Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Prevent jumping phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

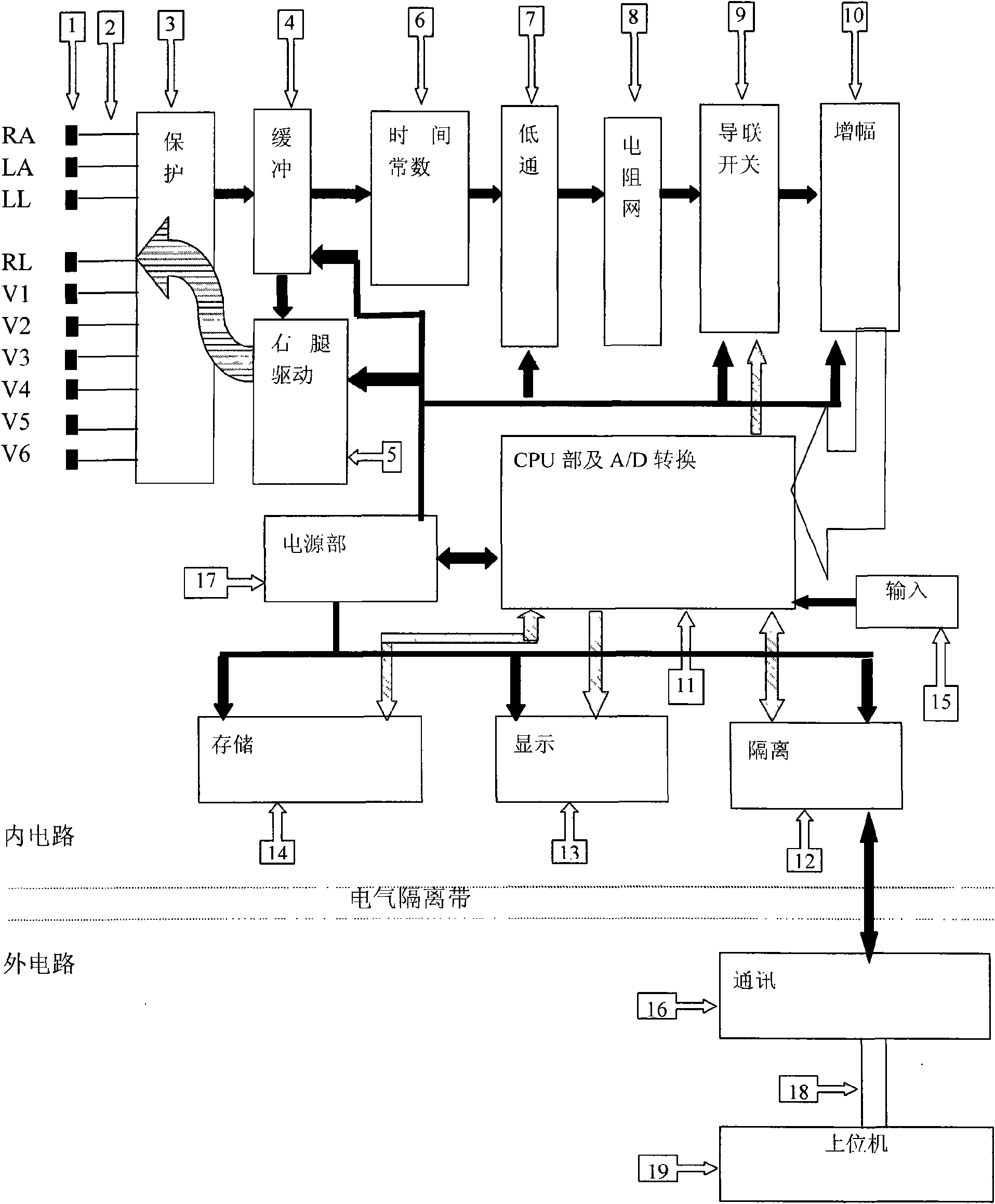

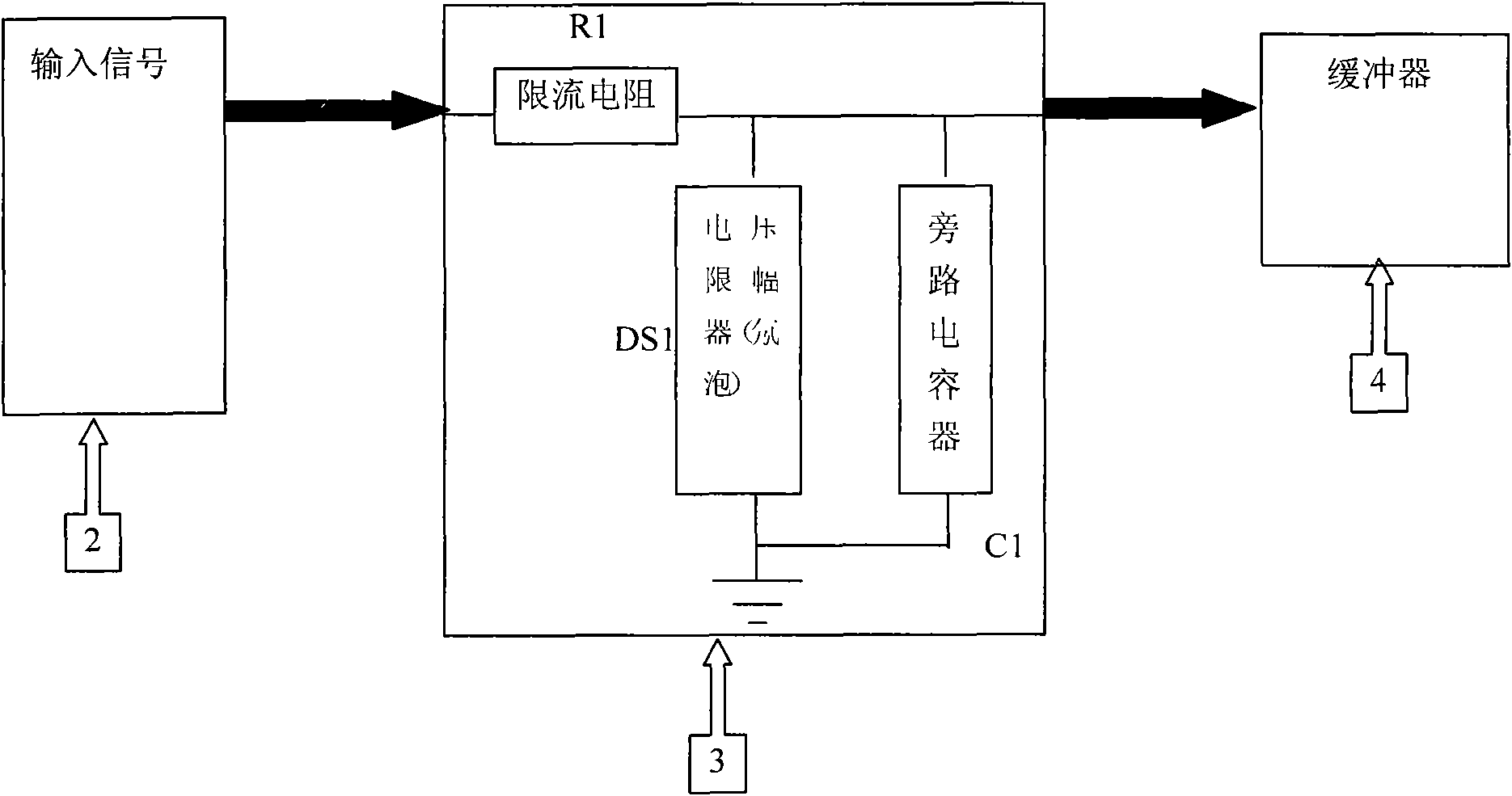

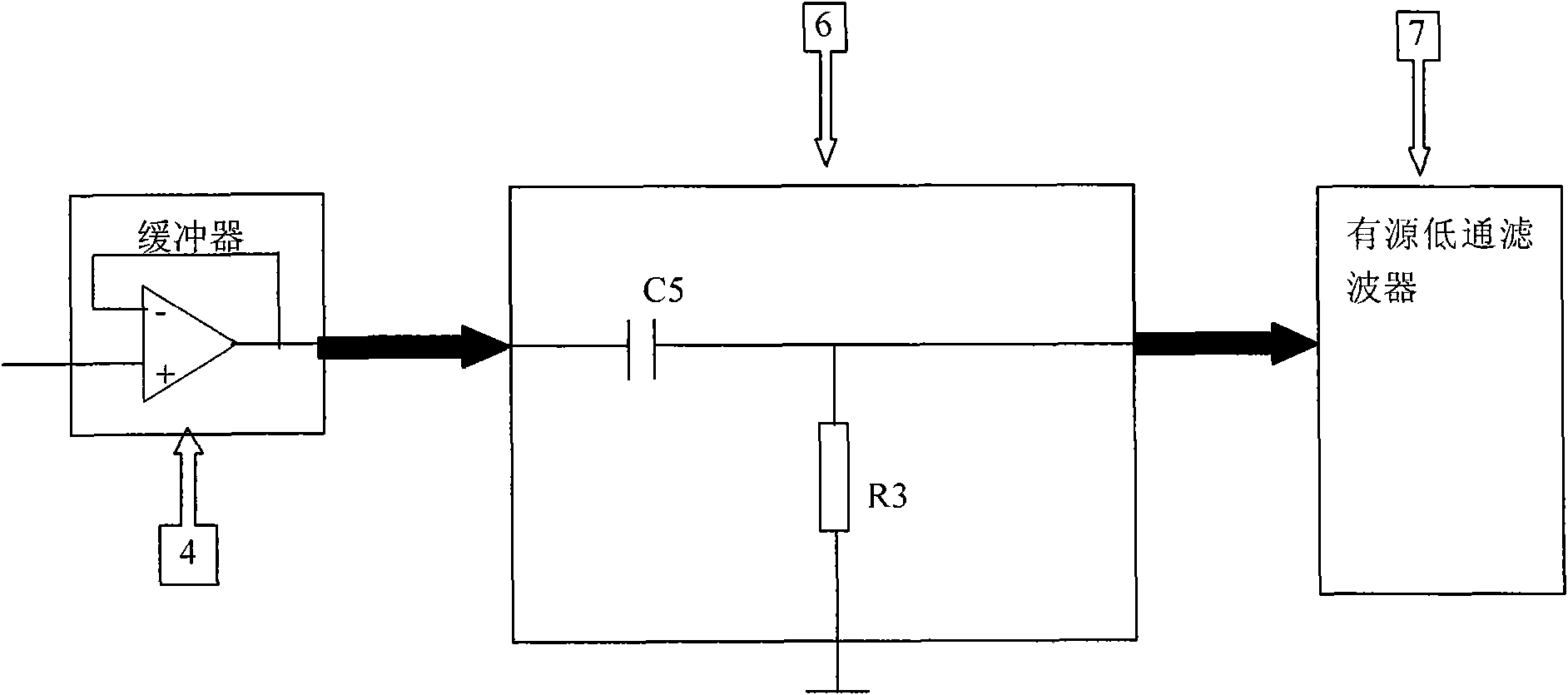

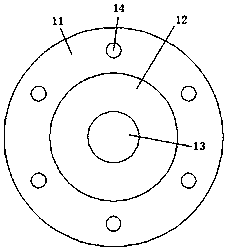

Digital pick-up device for body surface cardiac electric signals

InactiveCN101524272ASimple circuitLow costDiagnostic recording/measuringSensorsData memoryElectric signal

The invention relates to a digital pick-up device for body surface cardiac electric signals, and belongs to the field of medical appliances. The digital pick-up device adopts multiplexing and single-stage single-channel amplifier structures, and is a virtual instrument structure adopting a single-channel A / D convertor to realize synchronous acquisition of twelve-lead body surface cardiac electric signals. The instrument is provided with an isolating communication part and a detachable data storage device, and can meet corresponding medical electrical safety standard. The digital pick-up device has the advantages of small volume, low electric power consumption and low cost, is designed by taking EMC as reference, and is particularly suitable for popularization and application of families.

Owner:李平

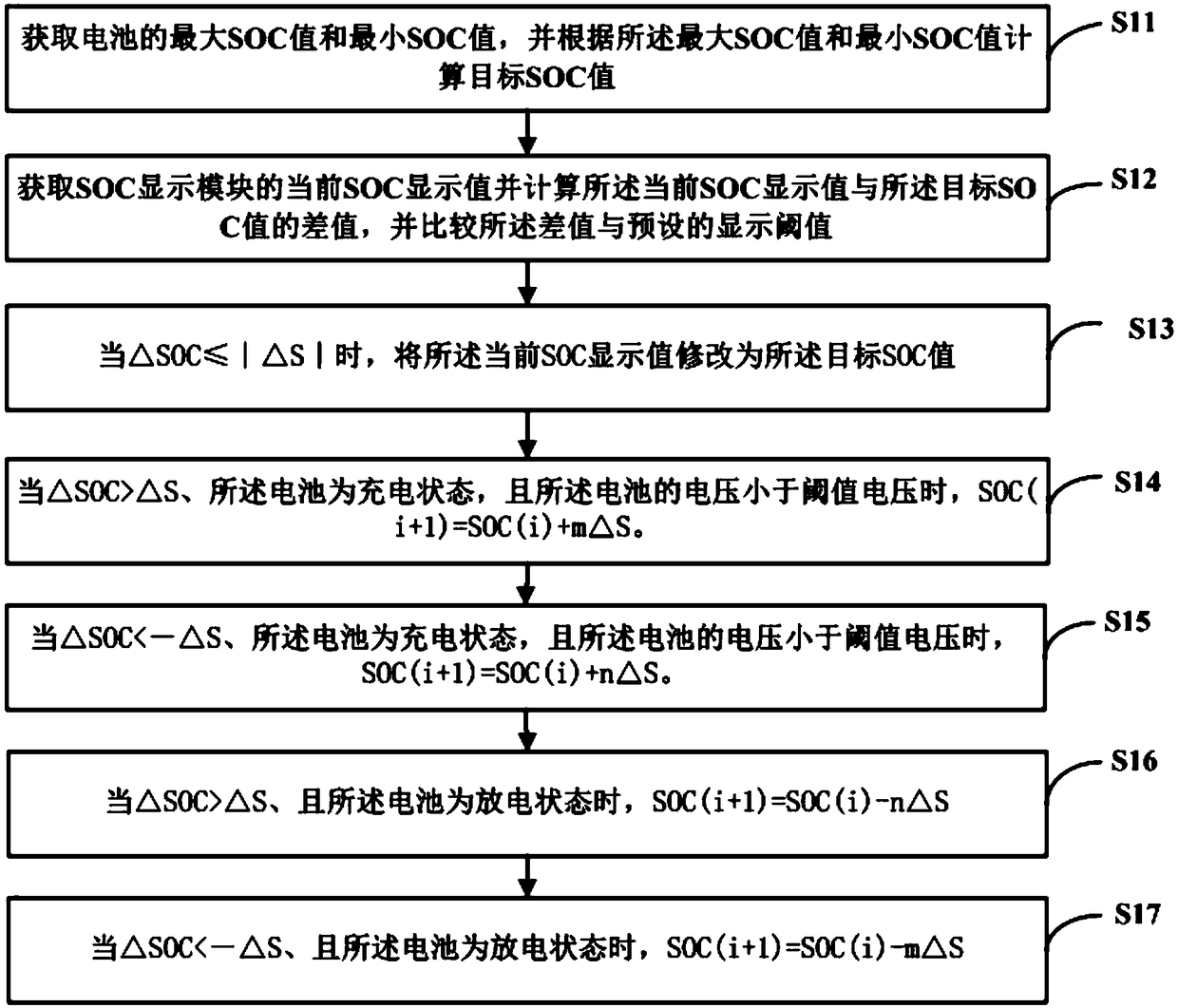

Battery SOC estimation algorithm

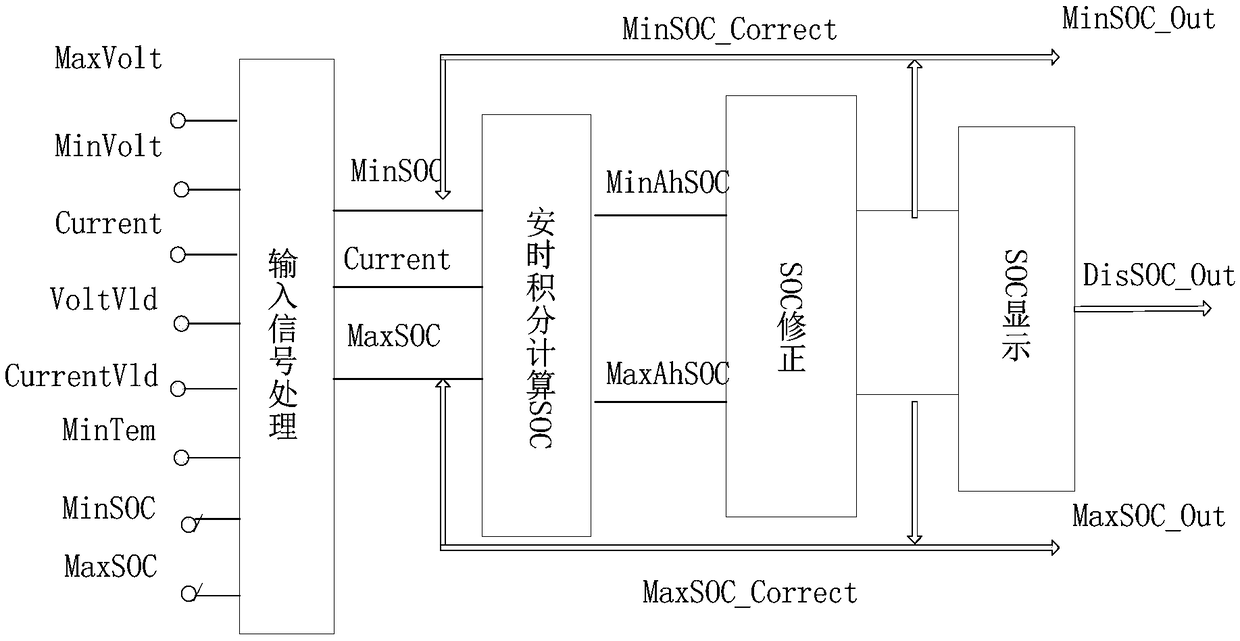

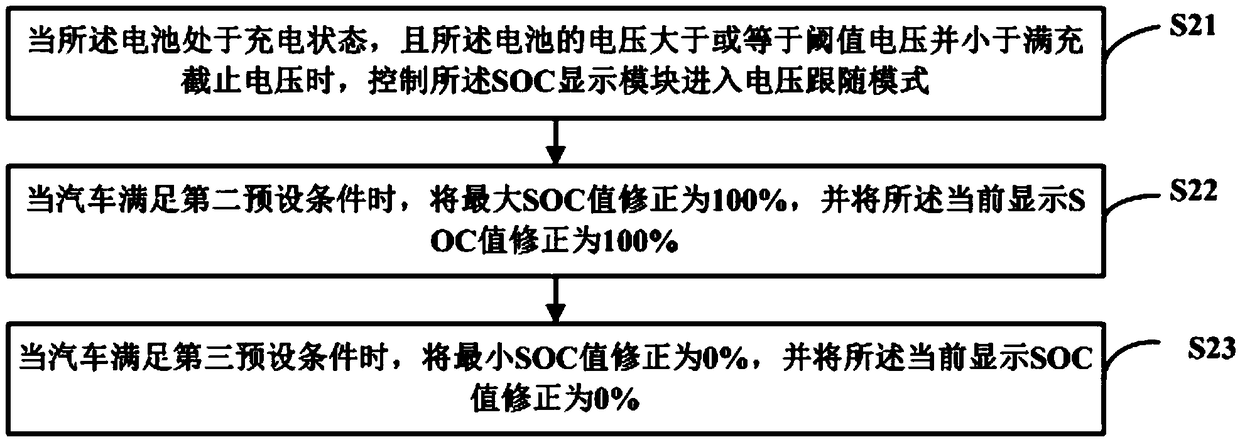

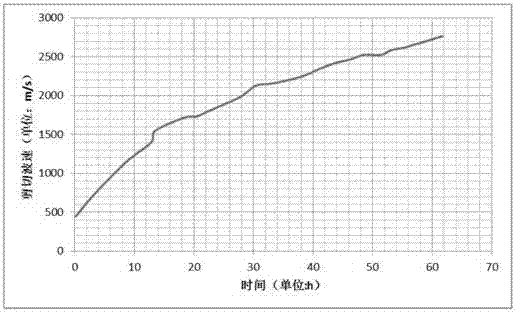

ActiveCN109001639ASmooth changePrevent jumping phenomenonElectrical testingEngineeringCharge and discharge

The invention discloses a battery SOC estimation algorithm. The battery SOC estimation algorithm comprises steps that a maximum SOC value and a minimum SOC value of a battery are acquired, and according to the maximum SOC value and the minimum SOC value, a target SOC value is calculated; a current SOC display value of a SOC display module is acquired, and a difference value between the current SOCdisplay value and the target SOC value is calculated, and the difference value is compared with a preset display threshold value; according a comparison result, the update rate of the current SOC display value during a charging and discharging process is determined, and the smooth change of the displayed SOC value is guaranteed, and the skip phenomenon of the SOC display value is prevented, and user experience is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

