Supercritical tower-type boiler medium and low temperature area dusting and energy-saving device

A tower boiler and energy-saving device technology, which is applied in the removal of solid residue, combustion product treatment, combustion methods, etc., can solve the problems of fouling and clogging of the air preheater of the boiler economizer, and achieve simple structure and reduce coal consumption. The effect of reducing the amount of ammonia injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

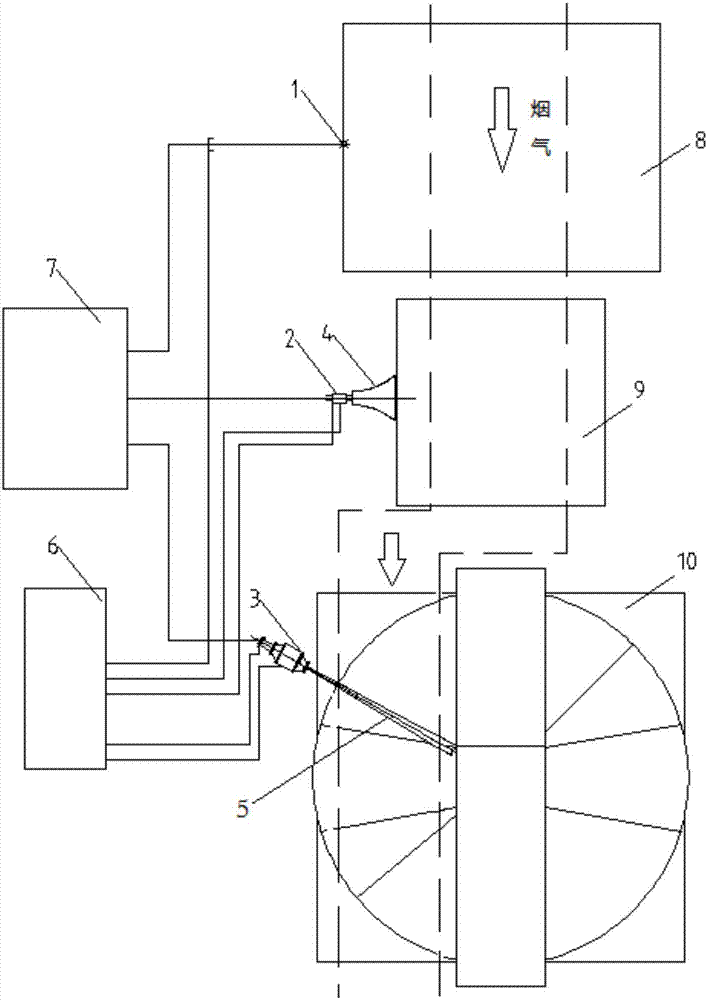

[0038] Such as figure 1 As shown, it is a schematic diagram of the ash removal and energy-saving device in the low-temperature area of the supercritical tower boiler provided in this embodiment, which includes an economizer 8, a denitrification selective catalytic reduction (SCR) reactor 9 and an air preheater connected in sequence 10. The first adjustable frequency high-intensity sound source 1 is set on the economizer 8, the second adjustable frequency high-intensity sound source 2 is set on the denitrification selective catalytic reduction (SCR) reactor 9, and the air preheater 10 is set There is a third frequency-adjustable high-intensity sound source 3, and the above-mentioned frequency-adjustable high-intensity sound sources are controlled by a unified control unit 6 to emit sound. The above adjustable frequency high-intensity sound sources are powered by a unified sound source power system 7, and the sound source power is gas with a certain pressure. The first freque...

Embodiment 2

[0042] The following is an example of installing a frequency-adjustable high-intensity sound source in a 600MW tower furnace in a power plant. The specific implementation method is as follows:

[0043] In the low-temperature area of the tower furnace: the economizer, denitrification selective catalytic reduction (SCR) reactor and air preheater are installed with frequency-adjustable high-intensity sound sources.

[0044] Among them, a total of 20 movable adjustable frequency high-intensity sound sources and corresponding platform escalators are installed symmetrically on both sides of the economizer area. During normal operation, the movable adjustable frequency high-intensity sound sources provide sound waves with a frequency of 20-600Hz, and pass The transmission mechanism enters and exits the economizer and performs efficient soot blowing to ensure the heat exchange efficiency of the economizer and reduce the coal consumption of the unit, thereby reducing the dust content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com