A guiding mechanism for the horizontal movement of the printing carriage

A technology of left and right movement and guiding mechanism, which is applied in the direction of printing, transfer printing materials, power transmission devices, etc., can solve problems such as deviation, character carriage jumping, and unsatisfactory printing effect of the printer, and achieves easy installation, not easy to change, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

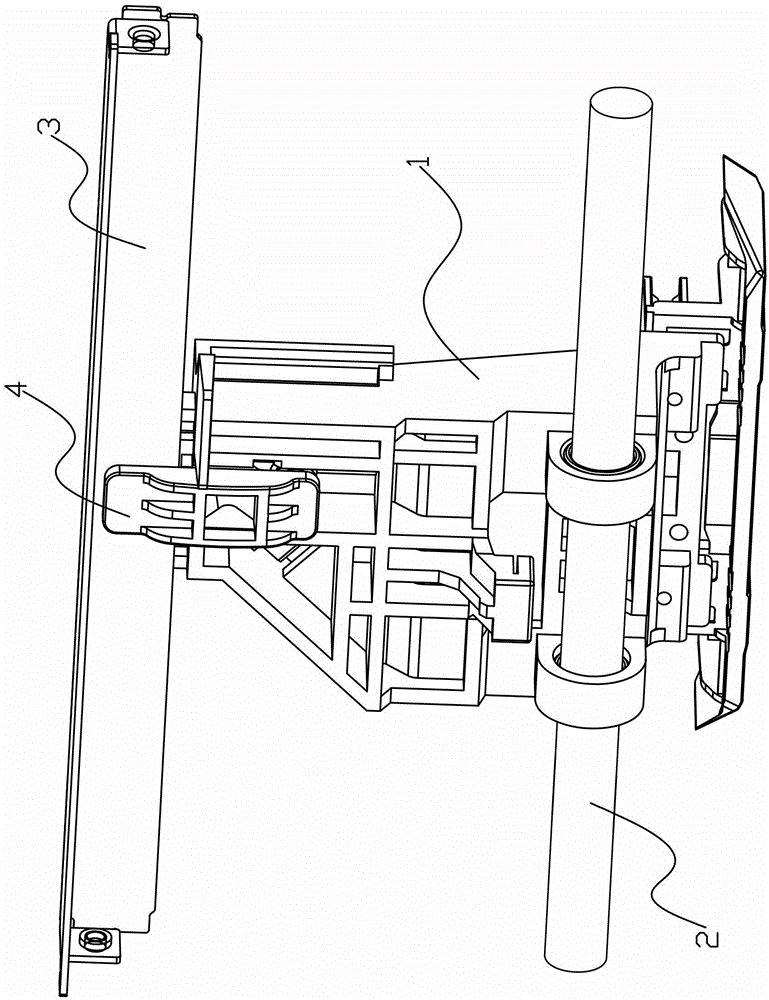

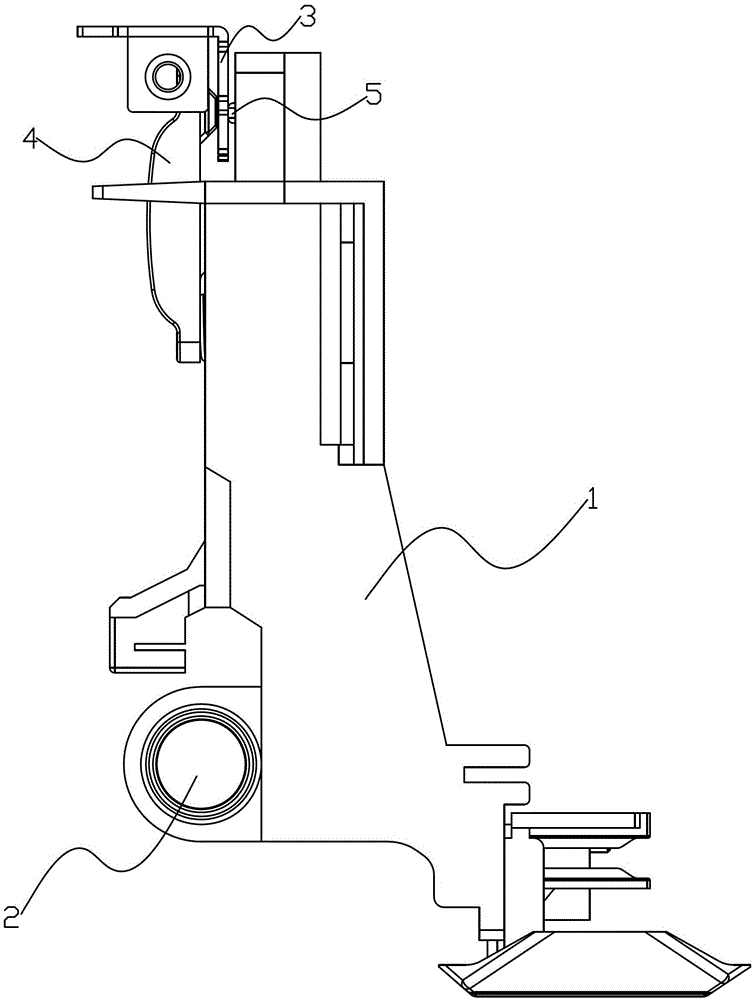

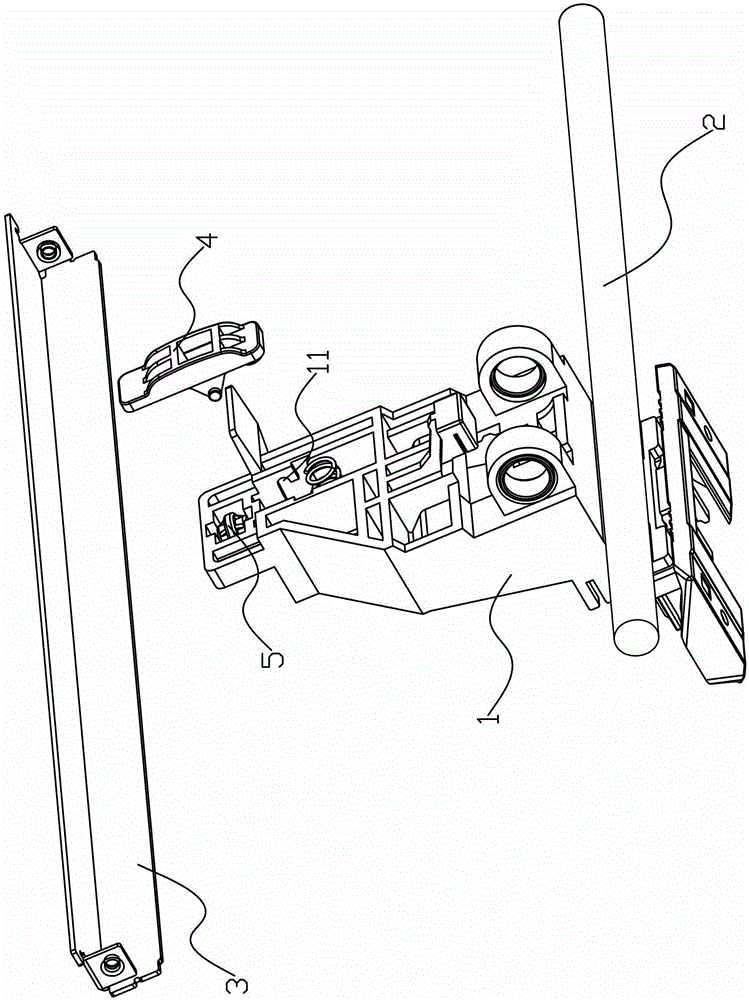

[0015] refer to Figure 1 to Figure 5 , a guiding mechanism for horizontally moving the character carriage of a printer, comprising a character carriage 1, the lower part of the carriage 1 is movable and equipped with a guide shaft 2, and a guide rail 3 parallel to it is arranged above the guide shaft 2, the said carriage The upper part of the frame 1 is provided with locking clips 4 and guide wheels 5 respectively located at the front and rear sides of the guide rail 3, and the locking clips 4 and guide wheels 5 are preferentially arranged at the middle position on the upper part of the word frame 1, and the middle part of the locking clips 4 and the The character frame 1 is hinged, and a spring 6 is arranged between the lower part of the locking clamp 4 and the character frame 1, which can make the locking clamp 4 rotate around the hinge and press against the guide wheel 5. The above-mentioned spring 6 preferably adopts a common Compression spring, certainly adopt gas spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com