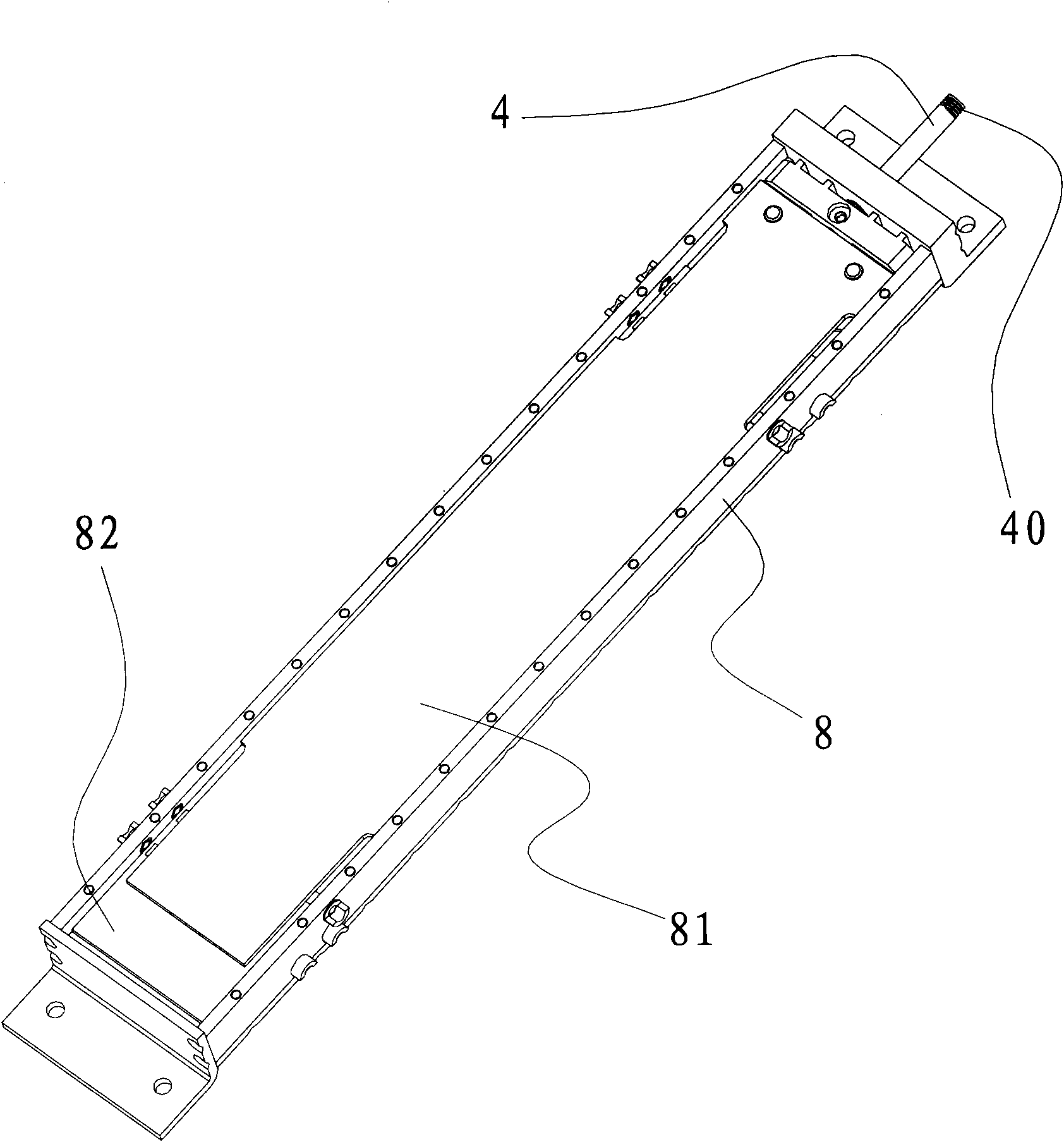

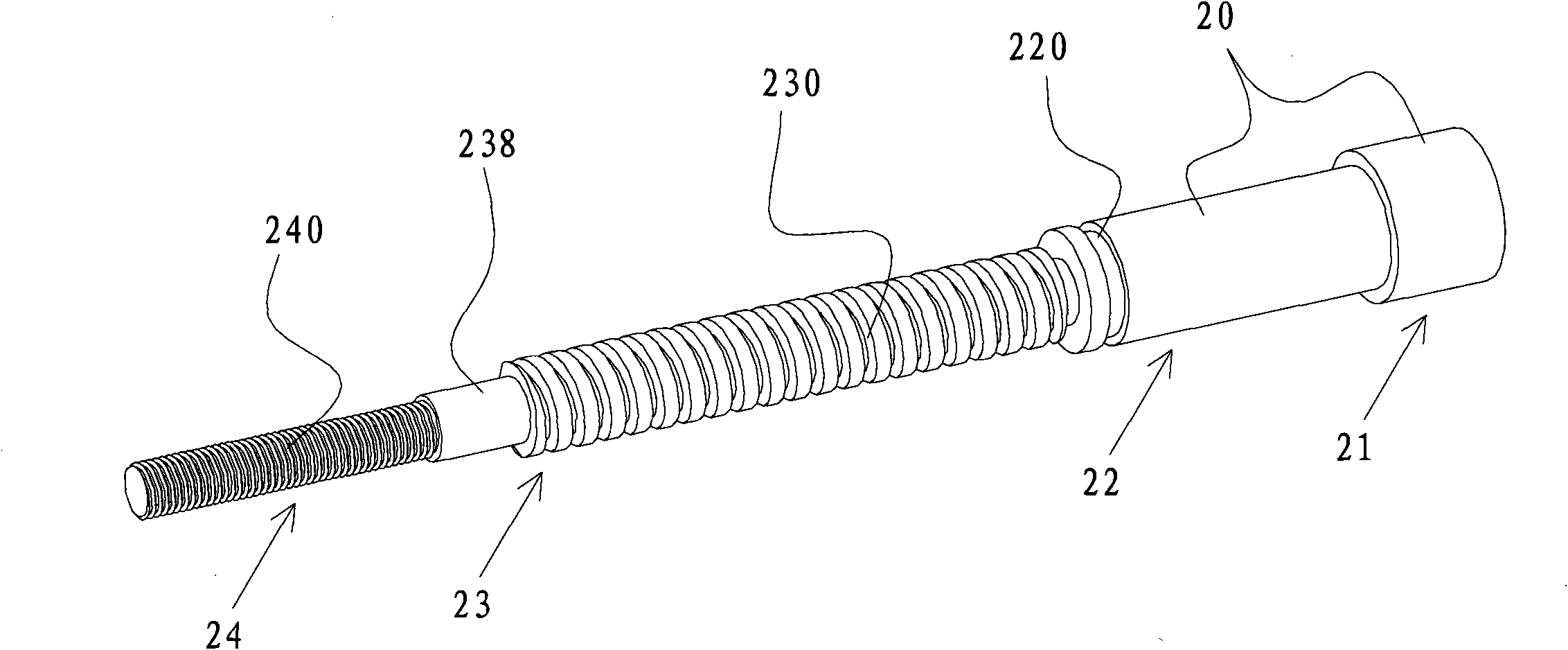

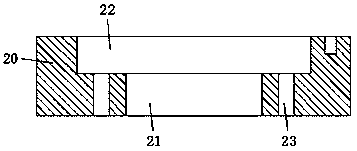

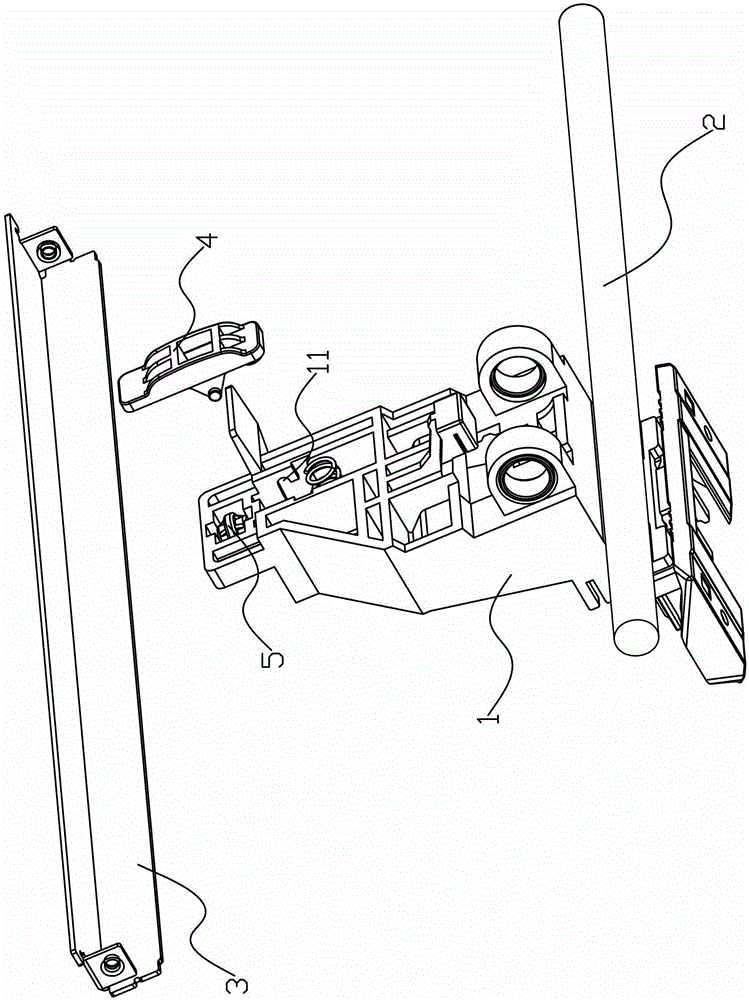

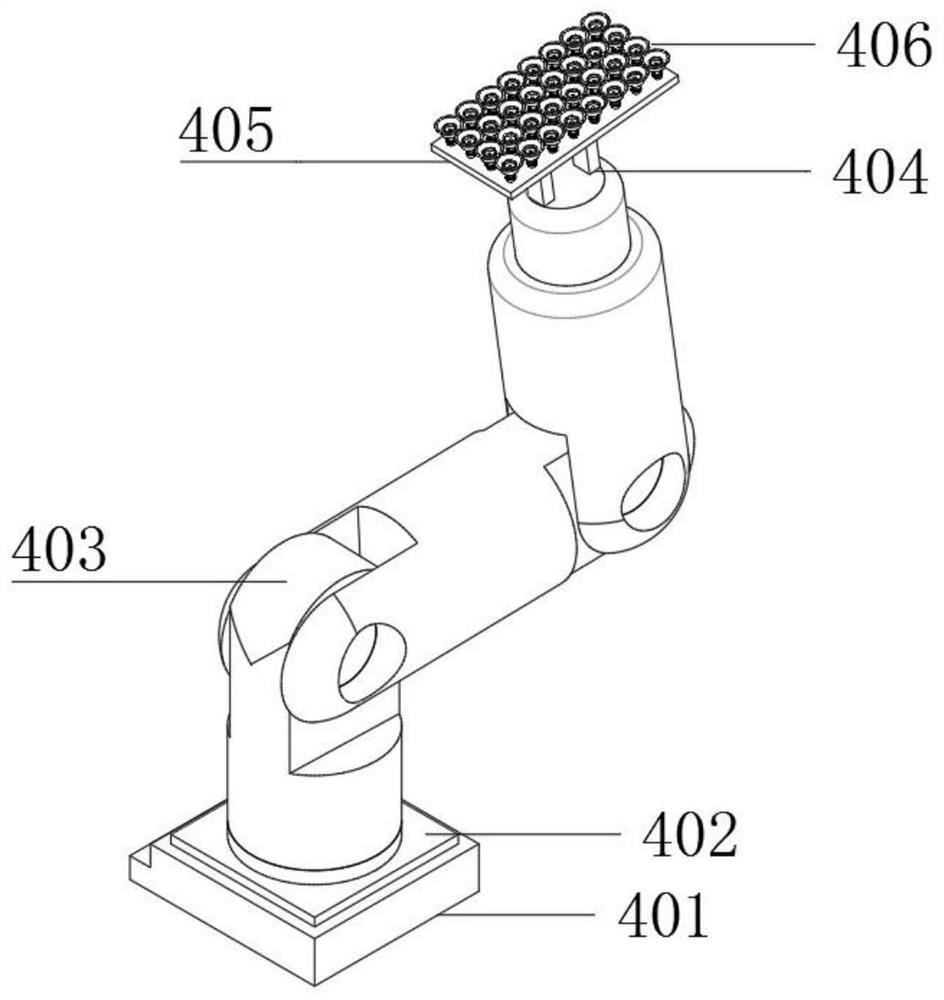

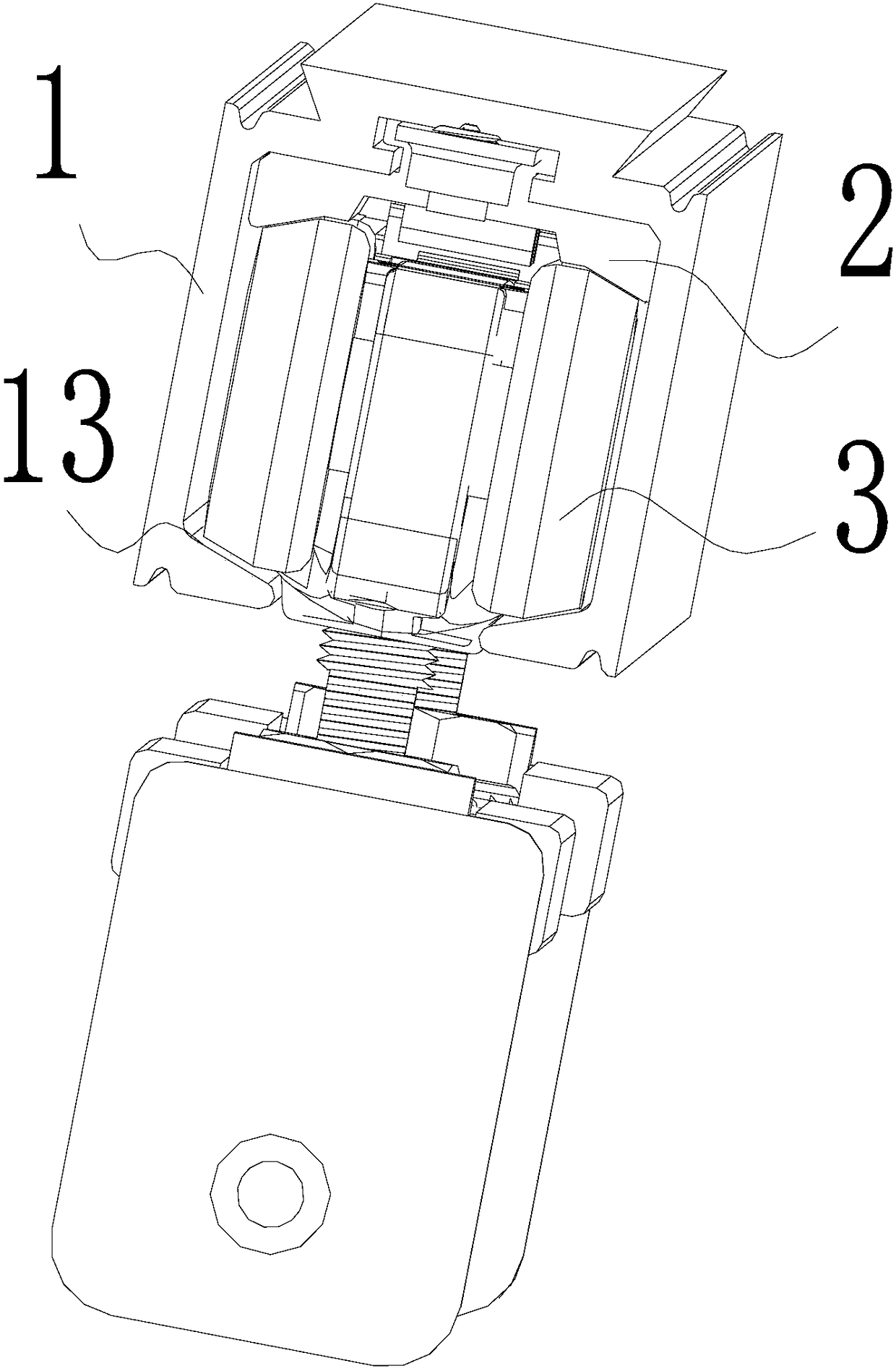

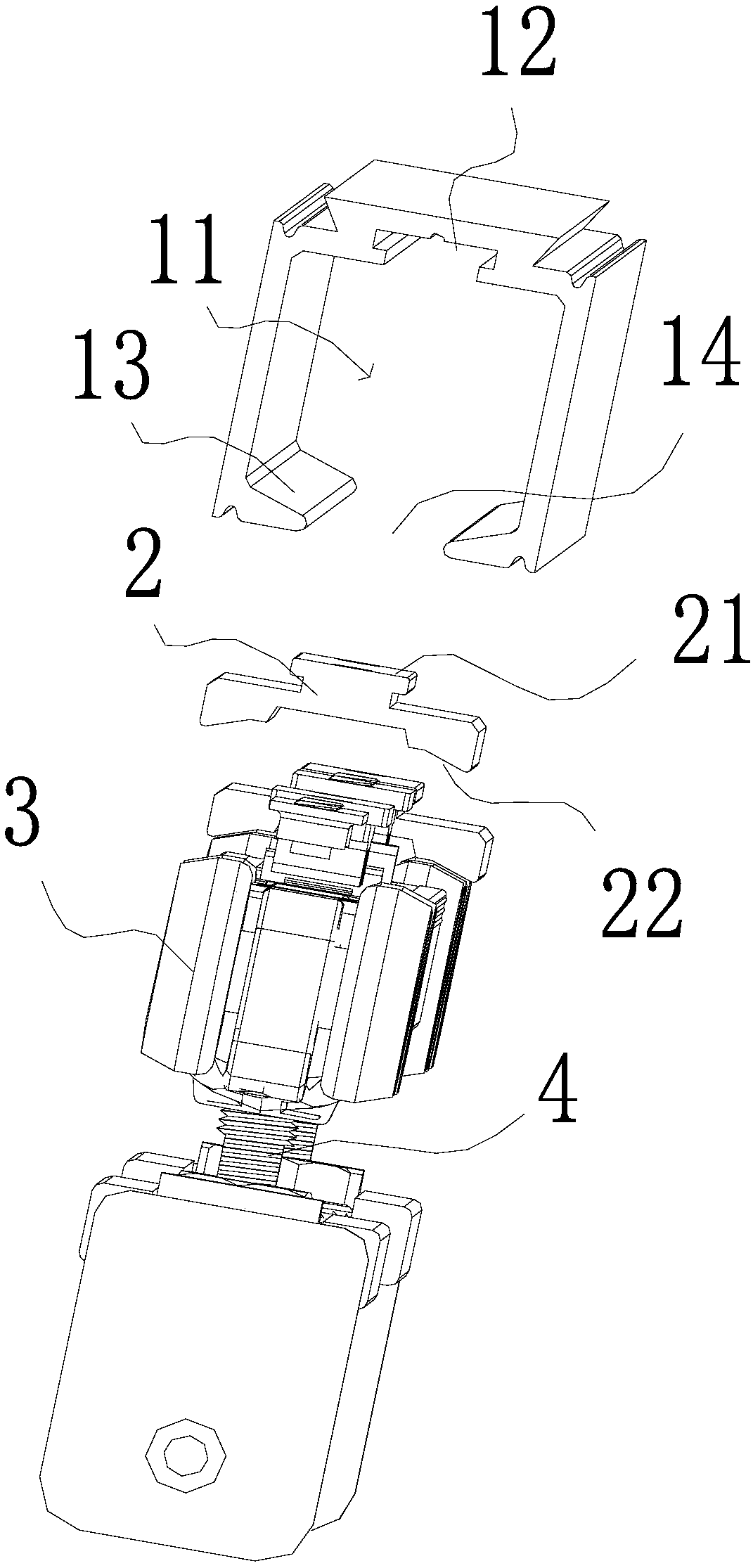

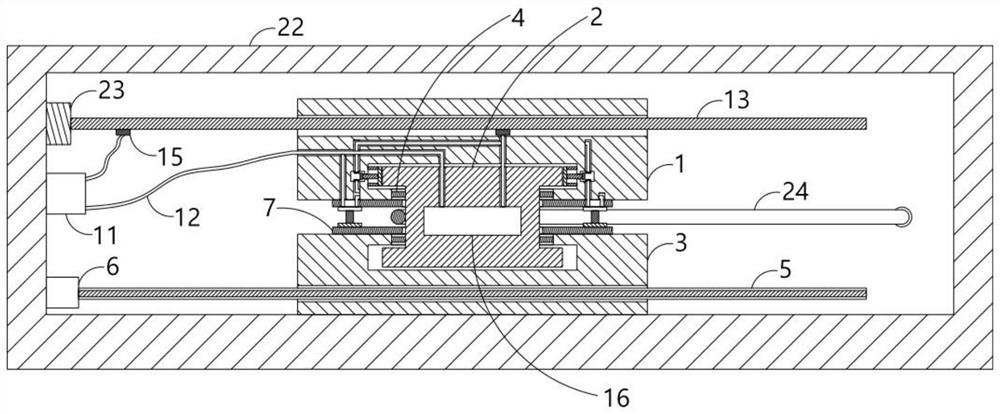

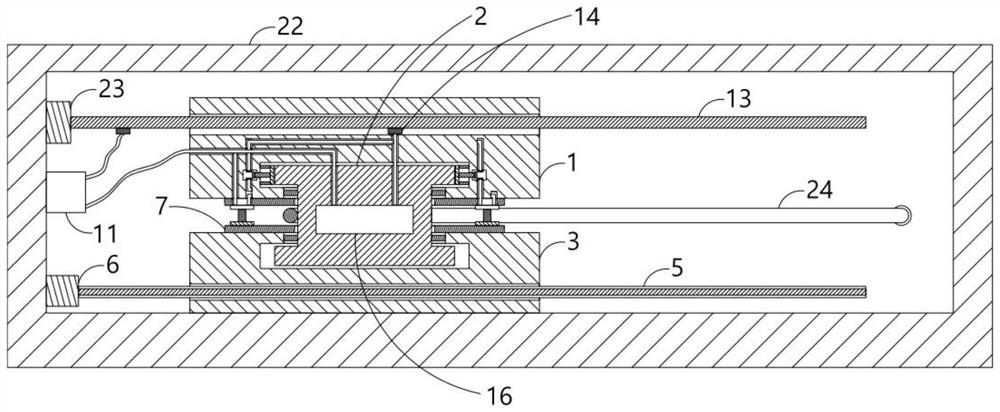

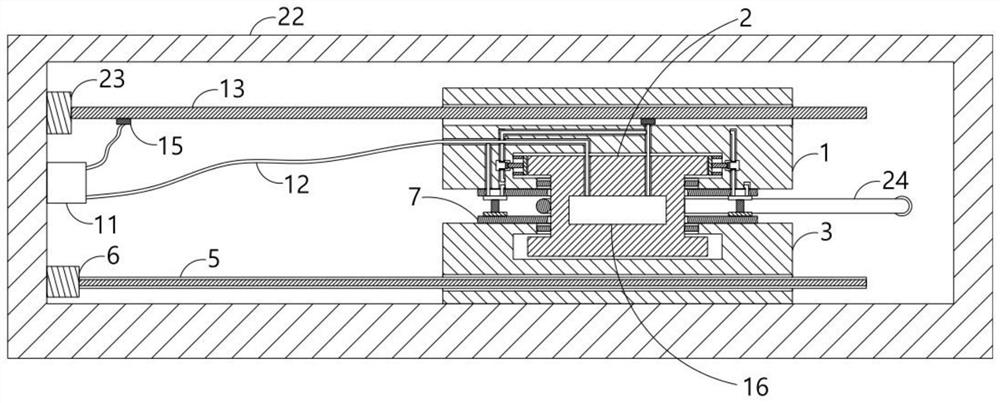

Phase shift driving device of electric tiled antenna

ActiveCN101826647ALow costSimple structureWaveguide type devicesAntennasPhase shiftedElectrical tuning

The invention discloses a phase shift driving device of an electric tiled antenna, which is used for shifting at least one phase shift component of a phase shifter in the electric tiled antenna so as to change the phase position of a signal. The driving device comprises an axially-limited drive rod and a transmission lever, wherein an operating part rotating around the circumference is arranged at the first end of the drive rod; the driving rod is axially arranged with the drive rod and axially moves under the action of the drive rod to drive at least one phase shift component of the phase shifter to synchronously move; the first end of the driving rod and the second end of the drive rod are in mutual threaded mesh and are movably connected; and the second end of the driving rod is linked with the phase shift component of the phase shifter. The driving device has the advantages of simple structure, normal driving work, stable operation, accurate phase position adjustment of the phase shifter and capability of well meeting the requirement of a mobile communication system.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

