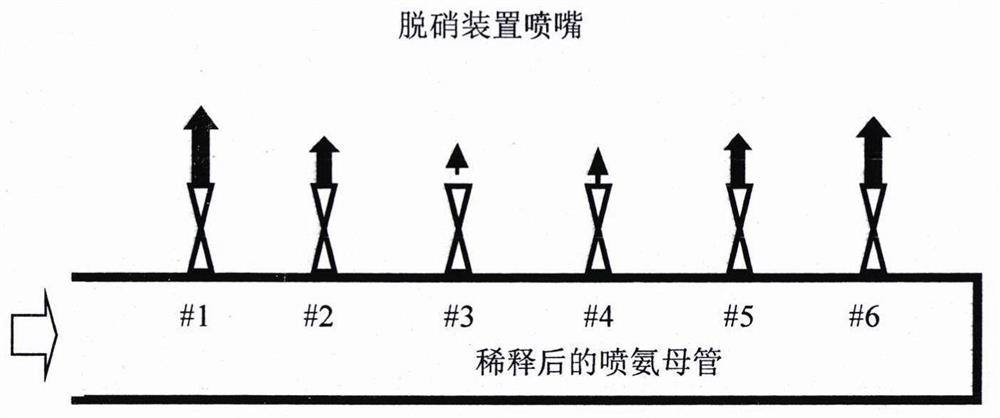

[0019] The specific implementation method of the patented technology of the present invention is as follows, under the condition that the load of the unit is constant and the amount of ammonia injection is constant, taking the central part as an example:

[0020] 1. First, fully open the 6 manual doors that control the amount of ammonia injection.

[0021] 2. Close the #3 and #4 manual doors in the middle by about 20% from the fully open state, and then decide whether to change the opening of these two valves according to the signal change of the denitrification outlet.

[0022] 3. Close the manual doors #2 and #5 by about 10% from the fully open state, and then decide whether to change the opening of these two valves according to the signal changes of the denitrification outlet, desulfurization inlet and clean flue gas.

[0023] 4. Close the #1 and #6 manual doors by about 5% from the fully open state, and then decide whether to change the opening of these two valves accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com