Method for inhibiting secondary release of mercury in seawater desulfurization process

A secondary release and seawater technology, applied in separation methods, chemical instruments and methods, water aeration, etc., to achieve the effect of reducing secondary release and improving mercury removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

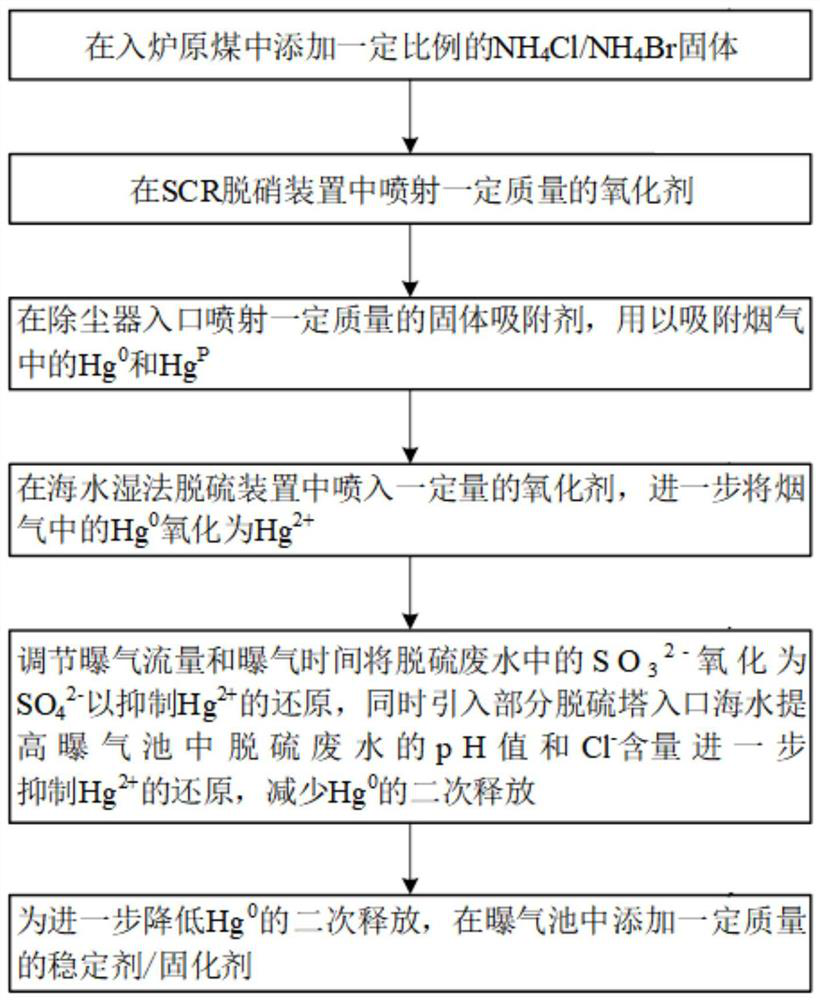

Method used

Image

Examples

Embodiment

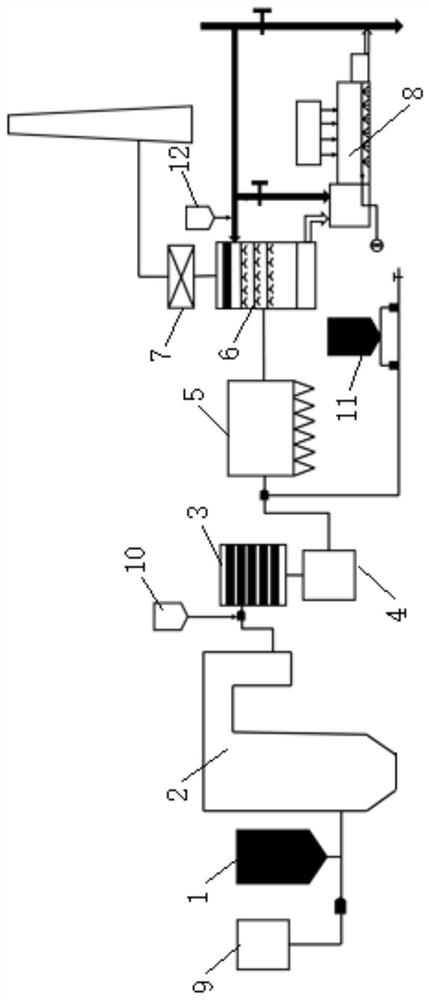