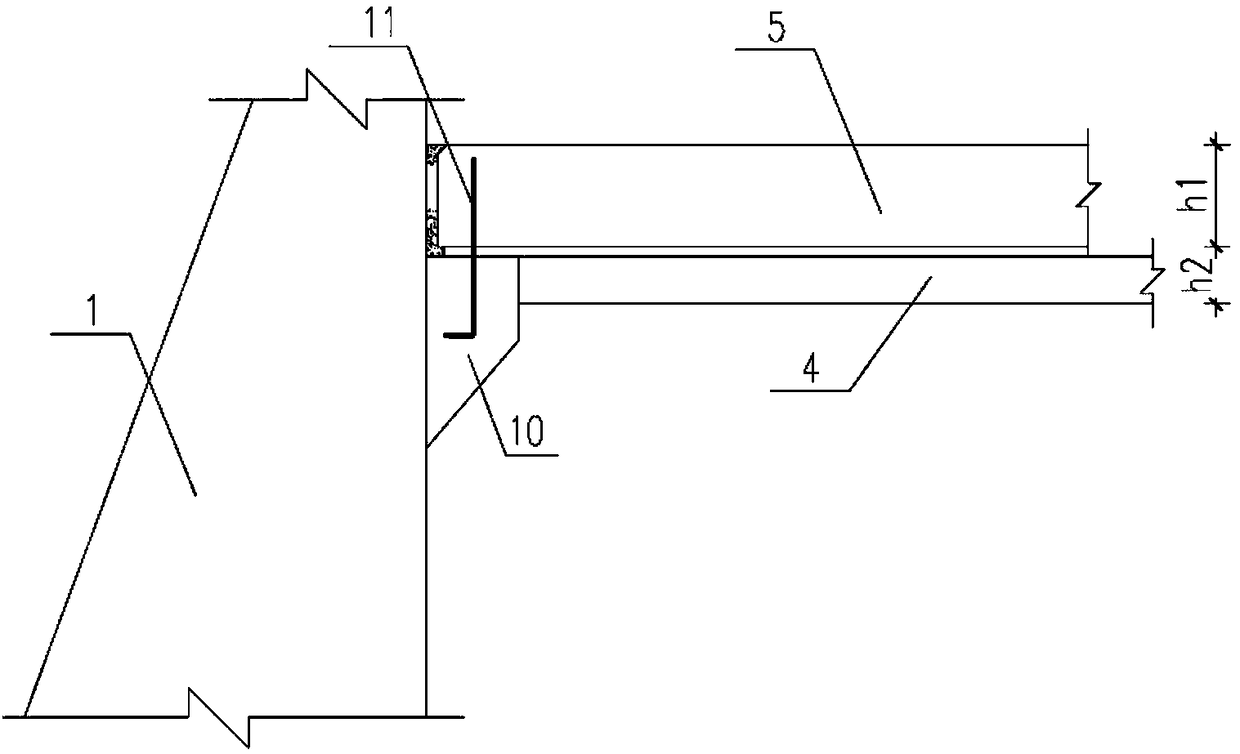

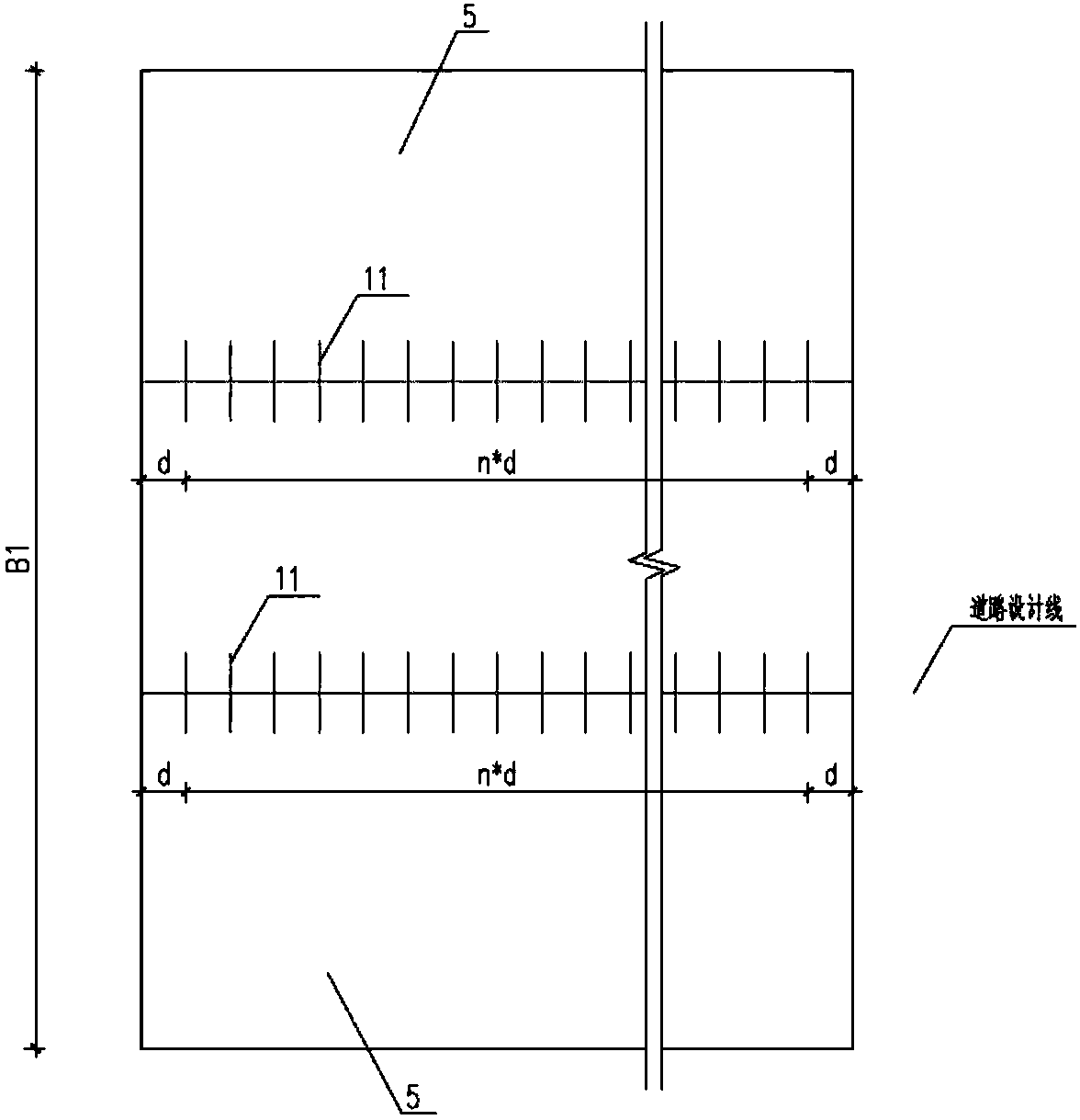

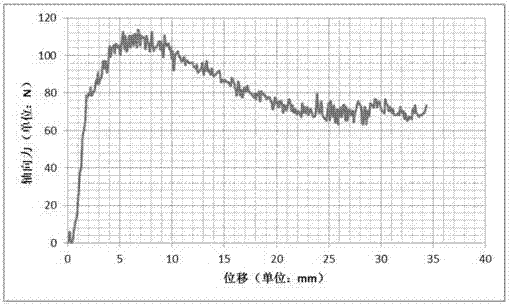

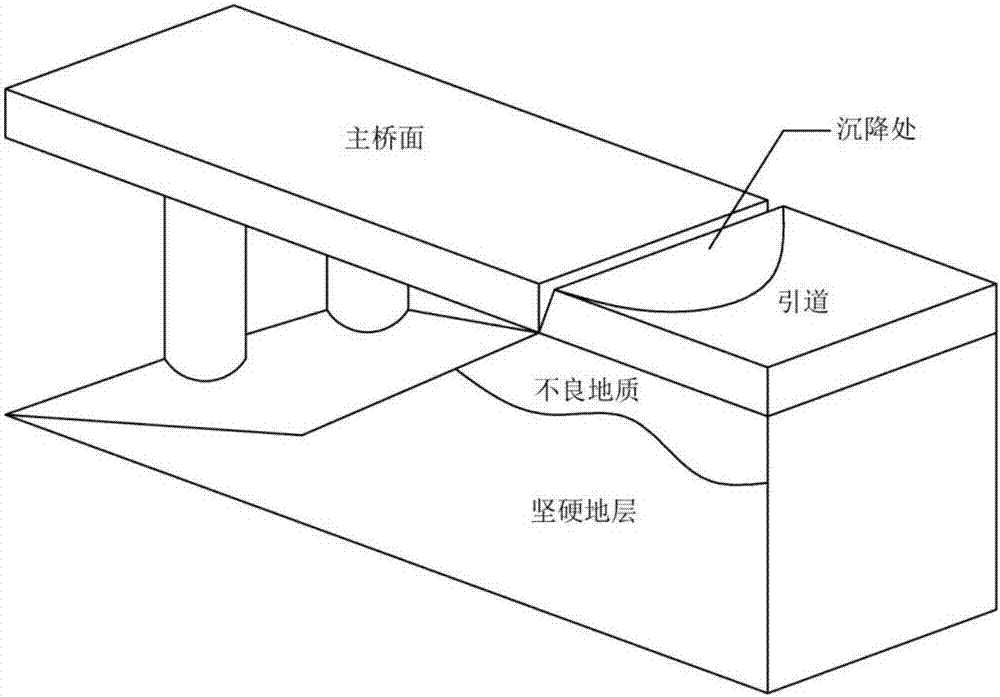

Roadbed reinforcement structure for preventing vehicle bump at bridge head and construction method thereof

InactiveCN108999045AAlleviate or solve disease problemsImprove bearing capacityRoadwaysAbutmentSubgrade

The invention discloses a roadbed reinforcement structure for preventing vehicle bump at bridge head, comprises an anti-settling plate arranged at the middle position of the bridge abutment and the backfill area behind the bridge abutment, wherein the anti-settling plate is connected with the bridge abutment rib plate through the brackets, a lower backfill area is arranged below the anti-settlingplate, an upper backfill area is arranged above the anti-settling plate, and a side of the anti-settling plate far away from the bridge abutment is a general roadbed backfill area. The invention alsodiscloses a construction method of a roadbed reinforcement structure for preventing vehicle bump at a bridge head. In the invention, the anti-settlement plate separates the backfill behind the abutment into two layers, reduces the height of the backfill behind the abutment, further reduces the settlement difference between the rigid abutment structure and the flexible embankment, strictly controlsthe compactness of the backfill on the abutment, thereby achieving the purpose of eliminating the uneven settlement between the abutment and the embankment, and effectively preventing the vehicle bump phenomenon at the bridge head.

