Control method and system for SCR denitration system of all-working-condition power station

A control method and technology of all working conditions, applied in separation methods, chemical instruments and methods, genetic laws, etc., can solve problems such as affecting the safe operation of units, ammonia escape, and difficulty in obtaining control effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

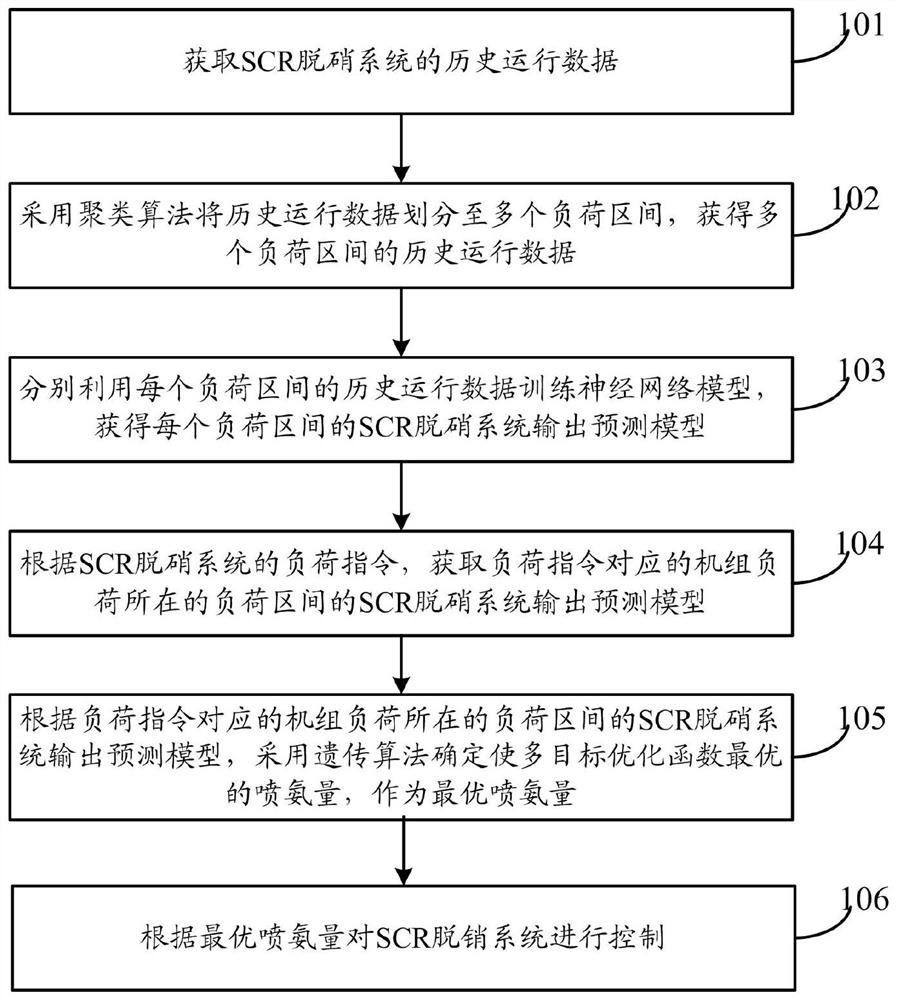

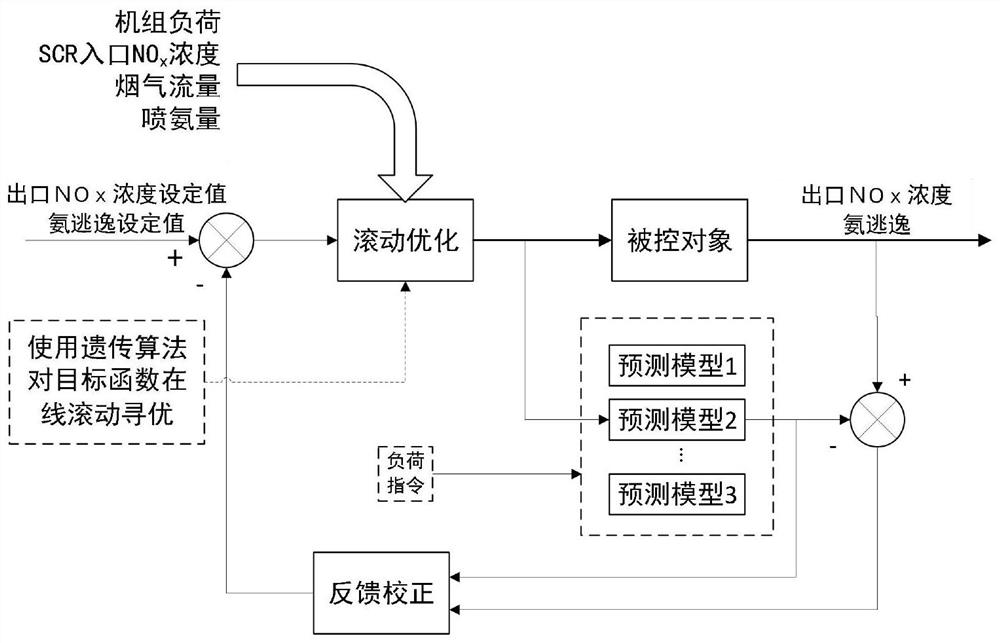

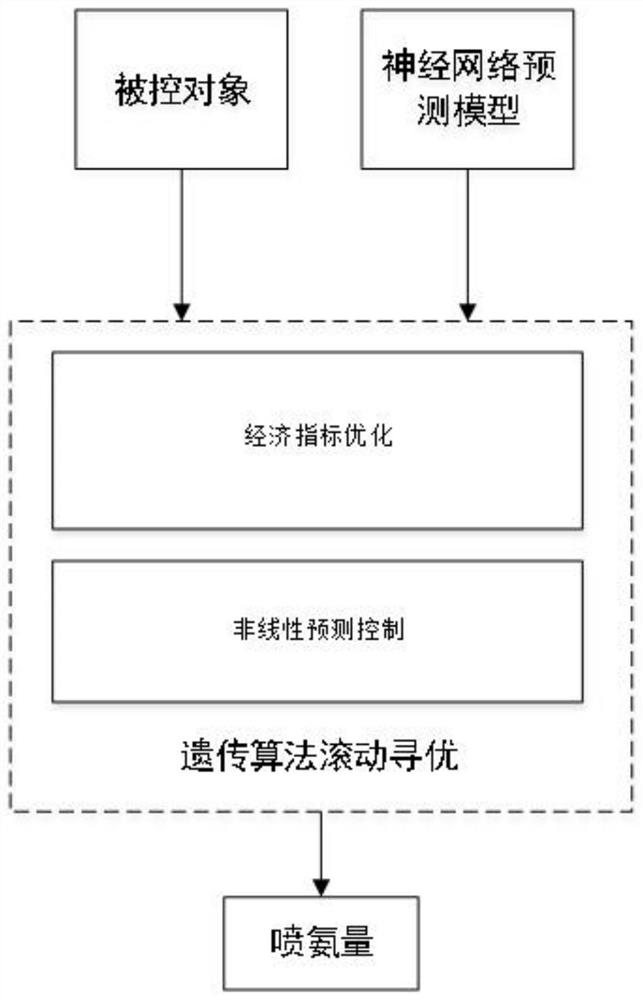

[0067]The purpose of the present invention is to provide a control method and system for the SCR denitrification system of a full-condition power station, so as to realize the optimized control of the denitrification system, and realize the economic operation of the unit while ensuring the emission standard.

[0068]In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0069]It should be noted that the terms "including" and "having" in the embodiments of the present invention and the drawings and any variations thereof are intended to cover non-exclusive inclusions. For example, a process, method, system, product, or device that includes a series of steps or units is not limited to the listed steps or units, but optionally includes unlisted steps or units, or optionally also includes Other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com