A urea pyrolysis denitrification control system

A control system and denitrification technology, applied in the field of urea pyrolysis denitrification control system, can solve the problems of poor anti-interference ability and large hysteresis of the control loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 provides a urea pyrolysis denitrification control system, the urea pyrolysis denitrification control system includes: a denitrification system and a predictive control system;

[0029] The predictive control system is used to obtain the controlled variable of the denitrification system, perform predictive control according to the controlled variable, and output the urea total flow control command generated according to the predictive control result to the denitrification system;

[0030] The denitration system is used to control the total flow of urea solution entering the pyrolysis furnace according to the total urea flow control command, so that the absolute value of the difference between the NOx concentration at the outlet of the denitrification system and the first set NOx concentration is less than or equal to the first preset value, Among them, the denitrification system includes a pyrolysis furnace.

[0031] The urea pyrolysis ammonia production tec...

Embodiment 2

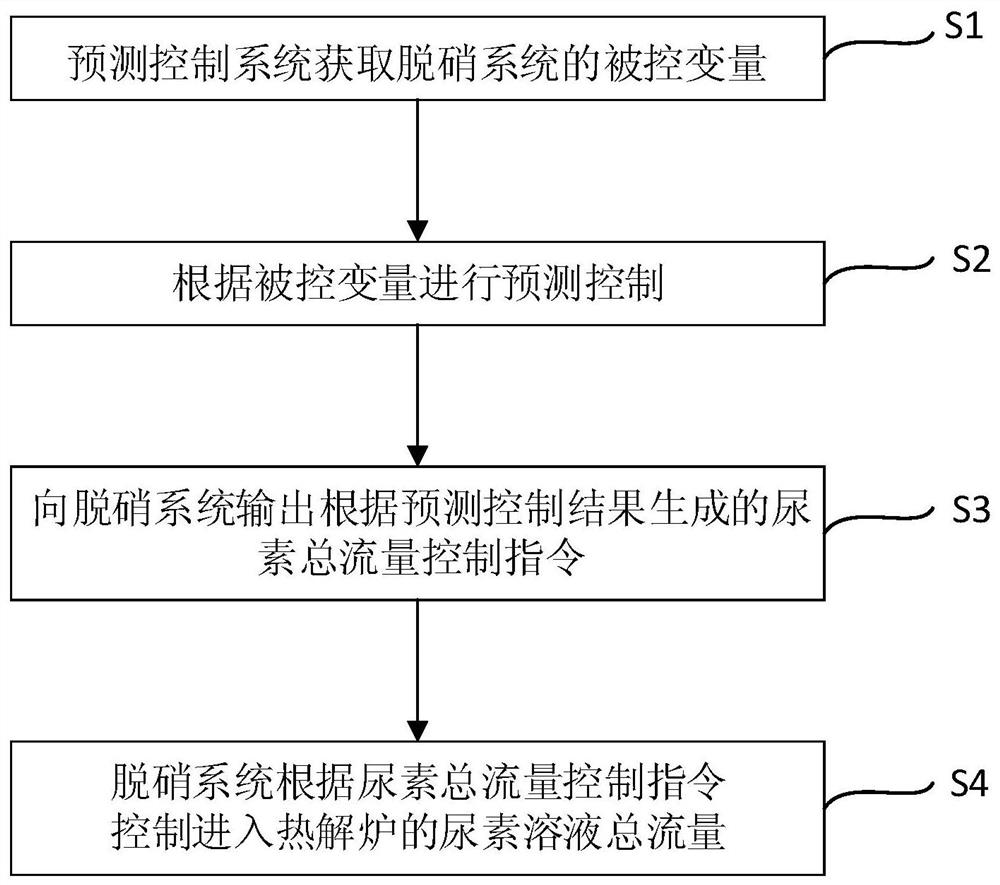

[0064] This embodiment provides a predictive control method for a urea pyrolysis and denitrification control system. The predictive control method is based on the urea pyrolysis and denitrification control system in Embodiment 1. figure 2 For the flow chart of the predictive control method of the urea pyrolysis denitrification control system, refer to figure 2 , the predictive control method includes the following steps:

[0065] S1: The predictive control system obtains the controlled variables of the denitrification system;

[0066] S2: Carry out predictive control according to the controlled variable;

[0067] S3: Output the urea total flow control command generated according to the predictive control result to the denitrification system;

[0068] S4: The denitrification system controls the total flow of urea solution entering the pyrolysis furnace according to the total flow control command of urea.

[0069]Specifically, the predictive control module receives the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com