Owner:WISDRI ENG & RES INC LTD +1

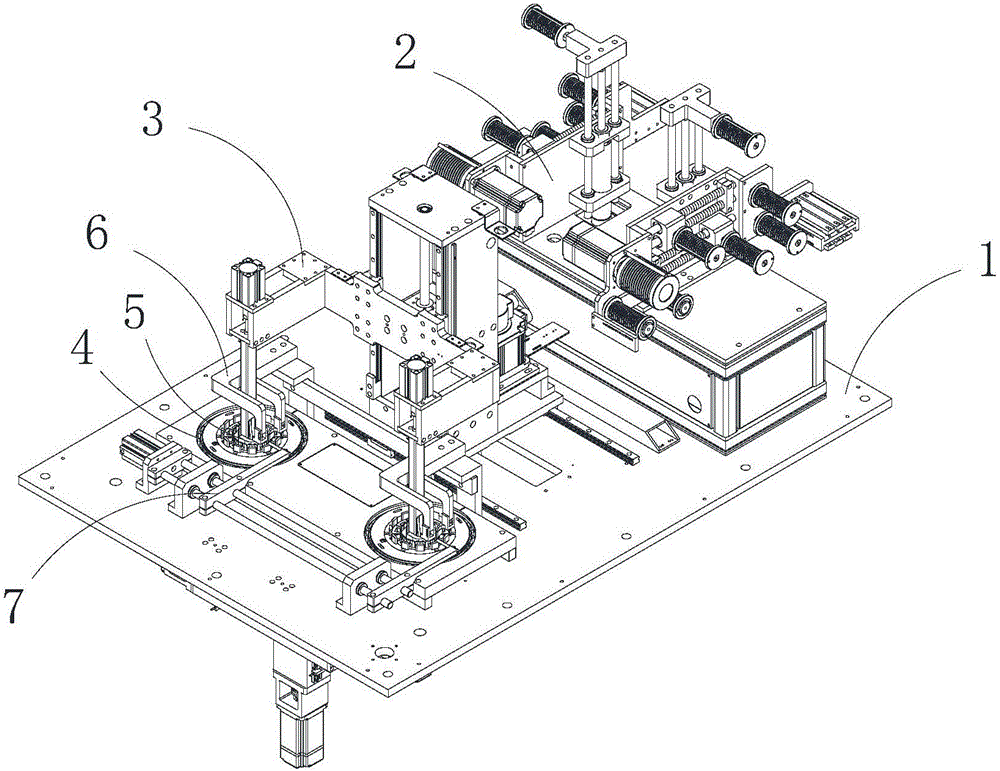

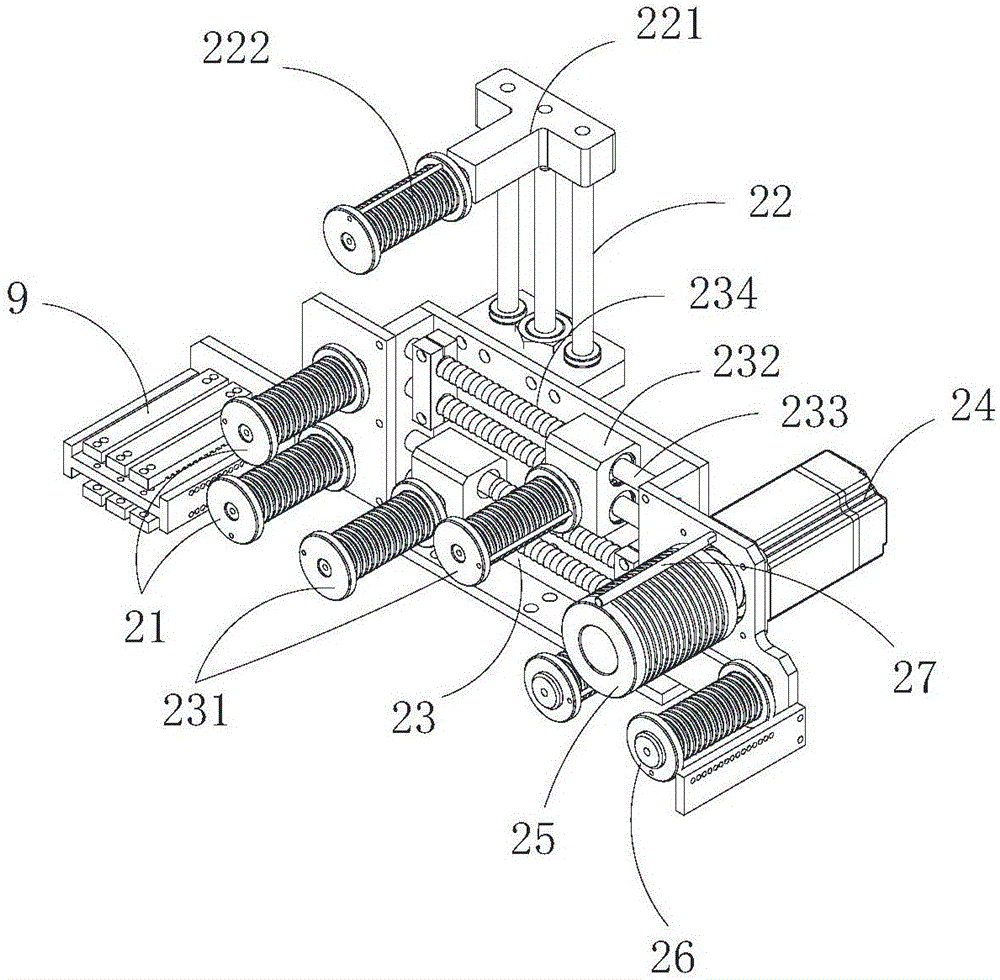

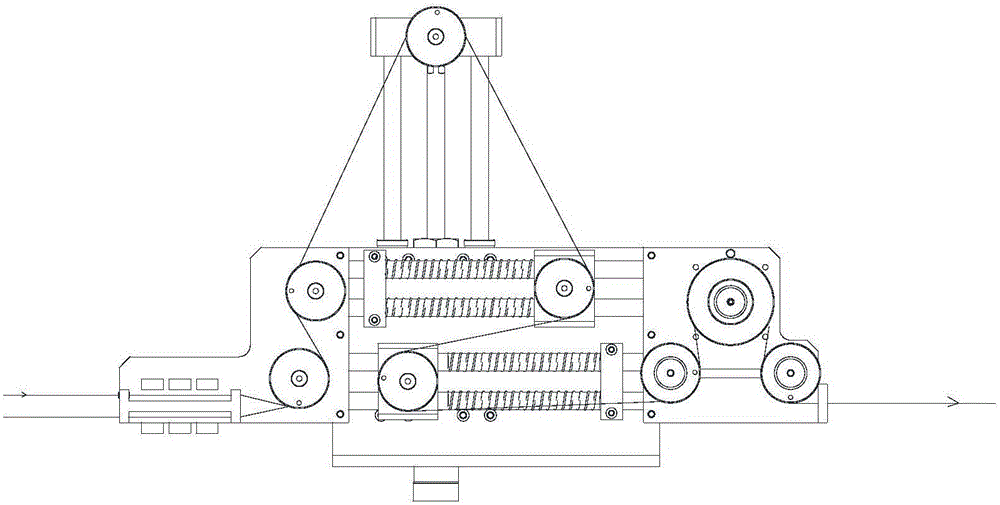

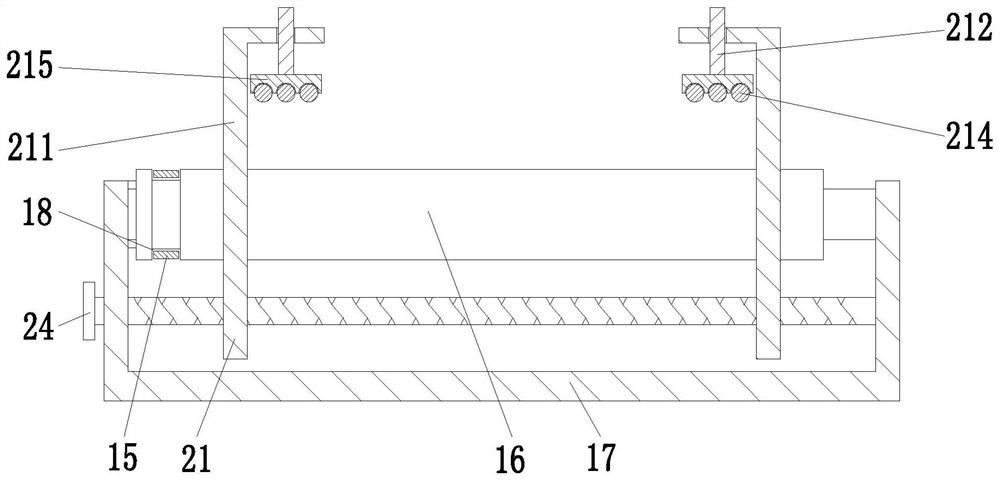

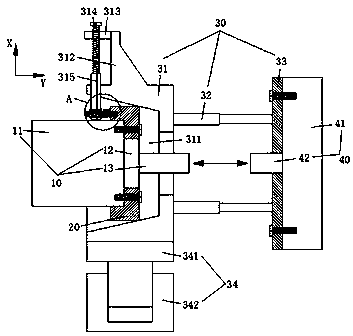

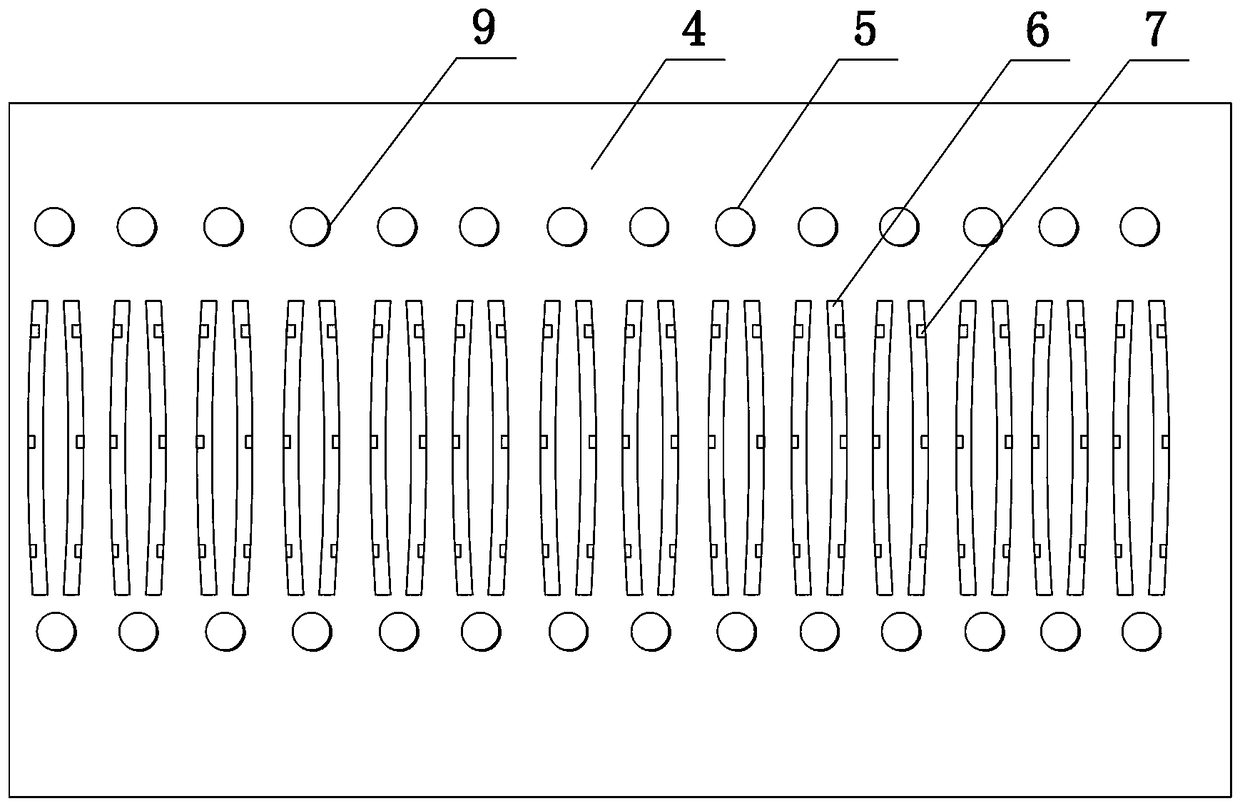

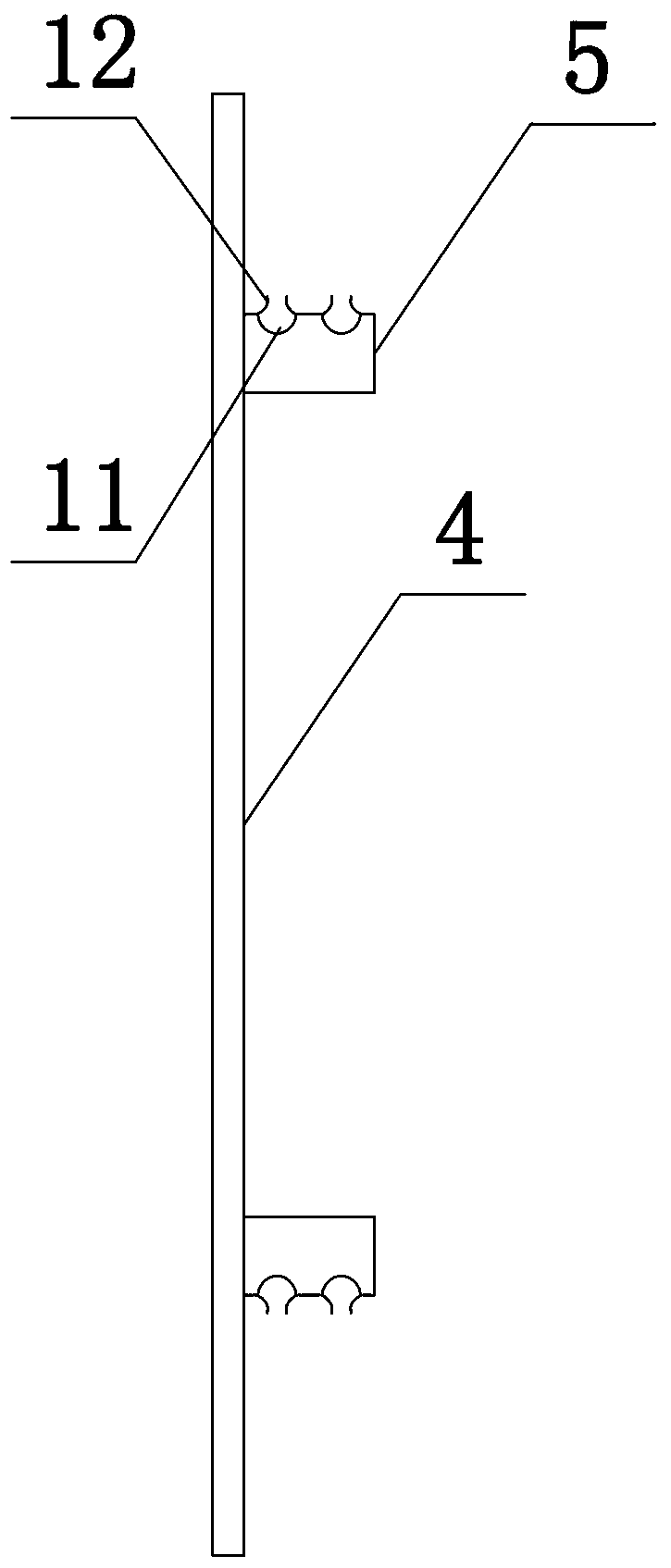

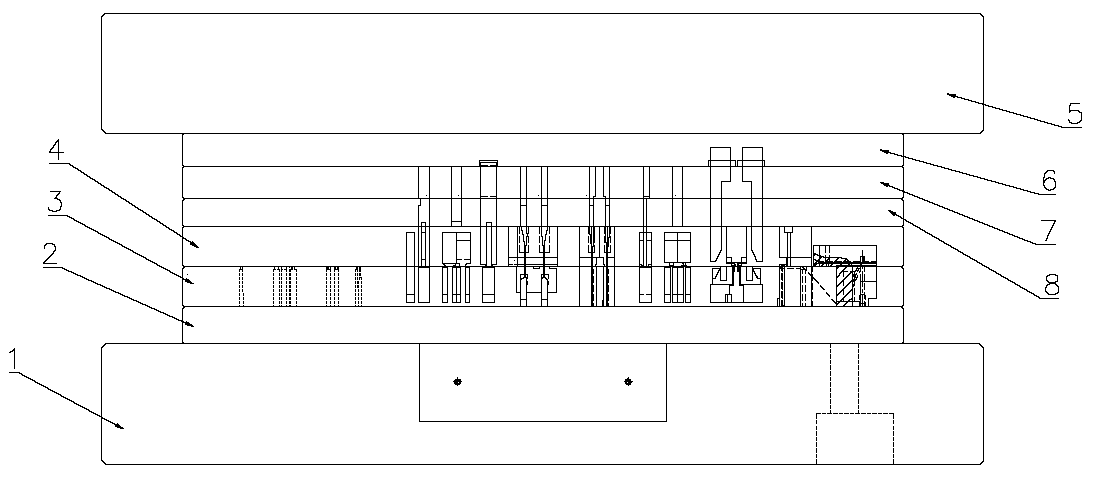

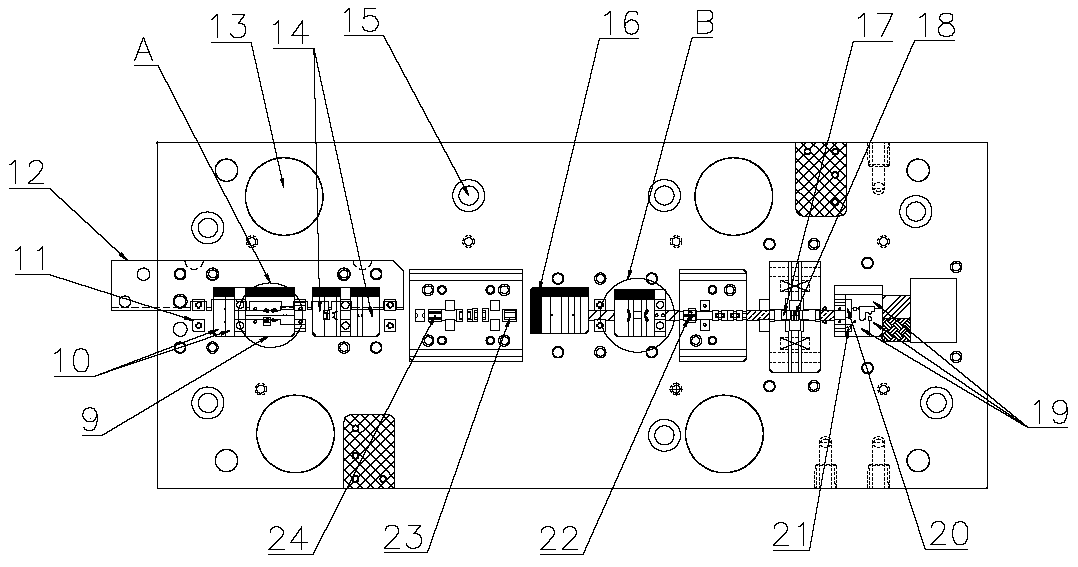

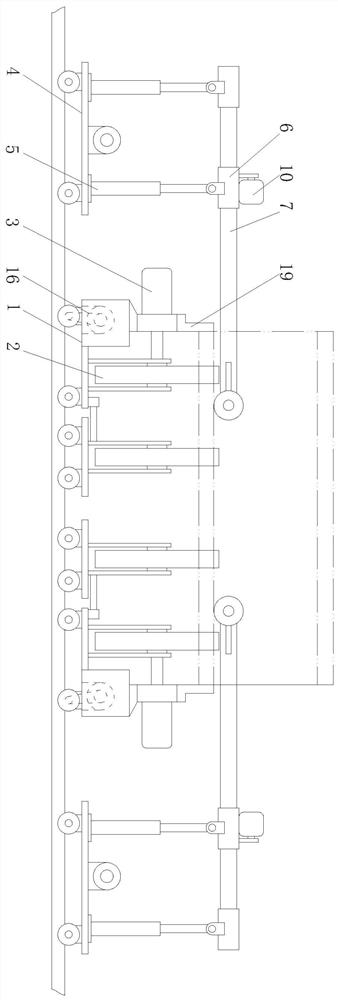

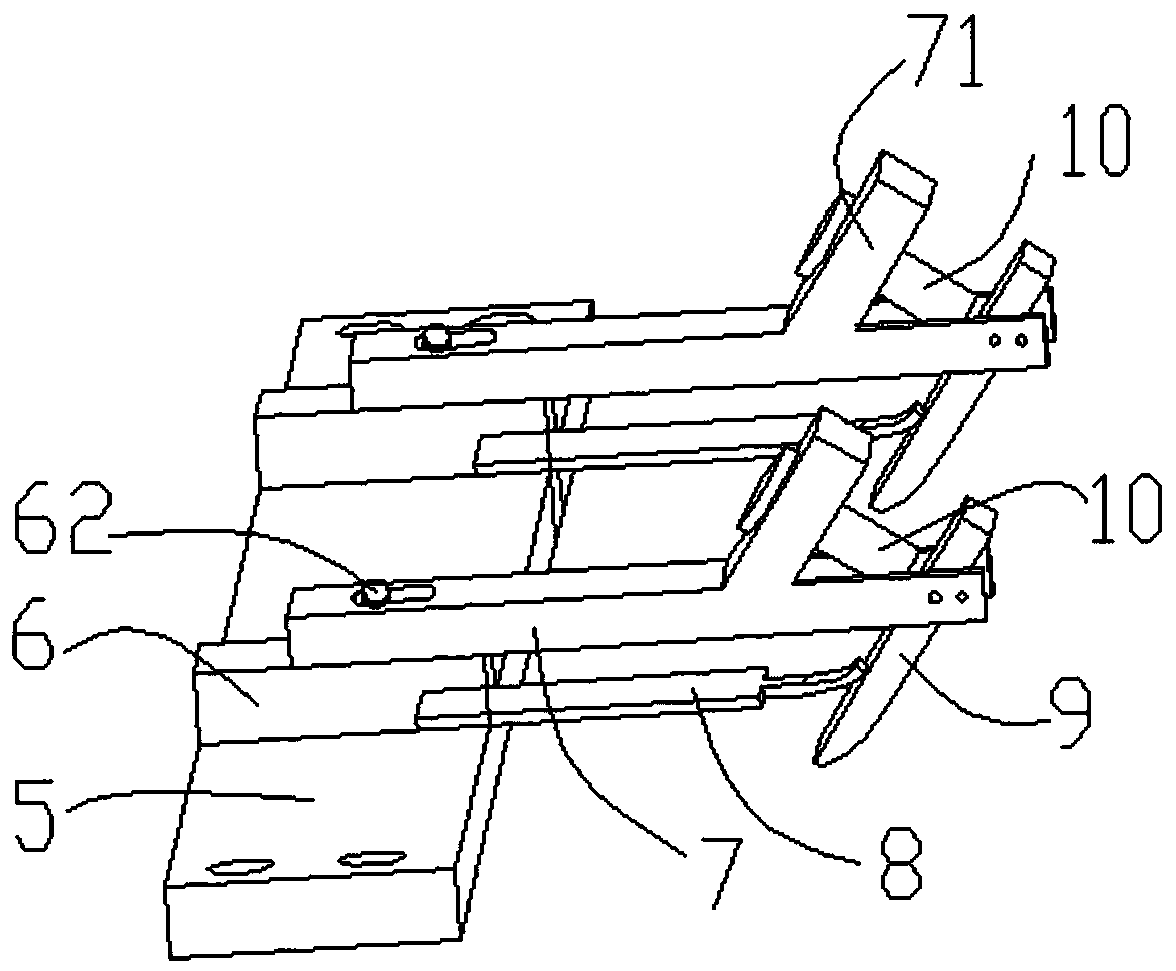

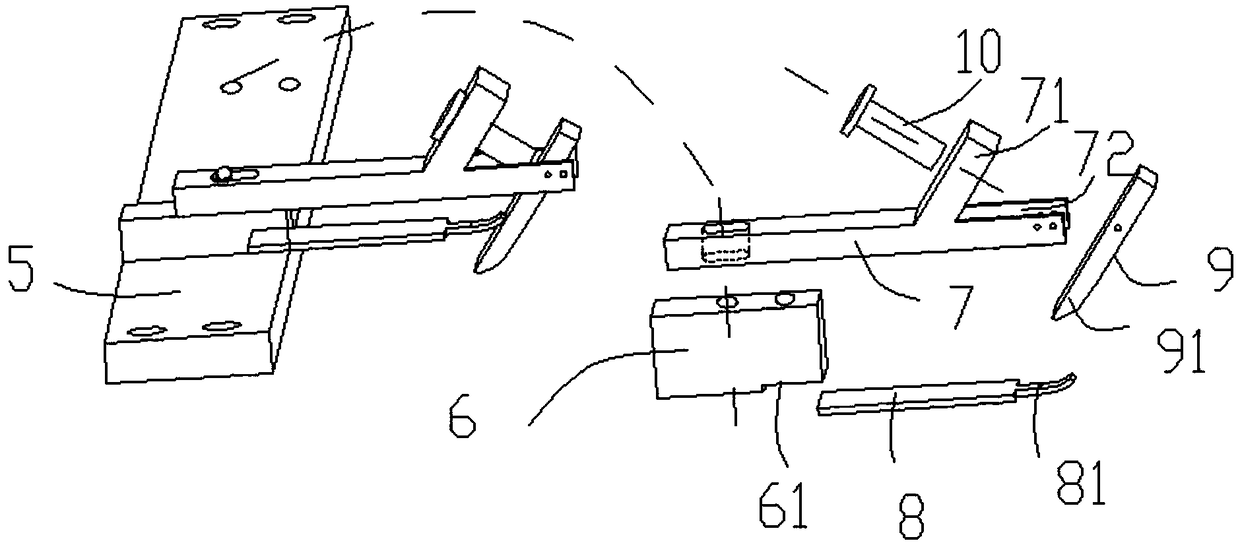

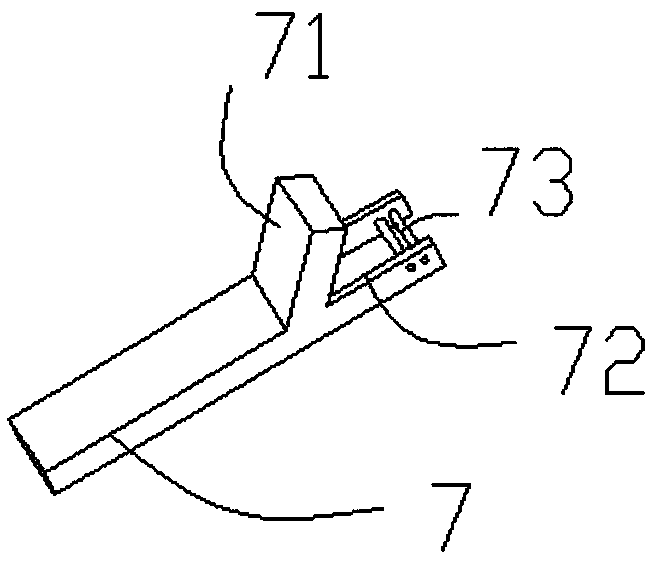

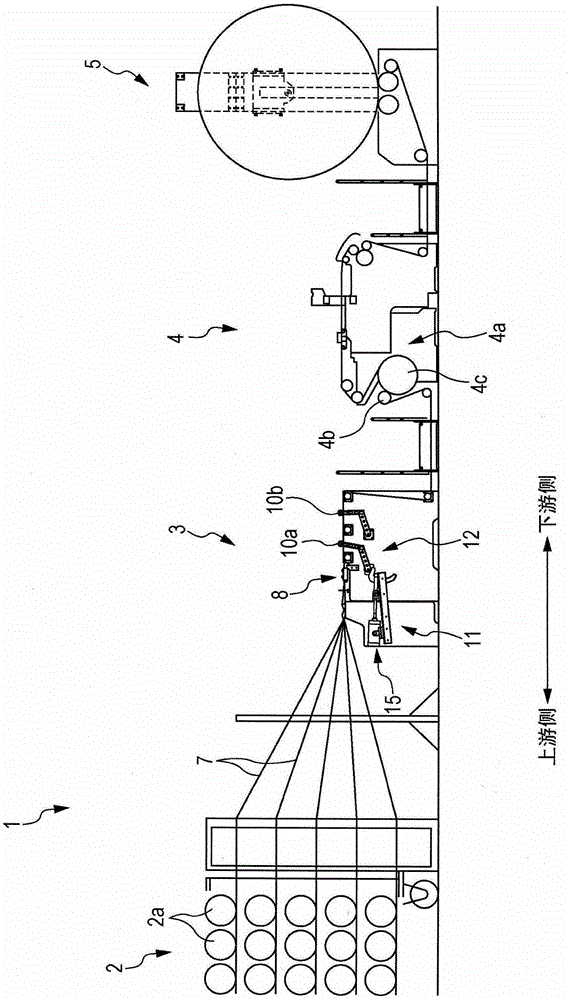

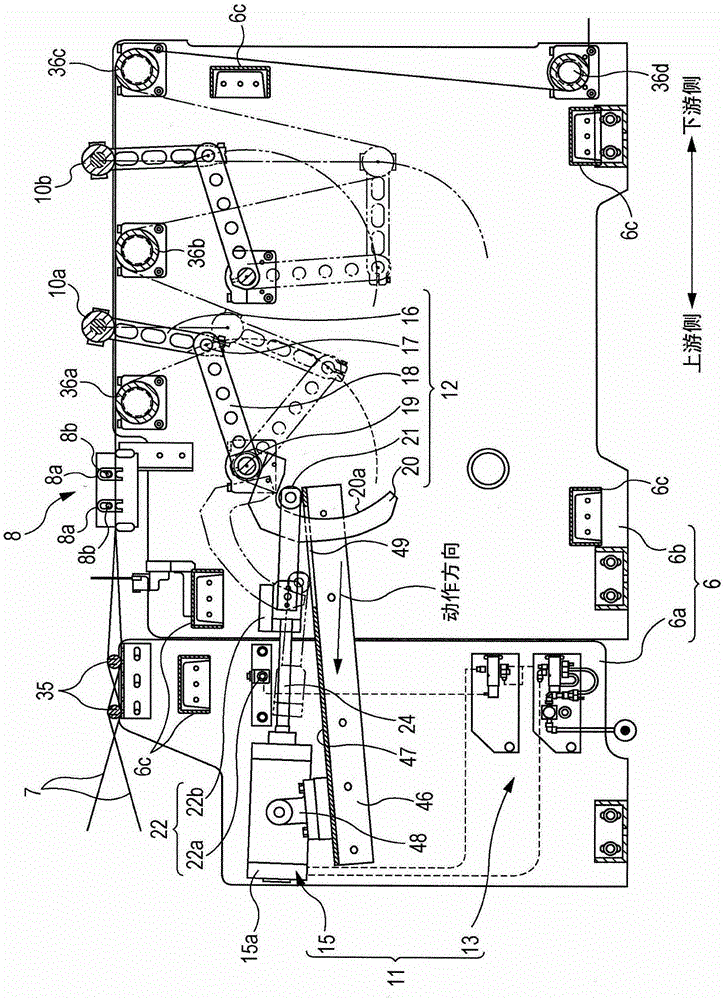

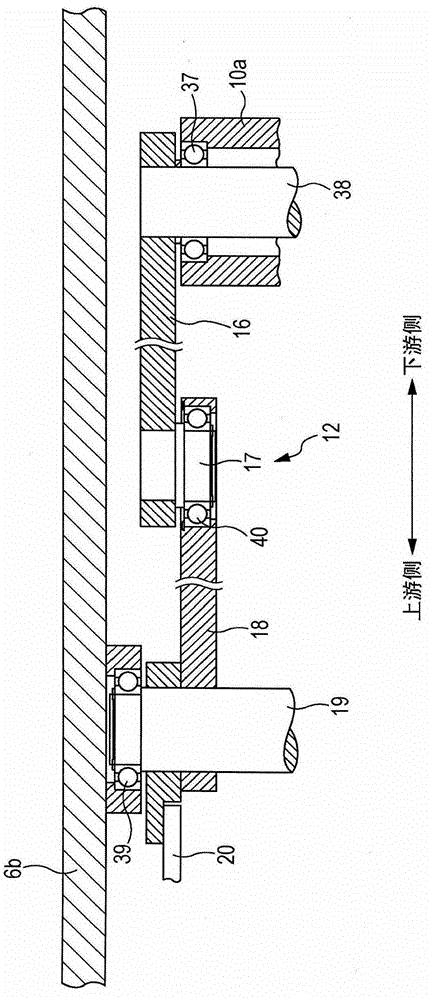

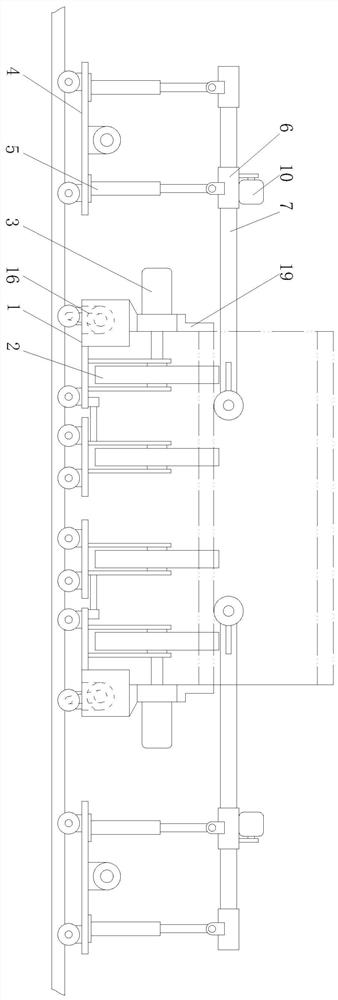

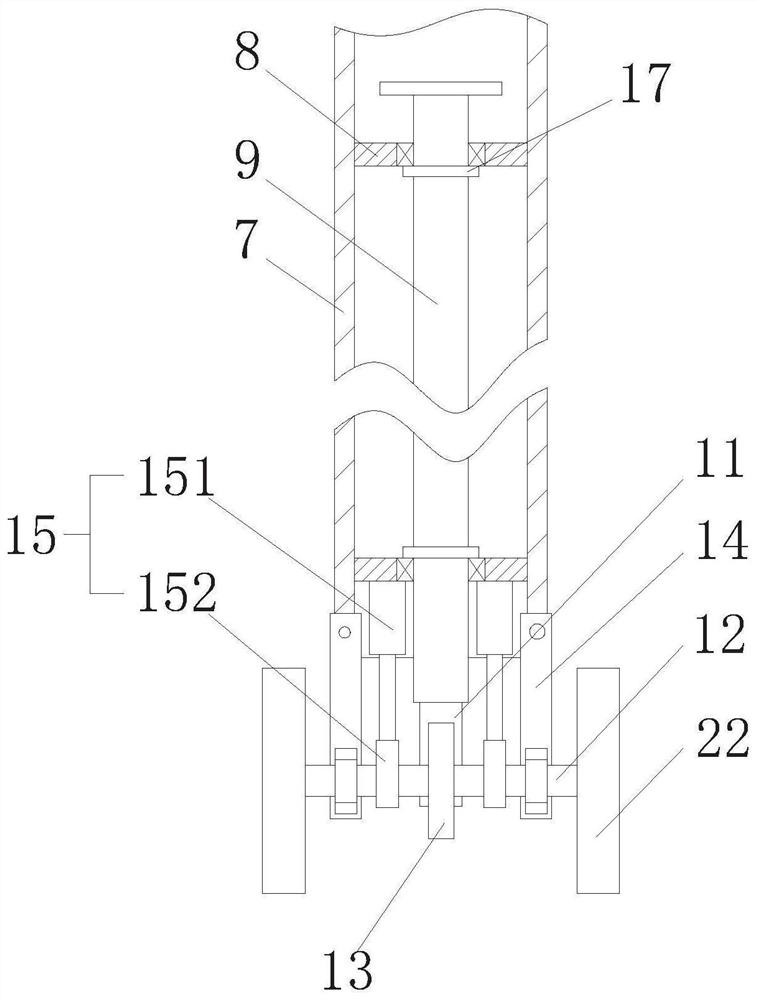

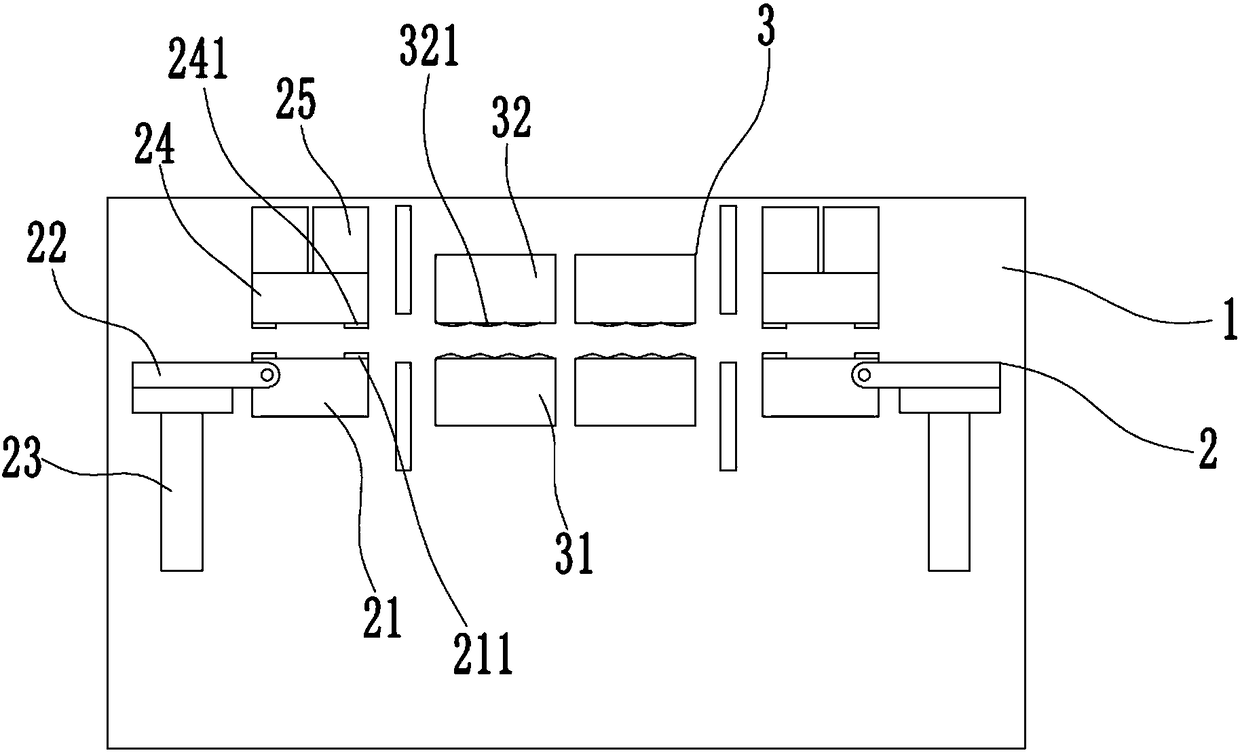

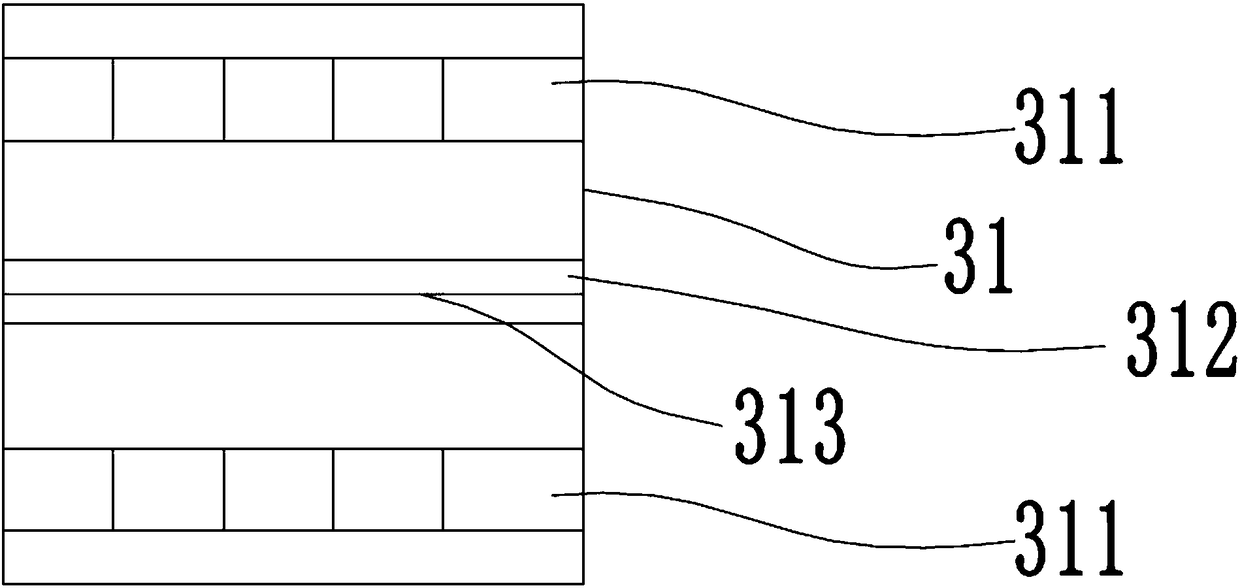

Multi-wire vertical-type internal winding machine

InactiveCN105743302APrevent crushingPrevent jumping phenomenonManufacturing dynamo-electric machinesWinding machineConductor Coil

The invention discloses a multi-wire vertical-type internal winding machine. The multi-wire vertical-type internal winding machine mainly comprises a machine frame, a tension force control mechanism installed on the machine frame and used for controlling the tension forces of enamelled wires, a vertical-type wire winding mechanism used for embedding the enamelled wires into a stator wire duct, a product rotating mechanism use for fixing a stator and driving the stator to rotate, an incoming wire guiding mechanism used for being matched with the vertical-type wire winding mechanism in the enamelled wire embedding process so as to guide the enamelled wires into the stator wire duct, a wire clamping and arranging mechanism used for limiting the positions of the enamelled wires in the stator wire duct, and a control assembly used for controlling all power sources on the internal winding machine. By adopting the multi-wire vertical-type internal winding machine, full-process automatic winding is carried out on an internal-winding stator, the winding is uniform, and the enamelled wires are prevented from being scratched in the winding process.

Owner:东莞拓蓝自动化科技有限公司

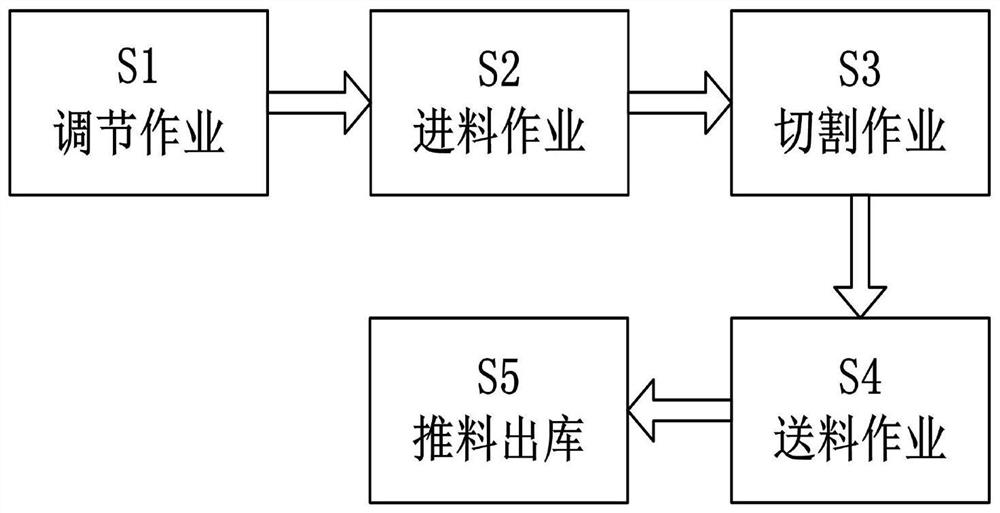

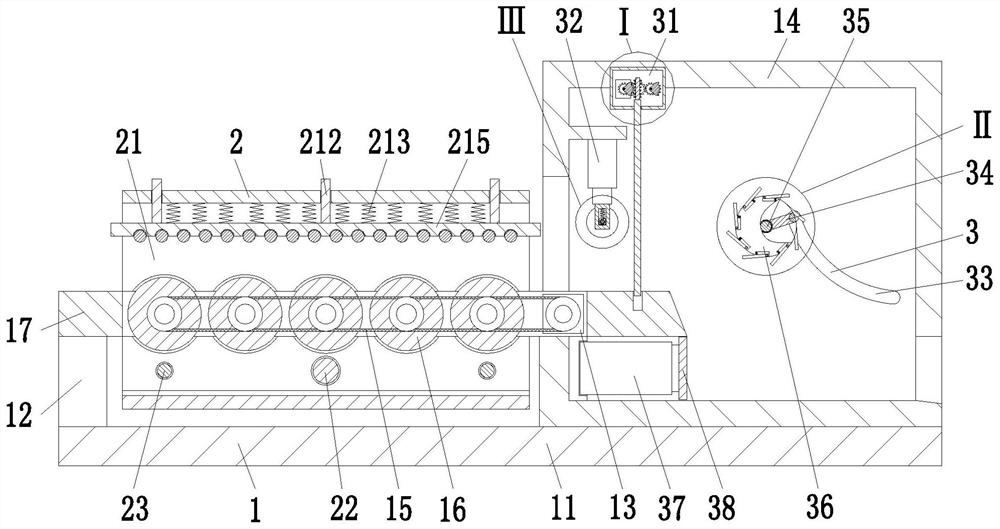

Pearl wool board manufacturing and processing technology

ActiveCN111923097AReduce shipping speedAvoid displacementMetal working apparatusProcess engineeringMachining process

The invention relates to a pearl wool board manufacturing and processing technology. The pearl wool board manufacturing and processing technology adopts cutting equipment, the cutting equipment comprises a conveying device, a fixing device and a cutting device, wherein the fixing device is installed on the upper end face of the conveying device, and the cutting device is installed on the right side of the conveying device. The pearl wool board manufacturing and processing technology can solve the problems that in the pearl wool board conveying process of existing equipment, the board cannot belimited and clamped, the conveying speed of the pearl wool board is reduced due to the small mass, the board displacement phenomenon can be generated, the subsequent machining of the board is affected, and in the pearl wool board cutting process of the existing equipment, after the pearl wool board is cut, necessary limiting measures are lacked, so that the cut pearl wool board jumps, and the pearl wool board is inconvenient to collect and store.

