Design method of pumping chamber of centrifugal submersible slurry pump

A design method and technology of pressurized water chamber, which are applied to non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc. High, low wear, not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

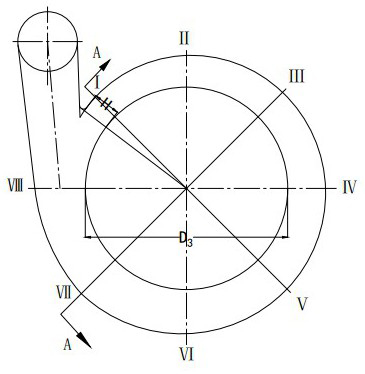

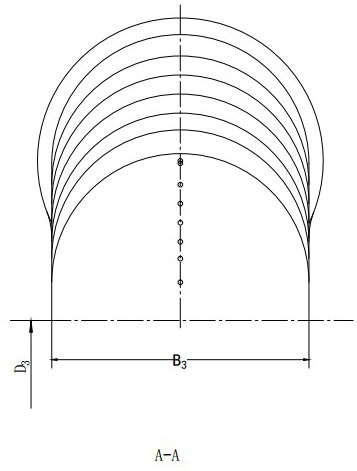

[0039] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~2 The present invention will be further described.

[0040] A design method for the pressurized water chamber of a centrifugal submersible slurry pump, including the width of the pressurized water chamber B 3 Calculation of the base circle of the pressurized water chamber D 3 The calculation of the radial section shape of the pressurized water chamber, the calculation of the area of the radial section of the pressurized water chamber, the calculation of the tongue-tongue angle of the pressurized water chamber, and the calculation of the angle of the diffusion tube.

[0041] The present invention will be further described below in conjunction with specific embodiments, yet those who are familiar with the art should understand that the detailed description given here in conjunction with the accompanying drawings is for better explanation, and the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com