Denitration system

A denitrification and flue technology, applied in the field of denitrification system, can solve the problems of low temperature of reductant flue gas, blockage of catalyst layer, deviation of denitrification efficiency, etc., to solve the problem of low flue gas temperature, avoid inlet deflection angle, and strengthen gas disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

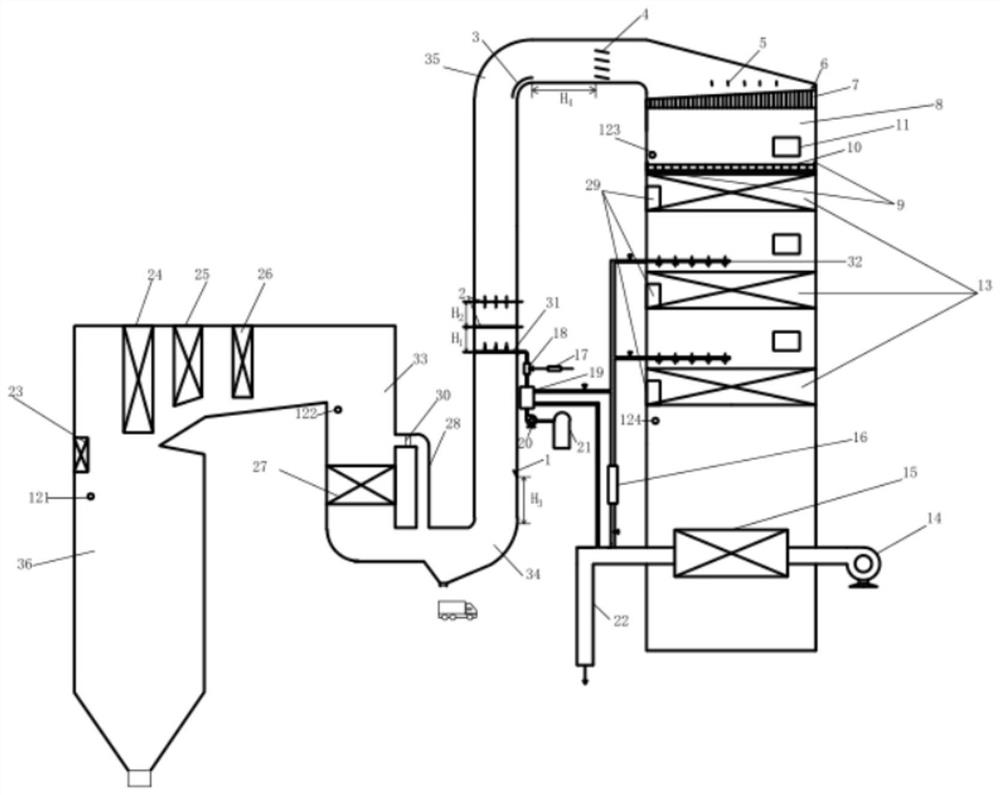

[0028] refer to figure 1 and figure 2 The denitrification system described in the present invention includes a furnace 36, a boiler tail flue 33, a first turning flue 34, a first vertical flue, a second turning flue 35, a horizontal flue, an SCR flue expansion section, a second Two vertical flues, signal device 17, ammonia injection controller 18, buffer tank 19, urea / liquid ammonia storage tank 21 and air supply pipe 22; furnace 36, boiler tail flue 33, first diverting flue 34, second flue A vertical flue, a second turning flue 35, a horizontal flue, an expansion section of the SCR flue, and a second vertical flue are arranged in sequence along the direction of flue gas flow, wherein the first vertical flue is provided with an ammonia spray grid A grid 31, a first probe 121 and an SNCR ammonia injection device 23 are arranged in the furnace 36, and a panel superhea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com