Owner:宁波轩祥新材料科技有限公司

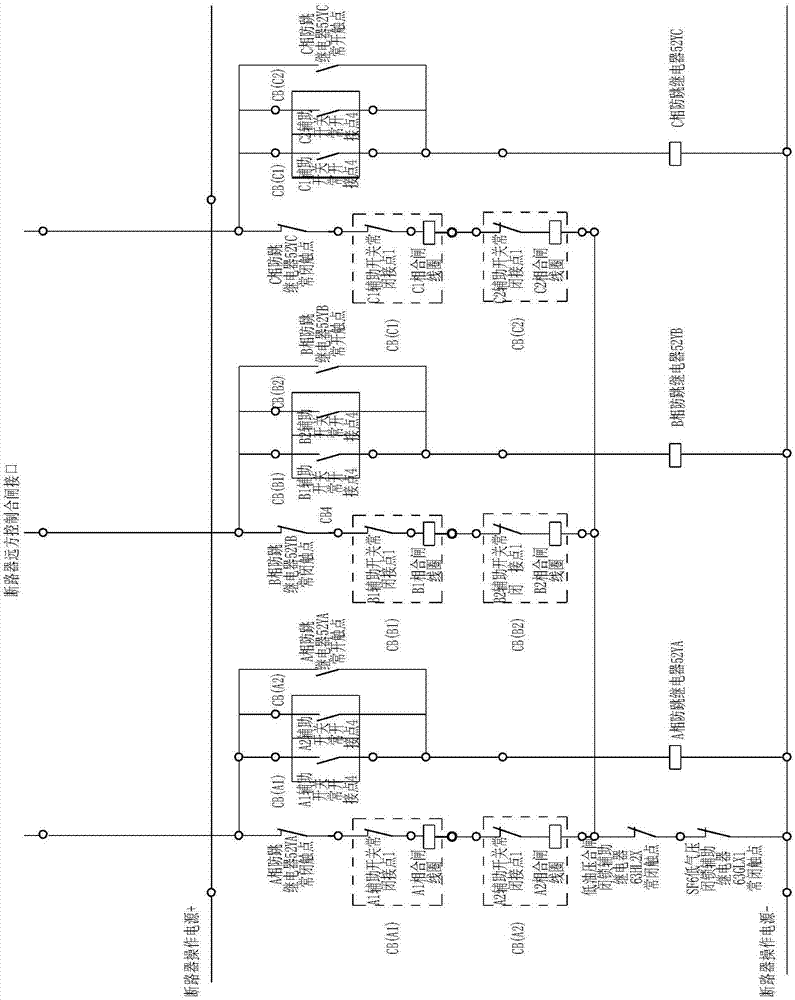

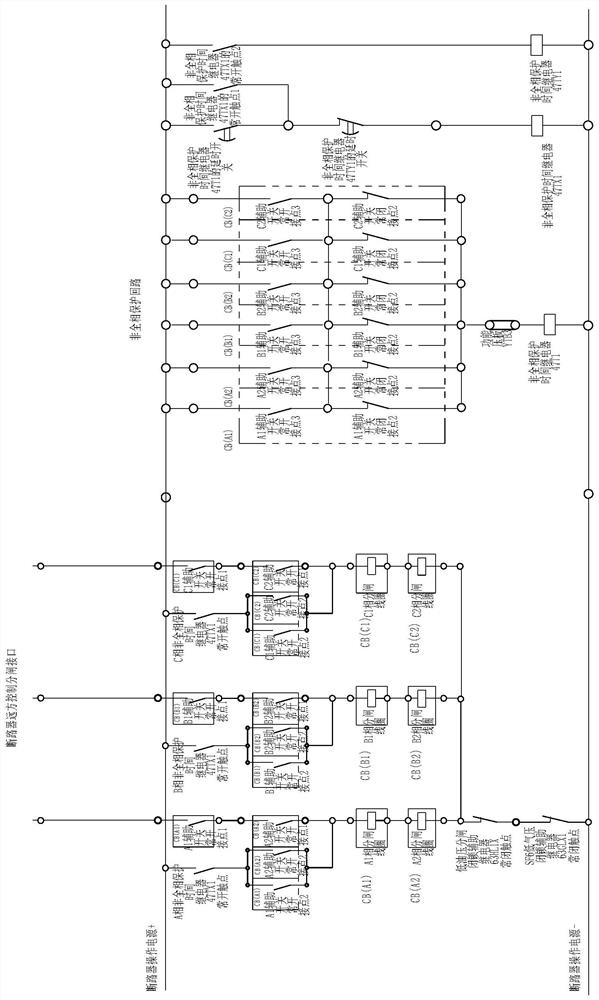

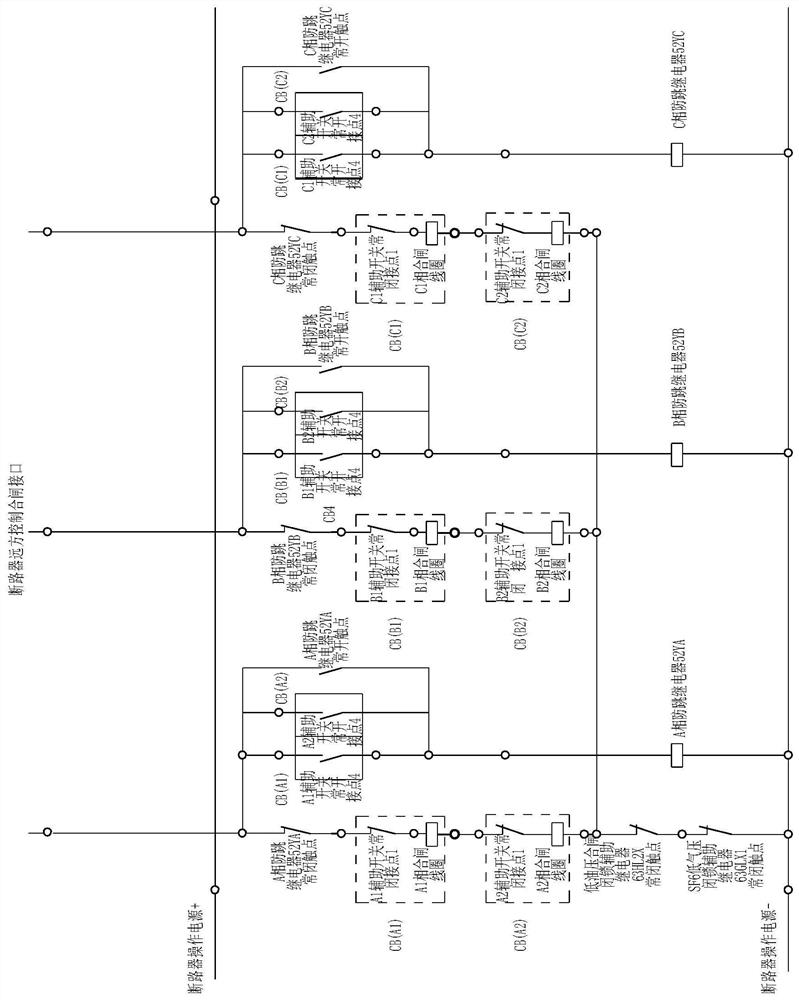

High-voltage circuit breaker secondary circuit

ActiveCN107994575APrevent jumping phenomenonGuaranteed to failElectric power transfer ac networkPhase timeEngineering

The invention provides a high-voltage circuit breaker secondary circuit. The synchronization problem between different poles and the same poles after two double-break circuit breakers are connected inseries can be solved, and functions of secondary control circuit anti-tripping and non-full-phase protection are achieved. The high-voltage circuit breaker secondary circuit includes an open circuit,a closed circuit, an anti-tripping protection circuit and a non-full-phase protection circuit. The open circuit includes parallel branches formed by A, B and C phase opening solenoid branches and being in series connection, a low oil pressure opening blocking auxiliary relay normally-closed contact and an SF6 low pressure gas blocking auxiliary relay normally-closed contact; the closed circuit includes a parallel branches formed by A, B and C phase closing solenoid branches and being in series connection, a low oil pressure closing blocking auxiliary relay normally-closed contact and an SF6 low pressure gas blocking auxiliary relay normally-closed contact; the anti-tripping protection circuit includes A, B and C phase anti-tripping circuits; and the non-full-phase protection circuit includes three branches in parallel connection, which are an auxiliary contact branch, a non-full-phase time relay 47T1 and non-full-phase time relays 47TX1 and 47TY1.

Owner:CHINA XD ELECTRIC CO LTD

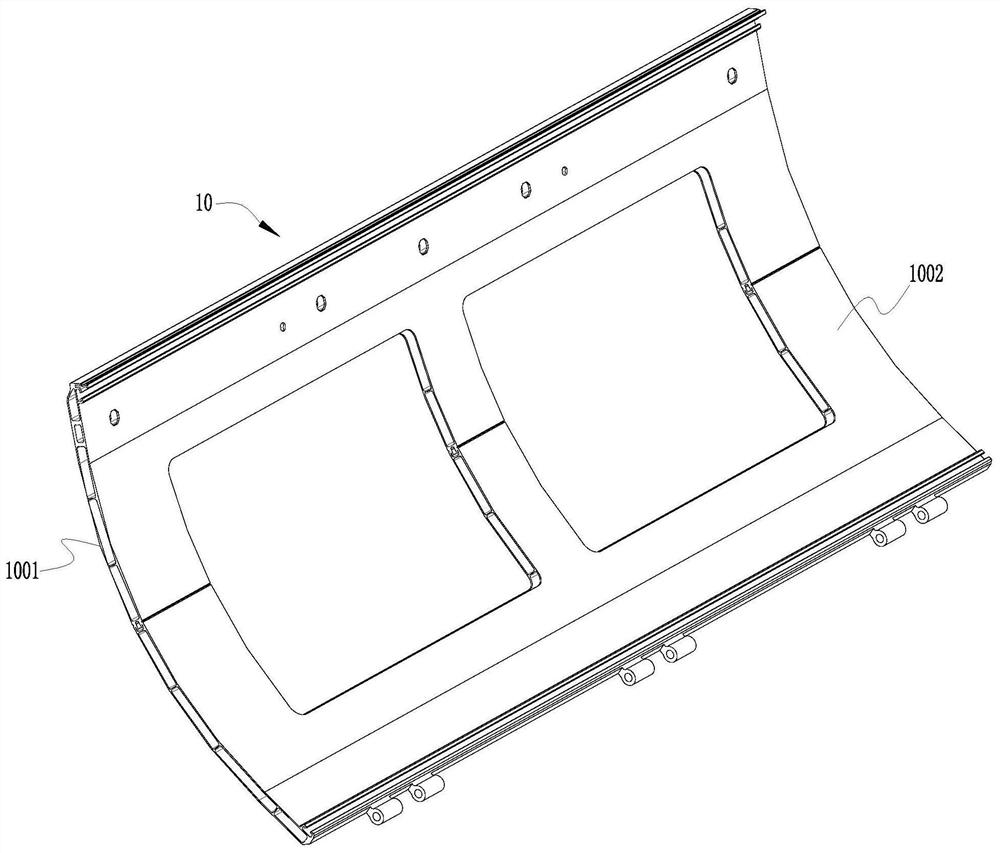

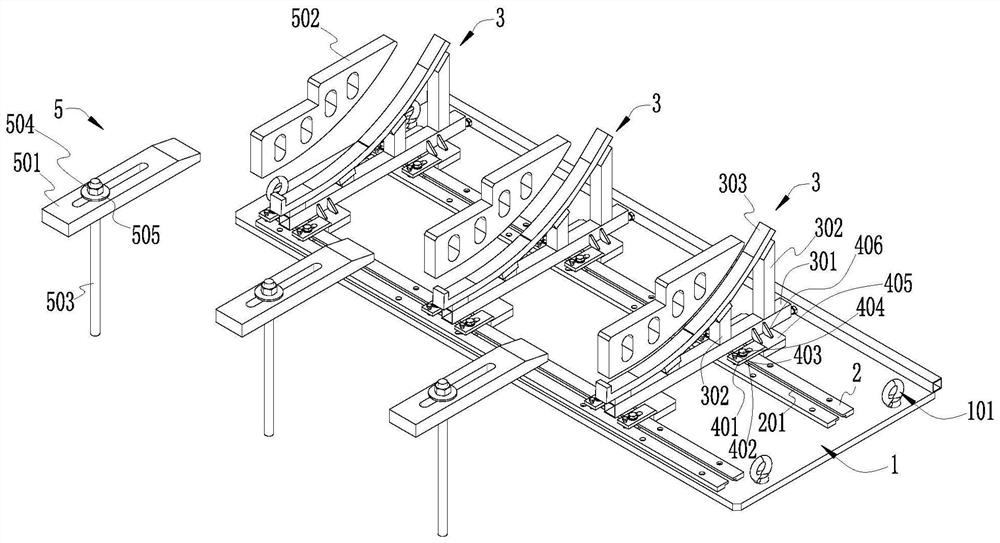

Thin wall type bogie skirtboard aluminum profile processing universal tooling

The invention discloses thin wall type bogie skirtboard aluminum profile processing universal tooling. The tooling comprises a bottom plate, a positioning strip, a bogie skirtboard outer surface supporting positioning mechanism, and a bogie skirtboard inner surface clamping positioning mechanism; the bogie skirtboard outer surface supporting positioning mechanism is provided with a first nylon cushion block; the bogie skirtboard inner surface clamping positioning mechanism is provided with a second nylon cushion block; and a positioning space of a bogie skirtboard is formed between the first nylon cushion block and the second nylon cushion block. The tooling realizes clamping positioning and fixation of the bogie skirtboard through the bogie skirtboard outer surface supporting positioningmechanism and the bogie skirtboard inner surface clamping positioning mechanism; at the same time, the first nylon cushion block and the second nylon cushion block are arranged on the bogie skirtboardouter surface supporting positioning mechanism and the bogie skirtboard inner surface clamping positioning mechanism respectively, so when tooling is in contact with the bogie skirtboard, the toolingis matched with the surface form of the bogie skirtboard and damage to the bogie skirtboard can be reduced by shock reduction effect of the nylon cushion blocks; and the product quality is improved.

