Connection structure and installation method of box-shaped steel column and unequal-height I-shaped steel beam

A technology of I-shaped steel and connection structure, which is applied in the direction of building structure and construction, can solve the problems of low construction efficiency, insufficient ductility of connection nodes, insufficient deformation capacity, and the need for on-site welding, etc., to achieve strong integrity and meet aesthetic and Functional requirements, effects of high ductility and deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

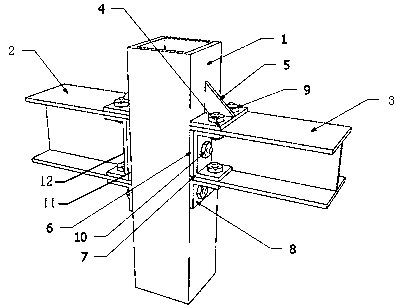

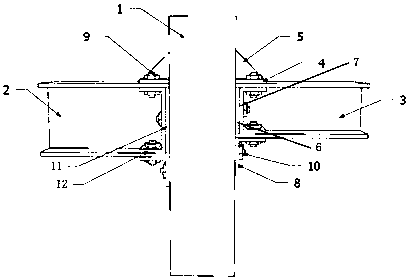

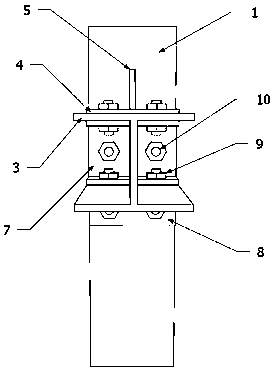

[0031] like Figures 1 to 5 The connection structure between box-shaped steel columns and unequal height I-shaped steel beams shown includes box-shaped steel columns 1, high-side I-shaped steel 2, low-side I-shaped steel 3, horizontal roof 4, triangular plate 5, the first The second beam end plate 6, the second U-shaped steel 7, the angle steel 8, the first bolt 9, the second bolt 10, the first beam end plate 11 and the first U-shaped steel 12, the first bolt 9 is a bilateral bolt, and the second bolt 10 It is a unilateral bolt, the triangular plate 5 is an isosceles right-angle triangular plate, the angle steel 8 is an equilateral angle steel, and both sides of the box-shaped steel column 1 are vertically welded with a horizontal top plate 4 and a triangular plate 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com