A large-scale coal-fired power plant co 2 Capture system and feed-forward control method

A neural network inverse, coal-fired power station technology, applied in the field of CO2 capture system and feedforward control of large coal-fired power stations, can solve the problems of measurement noise controller interference, difficulty in obtaining control quality, large inertia and delay, etc. Ensure control quality and improve the effect of dynamic adjustment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

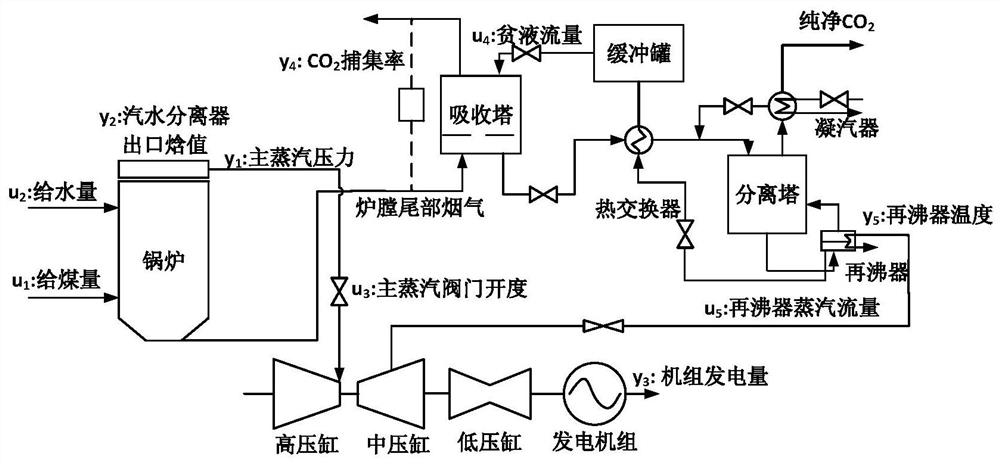

[0049] (1) Determine the CO of large coal-fired power plants 2 The capture system control loop and the corresponding control and controlled quantities are shown in Table 1:

[0050] Table 1

[0051]

[0052]

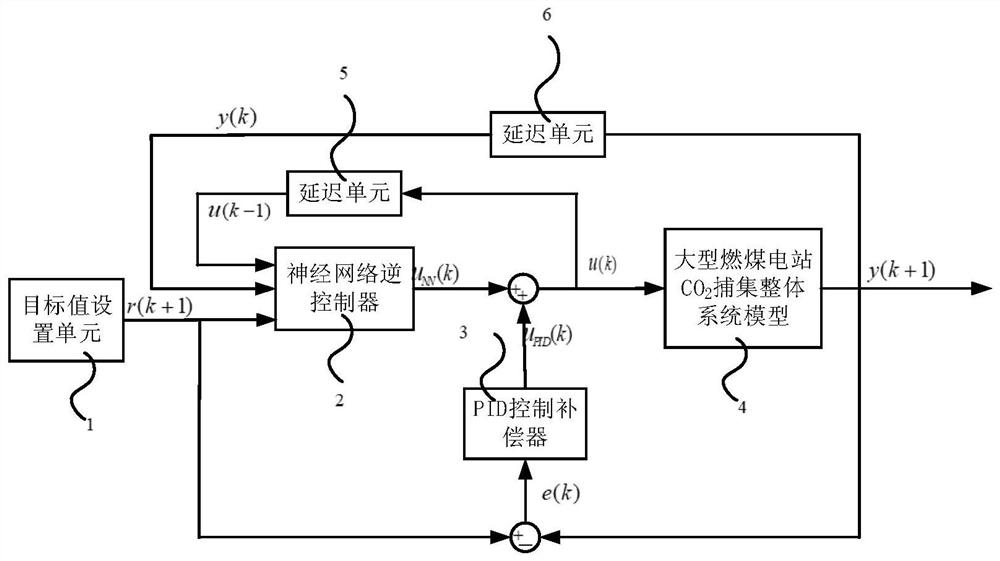

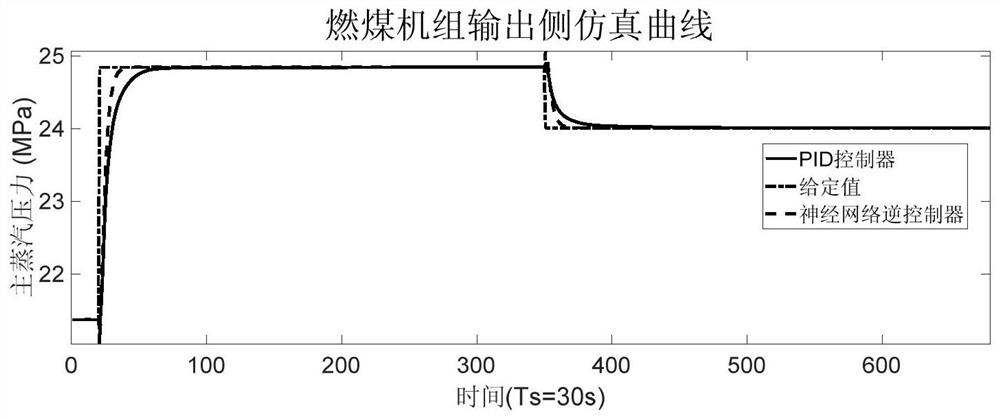

[0053] (2) Set sampling time T=30s, use controlled quantity data as neural network input, controller data as neural network data, use BP neural network toolbox to establish coal-fired power station CO 2 Capture system inverse model. The neural network contains two hidden layers, the number of neurons is 20 and 5 respectively, and the training function is traindm;

[0054] (3) According to the given value r(k+1) and the past input data u(k-1) and output data y(k), calculate the output u of the neural network inverse controller NN (k);

[0055] (4) Set the relevant parameters of the PID control compensator, as shown in formula (4):

[0056]

[0057] (5) Calculate the deviation. e(k)=r(k+1)-y(k+1);

[0058] (6) Calculate the PID control compensation output a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com