Owner:CHANGCHUN RAILWAY VEHICLE FACILITIES

Method for preventing and treating bridge abutment trip by using microorganism consolidation liquid and microorganism consolidation liquid

The invention discloses a method for preventing and treating bridge abutment trip by using microorganism consolidation liquid and the microorganism consolidation liquid. Microbial flora powder, treatment powder and water are adopted; the microbial flora powder is obtained by drying a bacterial enzyme solution; the treatment powder is obtained by drying inorganic cementing liquid treatment liquid;the bacterial enzyme solution is obtained by adding aerobic bacterial liquid subjected to enrichment culture into a buffer solution and performing ultrasonic crushing; the mass ratio of the microbialflora powder to the treatment powder is (1: 10) to (1: 20); and the mass of the water is 5 to 10 times that of the treatment powder. The method comprises the following steps: delivering the microbialflora powder to the site, mixing and stirring the microbial flora powder with the treatment powder, and adding the water to obtain the microorganism consolidation liquid; and performing consolidationtreatment on bridge abutment soil and bridge back soil for multiple times by using the microorganism consolidation liquid. According to the method, by use of cementation generated by microorganism consolidation, the strength and the rigidity of backfilling soil of the bridge back are greatly improved, so that non-uniform settling is avoided, and occurrence of the bridge abutment trip can be effectively prevented.

Owner:HOHAI UNIV

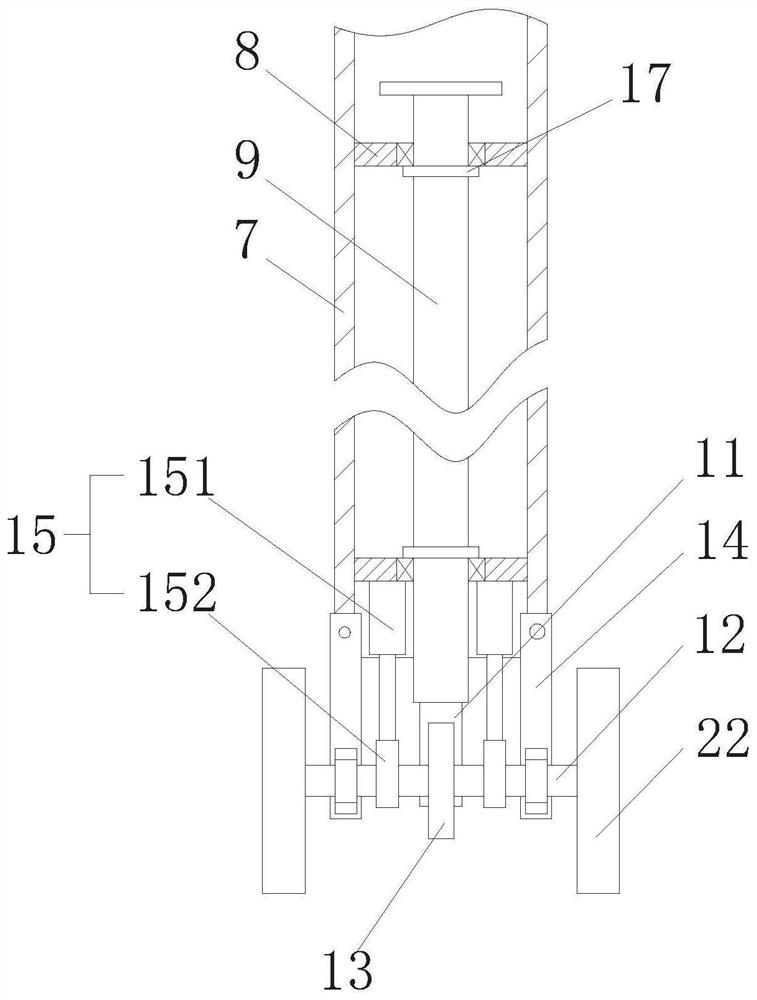

Rotary encoder fixing device

InactiveCN110748775AGuaranteed accuracyEasy to installStands/trestlesConverting sensor output opticallyComputer hardwareEngineering

The invention belongs to the technical field of rotary encoder mounting, and discloses a rotary encoder fixing device. The rotary encoder fixing device comprises a rotary encoder, a mechanical deviceand a fixing device main body, wherein the rotary encoder comprises an encoder main machine and an encoder shaft; the mechanical device comprises a mechanical main machine and a mechanical shaft; thefixing device main body comprises a matching assembly and a coaxial positioning assembly which are coaxially connected, wherein the matching assembly and the encoder shaft are coaxially mounted, the encoder shaft penetrates through the matching assembly and extends into the coaxial positioning assembly, the coaxial positioning assembly and the mechanical shaft are coaxially mounted, and the mechanical shaft extends into the coaxial positioning assembly and is connected with the encoder shaft. In conclusion, coaxial limiting connection can be effectively formed between the rotary encoder and the mechanical shaft of the mechanical device, so that the mounting accuracy of the rotary encoder is guaranteed, and in addition, the overall structure also has the advantage of being simple and convenient to operate.

Owner:扬州鑫三维精密机械有限公司

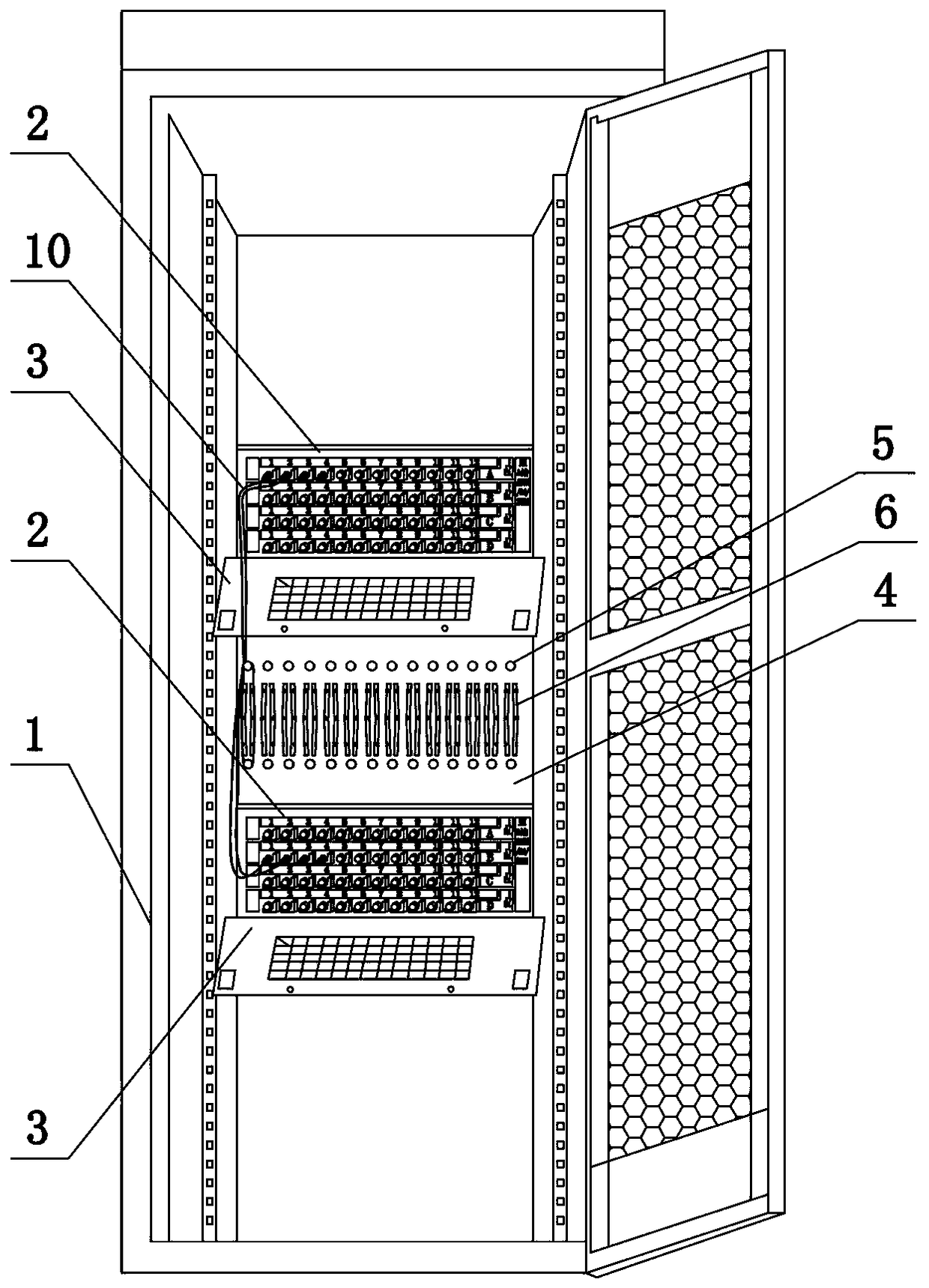

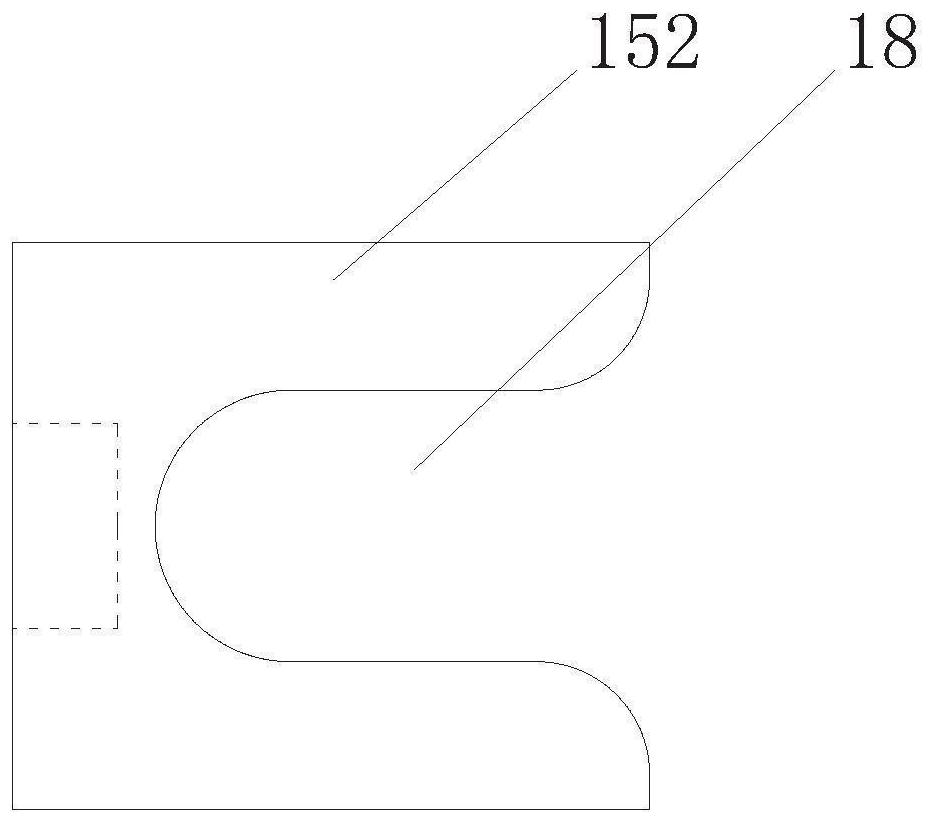

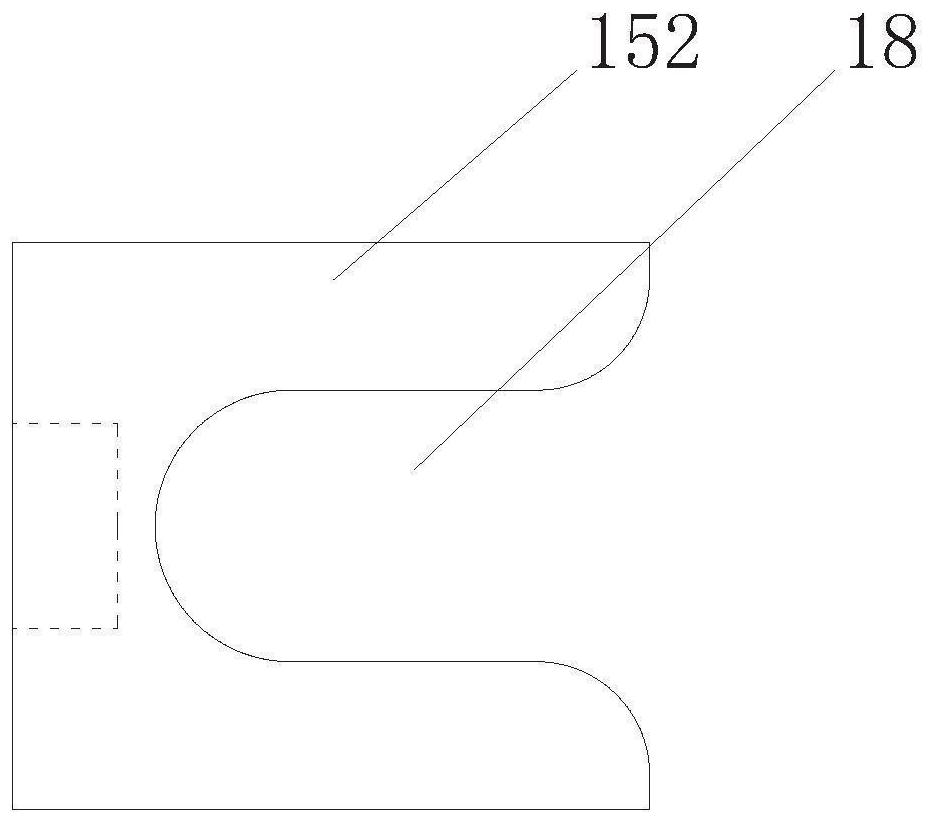

Optical fiber distribution cabinet

ActiveCN109116498AEasy and reasonable windingEasy to troubleshootFibre mechanical structuresDistribution frameSpecial design

The invention belongs to the technical field of communication equipment, in particular to an optical fiber distribution cabinet. The cabinet comprises a cabinet body and a plurality of distribution frames in the cabinet body. A winding mechanism is disposed between the adjacent distribution frames. Each winding mechanism comprises a winding plate, a plurality of winding posts on the winding plate,a plurality of wire sorting grooves disposed on the winding plate, wherein the winding posts are arranged in two rows and multiple columns, and the wire sorting grooves are located between two columns of winding posts. Through the special design of the winding mechanisms, each two winding posts arranged at the top and bottom are set as one group, and the same group of optical fibers are wound around the same group of winding posts, thereby facilitating the reasonable winding of the remaining optical fibers, facilitating the fault inspection, greatly improving the searching speed, and shortening the fault processing time.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

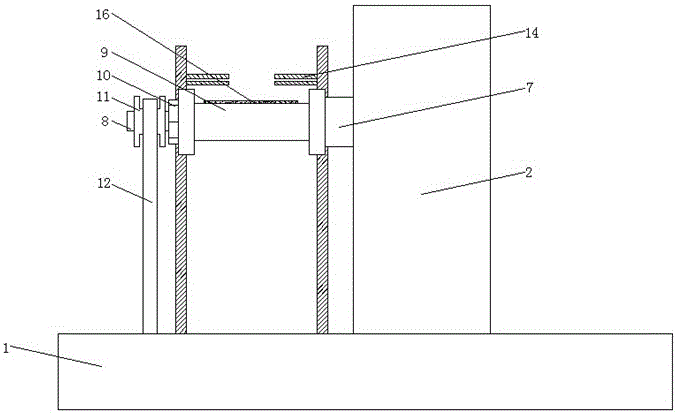

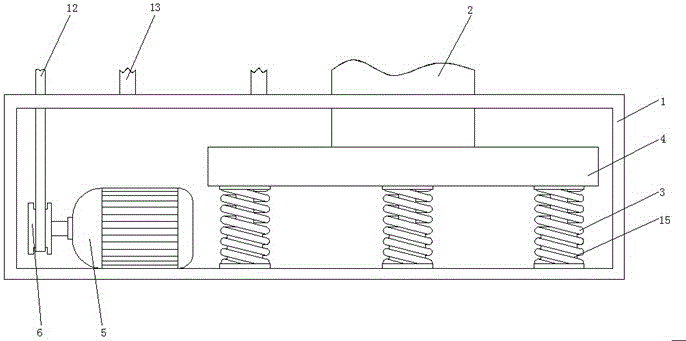

Kraft paper protective film winding device

The invention discloses a kraft paper protective film winding device. The kraft paper protective film winding device comprises a base and a supporting plate, the base is of a hollow structure, damping springs are fixedly connected to the bottom of an inner cavity of the base, the top ends of the damping springs are fixedly connected with the lower surface of a balance plate, the bottom end of the supporting plate penetrates through the upper surface of the base and is fixedly connected to the upper surface of the balance plate, a motor is fixedly connected to the left side of the bottom face of the inner cavity of the base, and an output shaft of the motor is fixedly connected with a driving wheel. An adhesive strip, supporting rods and clamping bars are arranged on the kraft paper protective film winding device, a protective film is laid on and adheres to the adhesive strip through the adhesive strip and is prevented from wrinkling or being rolled, by means of the clamping bars, the protective film penetrates through the two clamping bars and is fixed to a reel, in the winding process, as the clamping bars are arranged on the oblique upper portion of the reel, the protective film can be kept flat, the cylindrical clamping bars can prevent the protective film from being abraded, and the effect of keeping the protective film flat in the winding process is achieved.

Owner:无锡祁龙胶粘制品有限公司

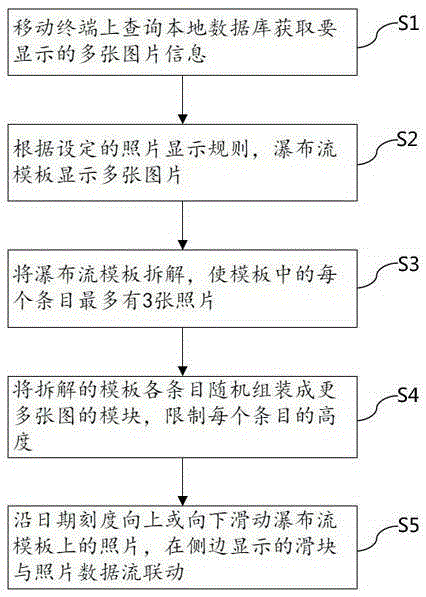

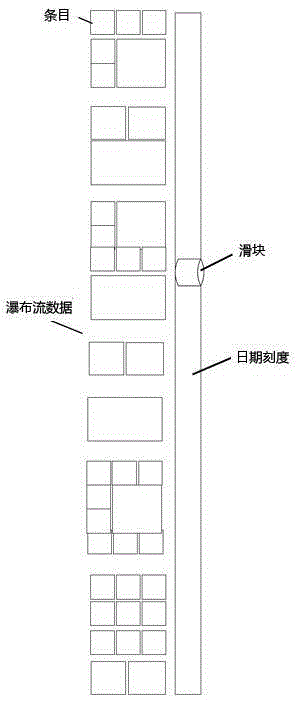

Method for solving sliding block jump of mobile terminal

InactiveCN105549926AEasy to findAvoid slider jumpingSpecial data processing applicationsDigital output to display deviceComputer scienceComputer terminal

The invention provides a method for solving sliding block jump of a mobile terminal. The method comprises the following steps: inquiring a local database on the mobile terminal and acquiring information of a plurality of pictures to be displayed; according to a set picture display rule, displaying the plurality of pictures by a waterfall flow template; dismantling the waterfall flow template, and making various entries in the template to have at most 3 pictures; and assembling various entries of the dismantled template into a module with more pictures at random, and limiting the height of each entry. Pictures on the waterfall flow template are slid up or down, and a sliding block displayed at a side is linked with a picture data flow. The method for solving the sliding block jump of the mobile terminal provided by the invention has the following beneficial effects that the sliding block is displayed at the side and linked with the data flow, thus specific pictures can be found more conveniently and the phenomenon of sliding block jump can be effectively avoided; besides, in combination with a technology of stopping sliding and loading pictures, better effects of fast loading, less memory consumption, smooth sliding and so on can be achieved.

