A precise control method for high-efficiency denitrification ammonia flow

A technology for precise control and ammonia flow, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as low reliability, large lag, and difficult debugging of advanced denitrification control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

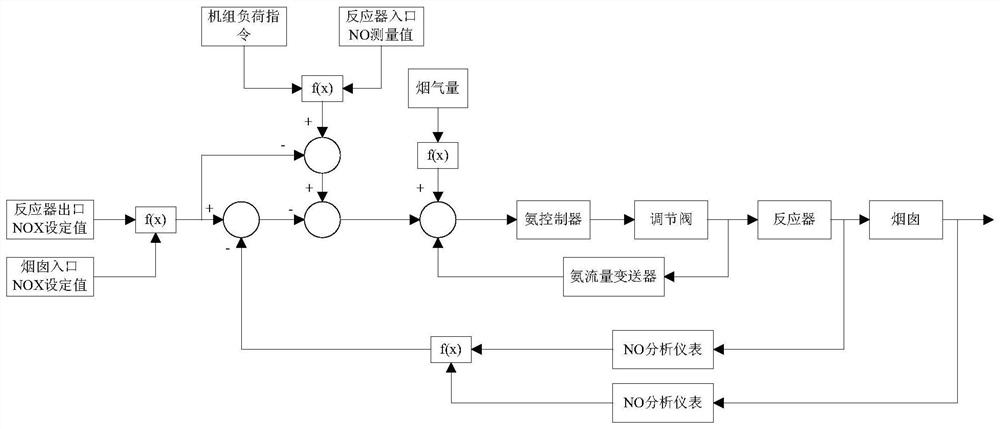

[0029] A precise control method for high-efficiency denitrification ammonia flow, which combines fuzzy control, intelligent model weighting algorithm and fuzzy PID, including the following steps:

[0030] (A) Determine the operating status of the boiler according to the unit load command and variable load rate;

[0031] (B) If the unit is running in a variable load state, call the fuzzy control system;

[0032] (C) If the unit is running at constant load, call the improved cascade control system;

[0033] In step (A), specifically include:

[0034] Directly read unit load command from DCS. When the unit load changes beyond a certain range (tentatively 5-10%), the unit is considered to be in a state of variable load, otherwise, the unit is considered to be operating in a state of constant load.

[0035] In step (B), specifically include:

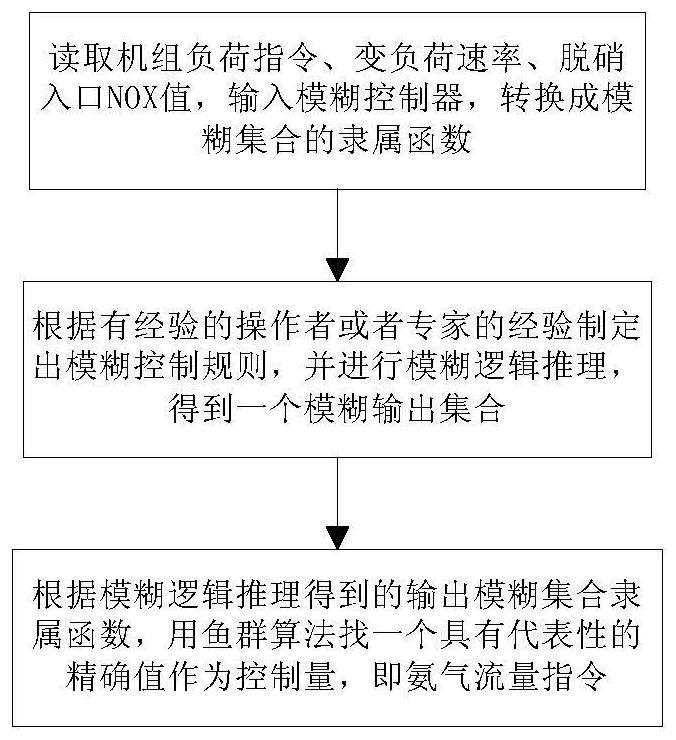

[0036] (B1) Directly read the unit load command, variable load rate, and NOx value at the denitrification inlet from the DCS, input it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com