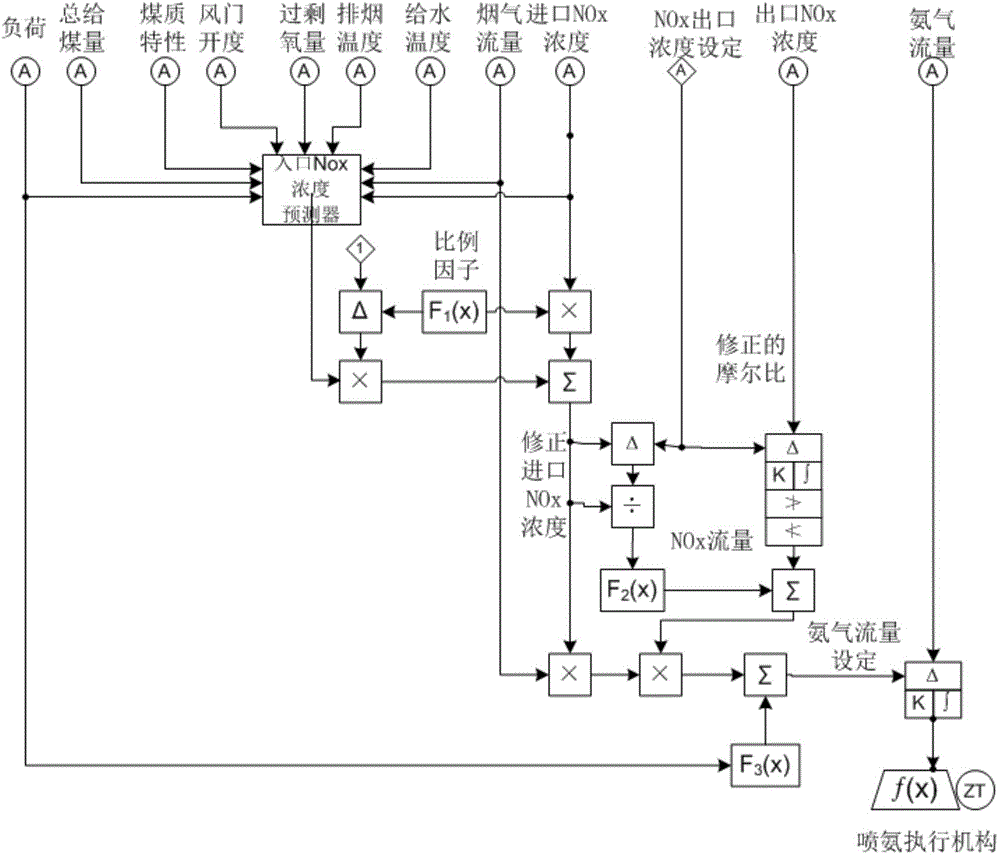

Control method for selective catalytic reduction flue gas denitrification system

A control method and technology of reduction method, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inconsistent ammonia injection amount and theoretical ammonia injection amount, deviation between measured value and actual value, etc., and achieve economical operation. cost, the effect of reducing the amount of ammonia injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

