Multipath water treatment control valve

A technology for water treatment and valve control, applied in multi-port valves, valve devices, mechanical equipment, etc., can solve the problems of affecting the output of through-hole water flow, reducing water flow output, and small water flow, so as to reduce production costs and reduce production costs. The effect of improving water quality and increasing water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

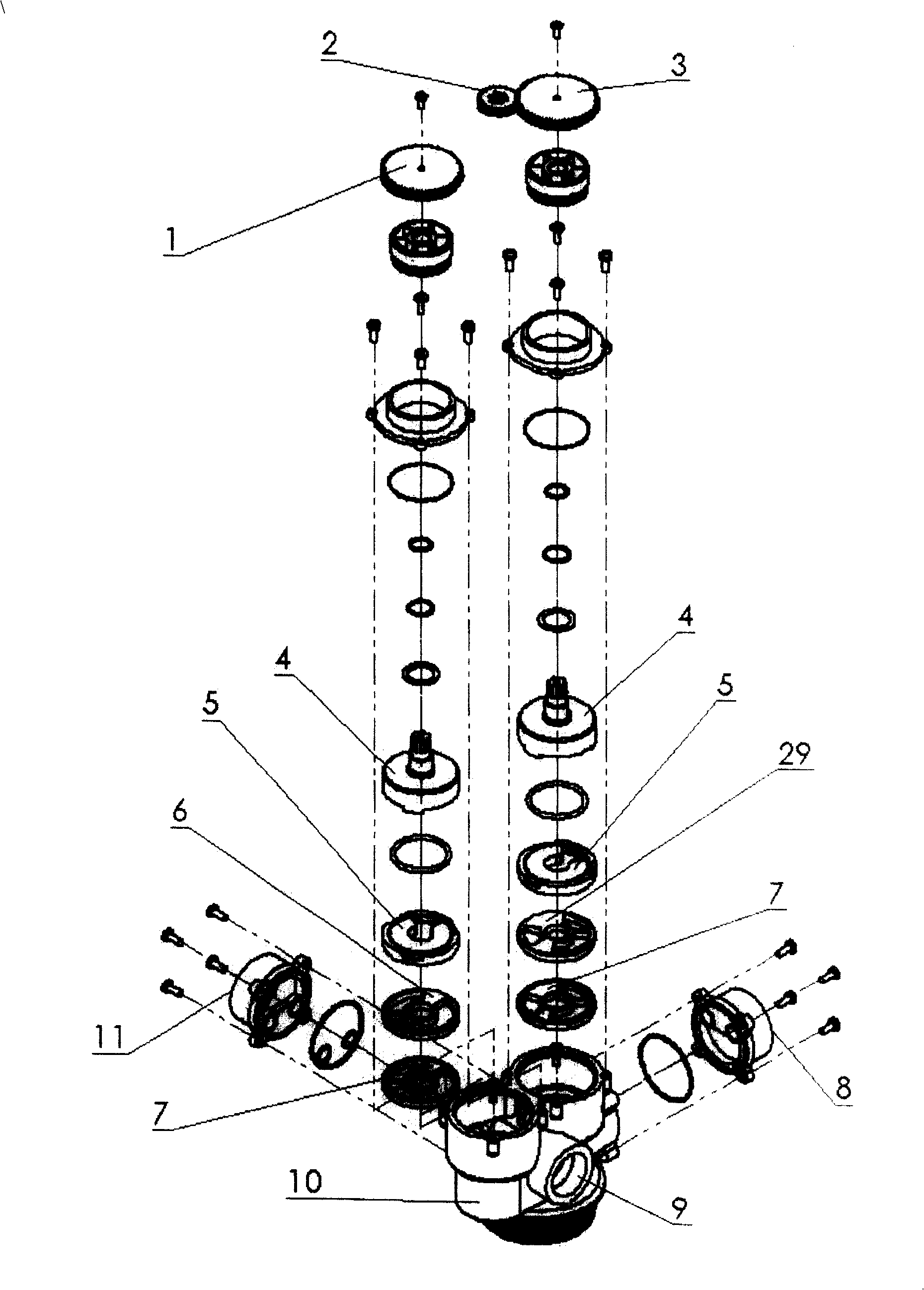

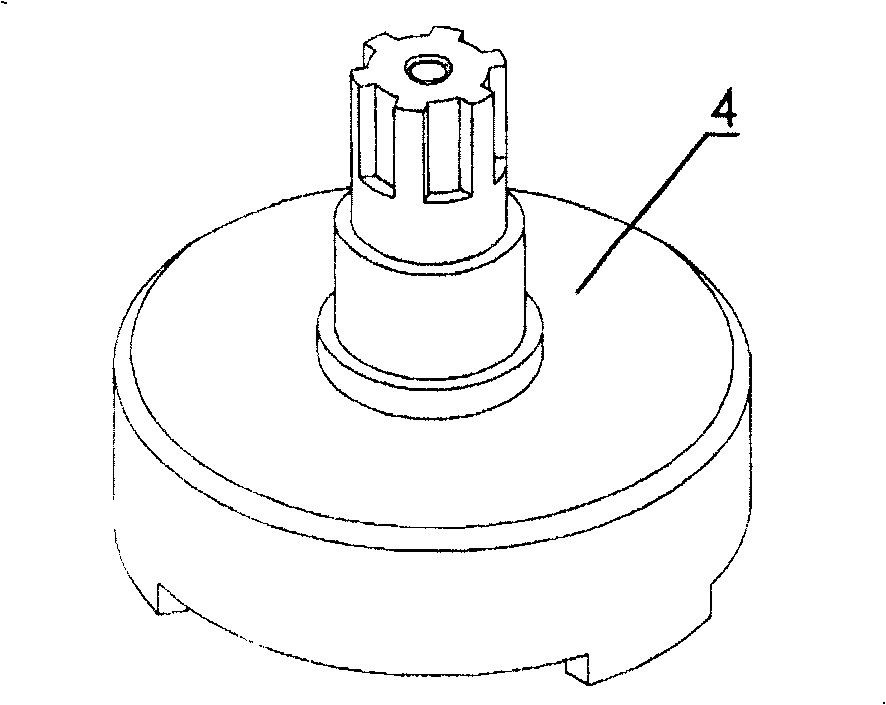

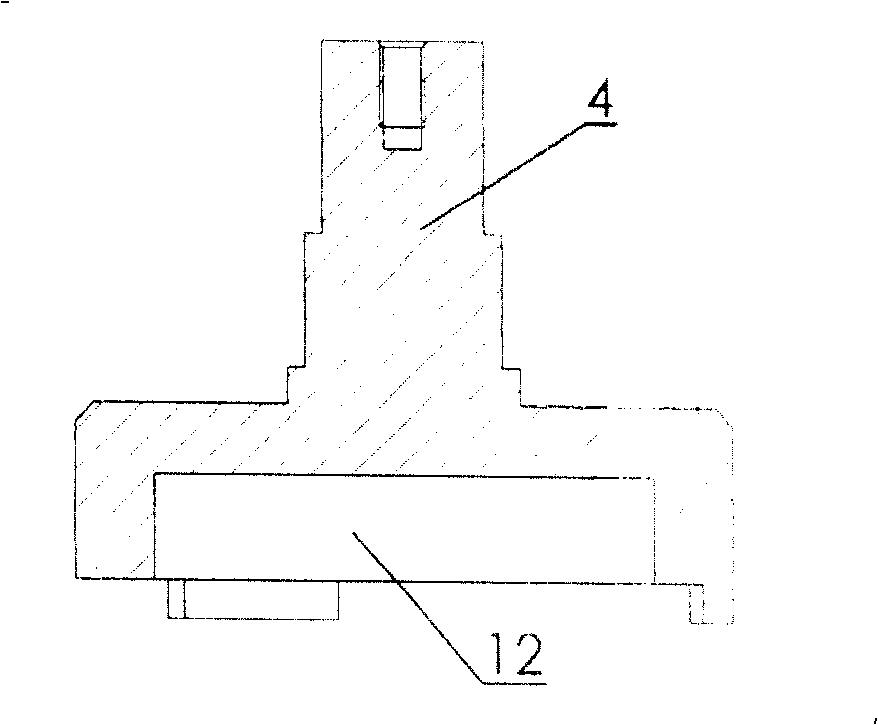

[0060] Embodiment one, Figure 1 to Figure 14 shown. This multi-channel water treatment control valve mainly includes a valve body connected with raw water inlet, clean water outlet and sewage outlet, and a valve core connected to the valve stem is placed in the valve body; the valve core connected to the valve stem 4 , placed in the left and right valve chambers of the valve body 10; the valve core is composed of a movable valve plate 5 and a fixed valve plate 6, 29 with left and right two pairs of end faces sealed and matched with each other; the two movable valves The end face of the sheet 5 and the end face of the valve stem 4 are respectively fitted and connected by grooves and protrusions ( Figure 2-Figure 5 shown); in order to increase the water flow and circulation space, a volume groove 12 is provided on the fitting end surface of the valve rod 4; on the end surface of the movable valve plate 5, a radially extending To the scalloped through hole 13 of its edge ( ...

Embodiment 2

[0061] Embodiment two, Figure 15-Figure 16 shown. The structure of the present invention is the same as that of the first embodiment and will not be described in detail. Its difference is, described valve body raw water inlet 11 place is connected with salt valve 25; The two salt input holes 30 of described salt valve 25 communicate with the salt inlet 31 and 32 on the valve body respectively ( Figure 13 ~ Figure 14 shown). On the end face between the water inlet hole 14 and the drain hole 16, the left fixed valve plate 6 is provided with a fan-shaped salt hole 23, which can be used as a downstream regeneration softening valve for water treatment.

Embodiment 3

[0062] Embodiment three, Figure 17-Figure 18 shown. The structure of the present invention is the same as that of the first embodiment and will not be described in detail. Its difference is that the raw water inlet 11 of the valve body is connected with a salt valve 25; the two salt input holes 30 of the salt valve 25 communicate with the salt inlets 31 and 32 on the valve body respectively ( Figure 13-Figure 14 shown). On the end face of the right fixed valve plate 29 provided with the water inlet hole 14 and the drain hole 16, a fan-shaped salt hole 23 is added. It can also be used as a countercurrent regeneration softening valve for water treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com