[0059] Taking a 300MW unit in a power plant as an example to elaborate, the unit layout figure 2 system shown. Under 300MW load, Hg in SCR inlet flue gas T The concentration is 55ug / m 3 , Hg 2+ The concentration is 33.8ug / m 3 , Hg 0 The concentration is 12.2ug / m 3 , Hg P The concentration is 9ug / m 3 ;SO 2 The concentration is 900 ppm, and the NOx concentration is 400 ppm.

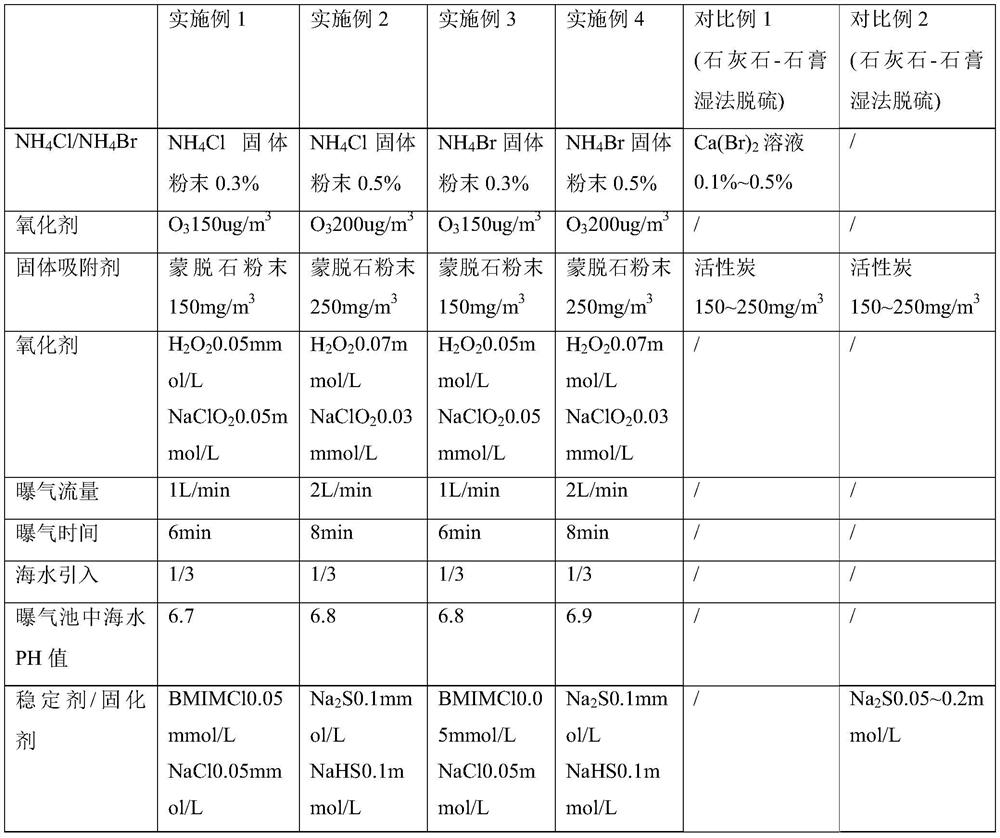

[0060] Table 1: Adding conditions:

[0061]

[0062] Table 2: Mercury removal effect:

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com