Nose structure for hair dryer and hair dryer with same

A machine head and heating tube technology, applied in hair or scalp washing devices, applications, hairdressing equipment, etc., can solve problems such as high energy consumption, increased motor load, and electric leakage, and achieve uniform swing arm movement and reduce motor Good effect of loading, hairdressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

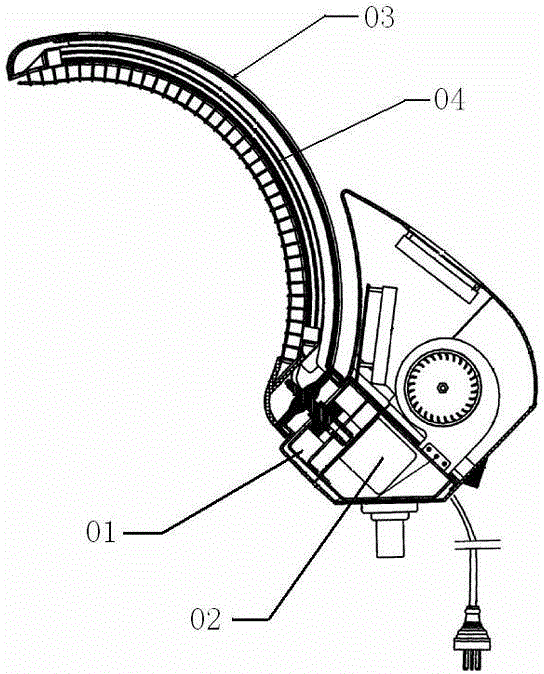

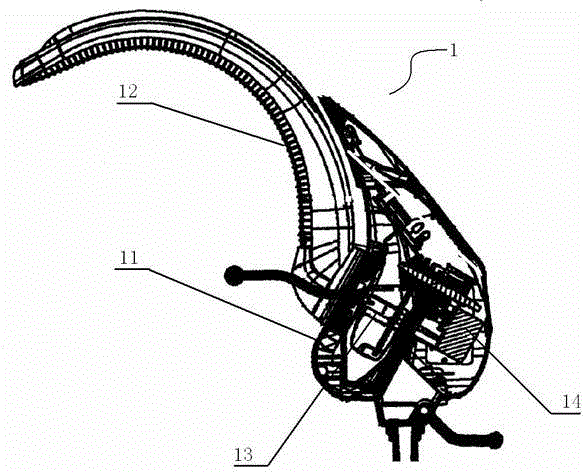

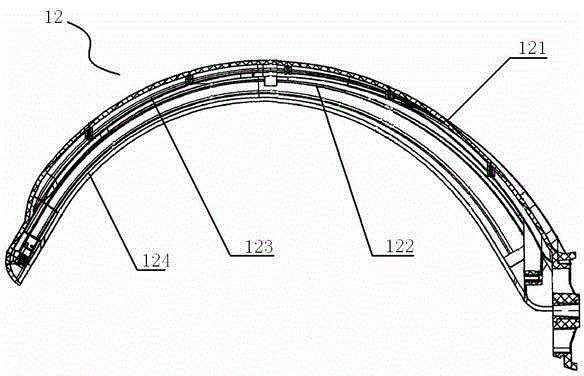

[0076] like Figure 10 As shown, a head structure 1 for a hair drying machine includes: a head body 11, two swinging pieces 12 arranged on the head body 11, a swing piece 12 fixed on the head body 11 Transmission part 13, be fixed on the motor 14 that links to each other with described transmission part 13 on the head main body 11, be fixed on the temperature indicator 15 on the head main body 11, be fixed on the anion generator 16 and the head shell on the head main body 11 17.

[0077] The head structure of a hair drying machine provided in this embodiment is basically the same as that in Embodiment 1, the difference is that:

[0078] 1. A temperature display device 15 is added. The temperature display device includes: a temperature detection module and a temperature display module. The temperature detection module is used to detect the temperature of the heating area of the pendulum, and the temperature display is fixed on the shell of the machine head to display the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com