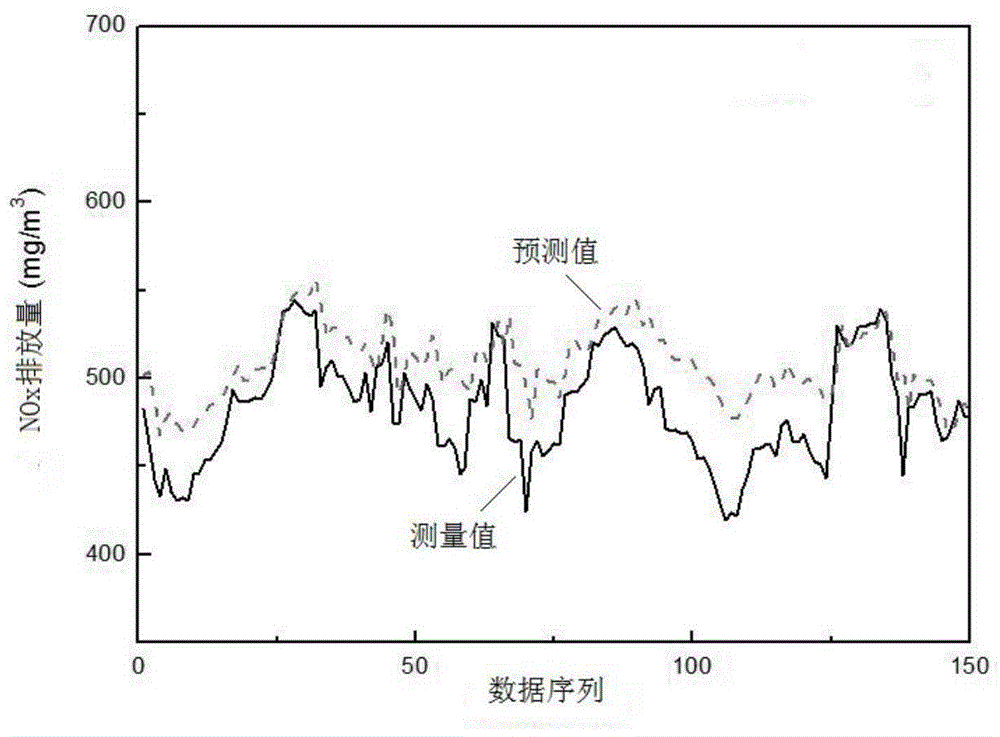

[0059] This embodiment is a coal-fired power plant with a 600MW unit. According to the above conditions, select data that can fully reflect the relationship between boiler load and other factors and NOx emissions, and use a new optimal regression model algorithm to perform simulation calculations. The result is as figure 2 The predicted values shown are close to the measured values, and the measured NOx emissions are close to the actual ones.

Embodiment 2

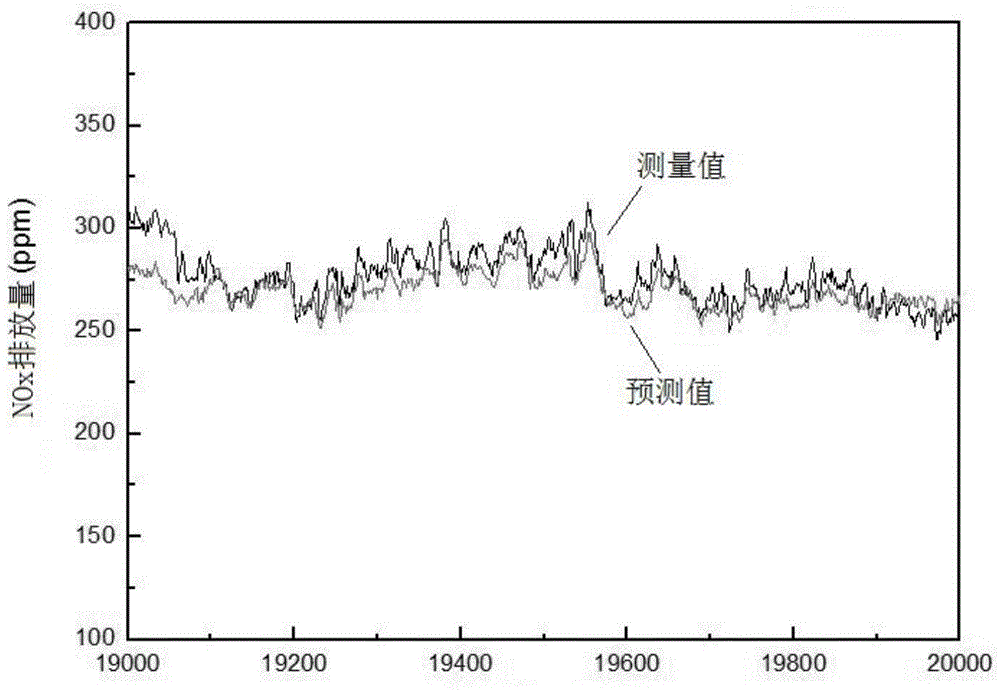

[0061] This embodiment is a coal-fired power plant with a 300MW unit. According to the content of this patent, data that can fully reflect the relationship between boiler load and other factors and NOx emissions are selected, and the optimal regression model algorithm is used to simulate and calculate the NOx concentration at the SCR inlet. The result is as image 3 As shown, the model predictions are close to the measured NOx emissions.

Embodiment 3

[0063] This embodiment shows the denitrification operation of a coal-fired power plant with a 600MW unit in variable operating conditions. The denitrification reactor of this unit has two parallel operating reactors, and the SCR operation is controlled by the method described in this patent. For comparison, one group closed the inlet NOx concentration predictor and kept the traditional PID control mode; the other group of denitration reactors put the inlet NOx concentration predictor for denitrification control. NH with or without predictive feedforward during variable operating conditions 3 The injection amount, NO emission comparison such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com