Owner:MEIBEIKE TECH CO LTD

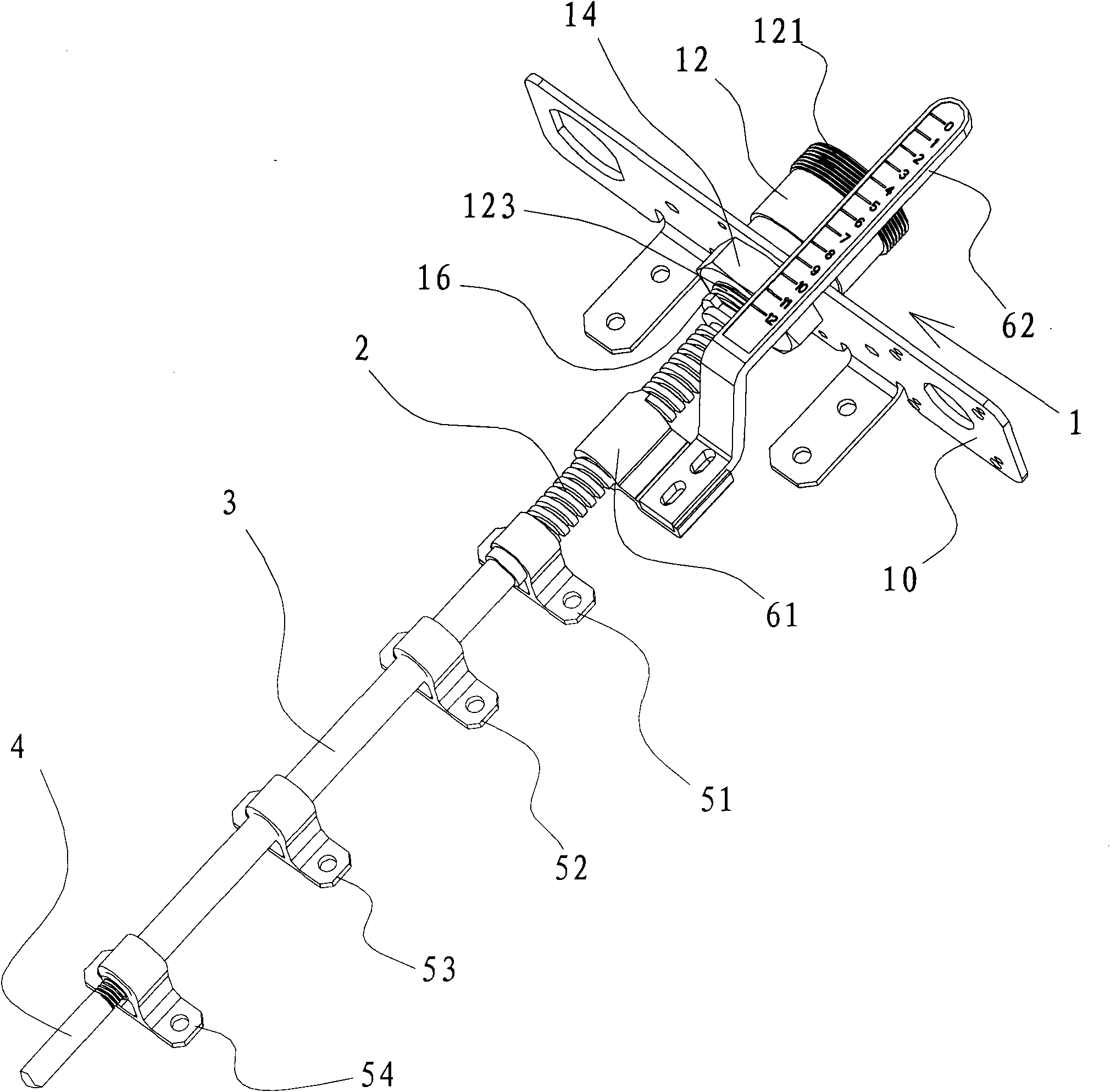

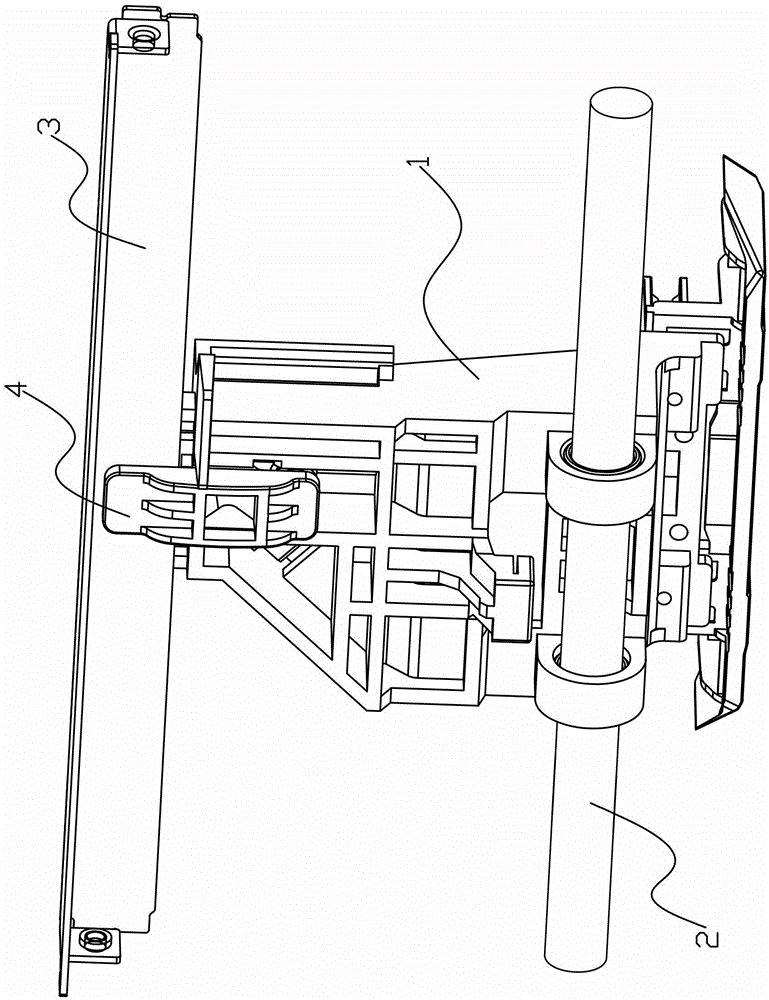

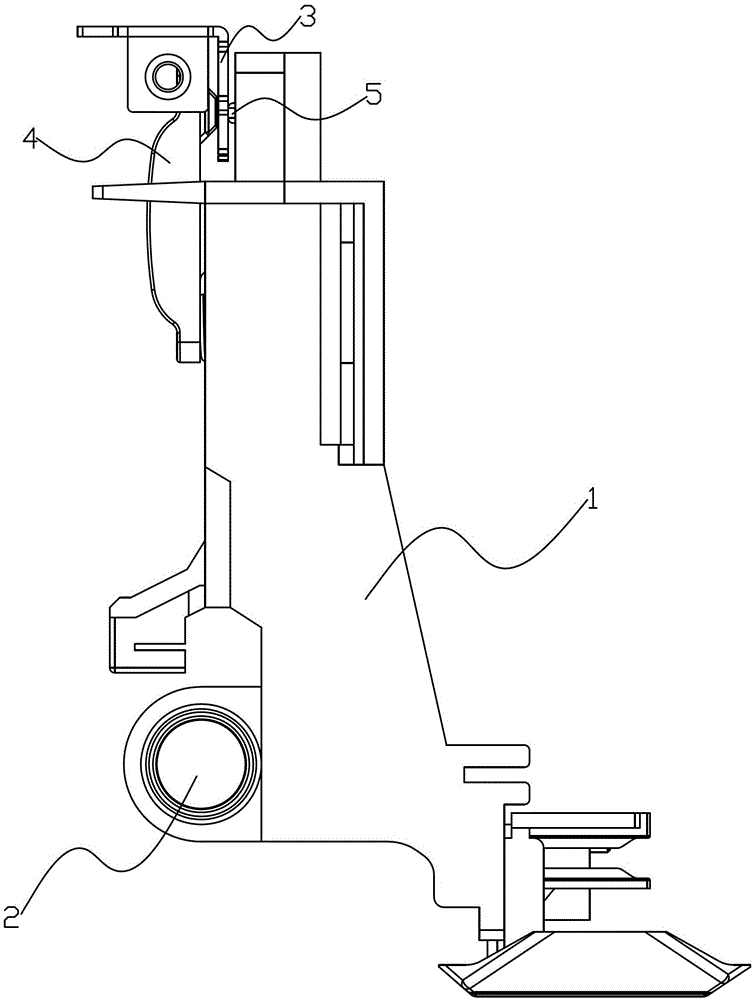

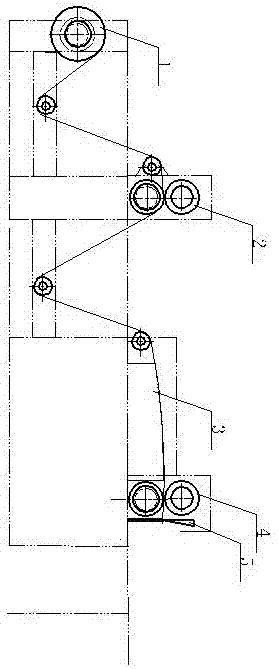

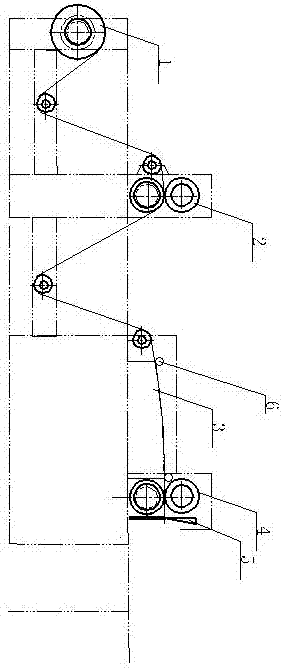

A guiding mechanism for the horizontal movement of the printing carriage

ActiveCN103101333BTorque stabilizationPrecise positioningPower drive mechanismsEngineeringMechanical engineering

The invention discloses a guide mechanism of horizontal moving of a carriage unit of a printer. The guide mechanism comprises a carriage unit frame, wherein a guide shaft is installed on the lower portion of the carriage unit frame in a movable and penetrating mode, a guide rail which is parallel with the guide shaft is arranged above the guide shaft, a locking clip and a guide wheel which are respectively located on the front side and the rear side of the guide rail are arranged on the upper portion of the carriage unit frame, the middle of the locking clip is hinged with the carriage unit frame, and a spring which is used for enabling the locking clip to rotate around the hinged position and be pressed towards the guide wheel. The locking clip exerts force which enables the lower portion of the locking clip to be far from the carriage unit frame on the lower portion of the spring, wherein the spring is located between the carriage unit frame and the lower portion of the locking clip, and the middle of the locking clip is hinged on the carriage unit frame. According to a lever principle, the upper portion of the locking clip rotates around the hinged position and is pressed towards the guide wheel, and accordingly the guide wheel and the locking clip are enabled to tightly clamp the guide rail between the guide wheel and the locking clip, the situation that the carriage unit is closely attached to the guide rail is ensured in the horizontal moving process of the carriage unit, and the mechanism is conductive to improvement of printing quality of the printer.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

Non-setting adhesive cutter

InactiveCN106914942APrevent jumping phenomenonSolve the cutting edgeMetal working apparatusAdhesiveEngineering

Provided is a non-setting adhesive cutter, comprising a material placing shaft, a front draw roll used to drag non-setting adhesive, an arc material supporting platform, a rear draw roll used to drag non-setting adhesive, and a cutting knife used to cut the non-setting adhesive. The upper surface of the arc material supporting platform is an arc curved surface, an angle between the upper surface and a horizontal line being 10 DEG.

Die for processing movable piece and production method for die

PendingCN110064701APrevent jumping phenomenonGuaranteed accuracyShaping toolsWaste materialIndustrial engineering

The invention provides a die for processing a movable piece and further provides a production method for the die. By the adoption of the die and the production method, the precision of continuous processing can be ensured, the phenomenon of scrap jumping up can be effectively prevented, and the quality of products can be improved. The die comprises an upper die base and a lower die base. An upperdie backing plate, an upper die plate, a discharging back plate, a discharging plate, a lower die plate and a lower die backing plate are sequentially arranged between the upper die base and the lowerdie base. Embedding holes with different sizes are formed in the lower die plate in the strip length direction. Female die inserts are detachably arranged in the embedding holes. The female die inserts are adapted to a processing part of the movable piece in shape and size, and a cutting edge is arranged on each female die insert. A chute for preventing material jumping in the edge line of the cutting edge is formed in the inner wall of each female die insert. A male die on the upper die plate corresponds to each female die insert.

Owner:无锡派尔福精密模具有限公司

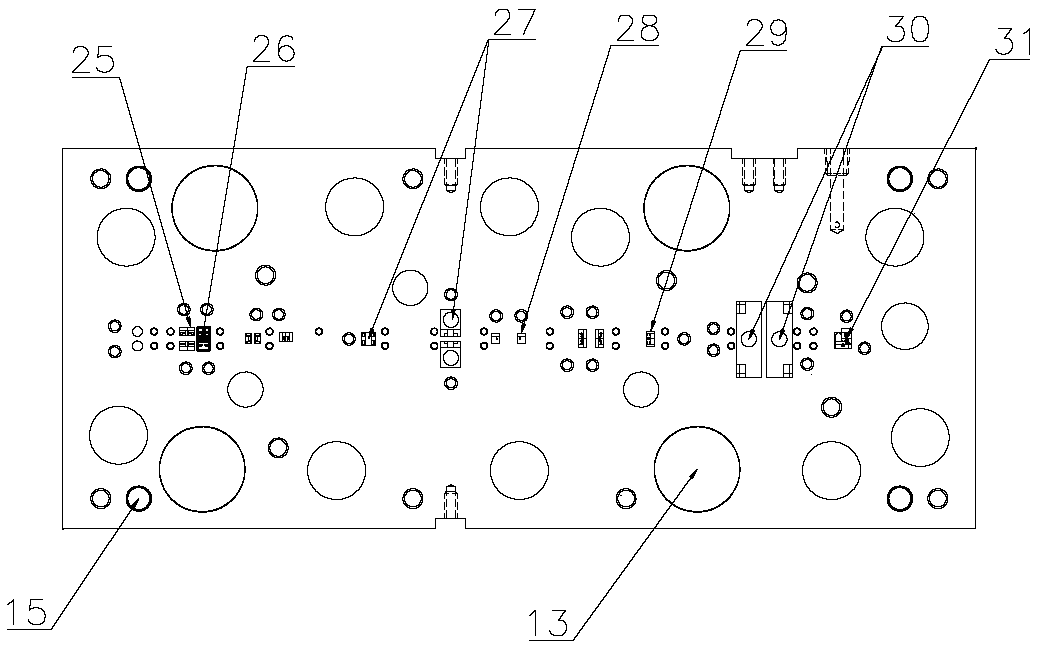

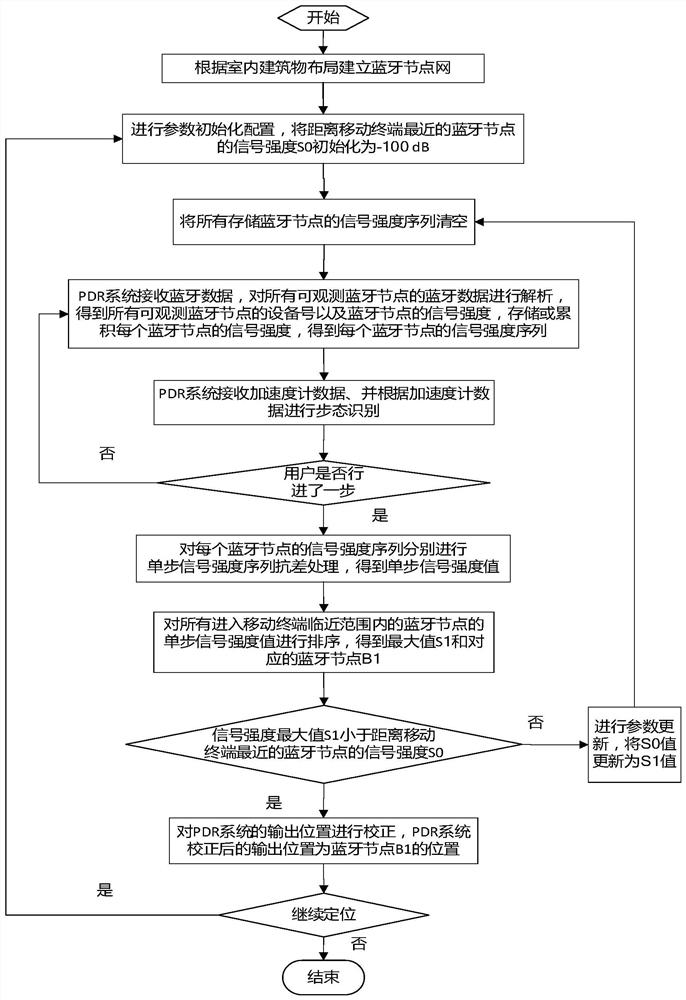

Positioning correction method based on Bluetooth signal single-step robust filtering and approximation discrimination

ActiveCN112135345ASolve the problem of large calibration errorsReduce calibration errorPosition fixationShort range communication serviceAccelerometer dataEngineering

The invention relates to the field of indoor positioning, and discloses a positioning correction method based on Bluetooth signal single-step robust filtering and approximation discrimination. The method comprises the steps of: building a Bluetooth node network; carrying out parameter initialization configuration; performing gait recognition according to the accelerometer data; dividing and analyzing Bluetooth signal data according to a single-step time period to obtain a Bluetooth node single-step signal intensity sequence; performing single-step signal intensity sequence robust processing onthe signal intensity sequence; respectively comparing the robust single-step signal intensity values with a signal intensity identification threshold value; sorting the single-step signal intensity values of observable Bluetooth nodes, and carrying out approximation judgment on the maximum signal intensity value; and carrying out proximity correction. According to the method, robust processing iscarried out on the signal intensity sequence of the observable Bluetooth node obtained in each step through a single-step robust filtering method, the gross error influence in the signal intensity value is reduced, large-amplitude jitter is eliminated, the problems of frequent error correction and track transfer are avoided, and the pedestrian walking positioning correction precision and reliability are improved.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

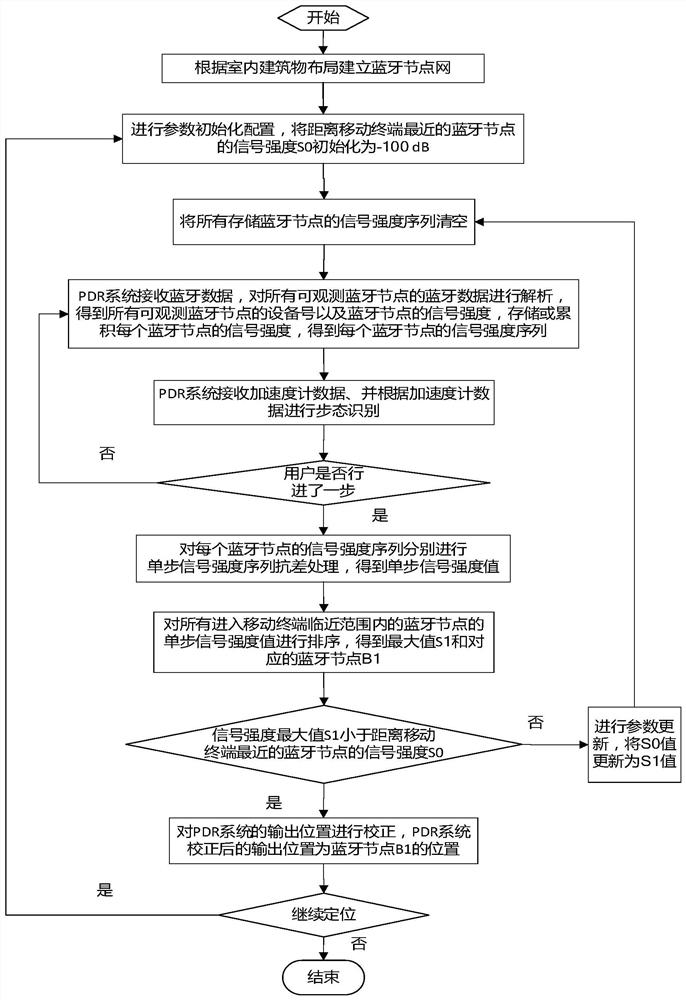

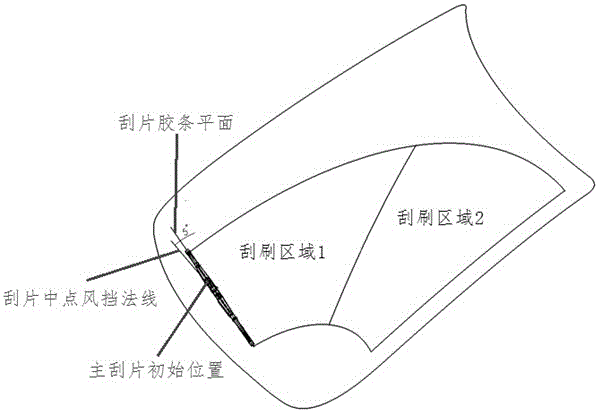

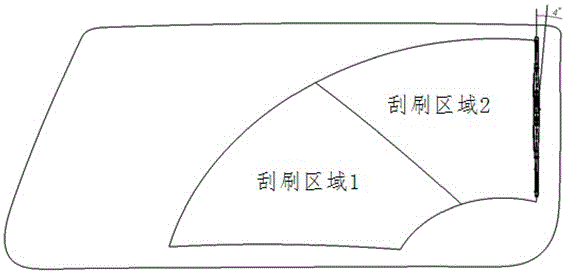

Automotive wiper system capable of automatically adjusting attack angle and wiping method thereof

The invention relates to an automotive wiper system capable of automatically adjusting an attack angle and a wiping method thereof. The automotive wiper system comprises an automotive wiper motor connecting rod structure, a wiper arm, a wiper blade and a controller; the automotive wiper motor connecting rod structure consists of a motor connecting rod assembly, a main output shaft and an auxiliary output shaft, wherein the main output shaft and the auxiliary output shaft are respectively arranged at the two ends of the motor connecting rod assembly. The automotive wiper system is characterized in that the wiper arm consists of an arm seat, an arm plate, a wiping rod, an output shaft, a motor and a spring, wherein the arm seat is hinged to the main output shaft and the auxiliary output shaft; the arm plate is hinged to the other end of the arm seat; the wiping rod is arranged at the other end of the arm plate; the output shaft arranged on the inner side of the arm plate; the motor is connected with the end part of the wiping rod; the spring is connected between the arm seat and the motor; a main angle sensor and an auxiliary angle sensor are respectively arranged at the end parts of the main output shaft and the auxiliary output shaft. The automotive wiper system is simple in structure design and reliable to use, and fundamentally solves the problem that a wiper blade rubber strip of an existing wiper reversely wipes on a windscreen, thereby being good in wiping effect and ensuring safety in driving.

