Method for preventing and treating bridge abutment trip by using microorganism consolidation liquid and microorganism consolidation liquid

A technology of microorganisms and reinforcement fluids, which is applied in the fields of civil engineering, microbial solidification, and traffic engineering, can solve the problems of long construction period and high cost, and achieve the effect of short construction period, low cost and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

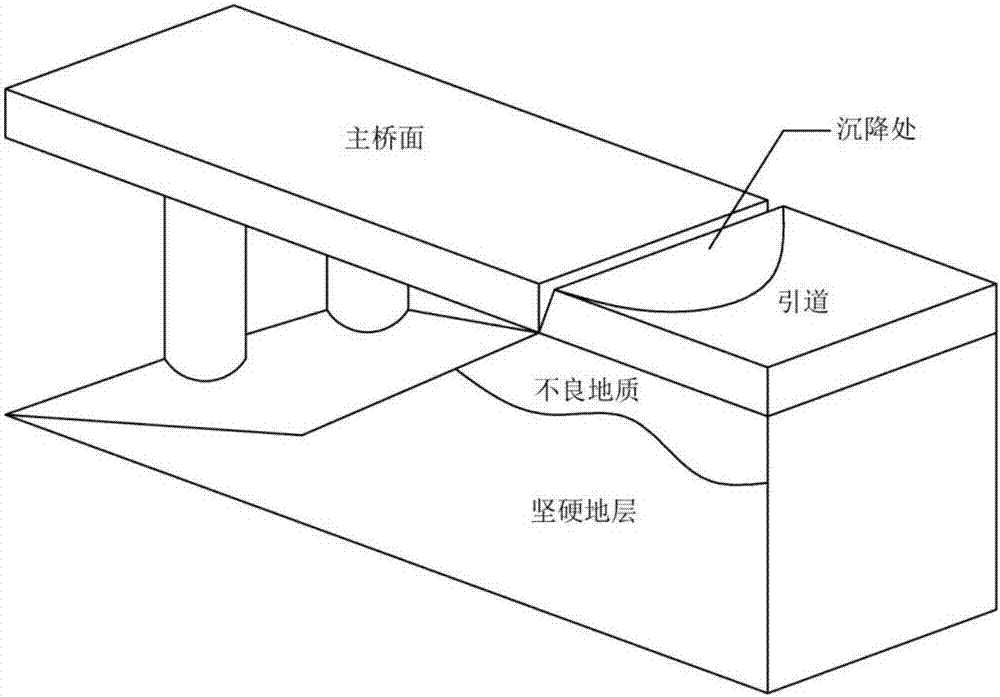

[0040] 1. Preparation of indoor abutment soil samples

[0041] The abutment soil samples were taken from the back of a bridge in Huai'an City where the abutment car jumping phenomenon occurred. About 25kg of soil samples were taken, placed in a model tank with a bottom size of 60cm×30cm, and compacted to a height of 10cm.

[0042] 2. Preparation of microbial reinforcement powder

[0043] 2.1 Prepare 2.5L of microbial culture medium, including 20g / L of yeast extract powder, 10g / L of ammonium chloride, 24mg / L of nickel chloride hexahydrate, 10mg / L of manganese sulfate monohydrate, adjust the pH to 9, and use pasteurization Autoclave at 121°C for 30 minutes;

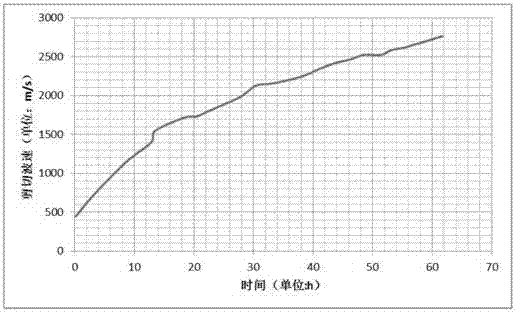

[0044]2.2 Add the strain of Sarcina pasteuriani into the culture medium, feed oxygen at a rate of 1.5L / min, add the strain into the culture medium and culture it in a constant temperature shaker with a set temperature of 30°C for 24 hours to obtain the obtained Bacteria solution is required;

[0045] 2.3 The bacterial so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com