Optimizing system and method for denitration-system ammonia injection grating

A technology of ammonia injection grid and optimization method, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., to achieve the effects of improving mixing uniformity, increasing catalyst utilization rate, and reducing ammonia injection amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

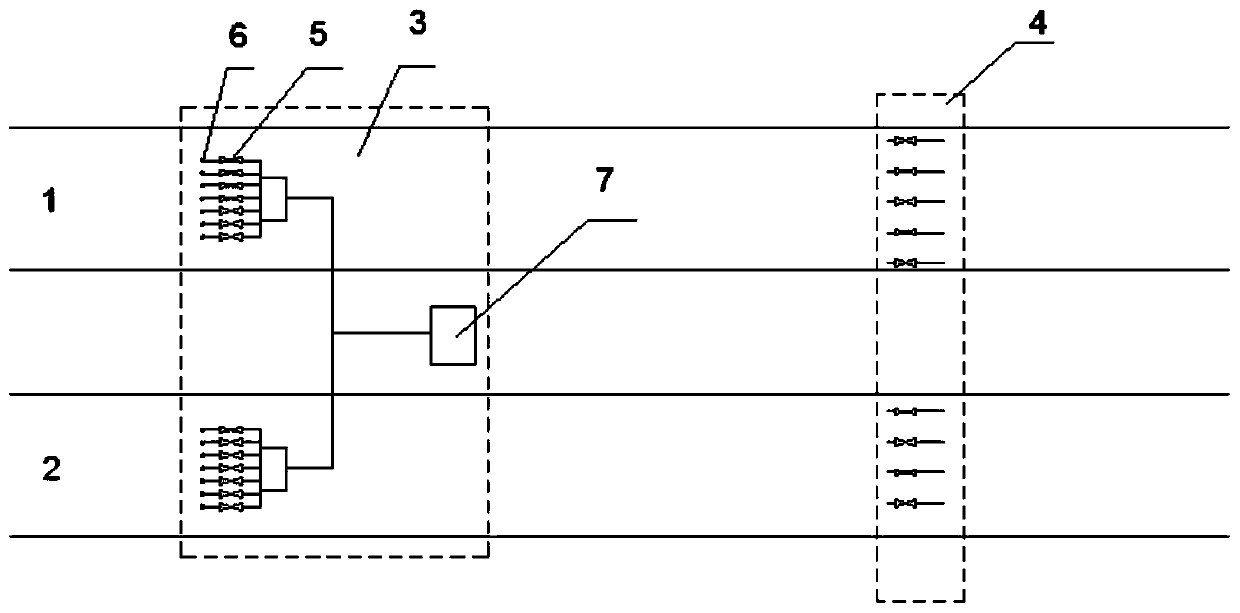

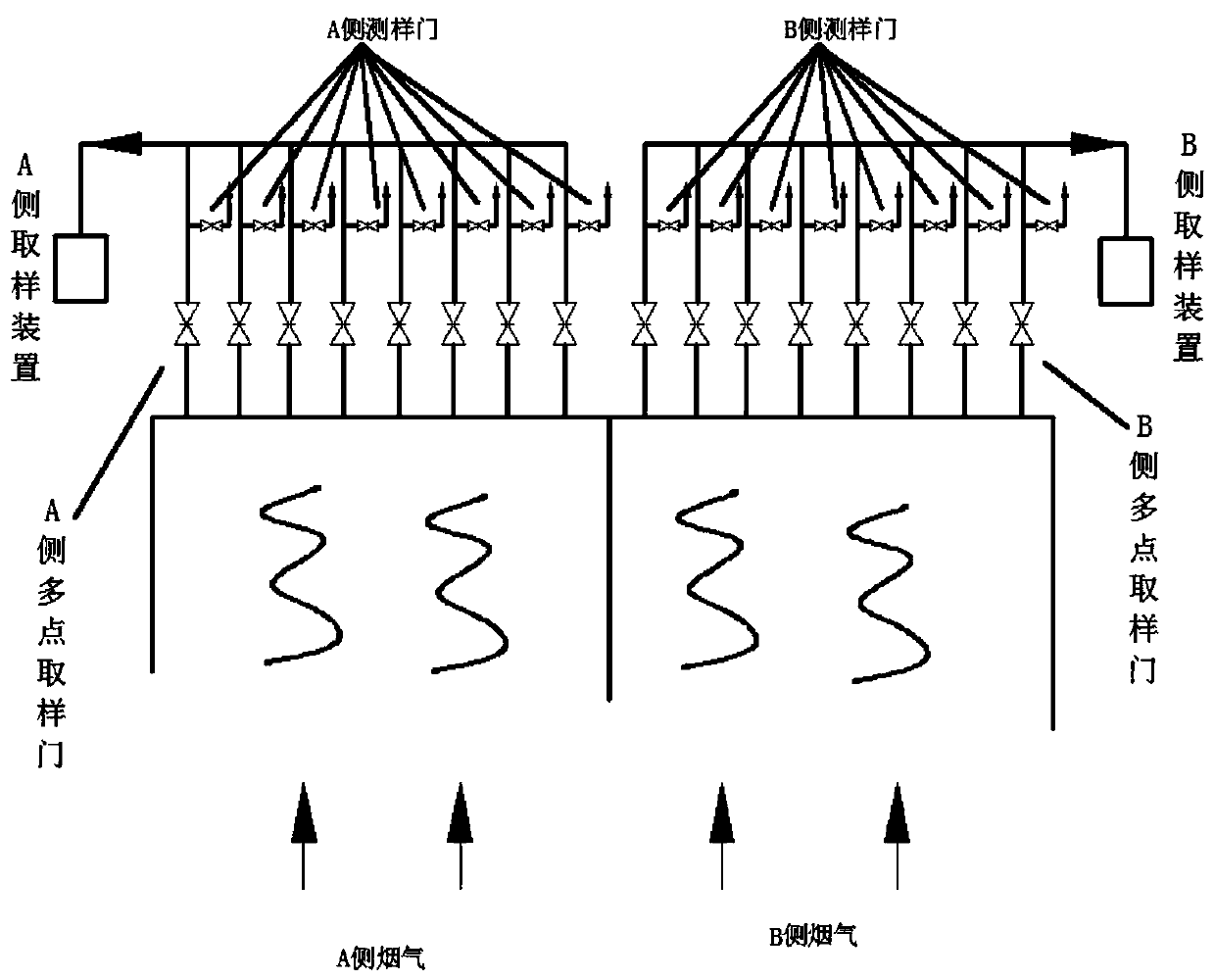

[0020] An ammonia injection grid optimization system for a denitrification system and an optimization method thereof, comprising an A-side flue gas outlet 1, a B-side flue gas outlet 2, a sampling device 3, and an ammonia injection control valve group 4; the A-side flue gas outlet 1 and Ammonia injection control valve group 4 is arranged in B-side flue gas outlet 2, and the sampling device 3 is installed in A-side flue gas outlet 1 and B-side flue gas outlet 2 and outside the ammonia injection control valve group 4. The above-mentioned sampling device 3 includes several sampling doors 6, and the sampling doors 6 are evenly arranged in the flue gas outlet 1 on the A side and the flue gas outlet 2 on the B side.

[0021] The sampling gate 6 is connected with the analyzer 7 after being connected in parallel through pipelines.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com