Owner:BRILLIANCE AUTO

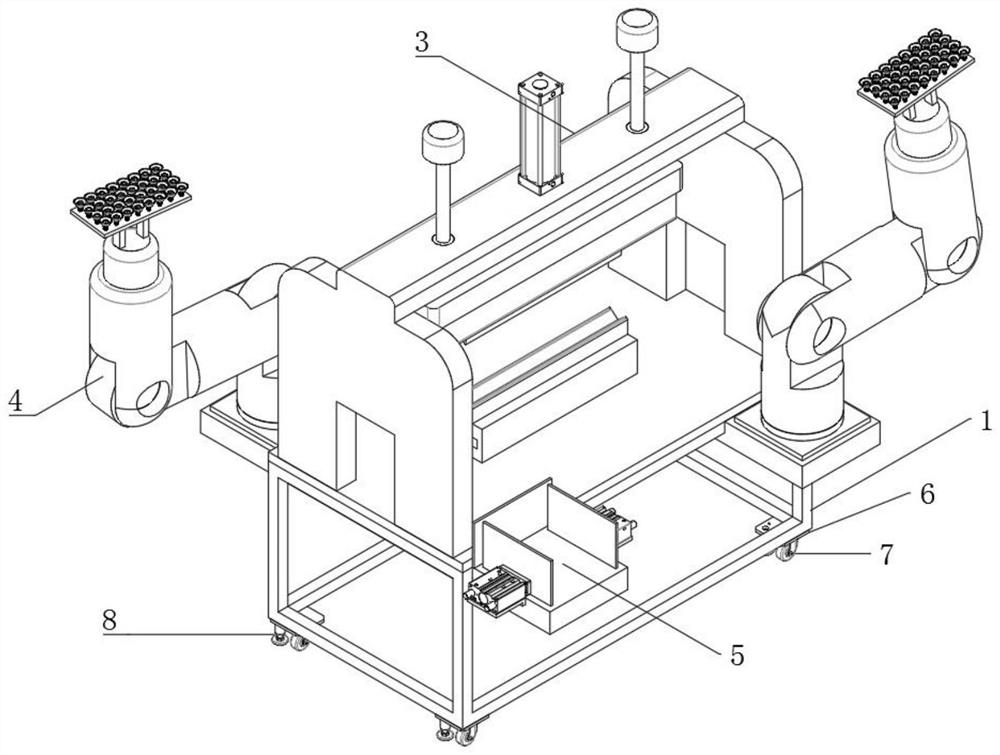

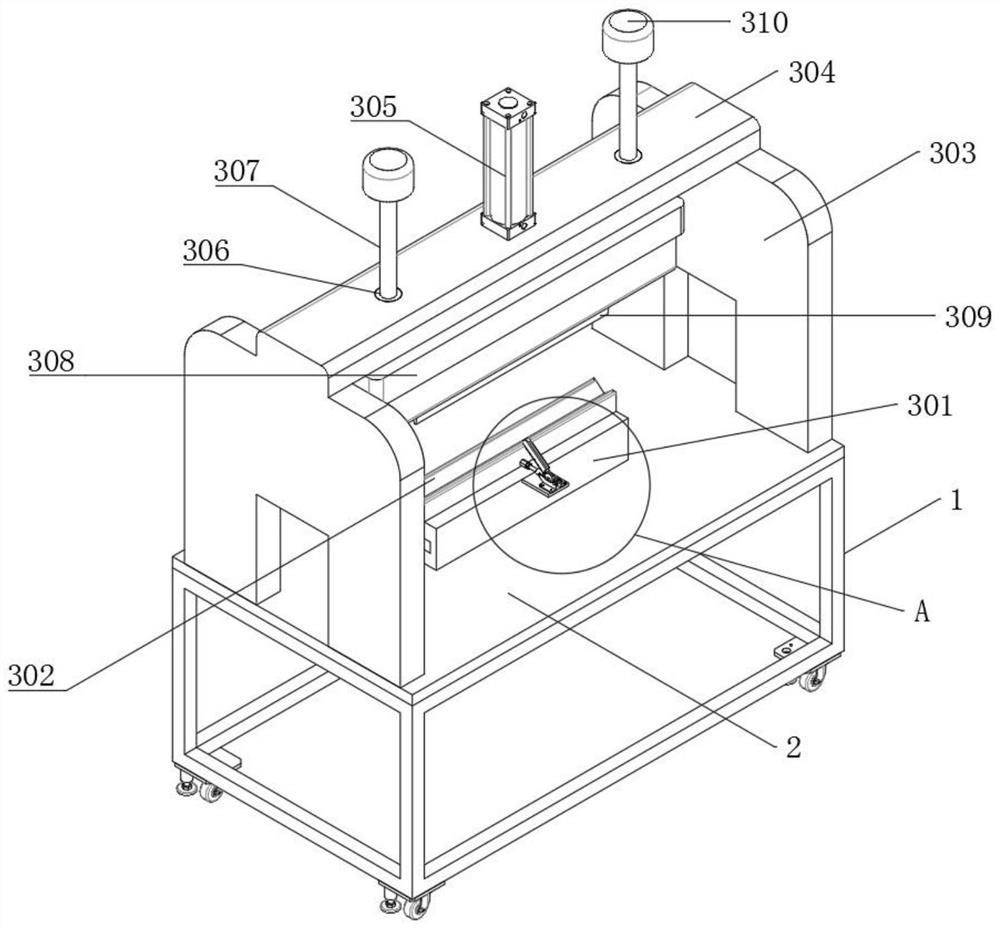

Metal product machining bending machine with discharging structure

InactiveCN114309321APrevent jumping phenomenonReduce security risksShaping safety devicesStripping-off devicesMachineIndustrial engineering

The invention discloses a metal product machining bending machine with a discharging structure. The metal product machining bending machine comprises a rack, a main bottom plate, a bending mechanism, a discharging mechanism, a discharging mechanism, a first supporting fixing base, a mechanical arm fixing base, a discharging mechanical arm, a suction cup fixing base, a suction cup connecting plate and a material taking suction cup. A discharging mechanical arm at the middle position of the top of a mechanical arm fixing seat is controlled to work through an operation panel, a suction cup connecting plate at the top of a suction cup fixing seat is driven to synchronously work at the middle position of the top of a first supporting fixing seat, and a material taking suction cup and a bent metal product synchronously work; according to the metal product bending device, the bending radian is adjusted, the phenomenon that when a metal product is bent, the metal product jumps due to the bending radian is avoided, so that the safety risk in the bending process is reduced, automatic discharging work is conducted after bending, the bent metal product is placed in the discharging mechanism, the workload of workers is greatly reduced, and the working site in the working process is greatly reduced.

Owner:重庆梦友佳科技有限公司

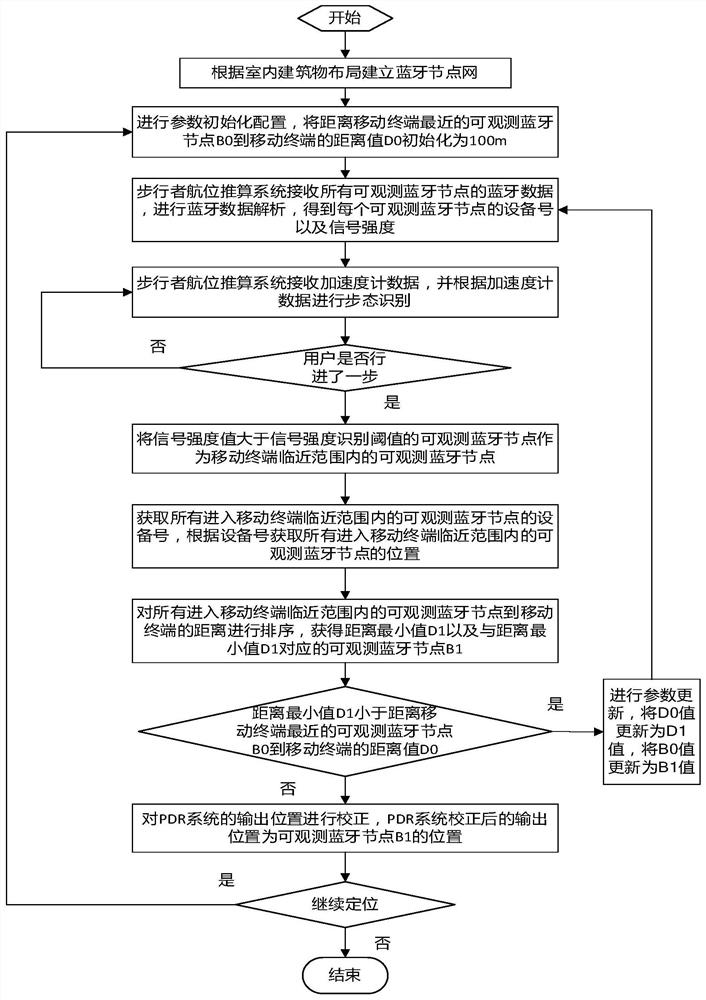

Pedestrian positioning correction method based on distance approximation discrimination Bluetooth

ActiveCN112135245AOvercoming the problem of large calibration errorsReduce calibration errorParticular environment based servicesLocation information based serviceAccelerometer dataSimulation

The invention relates to the field of indoor positioning, and discloses a pedestrian positioning correction method based on distance approximation discrimination Bluetooth. The method comprises the steps of: building a Bluetooth node network; performing parameter initialization configuration on a walker dead reckoning system; obtaining an equipment number and signal intensity of each observable Bluetooth node; performing gait recognition according to the accelerometer data; respectively comparing the signal intensity values of the observable Bluetooth nodes with a signal intensity identification threshold value; acquiring the positions of all observable Bluetooth nodes entering the proximity range of a mobile terminal according to the equipment number; sorting the distances from all the observable Bluetooth nodes entering the proximity range of the mobile terminal to the mobile terminal; performing observable Bluetooth distance approximation judgment; updating the parameters; performing proximity correction; and determining whether to continue positioning. According to the method, the problems that in the prior art, a signal intensity threshold method is large in correction error and has track bounce are solved, and the PDR correction precision and reliability are improved.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

Internal grinding machine for steel pipe

ActiveCN112171402AStable supportAvoid bendingRevolution surface grinding machinesVertical planeMachine

The invention discloses an internal grinding machine for a steel pipe. The internal grinding machine comprises a rail, a first trolley and a second trolley, wherein the first trolley and the second trolley are arranged on the rail; a riding wheel for supporting and driving the steel pipe to rotate is arranged on the first trolley; a lifting column, a connecting piece and a sleeve connected with the connecting piece are arranged on the second trolley; a first rotating shaft is arranged in the sleeve; and the first rotating shaft is connected with a worm. The worm is meshed with a worm wheel; asecond rotating shaft penetrates through the worm wheel; the second rotating shaft is connected with the sleeve through a parallel beam sensor; and a clamping mechanism is further arranged in the sleeve. The axis of a grinding wheel is perpendicular to the axis of the first rotating shaft; the first rotating shaft only bears the bending moment on the vertical plane instead of the bending moment onthe horizontal plane; and the first rotating shaft is prevented from being bent on the vertical plane under the supporting effect of the sleeve. The parallel beam sensor can detect the pressure of the grinding wheel on the inner wall of the steel pipe, so that the right amount that the inner wall of the steel pipe is ground is got by using the grinding wheel; and the influence of overlarge pressure on the inner diameter of the steel pipe is avoided.

Owner:HENAN HUIFENG TUBE IND

Deflection preventing mechanism for clamp automatic machining

PendingCN109318026APrecise positioningFacilitate automatic processingPositioning apparatusMetal-working holdersFixed frameMachining

The invention discloses a deflection preventing mechanism for clamp automatic machining, and belongs to the field of tool fixtures. The deflection preventing mechanism for clamp automatic machining ischaracterized by being mounted in a machining station of a clamp machining layer, and comprises fixed frames stopped at the most front ends of all machining layers and brackets mounted on the fixed frames and extending to the back ends; one-way gates for limiting backward movement of clamps are arranged at the back ends of the brackets, and can swing left and right; the movable leftmost sides under the one-way gates are contacted with spring pieces; and the clamps are positioned under the spring pieces after entering the mechanism from one-way valves. The deflection preventing mechanism for clamp automatic machining prevents inaccurate positioning caused by deflection of the clamps during milling, is convenient for precise machining, prevents troubles, and is convenient for subsequent continuous automatic machining.

Owner:湖南精专自动化技术有限公司

Warp yarn force application method and warp yarn tension adjustment device of warp yarn tension adjustment device of cord fabric weaving device

Owner:TSUDAKOMA KOGYO KK

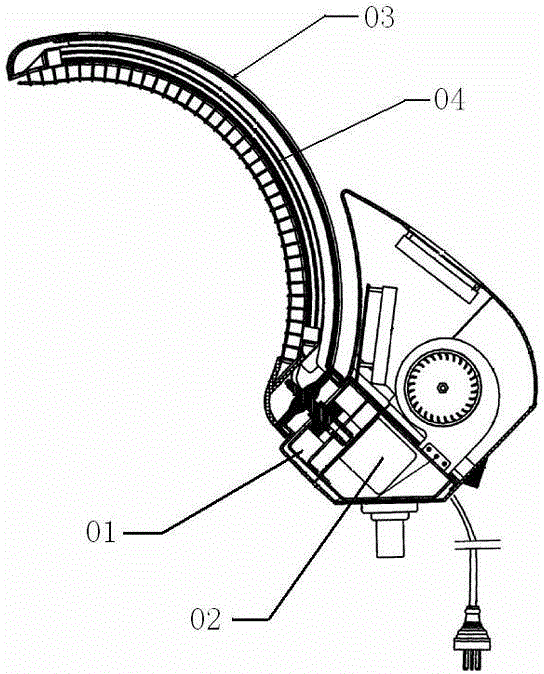

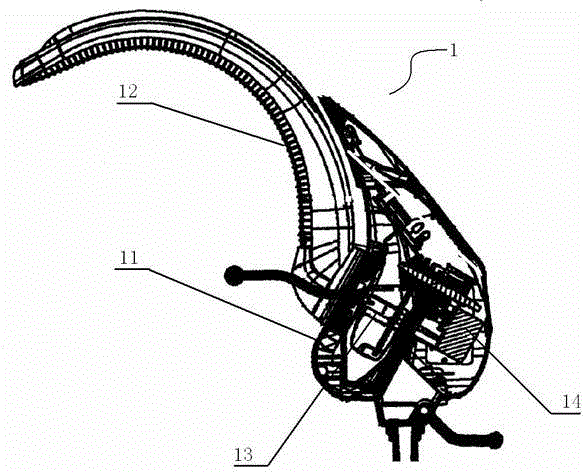

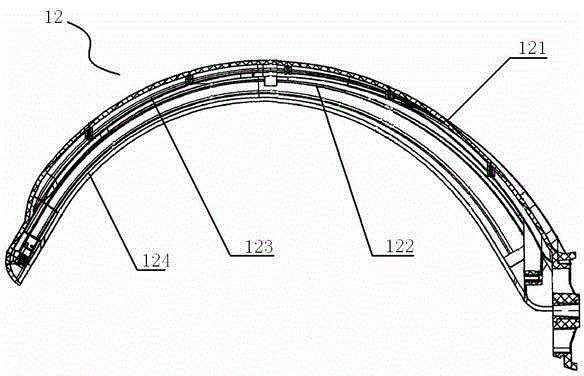

Nose structure for hair dryer and hair dryer with same

ActiveCN102657421BAchieve electrical connectionAvoid winding defectsHair dryingElectric machineEngineering

The invention discloses a nose structure for a hair dryer. The nose structure comprises a nose main body, two swinging arms arranged on the nose main body, a motor for driving the swinging arms to move, a temperature display for displaying the temperatures of the swinging arms, and a negative-ion generator for injecting negative-ions into the swinging arms. Compared with the traditional nose structure for the hair dryer, the nose structure for the hair dryer has the advantages of good synchronism and uniformity in heating because one same motor is used for driving two different swinging arms to move; meanwhile the swinging arms are designed to be of a gradual change structure with fine front end and thick rear end, so as to generate small moment during swinging, reduce load of the motor, and be low in energy consumption; and moreover, through integration assembly of the temperature display and the negative-ion generator, the nose structure for the hair dryer has the characteristics of strong temperature controllability and good hairdressing effect. Moreover, the invention also provides a hair dryer with the nose structure.

Owner:林贵佳

Internal grinding machine for steel pipe

ActiveCN112171402BStable supportAvoid bendingRevolution surface grinding machinesVertical planeClassical mechanics

The invention discloses an internal grinding machine for steel pipes, which comprises a track, a first trolley and a second trolley arranged on the track, the first trolley is provided with supporting wheels for supporting and driving the steel pipe to rotate, and the second trolley is provided with The lifting column, the connecting piece, and the sleeve connected with the connecting piece, the sleeve is provided with a first rotating shaft, the first rotating shaft is connected with a worm, the worm is meshed with a worm wheel, the worm wheel is threaded on the second rotating shaft, and the second rotating shaft The shaft is connected to the sleeve through a parallel beam sensor, and a clamping mechanism is also arranged in the sleeve; the axis of the grinding wheel of the present invention is perpendicular to the axis of the first rotating shaft, and the first rotating shaft is only subjected to the bending moment on the vertical plane, and It will not be subjected to the bending moment on the horizontal plane, and under the action of the support of the sleeve, the bending of the first rotating shaft on the vertical plane is avoided; and the parallel beam sensor can detect the pressure of the grinding wheel on the inner wall of the steel pipe, so that the grinding wheel The inner wall of the steel pipe has a suitable amount of grinding to avoid excessive pressure affecting the size of the inner diameter of the steel pipe.

Owner:HENAN HUIFENG TUBE IND

The anti-jump structure of the suspension wheel and the track

ActiveCN106948693BPrevent jumping phenomenonSimple structureWing suspension devicesMechanical engineeringJumping

The invention discloses a jumping-preventing structure with a lifting wheel and a rail which are matched. The jumping-preventing structure comprises a guide rail body made of a sectional material, and a jumping-preventing variable cavity body, wherein the guide rail body is provided with a guide rail cavity for a lifting wheel body to act in a reciprocating manner, the jumping-preventing variable cavity body is arranged in the guide rail cavity so that the fit clearance allowing the lifting wheel body to pass can become smaller, and the vertical action of the lifting wheel body can be limited so as to achieve jumping preventing. The jumping-preventing structure is simple, fast, safe and reliable to assemble and operate, capable of greatly reducing the manufacturing cost, good in transmission stability, capable of effectively preventing the jumping phenomenon before stopping of the lifting wheel, and good in mute effect. Thus, the jumping-preventing structure is a product having superior performance in economical performance and technicality.

Owner:GUANGDONG MINGMEN LOCKS IND

A kind of high voltage circuit breaker secondary circuit

ActiveCN107994575BPrevent jumping phenomenonGuaranteed to failElectric power transfer ac networkControl engineeringControl theory

The invention provides a high-voltage circuit breaker secondary circuit. The synchronization problem between different poles and the same poles after two double-break circuit breakers are connected inseries can be solved, and functions of secondary control circuit anti-tripping and non-full-phase protection are achieved. The high-voltage circuit breaker secondary circuit includes an open circuit,a closed circuit, an anti-tripping protection circuit and a non-full-phase protection circuit. The open circuit includes parallel branches formed by A, B and C phase opening solenoid branches and being in series connection, a low oil pressure opening blocking auxiliary relay normally-closed contact and an SF6 low pressure gas blocking auxiliary relay normally-closed contact; the closed circuit includes a parallel branches formed by A, B and C phase closing solenoid branches and being in series connection, a low oil pressure closing blocking auxiliary relay normally-closed contact and an SF6 low pressure gas blocking auxiliary relay normally-closed contact; the anti-tripping protection circuit includes A, B and C phase anti-tripping circuits; and the non-full-phase protection circuit includes three branches in parallel connection, which are an auxiliary contact branch, a non-full-phase time relay 47T1 and non-full-phase time relays 47TX1 and 47TY1.

Owner:CHINA XD ELECTRIC CO LTD

Yarn tension adjusting device and spinning equipment

PendingCN114701917ASuitable temperatureImprove magnetismFilament handlingRefrigeration safety arrangementSpinningStructural engineering

The invention discloses a yarn tension adjusting device and textile equipment, elastic connecting blocks are fixedly connected between an adjusting wheel and a first cover plate and between the adjusting wheel and a second cover plate, the outer side of the adjusting wheel is movably sleeved with two pressing plates, and electromagnets and magnetic plates which are magnetically attracted are fixedly arranged on the end faces of the two pressing plates correspondingly; an elastic supporting column is fixedly connected between the electromagnet and the magnetic plate, the control circuit comprises a power source, a resistance rod and a refrigerator which are electrically connected through a wire, the refrigerator is connected with a trigger circuit in parallel, the trigger circuit comprises two trigger switches which are arranged in parallel, and the adjusting wheel is located between the two trigger switches. Through cooperative arrangement of a resistance rod, a fixed power connection block and a sliding power connection block, the refrigerating capacity of the refrigerator is adjusted, and through cooperative arrangement of a trigger switch and an electromagnet, in the sliding process of the adjusting wheel, the problem that yarn is broken or jumps is solved.

Owner:南通宏澳纺织有限公司

Positioning correction method based on single-step robust filtering and approximation discrimination of bluetooth signal

ActiveCN112135345BSolve the problem of large calibration errorsReduce calibration errorPosition fixationShort range communication serviceAccelerometer dataAlgorithm

The invention relates to the field of indoor positioning, and discloses a positioning correction method based on Bluetooth signal single-step robustness filtering and approximation discrimination, including establishing a Bluetooth node network; performing parameter initialization configuration; performing gait recognition according to accelerometer data; dividing according to single-step time periods and analyze the bluetooth signal data to obtain the single-step signal strength sequence of the bluetooth node; carry out the single-step signal strength sequence anti-difference processing on the signal strength sequence; compare the single-step signal strength value after the anti-difference with the signal strength identification threshold; Observing the sorting of single-step signal strength values of Bluetooth nodes, and performing approximation judgment on the largest sorted signal strength value; performing proximity correction. The present invention performs robustness processing on the signal strength sequence of observable Bluetooth nodes obtained in each step through a single-step robustness filtering method, which reduces the influence of coarse errors in signal strength values, eliminates large jitters, and avoids frequent error corrections and The trajectory adjustment problem improves the accuracy and reliability of pedestrian positioning correction.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

Bending machining device applied to strip parts

The invention provides a bending machining device applied to strip parts. The device comprises a base, two bending mechanisms which are symmetrically arranged are arranged on the base, each bending mechanism comprises a bending comment and a guide component, each bending component comprises a first positioning block fixedly arranged, a push rod is hinged to one side of each first positioning block, the push rods are connected with first drive components, second positioning blocks opposite to the first positioning blocks are movably arranged on the base, and are connected with second drive components, each guide component comprises a first guide block and a second guide block which are oppositely arranged, each first guide block and the corresponding first positioning block are linearly arranged, each second guide block and the corresponding second positioning block are linearly arranged, and a toothed face is arranged on the side face of each first guide block. Compared with the priorart, jumping of products can be effectively overcome, the influence on the bending angle can be reduced, and bending precision can be improved.

Owner:苏州冬宝光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com