Sewerage system and method for bottom of box tank

A bottom sewage and tank technology, which is applied in the field of tank bottom sewage system, can solve the problems of sewage outlet blockage, poor discharge cleanliness, fouling, etc., to reduce the probability of pipeline blockage, improve the import form, and ensure normal operation running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

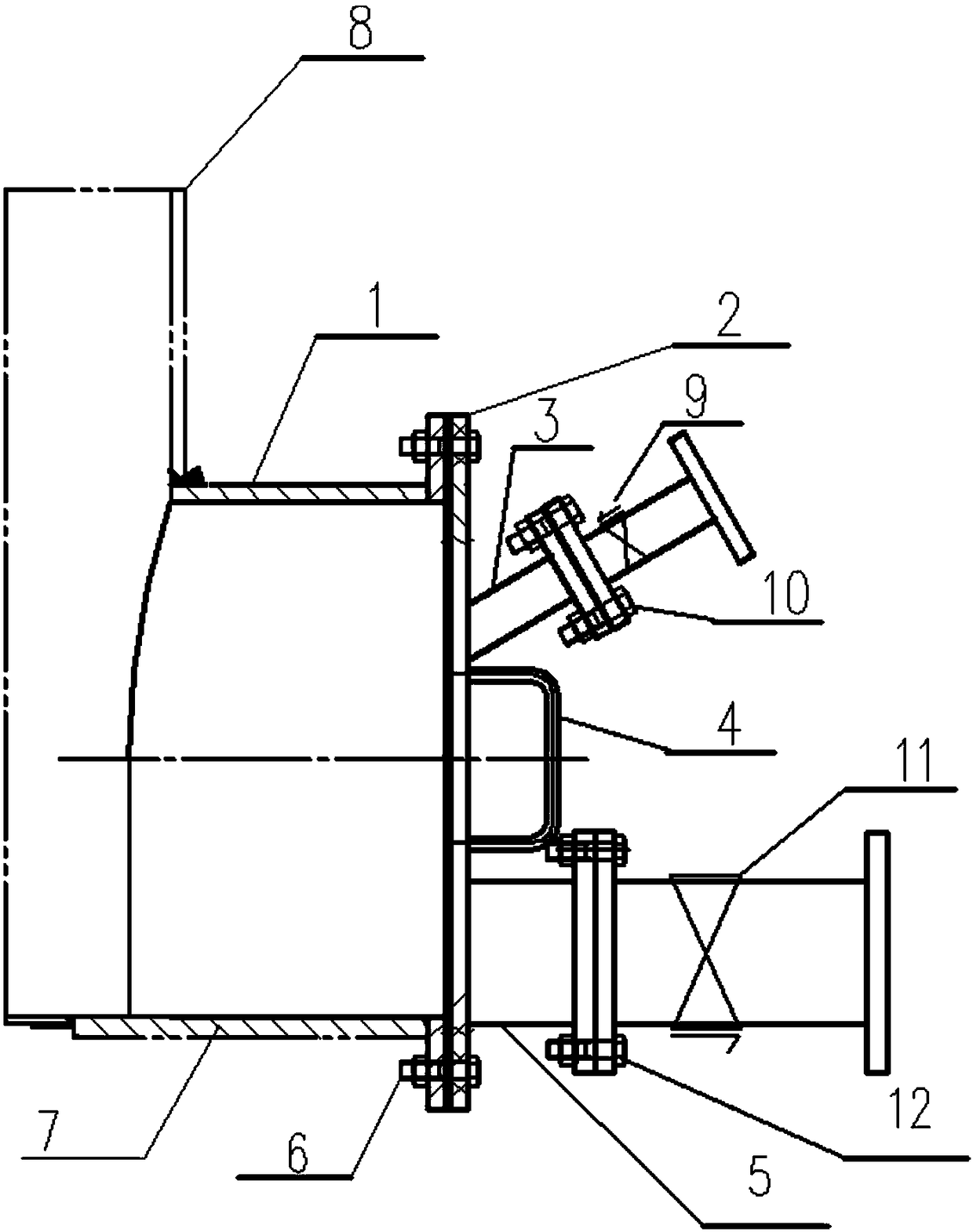

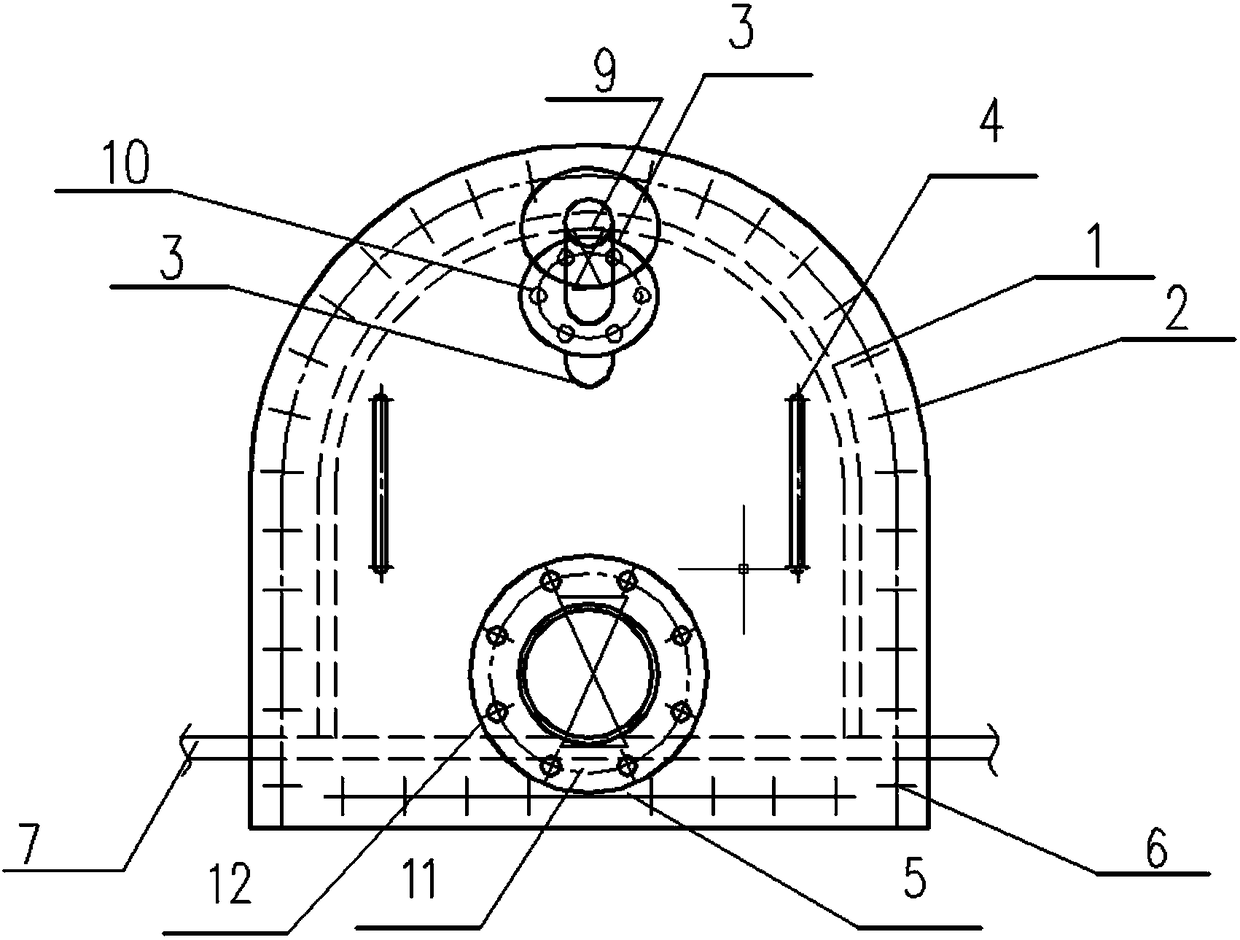

[0029] Example 1, such as figure 1 , 2 As shown, the sewage system at the bottom of the tank body described in the first embodiment of the present invention includes:

[0030] The cleaning device comprises a cleaning port 1, a flange cover 2 of the cleaning port, and a basic ring 7. One end of the cleaning port 1 is installed on the bottom side of the tank body 8, and the other end of the cleaning port 1 is connected to the The flange cover 2 of the clean discharge port is described, the flange cover 2 of the clean discharge port is provided with at least one oval opening and a circular opening, and the basic ring 7 is placed at the bottom of the clean discharge port 1;

[0031] At least two handles 4;

[0032] The connection between the handle 4 and the flange cover 2 of the drain port is welding;

[0033] The connection between the drain port 1 and the tank body 8 is welding;

[0034] The drain port 1 and the drain port flange cover 2 are fixedly connected by bolts C6; ...

Embodiment 2

[0042] Embodiment 2, the bottom sewage discharge method of the tank body of the second embodiment of the present invention includes:

[0043] Step 1, open all the one-way valves A9, and the flushing liquid enters the drain port 1 through the flushing pipes 3 from the outside, and flushes the dirty liquid in the drain port 1 for 1 minute;

[0044] Step 2, close all the one-way valves A9, open the one-way valve B11, and the dirty liquid in the tank body 8 is discharged through the discharge port 1 and the sewage pipe 5 in sequence;

[0045] Step 3, when no dirty liquid flows out, open all the one-way valves A9 again to flush the dirty liquid in the drain port 1 for 1 minute;

[0046] Step 4, close all one-way valves A9;

[0047] Step 5, when no dirty liquid flows out, close the one-way valve B11.

[0048] The pressure of the flushing liquid in the flushing pipeline 3 is 0.3 MPa.

[0049] This embodiment has the following beneficial effects: use high-pressure flushing liquid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com